DAF 95XF. Manual — part 785

9

REAR AXLE ALIGNMENT

Inspection and adjustment

2-6

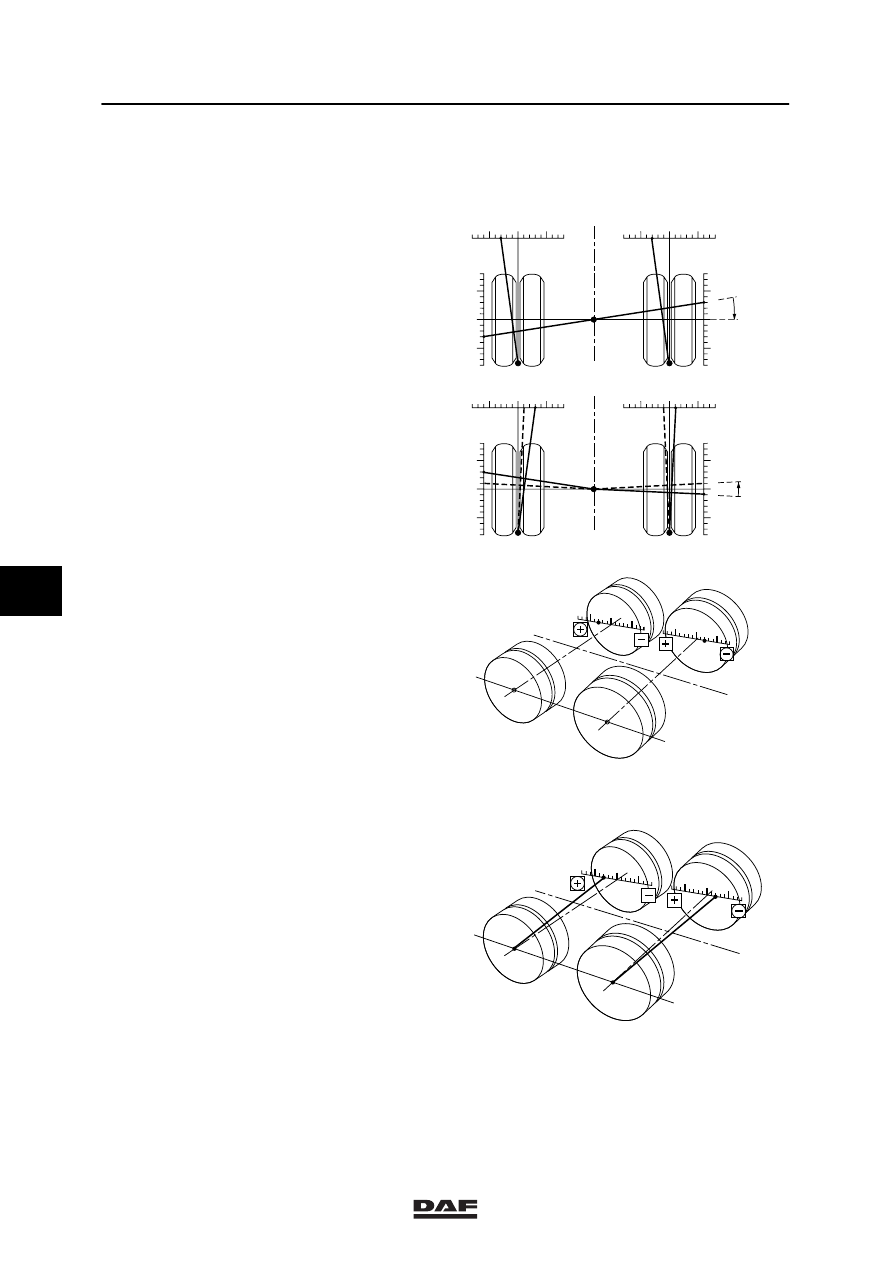

Example 3

This example refers to a vehicle with two rear

axles.

1.

The adjacent illustration shows the axles

from the previous examples. The positions

of the two axles in relation to the vehicle

centreline have already been determined.

2.

The angle (in mm/m) through which the

axles should have to be rotated in order for

them to be realigned in relation to the

vehicle centreline, corresponds with the

misalignment in relation to the vehicle

centreline.

Enter these values in the scale of the figure

at the bottom of drawing 11. Take care to

enter this value on the correct side (+ or

-- side) of the vehicle centreline indicated in

this drawing.

3.

From the small circle in the left wheels,

draw a straight line to the values on the

scale (illustration 12).

The position of the two axles in relation to

each other is now visible. It can now be

determined whether realigning is required

and which axle must be realigned.

If necessary, the required realignment can

also be indicated as a dotted line in the

figure.

Note:

Often it is only necessary to realign one of

the axles to ensure that the non-parallelism

of both axles in relation to each other is

within the permitted tolerance limits.

4.

The non-parallelism in this example is

5 mm/m. In this case it is therefore

sufficient to realign the front axle only.

Note:

The realignment option depends on the

type of axle suspension.

-

+

+

-

-

+

+

-

1

1

3

3

2mm/m

1

1

1

1

-

+

+

-

-

+

+

-

3

3

3

3

3mm/m

3

2

Afb. 11

W9 08 012

3

2

W9 08 013

Afb. 12

6

ǹ 200316

9

Inspection and adjustment

REAR AXLE ALIGNMENT

2-7

Measurement report

-

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

W9 08 014

6

ǹ 200316

9

REAR AXLE ALIGNMENT

Inspection and adjustment

2-8

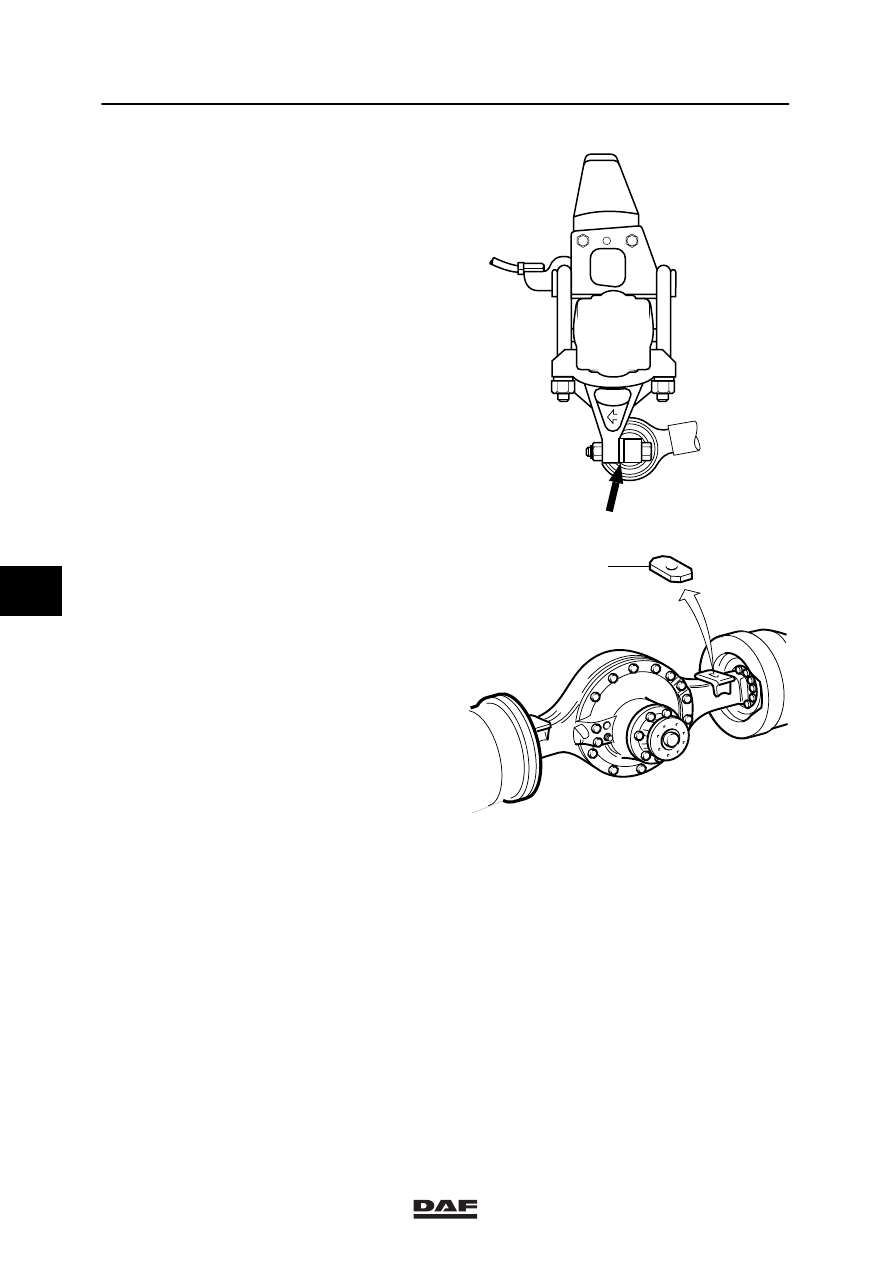

Adjusting the position of the air-sprung

axle(s) and tandem axle suspension

-

The misalignment of the axle can be

corrected by inserting a hardened steel ring

(DAF no. 0202838) between the torque rod

and the torque rod bracket. This ring is

3 mm thick. If necessary, grind down the

ring. It is not allowed to use more than 1

ring per bolt. The use of several rings would

increase the risk of a connection coming

loose.

-

The thickness of this shim in millimetres

should be equal to the rear-axle

misalignment in mm/m.

W9 08 015

Adjusting the axle position (leaf-sprung

trailing axle suspension)

To allow correction of the misalignment of the

driven axle in relation to the trailing axle

(non-parallelism), the position of the driven axle

can be adjusted.

The position of the driven axle is determined by

a metal block (A) placed in a recess of the axle

seat.

This block contains a hole for the spring

assembly centre bolt. Replacing this block with

a block with the hole further to the front or the

rear will cause the entire axle to shift forward or

backward at that side.

A

W9 08 016

6

ǹ 200316

9

Inspection and adjustment

REAR AXLE ALIGNMENT

2-9

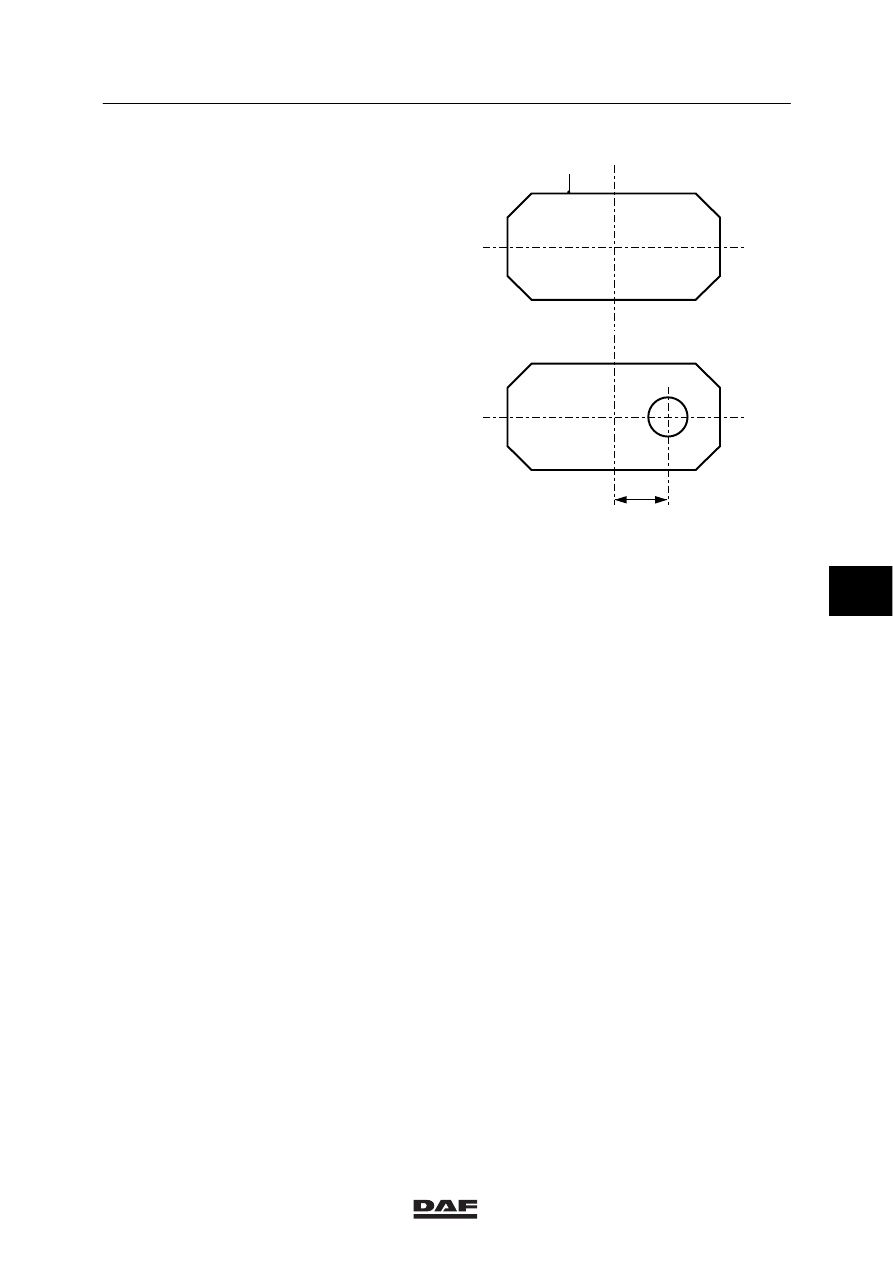

For correction purposes, blocks (B) without a

hole can be ordered under DAF-no. 0893145.

The hole must then be custom drilled in the

correct position.

1.

Have a block without a hole at hand.

2.

Determine the misalignment of the driven

axle in relation to the trailing axle in mm/m.

3.

This misalignment value corresponds with

the distance between the centre of the hole

to be drilled and the centre of the block

(distance L in the adjacent illustration).

4.

Very accurately drill a

∅ 17.5 mm hole in

the block in the correct place. Check the

distance.

5.

Remove the nuts from the U-bolts.

6.

Jack up the chassis until there is sufficient

clearance between the spring assembly and

the axle seat. Support the chassis in a safe

way.

7.

Remove the metal block which is now loose

in the axle seat.

8.

Place the new block in the axle seat,

making sure that the axle is realigned in the

correct direction.

9.

Fit the U-bolt nuts and tighten them to the

specified torque. See “Technical data”.

L

B

W9 08 017

6

ǹ 200316

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст