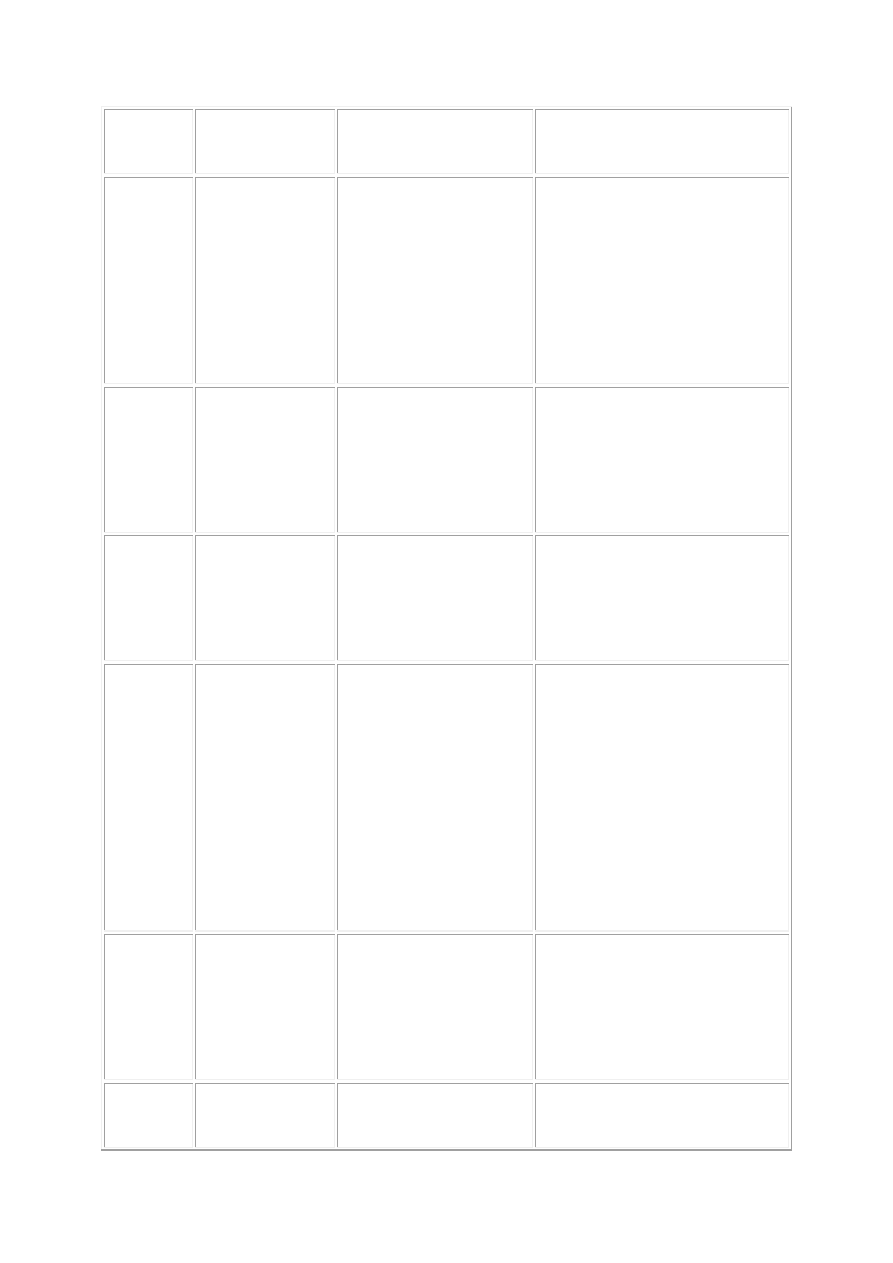

Jaguar XJ (X350). Manual — part 828

(leaking)

bulletin 05.1-29, or Vacutec

operating instructions)

P0444

Canister purge

valve circuit open

circuit

Canister purge valve

disconnected

Canister purge valve to

ECM drive circuit;

open circuit, high

resistance

Canister purge valve

failure

Check purge valve connections, GO

to Pinpoint Test G307413p2.

.

P0445

Canister purge

valve circuit short

circuit

Canister purge valve to

ECM drive circuit;

short circuit to

ground

Canister purge valve

failure

GO to Pinpoint Test G307413p2.

.

P0446

Canister close valve

malfunction (CCV

stuck closed)

Restricted flow through;

air vent, filter, CCV

or canister

Canister close valve

failure

Inspect the components listed, and

interconnecting pipework for

blockage, kinks or flattened areas

P0447

Canister close valve

circuit open circuit.

Canister close valve

power supply

circuit; open circuit,

short circuit

Canister close valve to

ECM drive circuit;

open circuit, high

resistance, short

circuit to B+ voltage

Canister close valve

failure

GO to Pinpoint Test G307413p3.

.

P0448

Canister close valve

circuit short circuit

Canister close valve to

ECM drive circuit;

short circuit to

ground

Canister close valve

failure

GO to Pinpoint Test G307413p3.

.

P0450

Fuel tank pressure

(FTP) sensor

FTP sensor

disconnected

Check FTP sensor connections. GO to

Pinpoint Test G307413p4.

malfunction (output

stuck/not changing)

FTP sensor failure

.

P0452

Fuel tank pressure

(FTP) sensor circuit;

low voltage (low

pressure)

FTP sensor

disconnected

FTP sensor to ECM

sense circuit; open

circuit, short circuit

to ground

FTP sensor to splice in

sensor supply

circuit; open circuit,

high resistance

FTP sensor failure

For FTP sensor supply tests, <<303-

14>> GO to Pinpoint Test

G307413p4.

.

P0453

Fuel tank pressure

(FTP) sensor circuit;

high voltage (high

pressure)

FTP sensor to splice in

sensor ground

circuit; open circuit,

high resistance

FTP sensor to ECM

sense circuit; open

circuit, short circuit

to high voltage

FTP sensor failure

Check fuel filler cap and seal,

pipework, etc. GO to Pinpoint Test

G307413p2.

. For fuel tank information, <<310-

01>>

P0455

Leak detected-large

Fuel filler cap missing

Fuel filler cap seal

defective

System leak (canister

damage, pipework

damage)

CCV stuck open

Canister purge valve to

engine purge pipe;

restricted, leaking,

disconnected

Canister purge valve

stuck closed

Fuel tank leak

Check fuel filler cap and seal,

pipework, etc. GO to Pinpoint Test

G307413p2.

. For fuel tank information, <<310-

01>>

www.

P0456

Leak detected - 20

thou

Fuel filler cap seal

defective

System leak (canister

damage, pipework

damage)

CCV leaking

Fuel tank leak

Check fuel filler cap and seal,

pipework, etc. GO to Pinpoint Test

G307413p2.

. For fuel tank information, <<310-

01>>

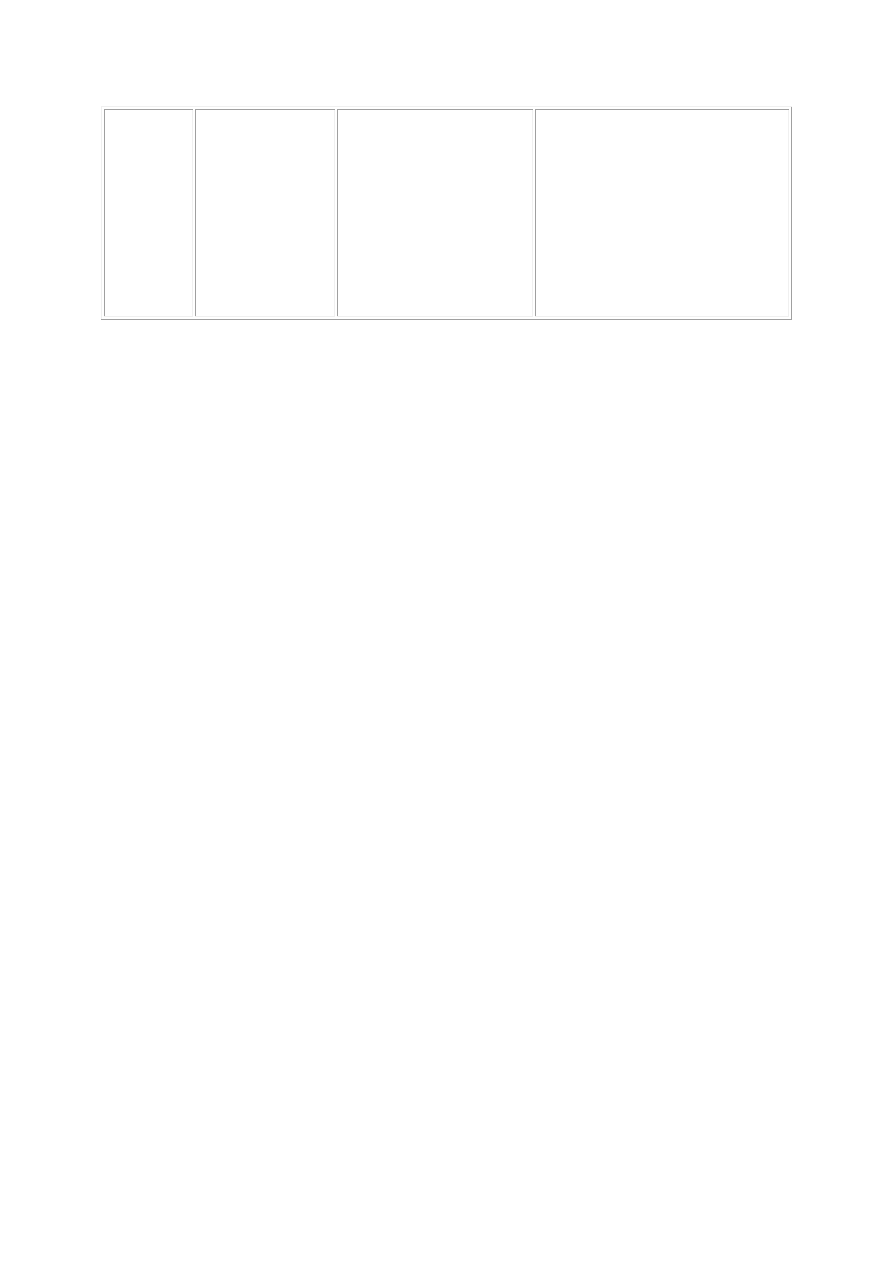

Pinpoint Tests

PINPOINT TEST G307413p1 : DTC

P0441; EVAPORATIVE SYSTEM

INCORRECT PURGE FLOW

G307413t1 : CHECK FUEL FILLER CAP FITMENT AND CONDITION OF

CANISTER, PIPES AND CONNECTORS

1. Make sure that the fuel filler cap is correctly installed and tightened. 2. Check the condition of the

carbon canister. 3. Check the condition of all accessible pipes and connectors in the vapor line.

Are the canister and all pipes and connectors in good condition?

-> Yes

GO to Pinpoint Test G307413t2.

-> No

REPAIR as necessary. CLEAR the DTC. Carry out a full evaporative system monitor drive cycle.

Recheck DTCs. For additional information, see "diagnostic drive cycles" above.

G307413t2 : CHECK EVAPORATIVE PURGE VALVE IS OPERATING

1. Disconnect the vapor pipe from the inlet port of the evaporative purge valve (ie, from fuel tank). 2.

RUN the engine for 2 minutes, making sure that the engine reaches normal operating temperature.

3. Check that the evaporative purge valve is operating, by touch or by sound (using a stethoscope, it

will be possible to hear the valve operating).

Is the valve operating?

-> Yes

Recheck DTCs. Carry out a flow check monitor drive cycle. For additional information, see "diagnostic

drive cycles" above.

-> No

CHECK for DTC P0444, P0445. Conduct "green" ECM drive cycle. For additional information, see

"diagnostic drive cycles" above.

PINPOINT TEST G307413p2 : DTC

P0442, P0444, P0445, P0455, P0456; LEAK

DETECTED: LARGE/20 THOU/40 THOU,

PURGE VALVE CIRCUIT

MALFUNCTION, OPEN/SHORT

CIRCUIT,

G307413t3 : CHECK FUEL FILLER CAP FITMENT AND CONDITION OF

CANISTER, PIPES AND CONNECTORS

1. Make sure that the fuel filler cap is correctly installed and tightened. 2. Check the condition of the

carbon canister. 3. Check the condition of all accessible pipes and connectors in the vapor line.

Are the canister and all pipes and connectors in good condition?

-> Yes

GO to Pinpoint Test G307413t4.

-> No

REPAIR as necessary. CLEAR the DTC. Carry out a full evaporative system monitor drive cycle.

Recheck DTCs. For additional information, see "diagnostic drive cycles" above.

G307413t4 : CHECK THE CANISTER PURGE VALVE DRIVE CIRCUIT FOR HIGH

RESISTANCE

1. Disconnect the battery negative terminal. 2. Disconnect the canister purge valve electrical

connector, EC63. 3. Disconnect the ECM electrical connector, PI01. 4. Measure the resistance

between EC63, pin 02 (UY) and PI01, pin 66 (UY).

Is the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full evaporative system monitor drive cycle.

-> No

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст