Jaguar XJ (X350). Manual — part 517

3

—

Spiral joint oil control

4

—

Ring gap lower compression

5

Upper compression ring

6

Lower compression ring

7

Oil control ring

All pistons are common single grade/single part number for all engines.

The piston top ring is a taper type and is fitted with a taper to the top of the piston. All rings marked

'top' are assembled with top to uppermost. All rings must be spaced evenly around the piston before

installing. The circumference gap of the double bevelled oil control ring must be opposite to the

spiral control joint.

Piston bowl volume is 20.025cc and the compression ratio is 17.3:1.

Cylinder Heads and Valve Gear

The cylinder head is of high quality aluminium and cannot be reworked. The cylinder head is secured

to the engine block by eight bolts.

The cylinder head incorporates four valves per cylinder, glow plugs and a knock sensor. A vertically

centrally placed fuel injector guarantees maximum distribution of fuel into the combustion chamber.

The cylinder head gasket is a three layer laminated steel construction that has an excellent service

life and sealing properties. The cylinder head gasket is available in five different thicknesses

depending on the piston protrusion height. The cylinder head gaskets are identified by serrations cut

into the front end of the gasket.

The valves are operated directly by steel roller rockers with hydraulic lash adjusters.

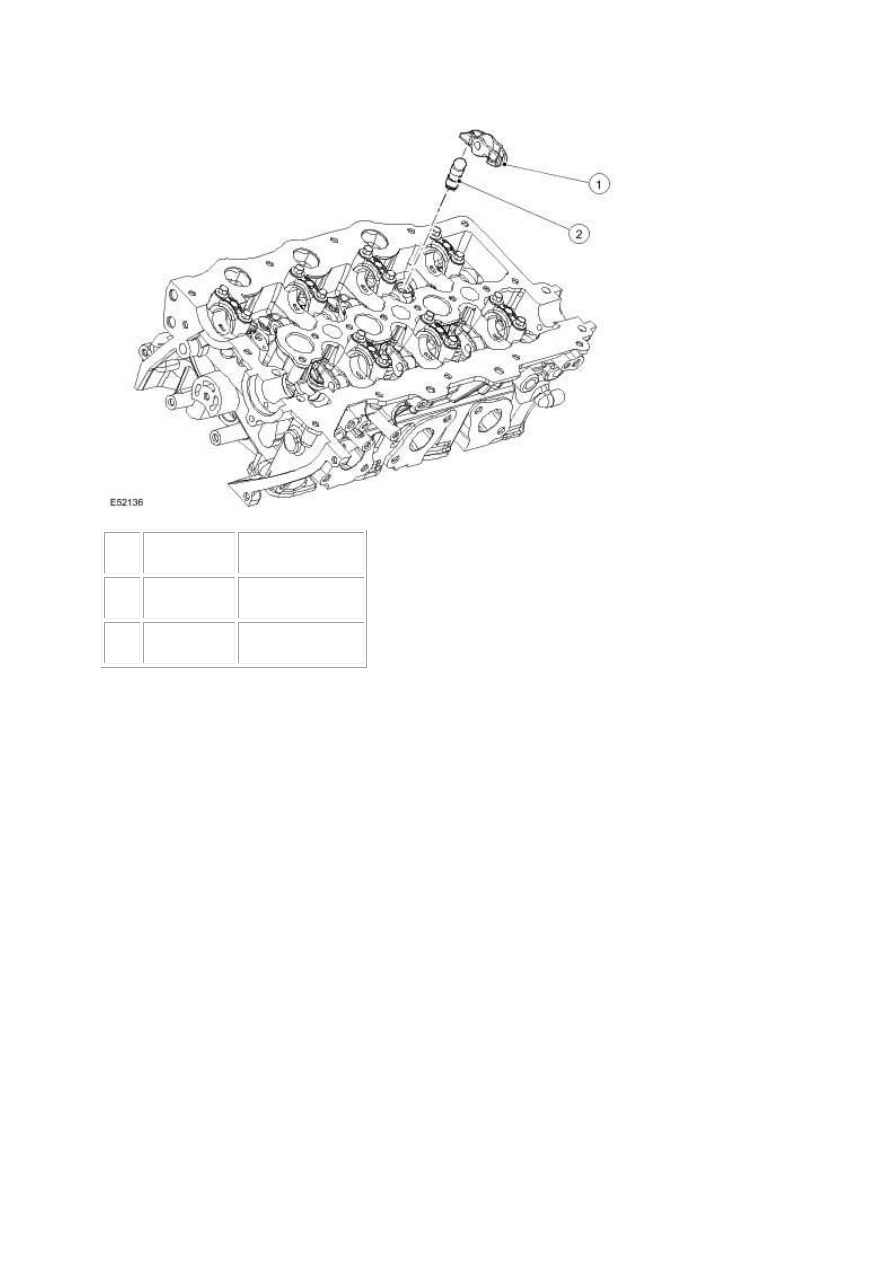

Item

Part Number

Description

1

—

Steel rocker

2

—

Hydraulic adjuster

Inlet Manifold

The induction is designed to optimise torque across the engine speed/load range. The air charge

enters the induction manifold from the EGR throttle valve and passes into the plenum for

distribution to the cylinders.

The purpose of the plenum is to maximise the air charge into the cylinders.

The inlet manifolds are of plastic composite construction and are handed for the left and right hand

bank. The manifolds incorporate a twin plenum intake system and integrated cam covers. The

plenum systems are vacuum operated, these are located at the rear of the manifolds and are ECM

controlled

The inlet manifolds/cam covers are secured to the cylinder head by 13 shouldered bolts and sealed

by means of rubber gasket.

Camshafts

The camshaft's construction is of hollow steel tube with pressed on syntered lobes. There are two

camshafts per cylinder head. The camshafts have pressed on drive sprockets which are marked for

timing purposes. The interconnecting drive chain is also marked for valve timing. The drive chain has

www.

a hydraulic tensioner. Both banks are of similar construction. They are not interchangeable.

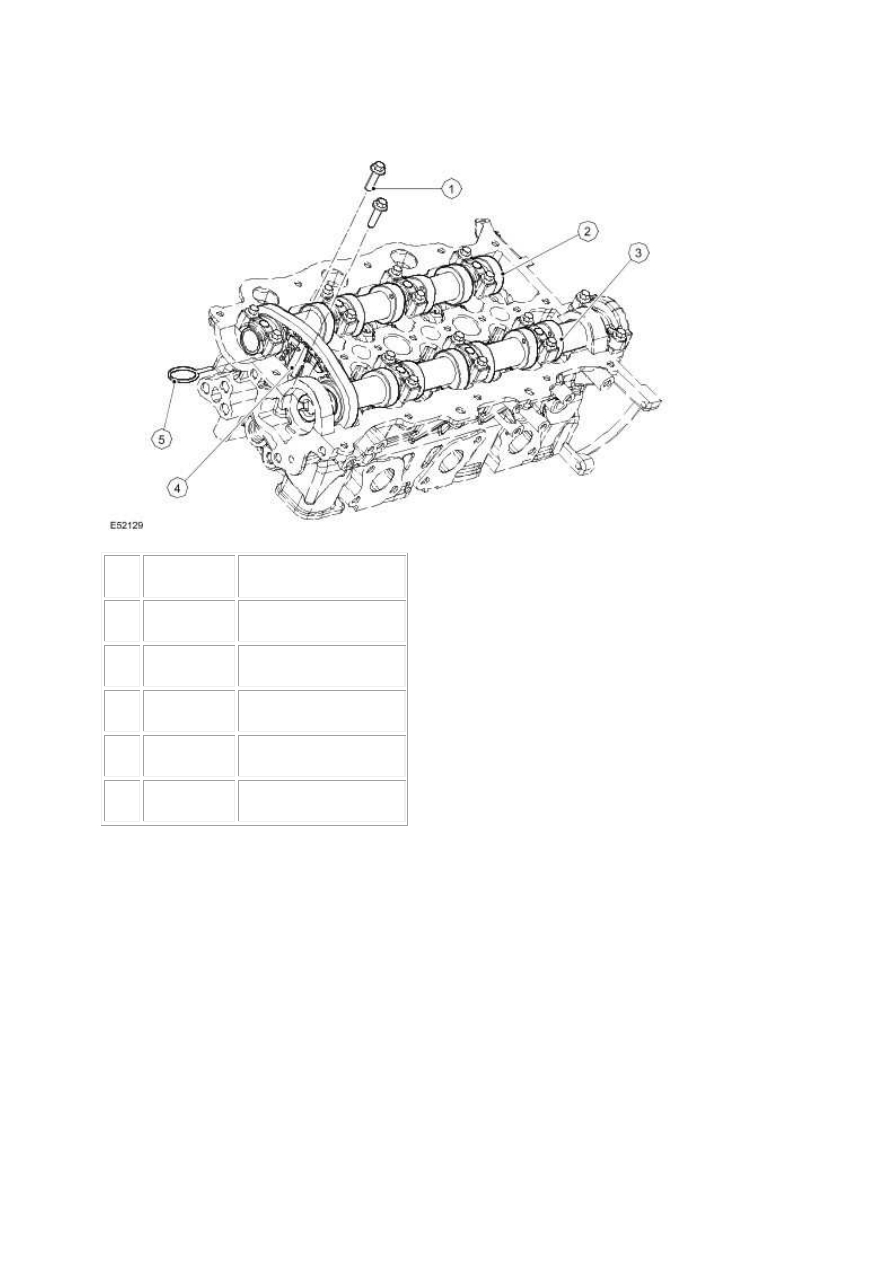

Item

Part Number

Description

1

—

Tensioner securing bolts

2

—

Camshaft bearing caps

3

—

Camshaft

4

—

Chain tensioner

5

—

Tensioner retaining pin

The drive sprockets also form the thrust faces for the camshaft. In production camshaft endfloat is

set to 0.065mm-0.185mm.

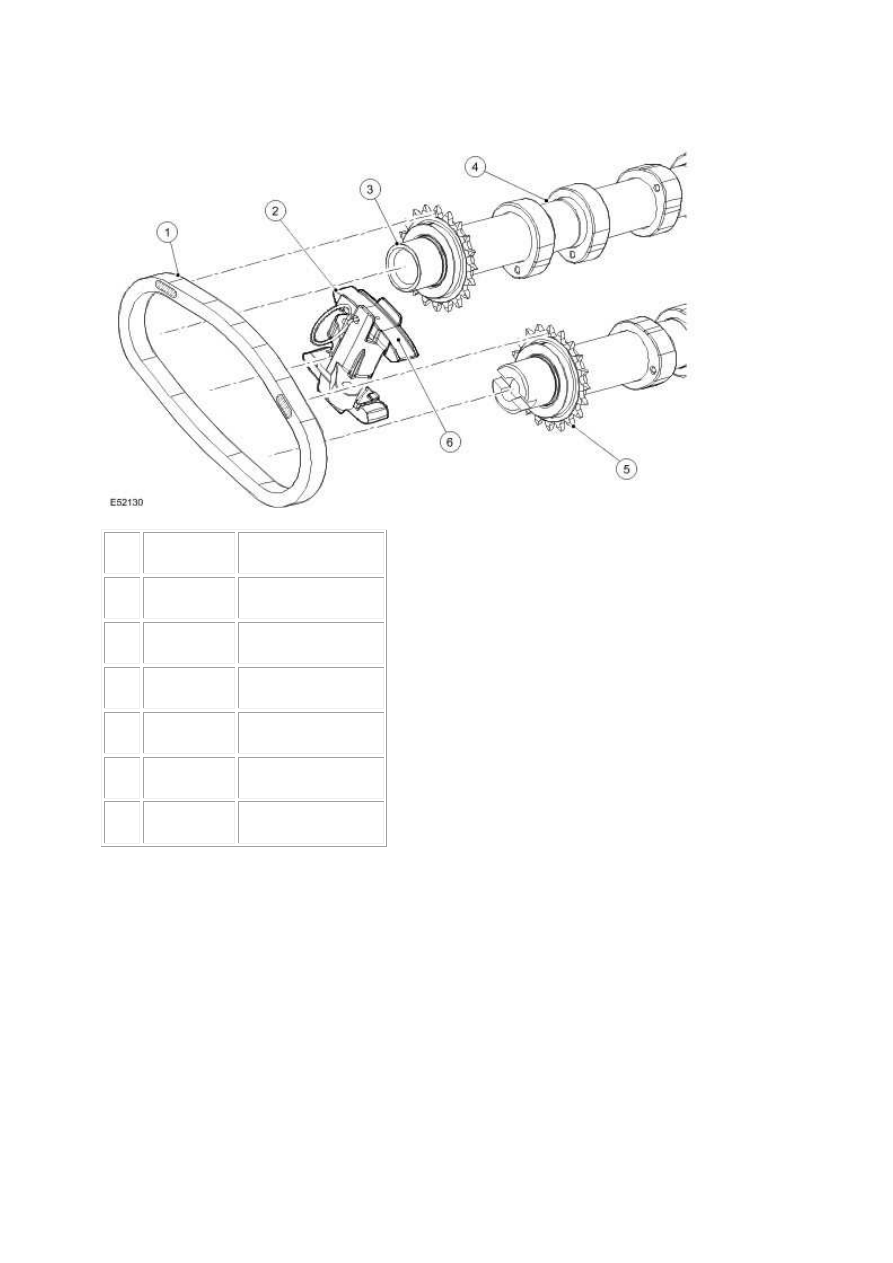

Item

Part Number

Description

1

—

Drive chain

2

—

Tensioner locking pin

3

—

Camshaft

4

—

Cam lobe

5

—

Drive gear

6

—

Tensioner

Camshaft Bearings

The camshafts are supported in five line bored bearings. The bearing caps, which are individually

identified, must be fitted in the correct sequence.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст