DAF LF45, LF55 Series. Manual — part 179

©

200505

4-3

Checking and adjusting

BE ENGINE COOLING SYSTEM

ΛΦ45/55 series

2

3

4.3 INSPECTION, VISCOUS FAN CLUTCH

Do not run the engine in an enclosed

or unventilated area. Make sure

exhaust fumes are properly

extracted. Remain at a safe distance

from rotating and/or moving

components.

Testing with a cold engine

During this test, the slip in the viscous fan clutch

is measured while the clutch is not operating.

This test must be carried out when the engine is

"cold" (coolant temperature approximately 50

C).

1.

Check the coolant level, and top up as

necessary.

2.

Start the engine and run it at idling speed for

at least 5 minutes.

Then use an optical rev counter to measure

the fan speed at different engine speeds

(from idling to maximum engine speed).

During this test procedure, the speed of the

fan should be approx. 600 to 1100 rpm.

Testing with a warm engine

This test checks whether the bimetallic strip starts

opening the valve at an operating temperature of

85 - 95

C.

1.

Check the coolant level, and top up as

necessary. Be careful when topping up the

coolant of a warm engine.

2.

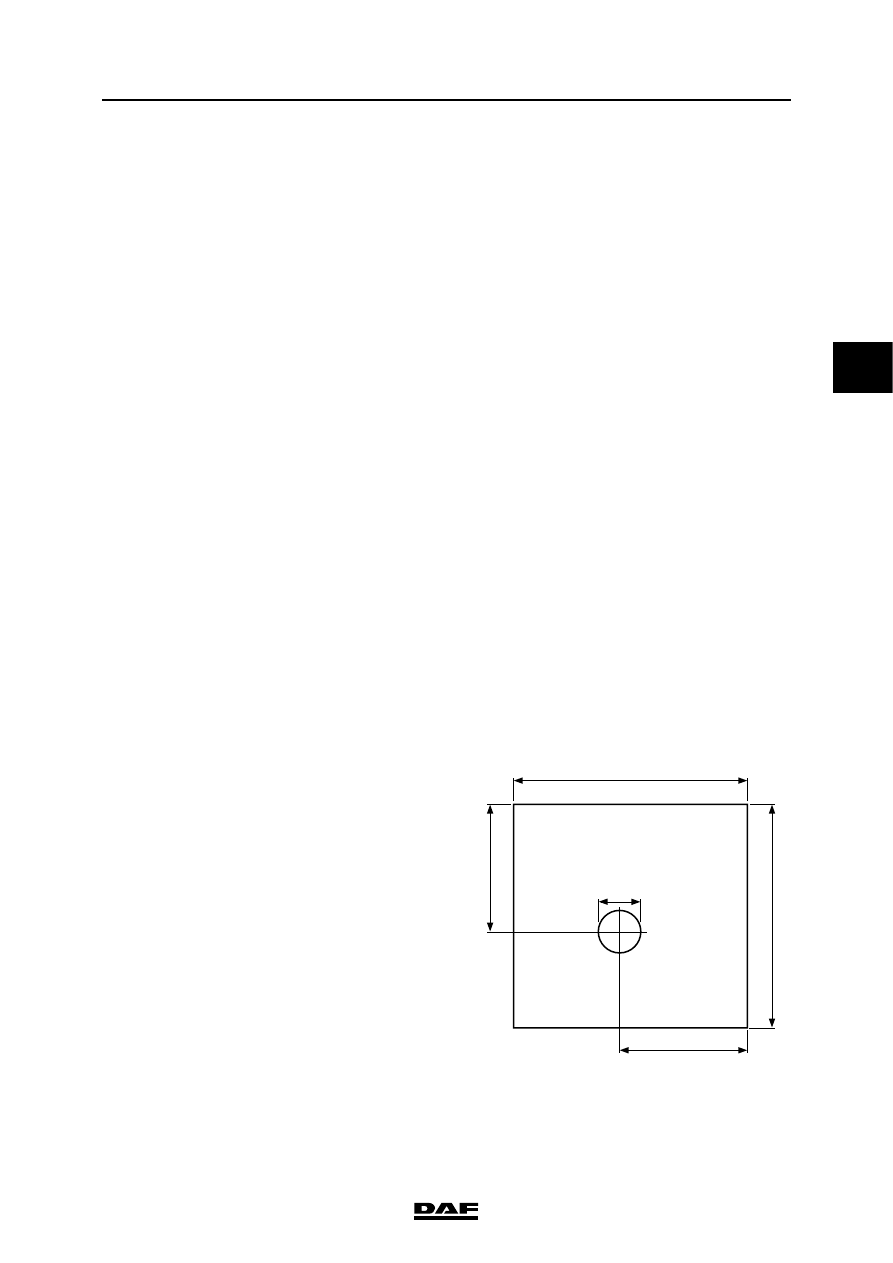

Take a sheet of cardboard with a 100 mm

hole, as shown in the drawing opposite, and

place it in front of the radiator, with the hole

in front of the viscous clutch.

3.

Check that the gearbox is in neutral.

4.

Bring the cooling system to operating

temperature.

5.

Allow the fan drive flange to run at a speed of

1000 rpm. Then use an optical rev counter to

determine the difference between the

rotating speeds of the fan and the drive

flange. The speeds will differ as a result of

slip in the viscous clutch. When the clutch is

fully engaged, the slip must not exceed 10%.

If it is more, the viscous fan clutch must be

replaced.

}

100

550

300

525

300

M201167

BE ENGINE COOLING SYSTEM

4-4

©

200505

Checking and adjusting

3

ΛΦ45/55 series

2

©

200505

5-1

Removing and installing

BE ENGINE COOLING SYSTEM

ΛΦ45/55 series

2

3

5. REMOVING AND INSTALLING

5.1 REMOVAL AND INSTALLATION, COOLANT PUMP

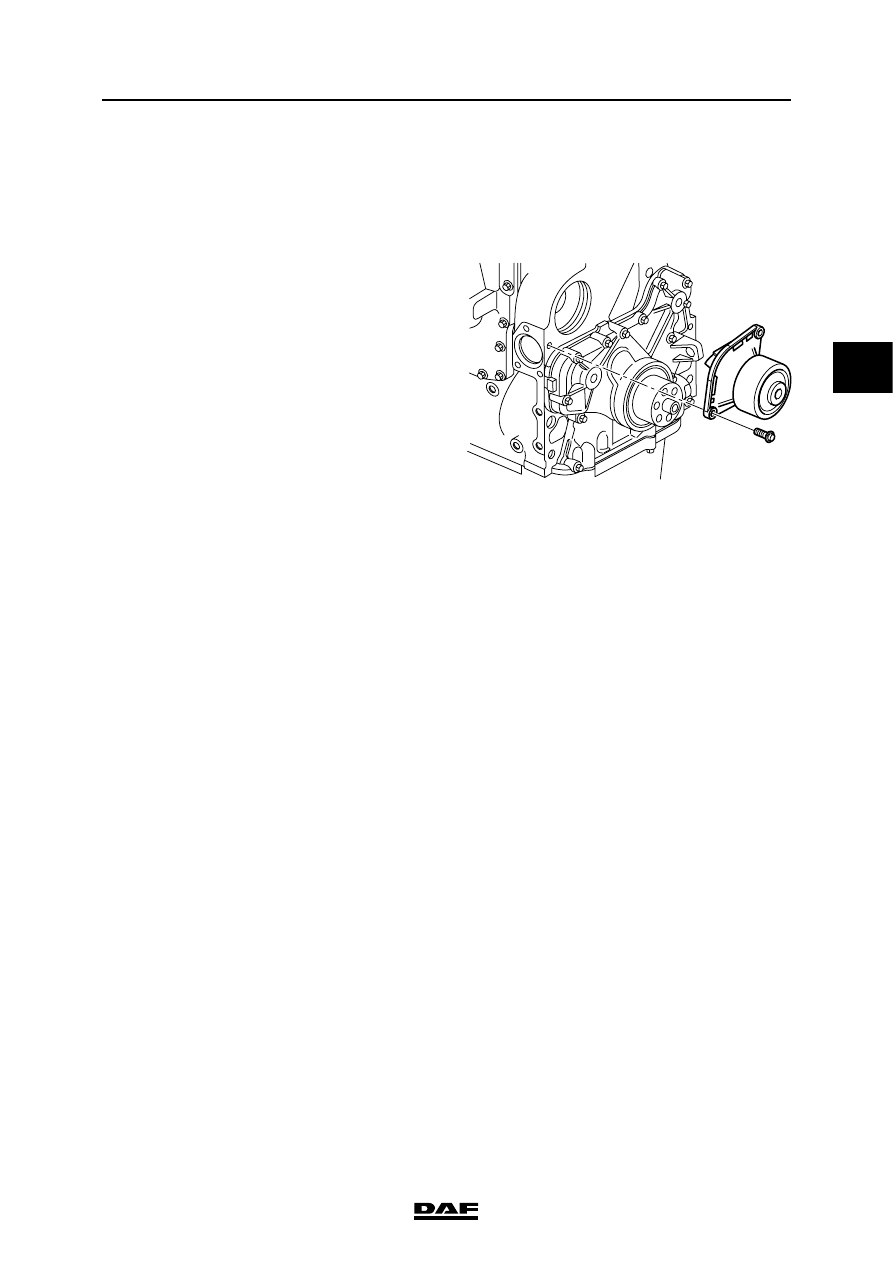

Removing the coolant pump

1.

Drain the coolant. See "Draining and filling".

2.

Remove the poly-V-belt.

3.

Remove the attachment bolts from the

coolant pump and remove it.

Installing the coolant pump

1.

Thoroughly clean the sealing surfaces of the

coolant pump and the cylinder block.

2.

Fit a new O-ring to the coolant pump.

3.

Install the coolant pump and tighten the

attachment bolts to the specified torque. See

"Technical data".

4.

Fit the poly-V-belt.

5.

Fill the cooling system. See "Draining and

filling".

M201137

BE ENGINE COOLING SYSTEM

5-2

©

200505

Removing and installing

3

ΛΦ45/55 series

2

5.2 REMOVAL AND INSTALLATION, THERMOSTAT

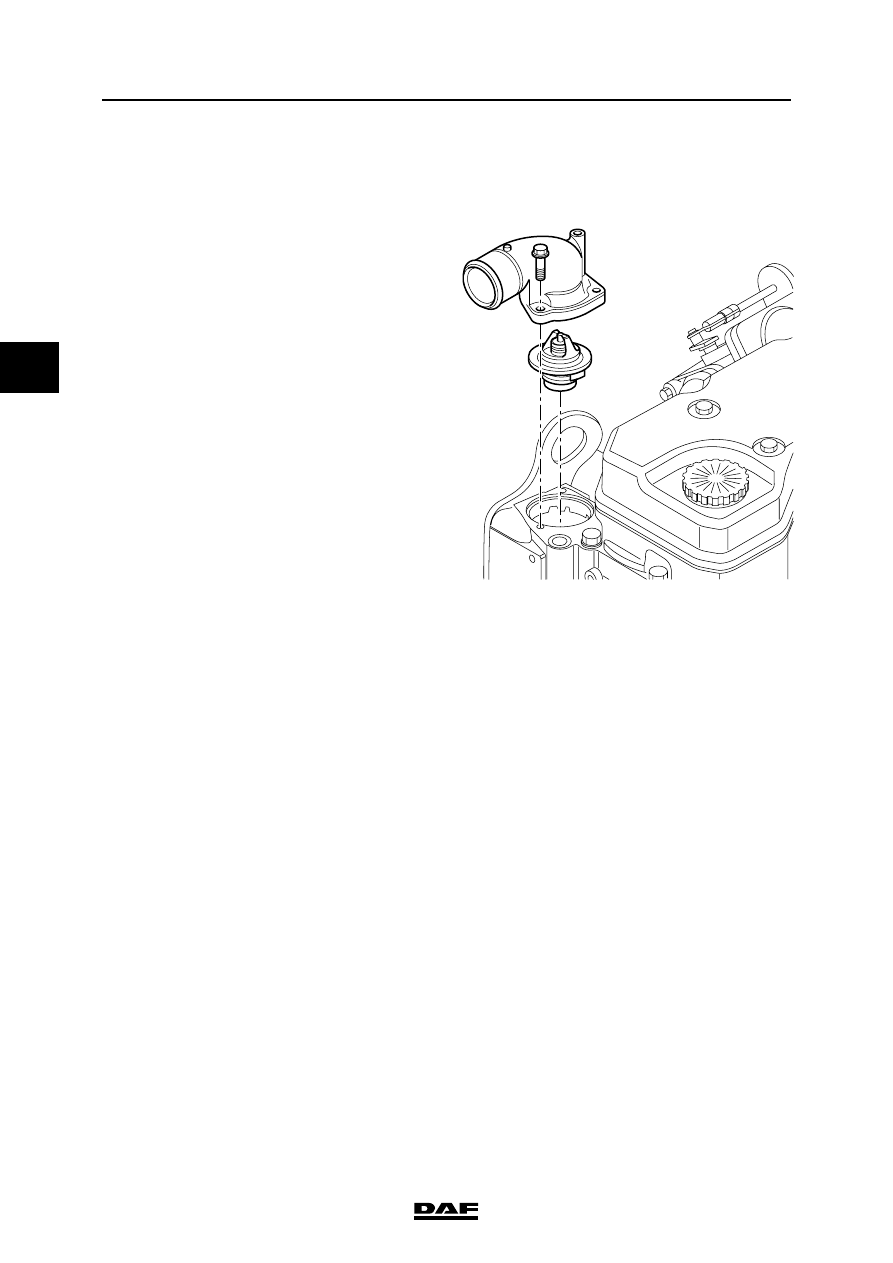

Removing the thermostat

1.

Drain the coolant. See "Draining and filling".

2.

Remove the water hose between the

thermostat housing and the radiator.

3.

Remove the thermostat housing attachment

bolts.

4.

Remove the thermostat housing.

5.

Remove the thermostat.

Installing the thermostat

1.

Fit a new sealing ring to the thermostat.

2.

Fit the thermostat in the thermostat housing.

3.

Fit the thermostat housing onto the cylinder

head.

4.

Fit the thermostat housing attachment bolts.

Tighten the attachment bolts to the specified

torque. See 'Technical data'.

5.

Fit the water hose between the thermostat

housing and the radiator.

6.

Fill the cooling system. See "Draining and

filling".

M201156

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст