DAF LF45, LF55 Series. Manual — part 293

©

200416

5-1

Removal and installation

BE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

2

5. REMOVAL AND INSTALLATION

5.1 REMOVAL AND INSTALLATION, INJECTOR PIPE

Never bend injector pipes as they

may kink or crack.

The injector pipes form part of the

high-pressure section of the fuel

system. When the unions are

unscrewed, fuel under high pressure

may escape. Take measures to

prevent fire and injury. Collect the

escaping fuel in a suitable container.

Dirt in the fuel system can lead to

significant damage to parts of the

system. Prevent this by cleaning the

parts before disassembly and then

sealing all open connections.

Note:

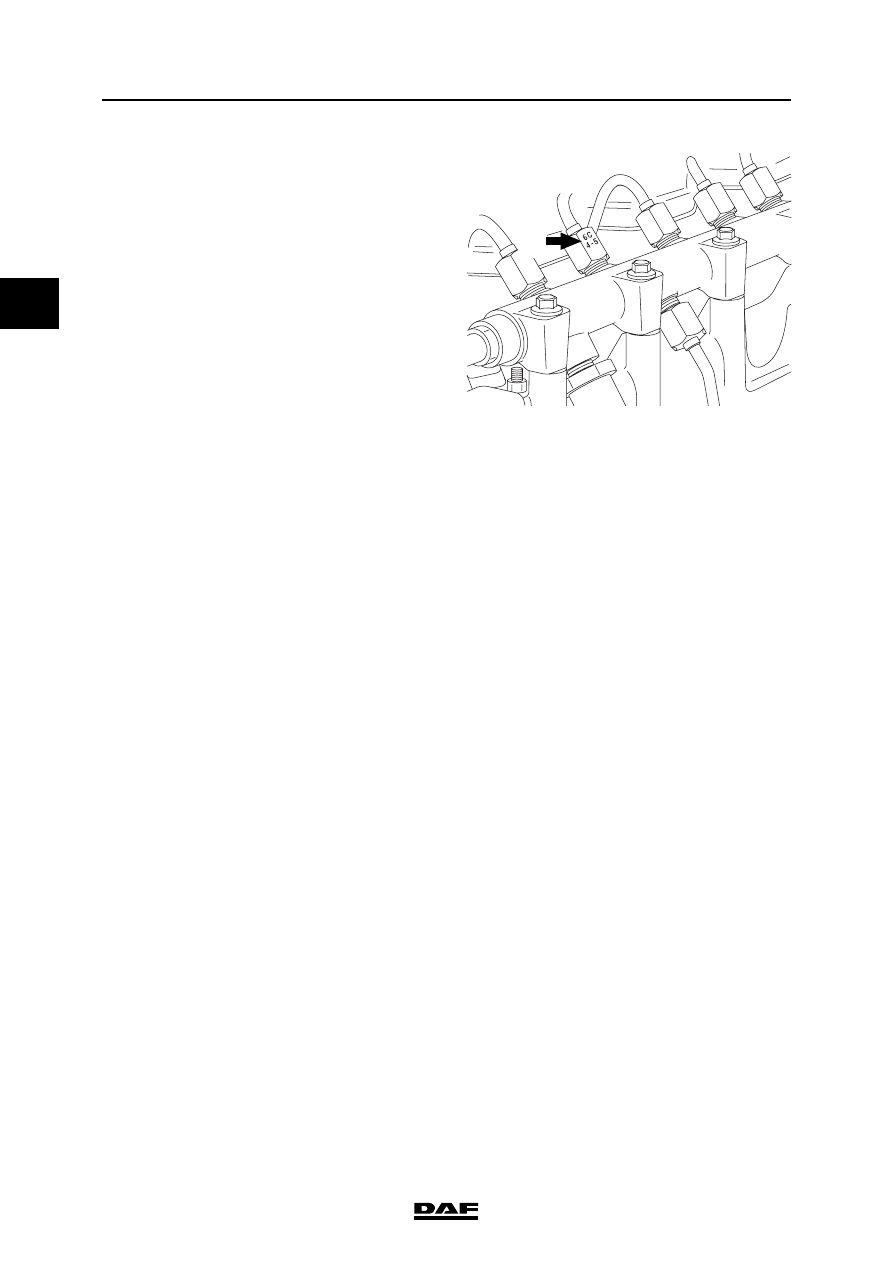

Codes (1) are stamped in the injector pipe unions

to enable correct positioning. The first figure is

the number of cylinders of the engine followed by

the fitting position.

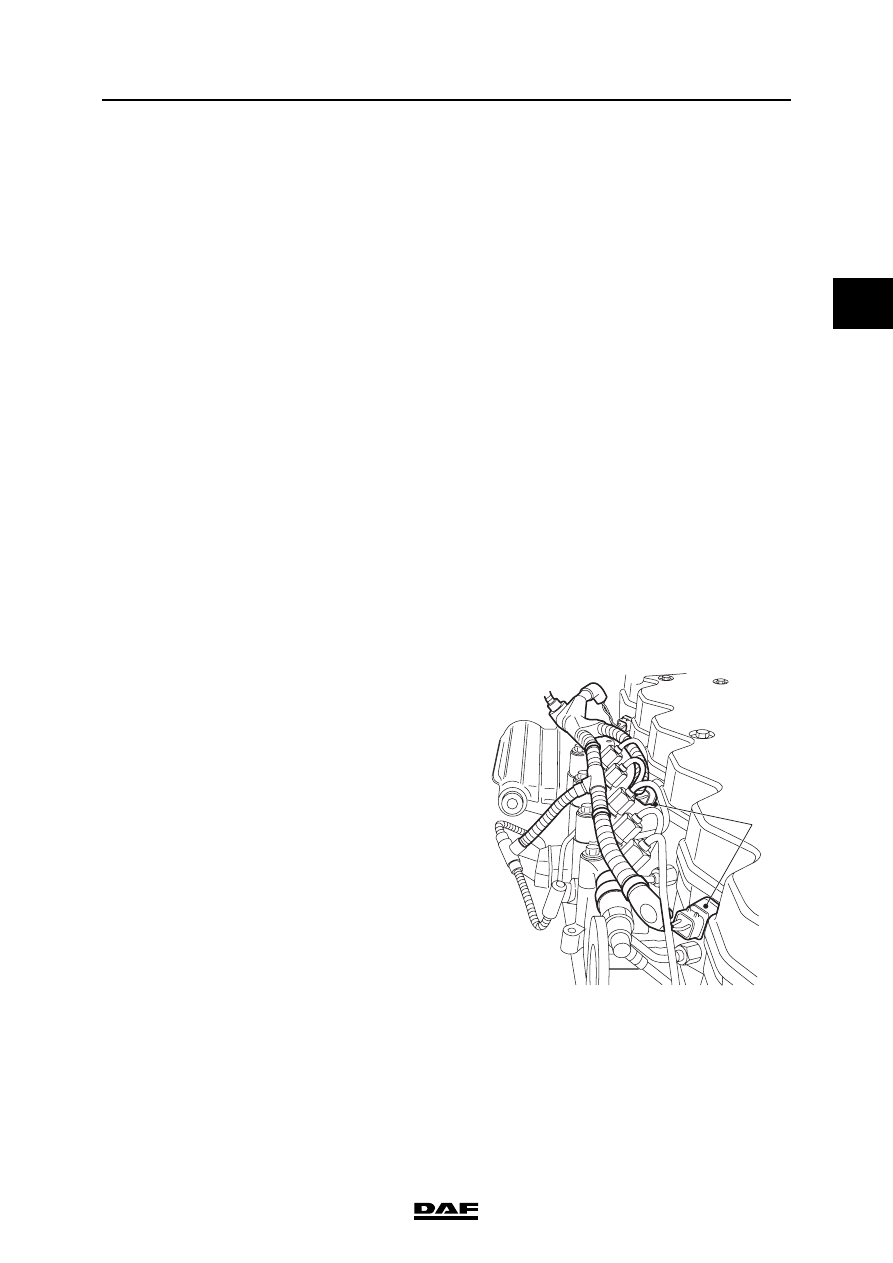

Removing the injector pipe

1.

Clean the area surrounding the unions, both

near the injectors and near the fuel rail.

2.

Remove the connectors (1) of the injectors

from the valve sleeve.

}

}

i400852

1

BE ENGINE FUEL SYSTEM

5-2

©

200416

Removal and installation

2

ΛΦ45/55 series

4

Note:

Note the sequence in which the injector pipes are

removed. They should be re-fitted in precisely the

reverse order.

3.

Unscrew the unions on both sides of the pipe

and remove the pipes.

4.

Immediately plug the openings.

Installing the injector pipe

1.

Clean the injector pipe and blow-clean it with

dry compressed air.

2.

Fit the injector pipes in reverse order and

hand-tighten the unions. When all the pipes

and unions are correctly fitted, the unions

must be tightened to the specified torque.

See "Technical data".

3.

Fit the connectors of the injectors in the valve

sleeve.

4.

Start the engine to bleed the high-pressure

section of the fuel system and inspect all fuel

pipes for leaks.

1

i400482

©

200416

5-3

Removal and installation

BE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

2

5.2 REMOVAL AND INSTALLATION, FUEL SUPPLY PIPE

When removing a fuel pipe, fuel will

escape. Collect the fuel and avoid

the risk of fire.

Dirt in the fuel system can lead to

significant damage to parts of the

system. All open connections must

therefore be sealed.

Removing the fuel supply pipe

1.

Disconnect the injector pipes.

2.

If necessary, remove the fuel rail.

3.

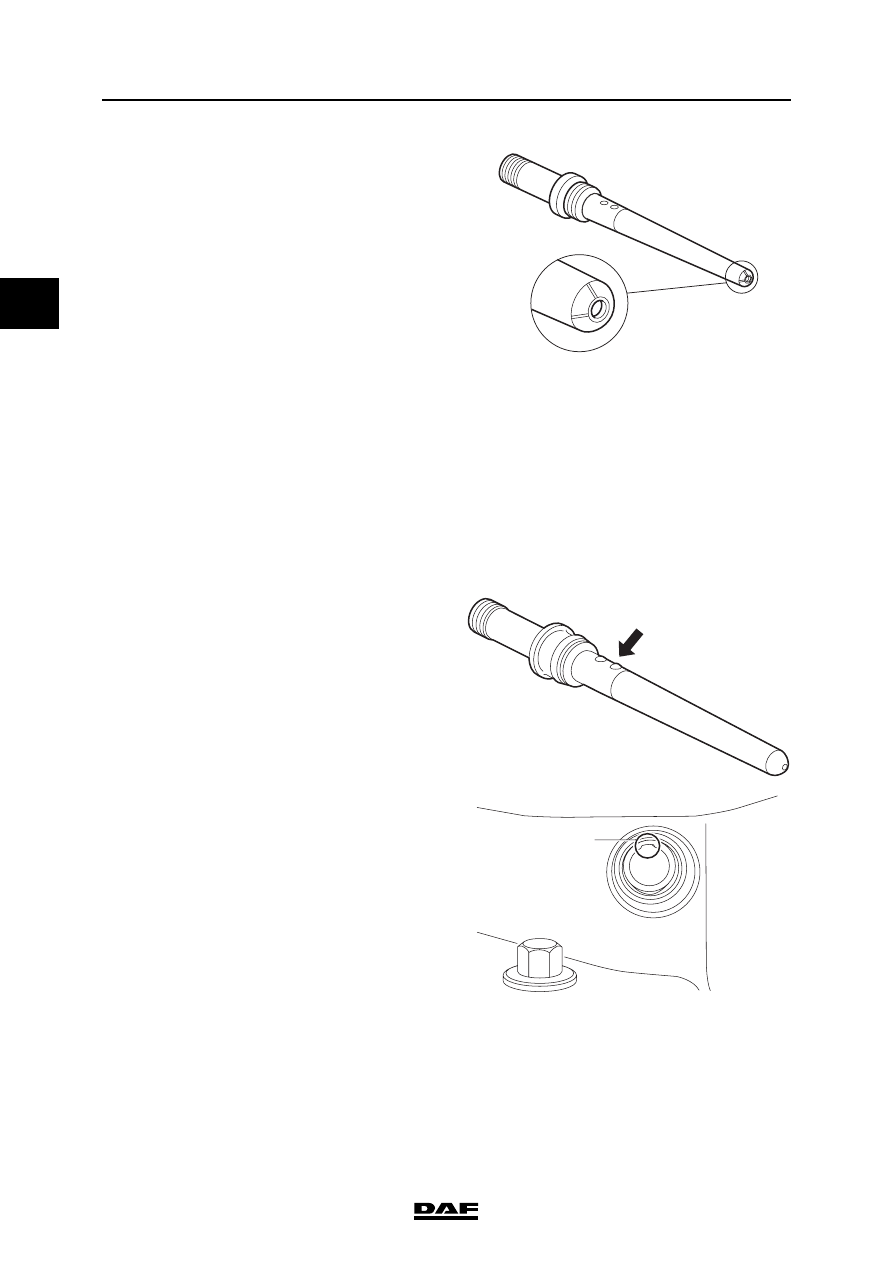

Remove the nut (1) from the fuel supply pipe.

4.

Mark the positions of the fuel supply pipe (1)

and pull it out of the cylinder head with

special tool (DAF no. 1329473) (2).

Note:

If the injector is not replaced, the fuel supply

pipe may be re-used provided it is fitted with

the original injector.

Installing the fuel supply pipe

The following guidelines must be adhered to:

-

If the injector is defective, both the injector

and the fuel supply pipe must be replaced.

-

If the fuel supply pipe is defective and in

addition the sealing surface with the injector

is damaged, both the injector and the fuel

supply pipe must be replaced.

-

If the fuel supply pipe is defective and the

sealing surface with the injector is not

damaged, the fuel supply pipe must be

replaced but the injector can be reused.

}

}

1

i400486

i400823

2

1

BE ENGINE FUEL SYSTEM

5-4

©

200416

Removal and installation

2

ΛΦ45/55 series

4

1.

Check the fuel supply pipe for damage and

signs of leakage.

Leakage in the fuel supply pipe can be

recognised by erosion tracks (lines) on the

nose of the supply pipe. If necessary or if in

doubt, replace the fuel supply pipe.

Note:

If any indications of leakage are visible,

remove the injector and check the injector

fuel connection for signs of leakage.

2.

Fit a new O-ring on the fuel supply pipe.

3.

Apply a thin layer of clean engine oil to the O-

ring of the fuel supply pipe, the screw thread

of the nut and the contact surface of the nut

with the fuel supply pipe.

4.

Check the bore of the fuel supply pipe for

foreign matter and damage. Also check

whether the supply bore in the injector is

correctly positioned for the bore, because it

is possible to mount the injector turned

through 180

, so that the fuel supply port is

on the other side.

Note:

The fuel supply pipe has one or two positioning

balls. The fuel supply pipe can only be installed

with the ball(s) on top, as the bore in the cylinder

head has a groove (1) at the top. Press the fuel

supply pipe as far as possible into the bore, with

the ball pointing upwards. Ensure that the O-ring

is not damaged in this process.

i400776

i400790

1

i400807

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст