DAF LF45, LF55 Series. Manual — part 644

©

200515

3-5

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

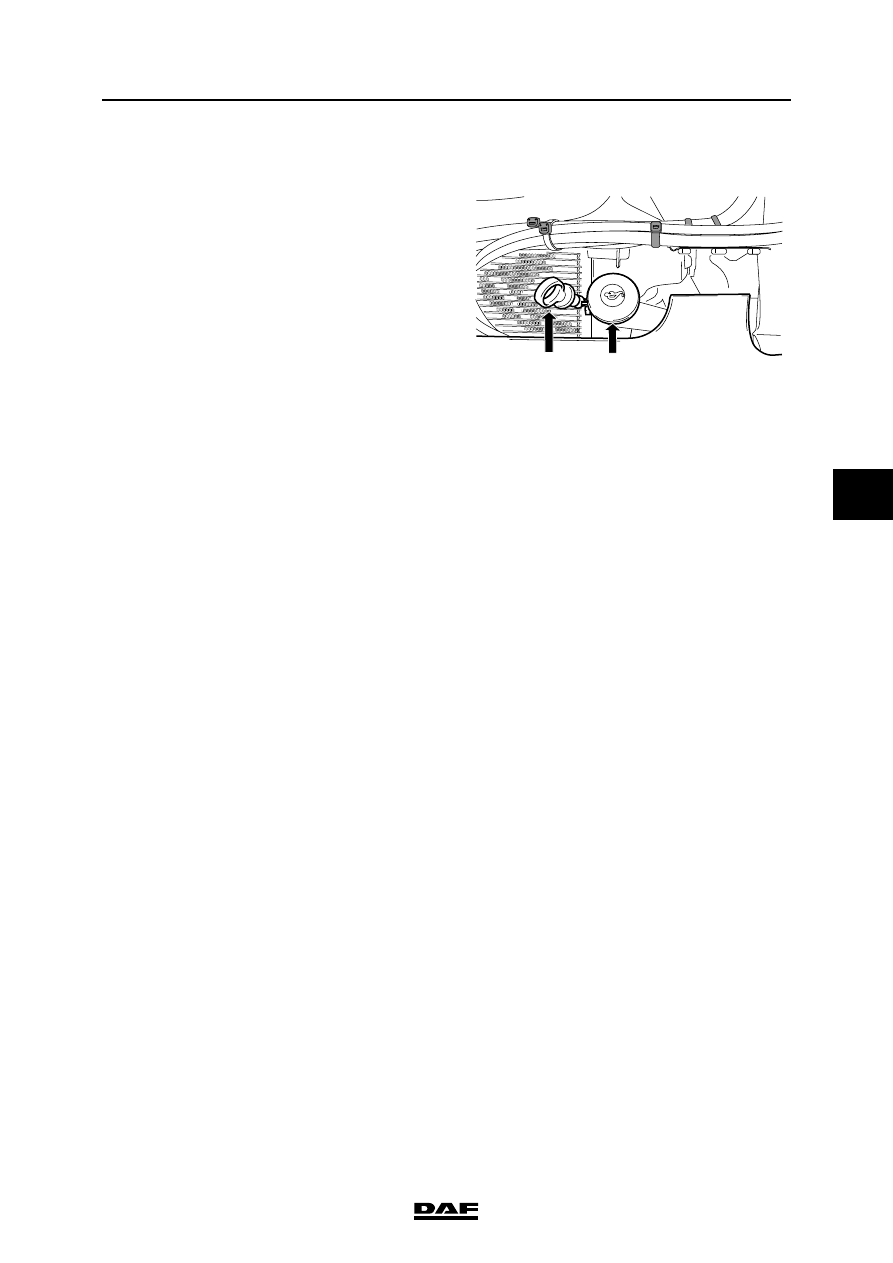

3.8 CHECKING THE ENGINE OIL LEVEL

1.

Ensure that the vehicle is entirely horizontal.

2.

Pull the dipstick (2) out of the holder.

3.

Wipe the dipstick clean with a lint-free cloth.

4.

Put the dipstick back into the holder.

5.

Pull the dipstick out again and check the oil

level.

Note:

It takes approx. 20 minutes for all the oil to

run into the sump when the engine is "warm".

If the dipstick is checked immediately after

switching the engine off or immediately after

oil has been added, the level shown on the

dipstick will be too low.

6.

Fill oil through the filler opening (1) until the

oil level reaches the maximum mark. See

"Draining and filling". Always use the

specified oil. Do not top up above maximum

level.

Note:

For the difference between minimum and

maximum engine oil level, see "Technical

data".

2

1

G0 00 212

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-6

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

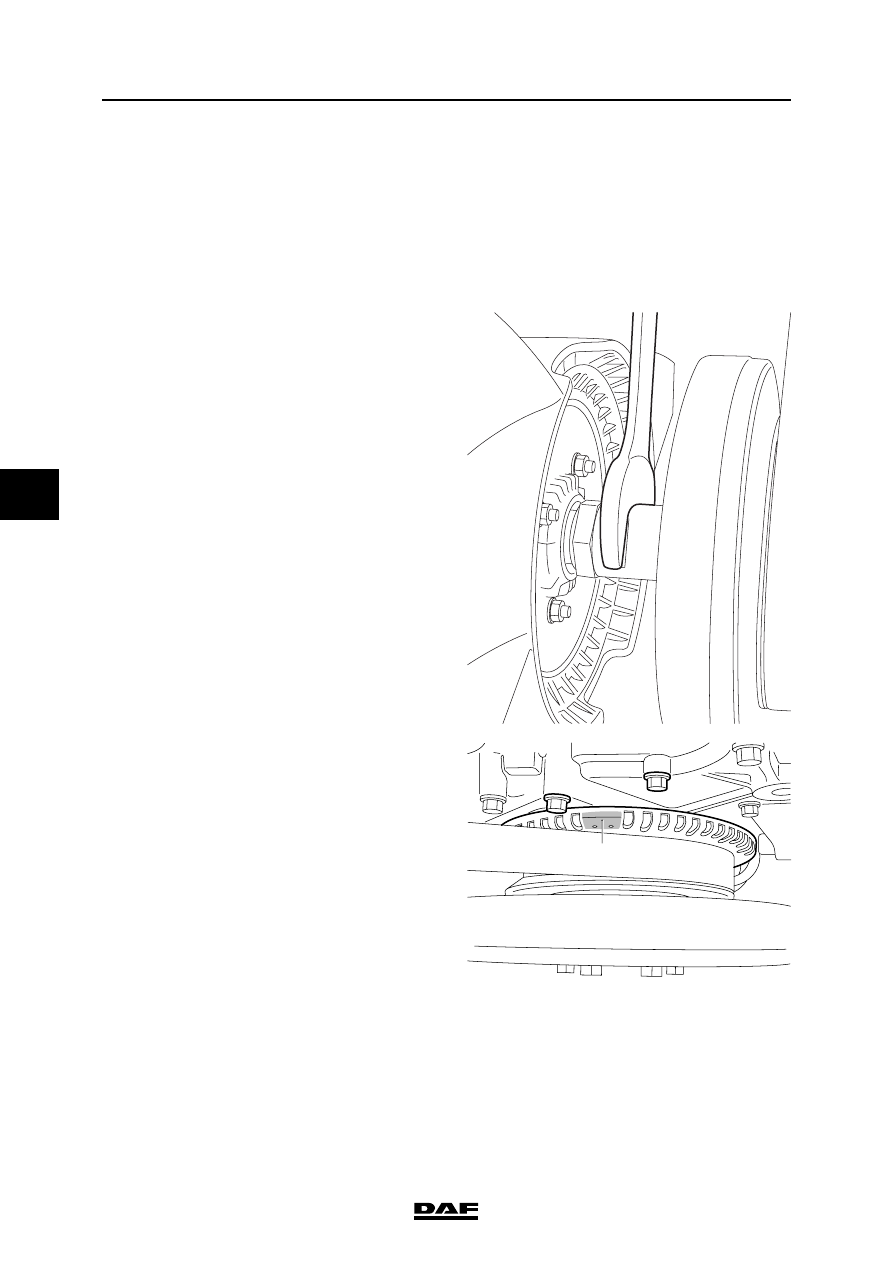

3.9 CHECKING AND ADJUSTING BE ENGINE VALVE CLEARANCE

Note:

Checking and adjusting valve clearance must

only be done when the engine is cold.

1.

Remove the valve cover. See "Removing

and installing".

2.

Use an open-end spanner on the fan shaft to

turn the crankshaft clockwise, as seen from

the vibration damper end (this is the engine's

normal direction of rotation), until the mark

(A) is between the bolts (B) and the valves of

cylinder 1 are in overlap position.

Note:

"Overlap" is the moment at which the inlet

valves start opening and the exhaust valves

stop closing.

The inlet valves are operated by the short

rockers and the exhaust valves by the long

rockers.

M201318

M201065

A

B

B

©

200515

3-7

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.

Check/correct the valve clearance of the

specified inlet and exhaust valves. Set the

correct valve clearance by loosening the lock

nut and rotating the adjusting screw in the

correct direction; see "Technical data" for the

correct valve clearance.

4.

Using an open-end spanner on the fan shaft,

turn the crankshaft one rotation further so

that the mark (A) is once again between the

bolts (B) and the valves of cylinder 4 overlap.

5.

Check/correct the valve clearance of the

specified inlet and exhaust valves. Set the

correct valve clearance by loosening the lock

nut and rotating the adjusting screw in the

correct direction; see "Technical data" for the

correct valve clearance.

6.

Fit the valve cover. See "Removing and

installing".

7.

Fit the flexible pipe, air inlet pipe and bracket.

M201064

Cylinder

Inlet valve

Exhaust valve

1

2

X

3

X

4

X

X

M201065

A

B

B

Cylinder

Inlet valve

Exhaust valve

1

X

X

2

X

3

X

4

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-8

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

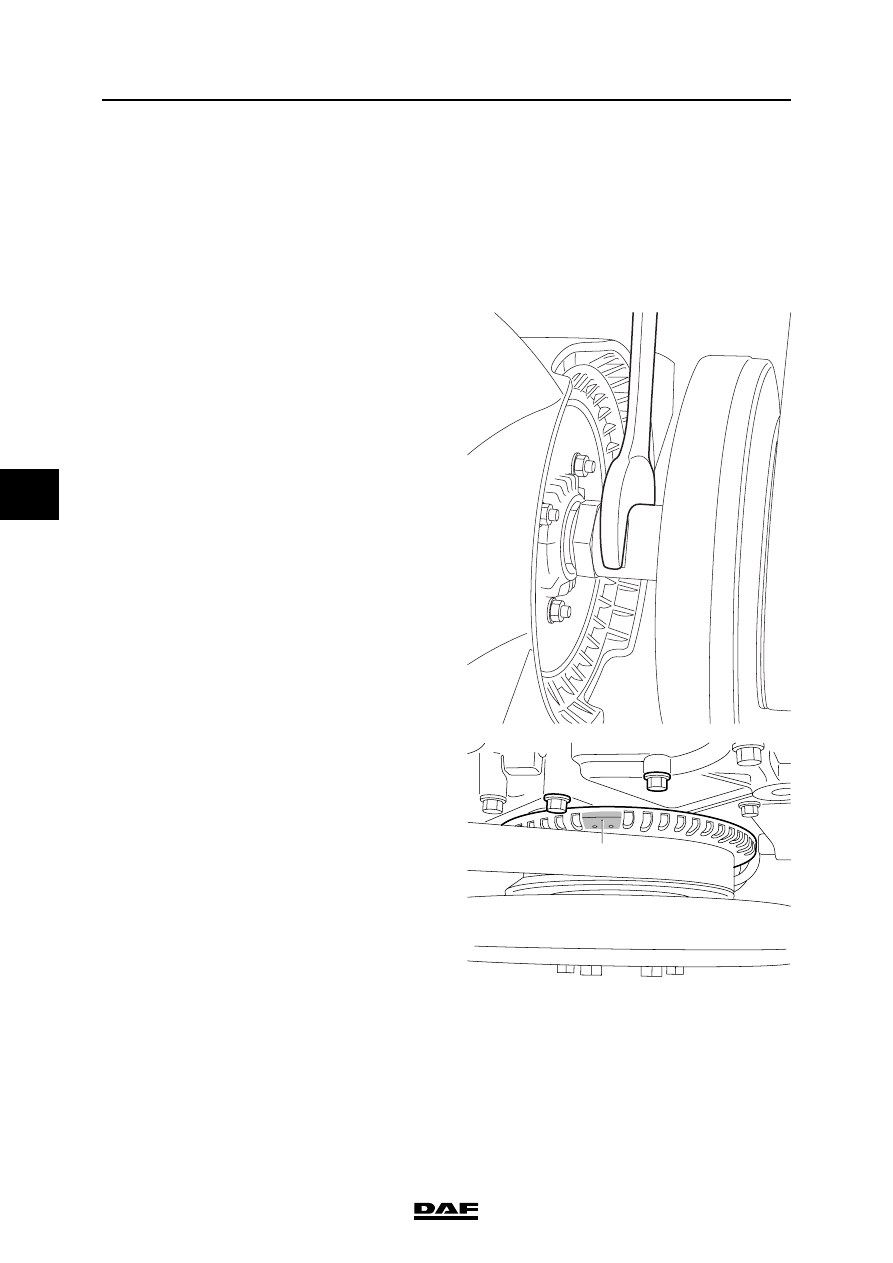

3.10 INSPECTION AND ADJUSTMENT, CE ENGINE VALVE CLEARANCE

Note:

Inspection and adjustment of valve clearance

must only be carried out when the engine is cold.

1.

Remove the valve cover. See "Removal and

installation".

2.

Use an open-end spanner on the fan shaft to

turn the crankshaft clockwise, as seen from

the vibration damper end (this is the engine's

normal direction of rotation), until the mark

(A) is between the bolts (B) and the valves of

cylinder 1 are in overlap position.

Note:

"Overlap" is the moment at which the inlet

valves start opening and the exhaust valves

stop closing.

The inlet valves are operated by the short

rockers and the exhaust valves by the long

rockers.

M201318

M201065

A

B

B

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст