Jaguar XJ (X350). Manual — part 519

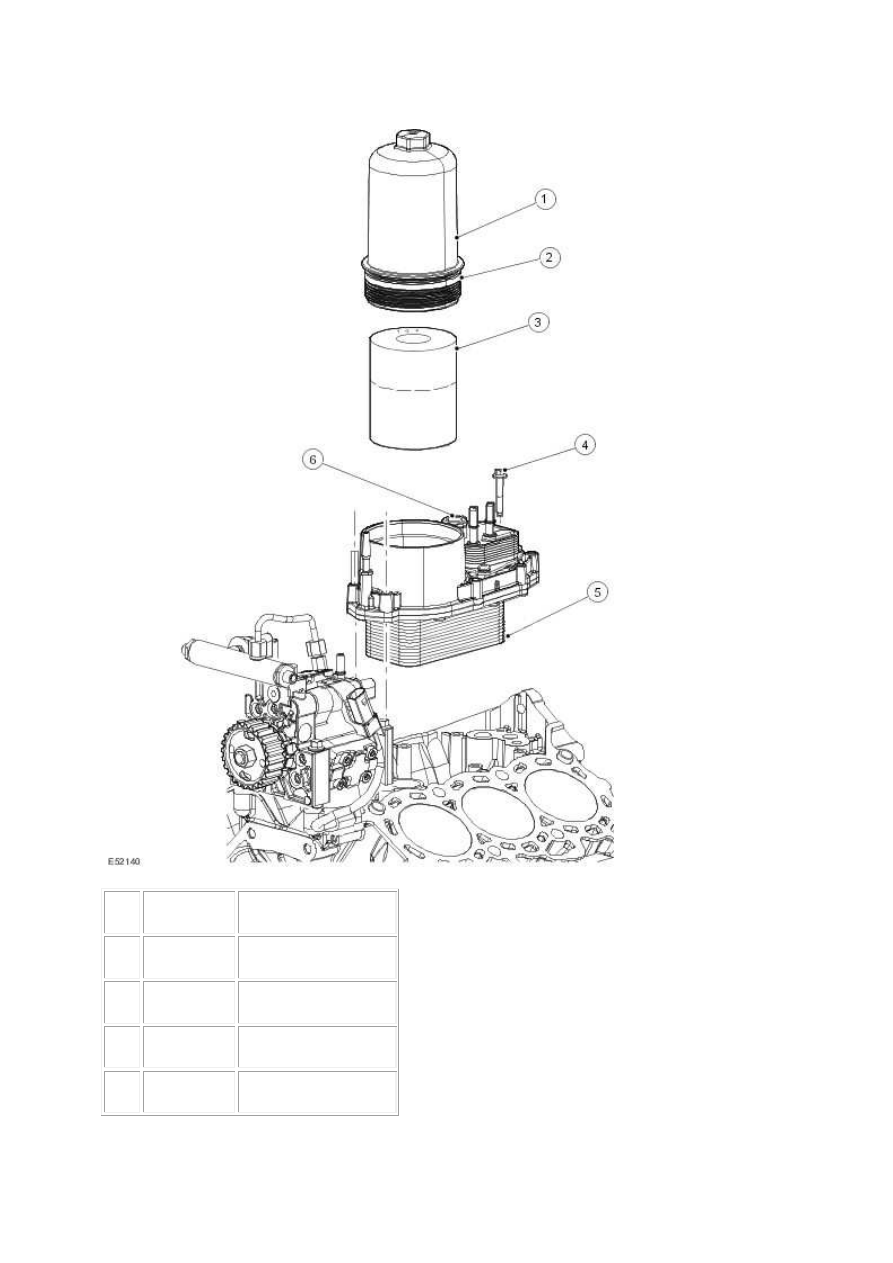

Item

Part Number

Description

1

—

Filter housing

2

—

'O' ring seal

3

—

Paper element

4

—

Retaining bolts

5

—

Cooler assembly

6

—

Water inlet connection

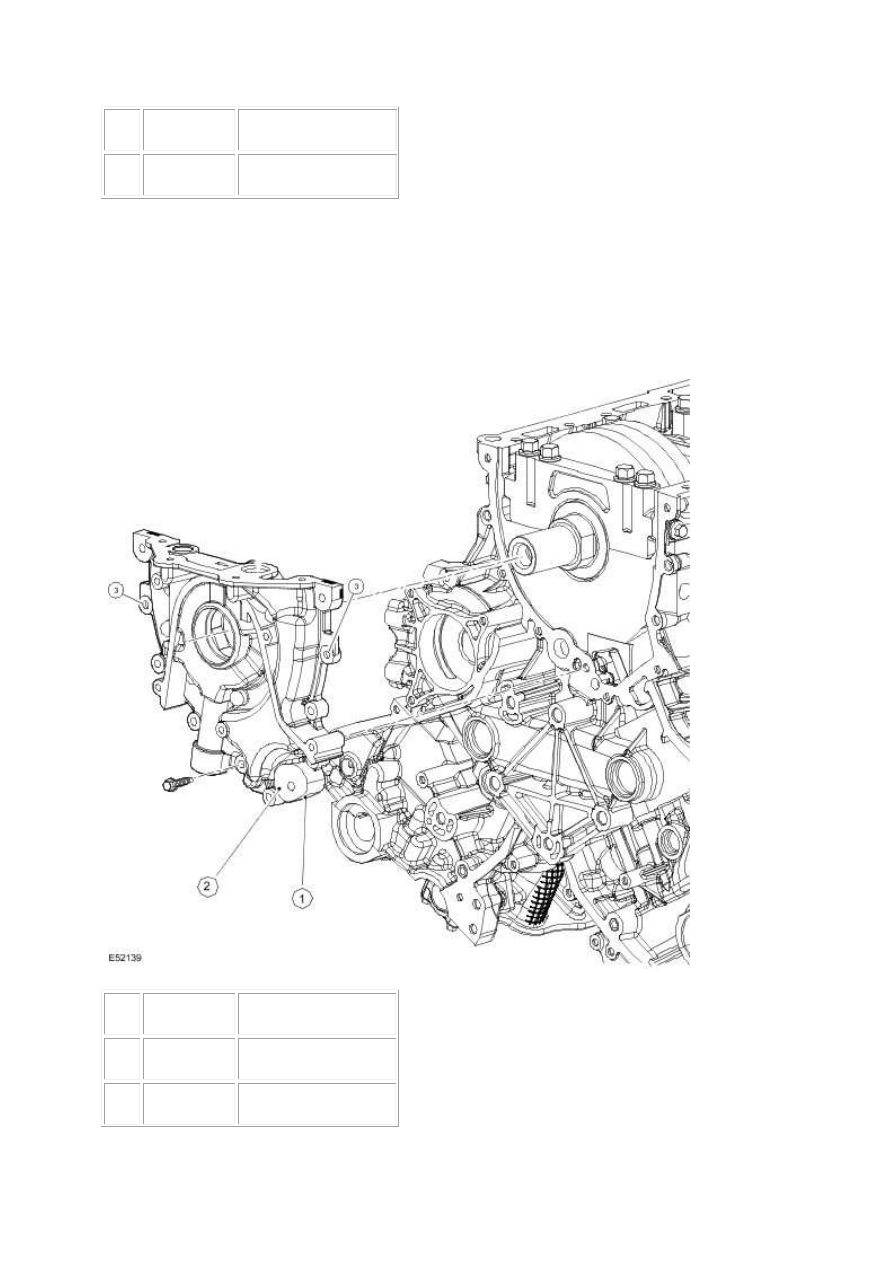

Oil Pump

The oil pump is a gear type pump and is bolted and dowelled to the front of the engine block. It is

sealed by means of rubber gasket which is recessed into the oil pump casing. The pump is driven

directly by two flats from the front of the crankshaft. The oil relief valve is an integral part of the

pump.

Item

Part Number

Description

1

—

Oil pump

2

—

Primary tensioner boss

www.

3

—

Draining bolt

4

—

Sump pan

5

—

Retaining bolts

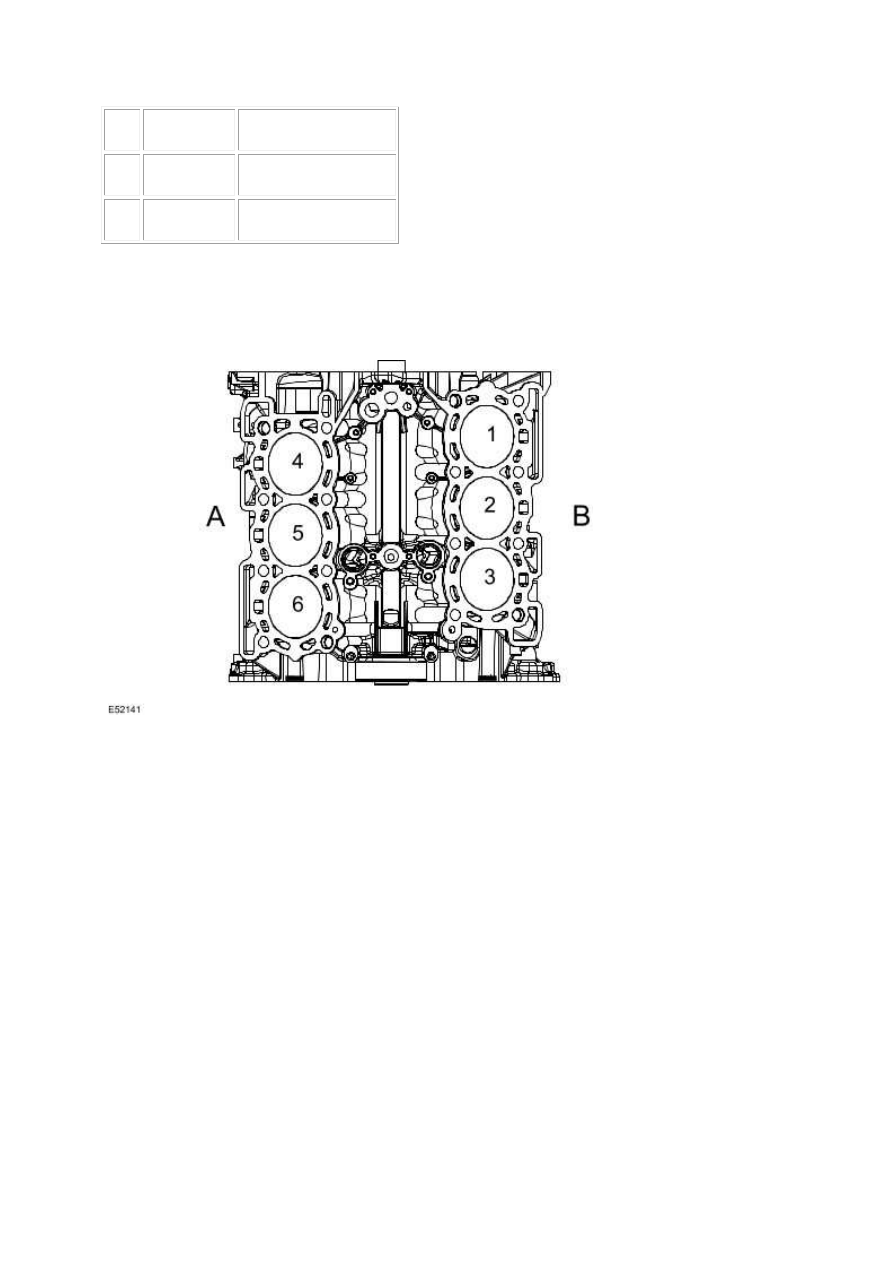

Oil spray jets are bolted in place under the cylinder bores between the crank bearing journals. The oil

jets help to keep the pistons cool under arduous conditions and also prevent the oil draining back

when the engine is stopped.

Engine Management

The ECM's (Engine Control Module) high capacity processor employs advanced software strategies

that continuously control the engine's operating parameters. It gathers information from an array of

sensors and provides output to the actuators. The ECM also operates a port deactivation system,

which closes or opens flaps in the inlet system to provide the optimum swirl and flow conditions

throughout the operating range of the engine.

In addition, the ECM controls the actuation of the Exhaust Gas Recirculation system, the Variable

Geometry Turbochargers and the throttle, giving faster and more accurate response. A full torque-

based strategy supports multiple injection control and integration with transmission and braking

controllers. Transient torque and boost control enables vehicle performance to be optimised without

compromising engine durability

System Components

All engine functions are controlled by the Siemens common rail ECM

Crank position (CKP) sensor

The CKP signal is used to determine: the quantity of fuel to be injected, the start of fuel delivery and

the quantity of exhaust gases to be recirculated.

The crank position sensor is located at the rear of the crankshaft behind the flywheel.

The crankshaft position sensor (CKP ) is a Hall effect sensor which scans a magnetic disc on the

crankshaft. The air gap between the magnetic disc and the CKP is predetermined by the mounting of

the sensor.

Camshaft position (CMP) sensor

Location: on the cylinder head behind the left hand camshaft timing belt pulley.

The CMP sensor is Hall effect type and is required to identify cylinder No. 1. (This is to synchronise

engine to camshaft). The sensor scans a ring incorporated in the left hand camshaft timing belt

pulley. The air gap between the magnetic ring and the CMP sensor is predetermined by the mounting

of the sensor.

Engine coolant temperature (ECT) sensor

Location: in the top outlet hose.

The ECT is a NTC type sensor and is fitted into the top water outlet hose. The sensor has a bayonet

type fitting.

Mass Air Flow (MAF) sensor

The MAF sensor is used to calculate the air mass. The MAF sensor is capable of detecting the mass air

flow extremely precisely.

Location: there are two MAF sensors fitted. Each sensor is fitted to separate intake pipes.

On engines with a variable turbocharger, the MAF sensor is used solely to control the exhaust gas

recirculation (EGR) and not the fuel metering. The MAF sensor also incorporates the Intake Air

Temperature (IAT) sensor.

The IAT sensor measures the intake air or, the charge air temperature and supplies the ECM with an

analog voltage signal.

Manifold Absolute Pressure (MAP) sensor

Location: fitted to the top of the throttle valve.

The MAP sensor measures the charging pressure in the intake pipe and sends the ECM an analog

voltage signal.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст