Loader Bobcat 853, 853H. Manual — part 63

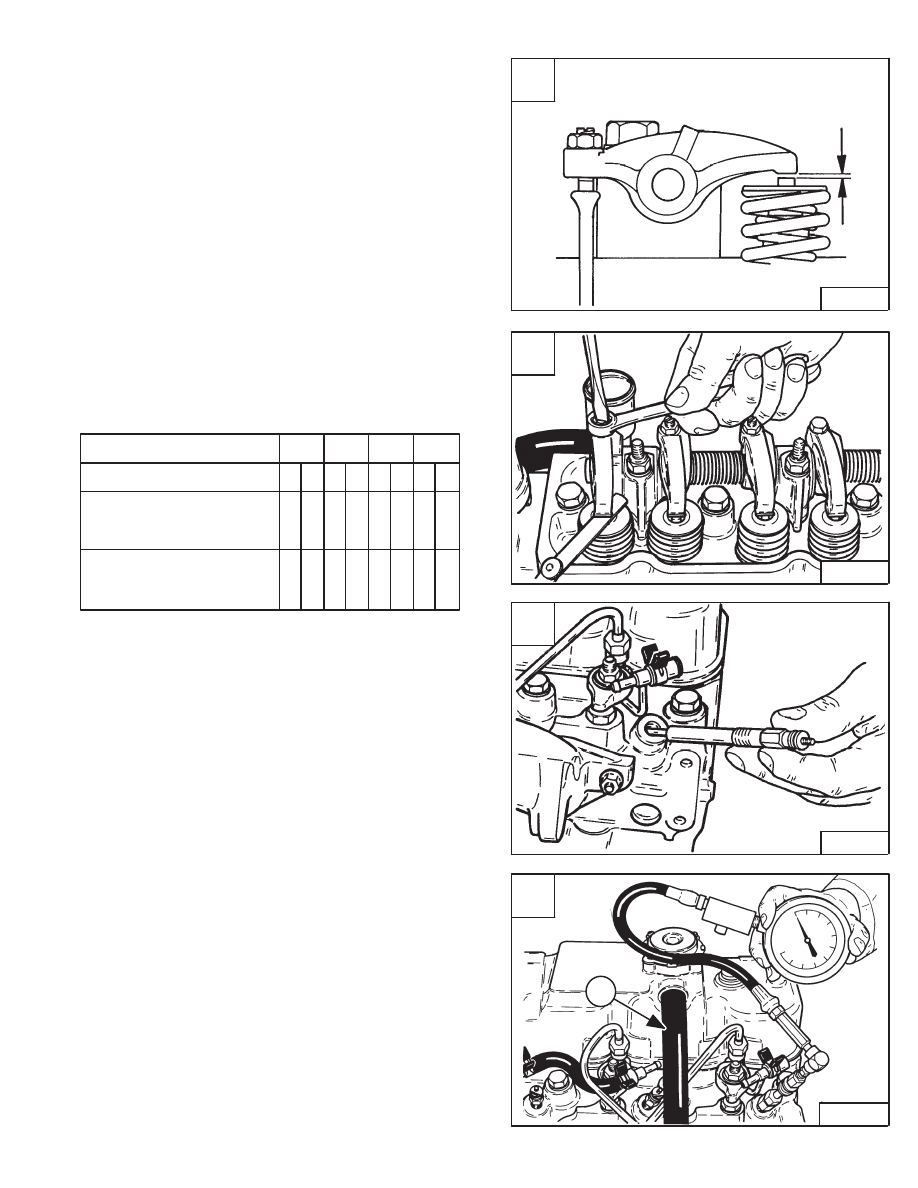

VALVE CLEARANCE

Adjustment

Make the valve clearance adjustment with engine

stopped and cold.

The correct clearance is 0.016 inch (0,41 mm) with the

engine cold [A].

Put the correct size feeler gauge between the rocker arm

and the valve stem. Turn the adjustment bolt until the

clearance is correct [B].

Use the following sequence to set the valve clearance:

Cylinder No.

1

2

3

4

Valve arrangement

I

E

I

E

I

E

I

E

Piston in No. 1 cylinder is

at TDC on compression

stroke

Piston in No. 4 cylinder is

at TDC on compression

stroke

• • •

•

• •

• •

Front

Rear

ENGINE COMPRESSION

Checking

The tools listed will be needed to do the following

procedure:

OEM1074 – Engine Compression Kit

MEL1268 – Compression Gauge Test Adapter

The engine must be at operating temperature.

Remove the glow plugs [C]. (See Page 7–40.)

Install the correct compression adapter into the cylinder

head.

Connect the compression gauge [D].

The engine must be turning at about 175 RPM.

The compression must be between 300–500 PSI

(2069–3448 kPa) with no more than 50 PSI (345 kPa)

difference between cylinders.

The engine has an open crankcase ventilation system.

The ventilation hose comes from the valve cover tube

(Item 1) [D] and passes down the side of the engine block.

A

B–04123

0.016 inch

(0,41 mm)

Cold

C

B–08922

D

B–08920

1

853, 853H Loader

–7–41–

Service Manual

B

B–08934

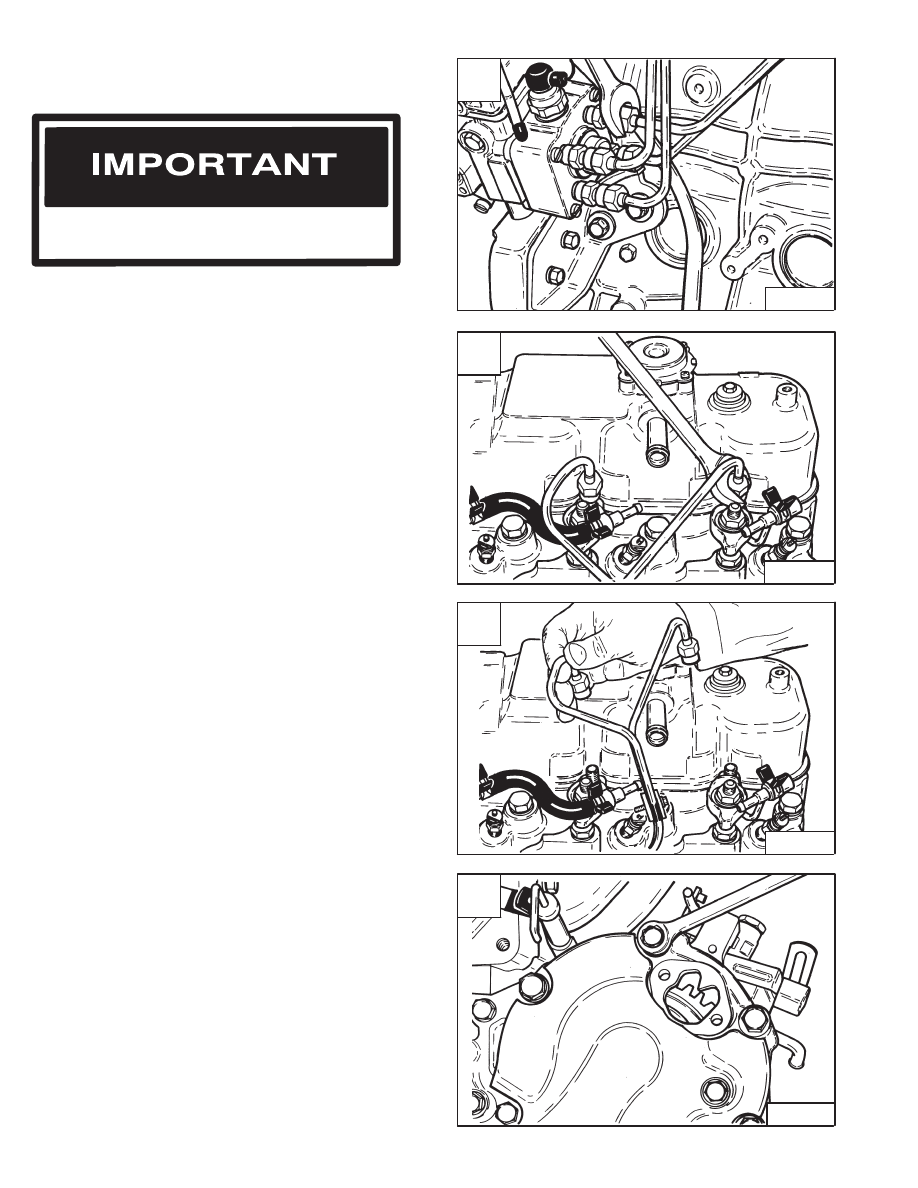

FUEL INJECTION PUMP

Description

The injection pump contains parts which have a very

close tolerance and its operation has a direct effect on the

performance of the engine.

Do not attempt to maintain or adjust unless

you are trained and have the correct

equipment.

I–2028–0289

Removal And Installation

Disconnect the throttle linkage.

Disconnect the shut–off wire [A].

Remove the valve cover.

Rotate the engine until No. 1 piston is at TDC. Both valves

at No. 1 cylinder are not moving and have clearance [B].

The TDC mark (Item 1) [C] is located on the engine pulley

v–belt groove.

There are two sets of timing marks on the engine pulley,

one at 12 o’clock and the other at the 3 o’clock position.

Use the timing marks located at the 3 o’clock position

(Inset) [C].

A

B–08976

C

P–04949

MC–01665

1

2

12 o’clock Position

12

°

14

°

TDC

3 o’clock

Position

16

°

–7–42–

853, 853H Loader

Service Manual

B

B–08935

FUEL INJECTION PUMP (Cont’d)

Removal And Installation (Cont’d)

Use the parting line (off–set) (Item 2) [A] or (Item 1) [B]

of the timing case cover to make alignment of the TDC

mark.

Early S/N Loader:

Disregard the pointer (Item 1) [C] in the belt shield for

timing reference.

Align the mark on the injection pump gear with the pointer

in the window [D].

A

P–04949

1

C

1

D

B–08939

853, 853H Loader

–7–43–

Service Manual

B

P–04952

1

FUEL INJECTION PUMP (Cont’d)

Removal And Installation (Cont’d)

Do not bend the high pressure fuel injection

tubes when removing or installing them.

I–2029–0289

Disconnect the high pressure fuel lines at the injection

pump [A].

Disconnect the fuel lines at the injectors [B].

Installation: Tighten the fittings on the high pressure fuel

lines to 14–29 ft.–lbs. (19–39 Nm) torque.

Remove the high pressure fuel lines from the engine [C].

Align the mark in the window before removing the

injection pump [A].

Remove the bolts at the front of the timing case cover [D].

Installation: Tighten bolts & nuts to 10–17 ft.–lbs. (14–23

Nm) torque.

A

B–08975

C

B–08915

D

B–08938

–7–44–

853, 853H Loader

Service Manual

B

B–08917

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст