DAF LF45, LF55 Series. Manual — part 445

©

200436

2-1

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

2. DESCRIPTION OF COMPONENTS

2.1 COMPRESSOR

The compressor is a 225-cm

3

one-cylinder

design with a water-cooled cylinder head. The

compressor is mounted on the left side of the

engine against the flywheel housing.

The compressor is driven by the camshaft gear

via a gear wheel.

OPERATION OF BRAKE COMPONENTS

2-2

©

200436

Description of components

3

ΛΦ45/55 series

6

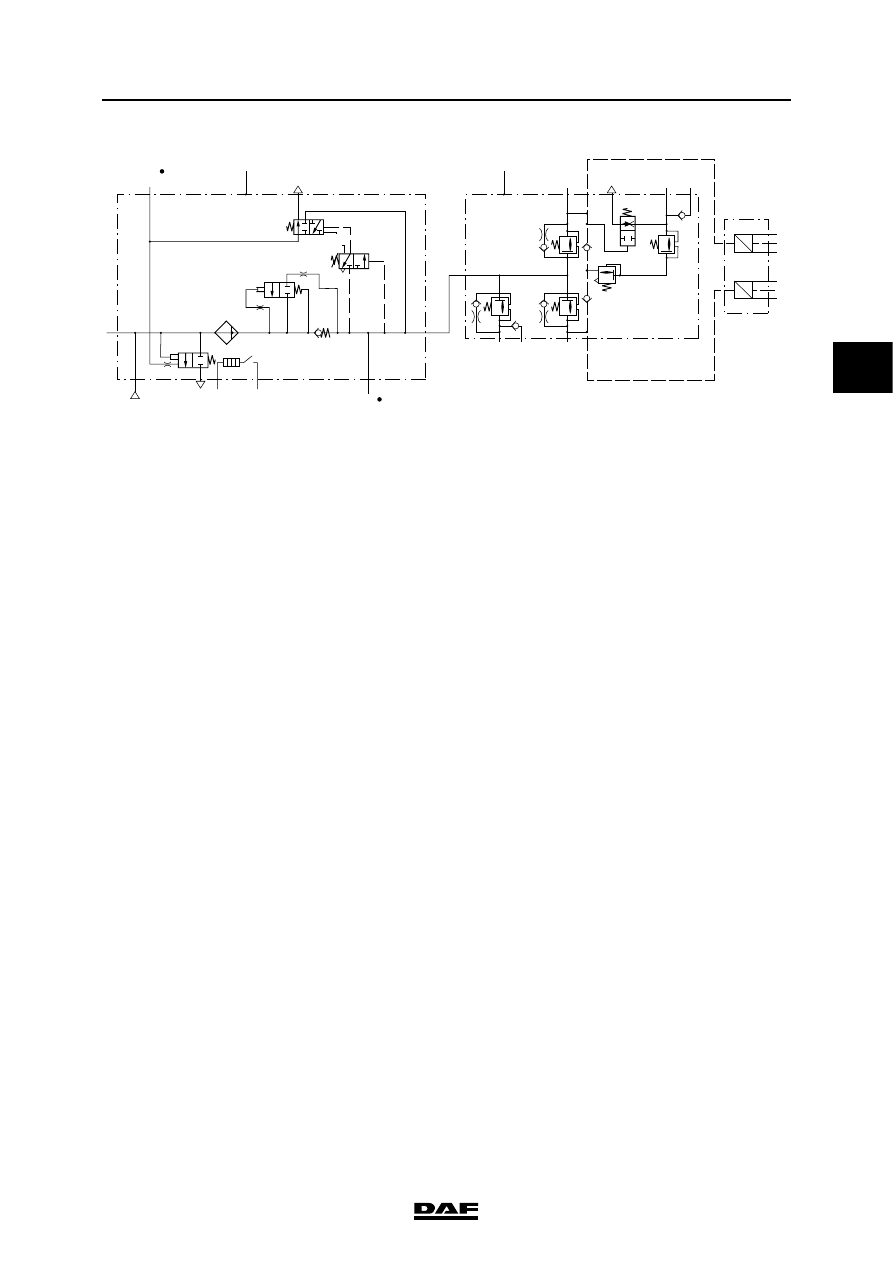

2.2 AIR SUPPLY UNIT

Purpose

The air supply unit is a combination of an air

dryer, pressure regulator and four-circuit safety

valve and has the following functions:

-

removing water, oil and other foreign matter

from the air before it enters the brake

system;

-

setting the system pressure by means of a

built-in pressure regulator;

-

limiting the pressure build-up to a given

value;

-

splitting the brake system into four circuits

and, should one circuit fail, protecting the

other circuits against running empty.

Air dryer function

Filling the system

The air supplied by the compressor reaches the

air dryer via connecting point 1/12. In the filter

element (1), the air passes through the coarse

filter (2), which sieves out the oil and dirt particles.

In addition, the air condenses against the cool

wall of the element. Subsequently, the air flows

through filter grains (3), which extract the water

vapour from the air. The air thus dried flows via a

non-return valve (4) to connecting point 21.

R600359

R600504

10

9

6

7

11

5

8

b

c

a

16

12

21

1/12

23

3

4

2

1

18

17

14

13

15

19

©

200436

2-3

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

Operation, pressure regulator

The pressure increase occurring during filling is

returned to the built-in pressure regulator via

bore 12.

When the pre-set cut-out pressure is reached, the

control piston (13) is moved to the right against

the pressure of spring 14. This releases bore 15

in pin 16. The system pressure will enter space

"a" above blow-off valve 8 via bore 17, opening

the blow-off valve (8) against the pressure of the

spring (18).

If the pressure in the brake system drops to the

cut-in pressure due to air consumption, the

control piston (13) will move to the left and shut

bore 15 in pin 16. This bore, and therefore

channel 17 and space a, will now be bled via

bore 19. The blow-off valve (8) will close. The

compressor will now again build up the pressure

in the air system.

Regenerating

A regeneration tank is no longer necessary,

because the air inside the circuits is used.

A built-in pneumatic time switch controls the

regeneration process:

-

throttle 5 determines the amount of air;

-

throttle 6 determines the length of time.

24

21

1

F

D

H

K

3

A

E

C

G

1

12

24

26

22

21

23

3

23 25

P

U

6.2

6.3

6.4

6.1

6.2

P

U

6.5

6.6

6.7

B

R600580

0

OPERATION OF BRAKE COMPONENTS

2-4

©

200436

Description of components

3

ΛΦ45/55 series

6

Air is admitted to chamber "b" via throttle 6 and air

is also admitted to chamber "c" via bore 7 in the

piston (9). On cut-out by the pressure regulator,

the blow-off valve (8) is opened and chamber "c"

is bled via bore 7. The piston (9) is moved to the

right against the pressure of spring 10 as a result

of the difference in pressure between chambers

"b" and "c". This releases the piston (9) from its

seat (11) and air will flow in the opposite direction

via throttle 5 from the system through the filter

element. At the same time, pressure is reduced in

chamber "b" via throttle 6. The piston (9) moves

to the left until it abuts the seat (11). Regeneration

is now complete.

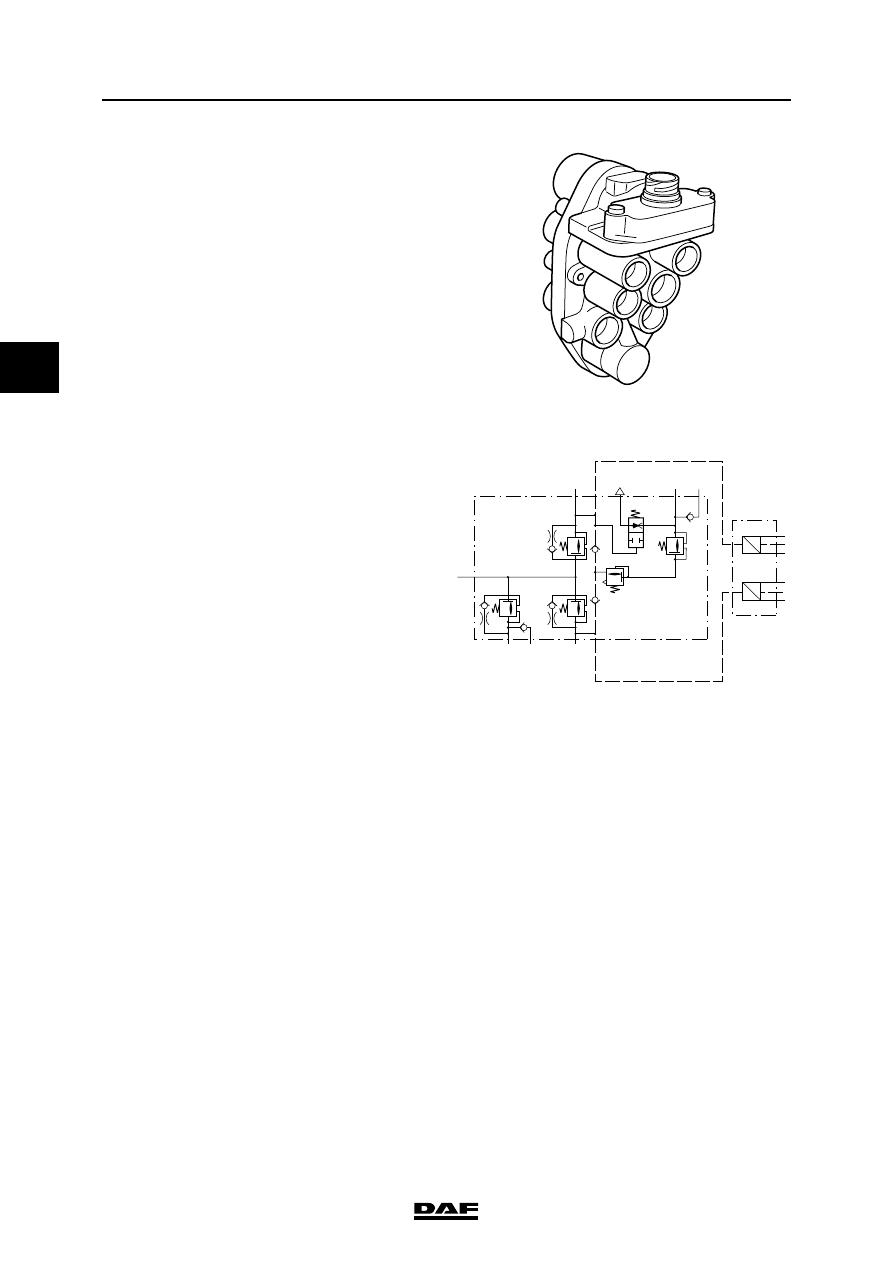

Four-circuit safety valve operation

The air supply enters via connecting point 1.

From there, the air flows to the built-in pressure

relief valves of circuits 1, 2 and 4.

As soon as the valve of circuit 1 and/or circuit 2

opens, the air will be able to flow through to

circuit 3, the trailer brake and parking brake

circuit. For reasons of safety, a built-in flowback

function empties circuit 3 when the pressure in

circuit 1 is too low. This is done to activate the

emergency brake function.

R600475

24

1

H

K

26

22

21

3

23 25

P

U

6.2

6.3

6.4

P

U

6.5

6.6

6.7

R600476

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст