DAF 95XF. Manual — part 133

6

Inspection and adjustment

BRAKE COMPONENTS

1-15

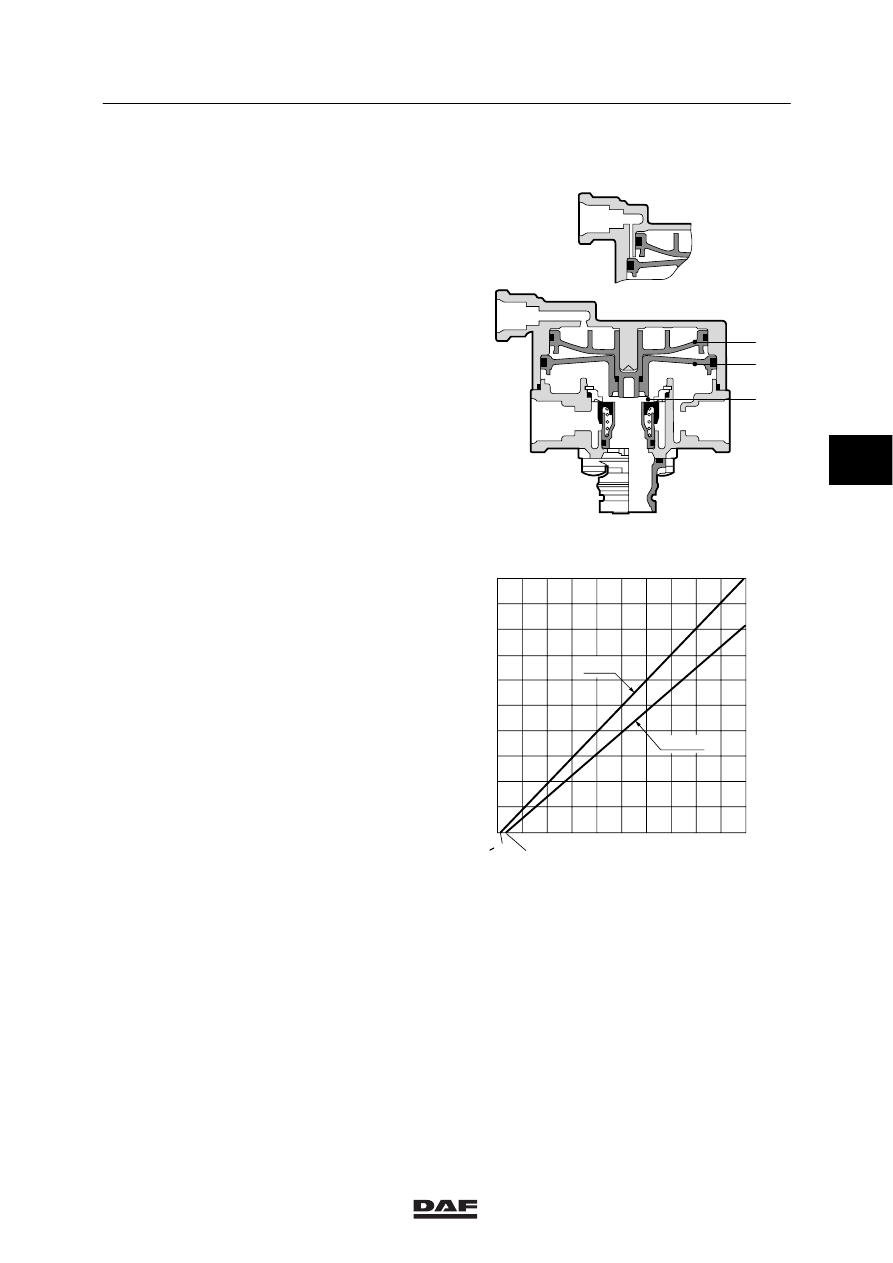

1.9 INSPECTION CHECK/RELAY VALVE

Checking the relay operation

1.

Ensure there is sufficient system pressure.

2.

Via a T-piece, connect a pressure gauge to

port (42) of the double check/relay valve,

and a pressure gauge to port (12) of the

spring-brake cylinder.

3.

Place the emergency parking brake valve in

the driving position, and check the reduced

output pressure from the double

check/relay valve to port (12) of the

spring-brake cylinder (see graph, line

P41 = 0 bar).

Checking non-increment function

1.

Ensure there is sufficient system pressure.

2.

Via a T-piece, connect a pressure gauge to

port (4) (test connection) of the

load-sensing valve, and a pressure gauge

to port (12) of the spring-brake cylinder.

3.

Set the parking brake valve in the parking

position.

4.

Slowly depress the brake pedal; both

gauges should indicate a similar pressure

increase (see graph, P42

≤41).

41

42

1

2

1

2

3

R600082

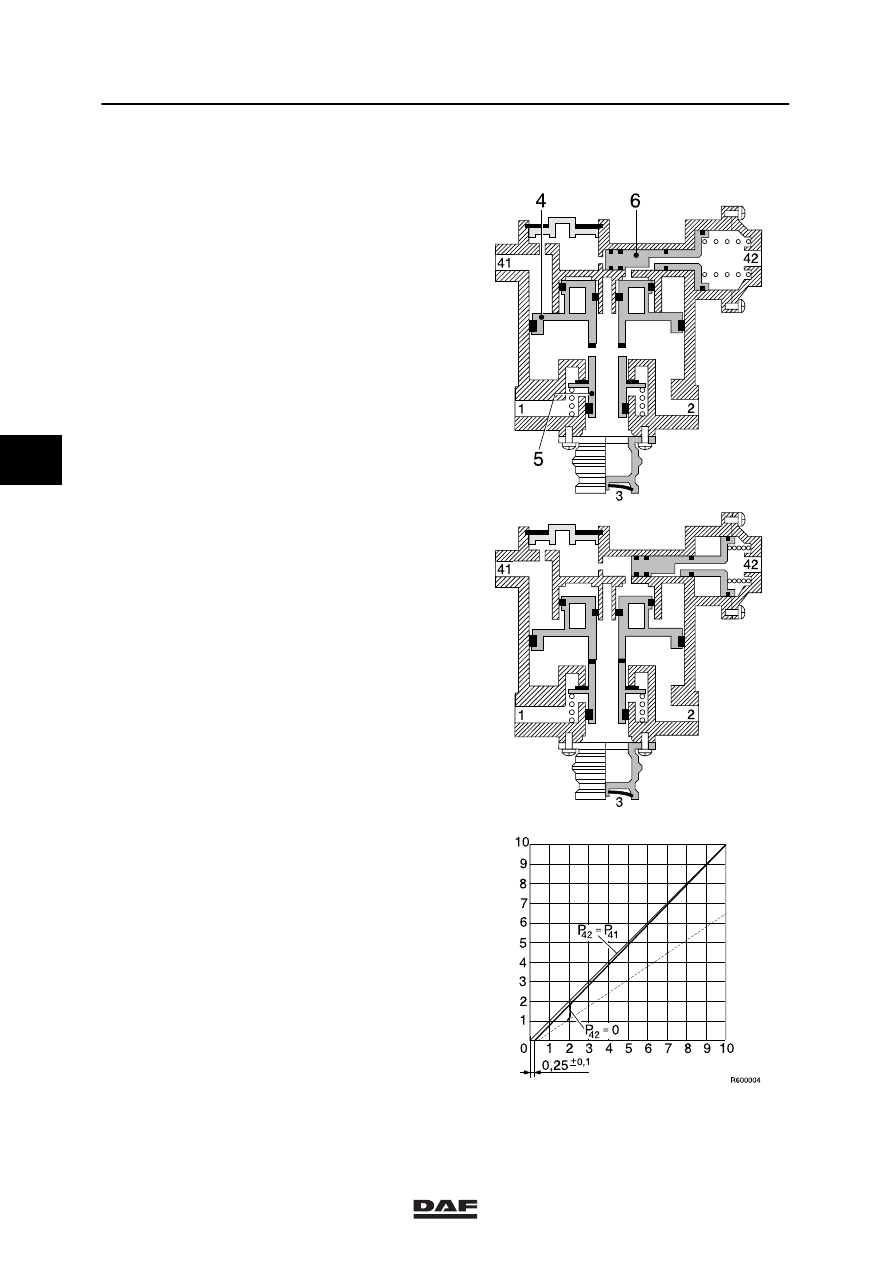

0

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

P

2

(bar)

P

41/42

(bar)

=

0.2

0.3

±

0.15

10

±

0.3

8.3

±

0.2

P

42

≤ 41

P

41 = 0 bar

R 600084

4

ǹ 0006

6

BRAKE COMPONENTS

Inspection and adjustment

1-16

1.10 INSPECTION EMPTY/LOAD RELAY VALVE

1.

Using a T-piece, connect a pressure gauge

to port (41).

2.

Connect a pressure gauge to the test

connection on one of the brake chambers

of the front axle.

3.

Connect a pressure gauge to the test

connection on one of the brake chambers

of the rear axle.

4.

Pressurise the system.

Testing when empty

5.

Set the load-sensing valve to the empty

position.

6.

Slowly depress the brake pedal.

The pressure increase on the front axle

should rise gradually, not in jumps.

The pressure at the front axle will increase

more gradually than at port (41). (An empty

vehicle will show a larger difference than a

partially loaded vehicle.)

Testing when fully loaded

7.

Set the load-sensing valve to the full-load

position.

8.

Slowly depress the brake pedal.

The pressure increase on the front axle

should rise gradually, not in jumps.

The pressure at the front axle will increase

as quickly (approx. 0.2 bar) as at port (41).

It should be possible to achieve system

pressure.

Testing when faulty

9.

Disconnect the line at port (42), and plug off

this line.

10. Repeat point 8.

11. Set the load-sensing valve as specified.

12. Reconnect the lines to ports (41) and (42),

as originally fitted.

13. Remove the pressure gauges.

4

ǹ 0006

6

Inspection and adjustment

BRAKE COMPONENTS

1-17

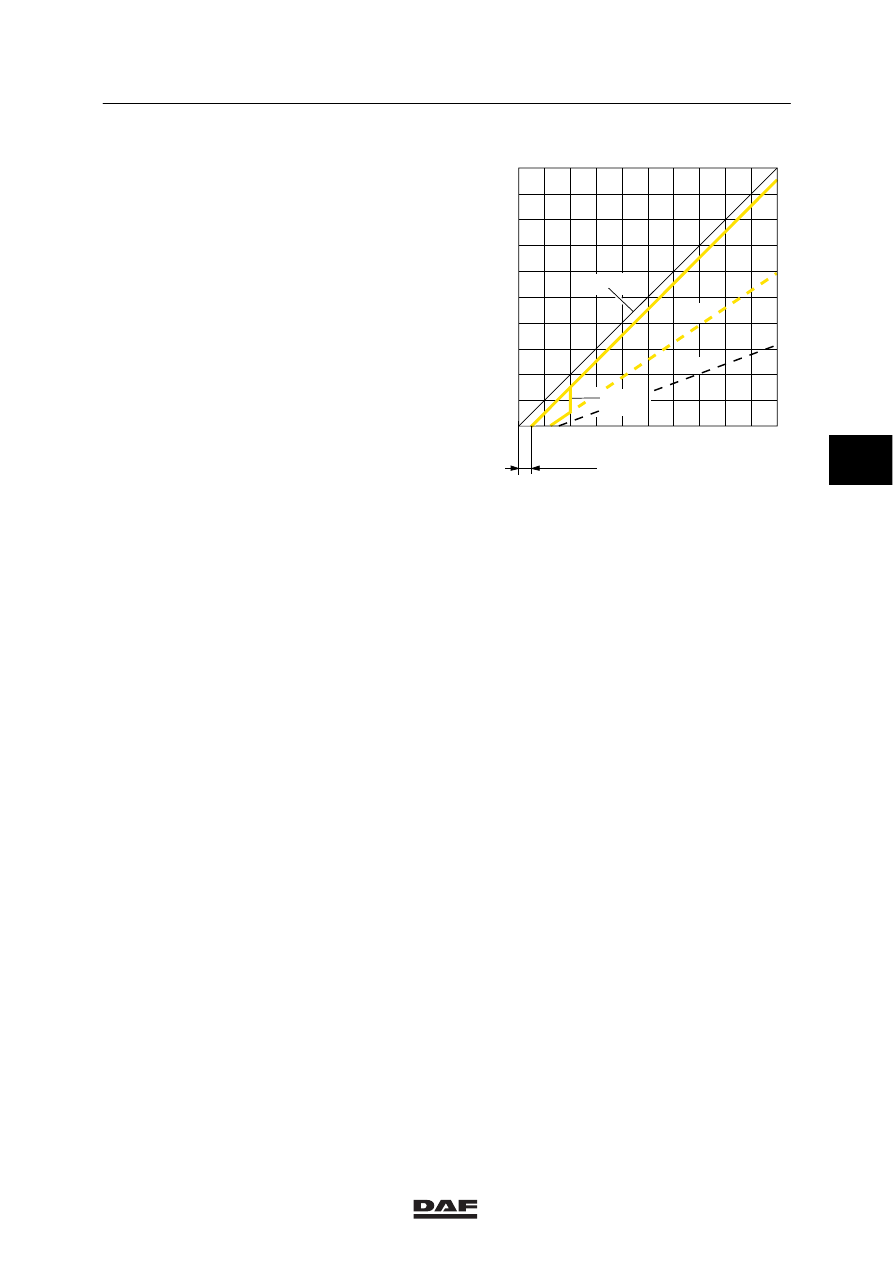

Checking the output pressure to the front

axle

1.

Measure the rear axle load.

2.

Check the setting of the load-sensing valve.

3.

Connect a pressure gauge to the test

connection for the load-sensing valve (input

pressure) and a pressure gauge to the test

connection on the spring-brake cylinder of

the front axle.

4.

Make sure that the reservoir pressure

exceeds 6.5 bar.

5.

Depress the brake pedal until the pressure

gauge on the test connection of the

load-sensing valve reads 6 bar, and read off

the braking pressure on the pressure gauge

on the front axle.

6.

Compare this value with the data on the

table, mounted on the door post.

0

0,1

0,5

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

+

_

P

0

42

=

P

42

P

41

=

1:2,7

1:1,5

41(bar)

p

2(bar)

p

R600339

Pressure reduction models with increase of

control pressure

4

ǹ 0006

6

BRAKE COMPONENTS

Inspection and adjustment

1-18

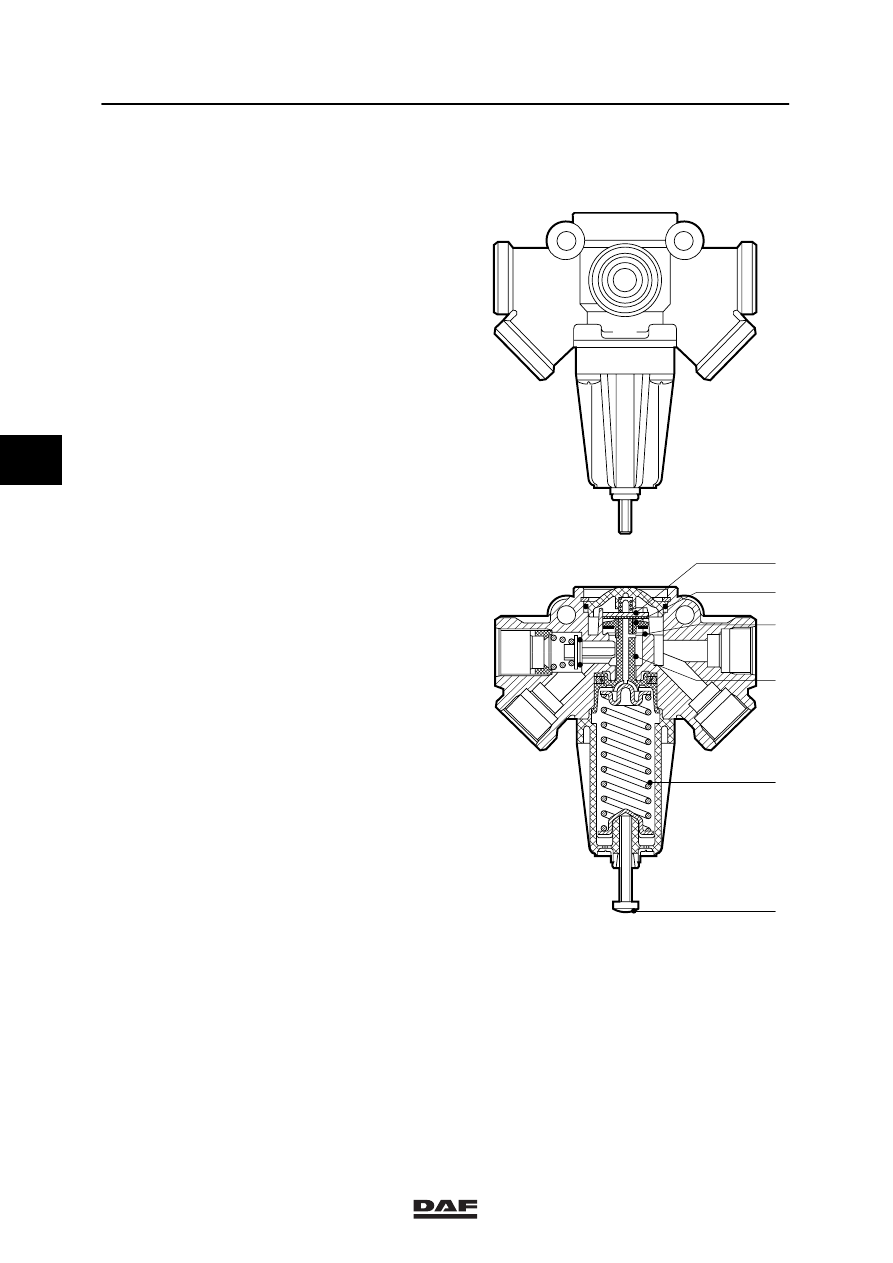

1.11 INSPECTION AND ADJUSTMENT, PRESSURE-LIMITING VALVE WITH

INTEGRATED NON-RETURN VALVE

Inspection pressure-limiting valve

1.

Place pressure gauges on ports (22) and

(23).

2.

Increase and decrease the pressure at port

(11) or (12) without exceeding the limiting

pressure; the gauge reading should rise

and fall simultaneously.

3.

Increase the pressure at port (11) or (12)

until it exceeds the limiting pressure; the

pressure gauge should indicate the limiting

pressure.

Adjust the pressure limiting valve, if

required.

Checking the non-return valve

1.

Place pressure gauges on ports (22) and

(23).

2.

Make sure that the reservoir pressure

exceeds 6.5 bar.

3.

Simulate a defect at port (21).

4.

The pressure gauge readings on both

pressure gauges (ports 22 and 23) should

not fall.

Adjustment pressure-limiting valve

1.

The pressure-limiting valve can be adjusted

with the adjustment screw.

R600226

11

2

3

6

5

12

23

21

22

1

4

4

ǹ 0006

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст