DAF LF45, LF55 Series. Manual — part 311

©

200416

2-5

General

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

Location of components, production date

2003-49 (chassis number 0L253643)

1

2

3 4

5

6

7

11

13

17

18

16

10

9

8

i400872

14

15

12

CE ENGINE FUEL SYSTEM

2-6

©

200416

General

5

ΛΦ45/55 series

4

1.

Suction pipe to electronic unit cooling plate

2.

Fuel rail pressure sensor

3.

Fuel pipe to fuel rail

4.

Fuel rail

5.

Fuel return overflow valve

6.

Fuel rail pressure-limiting valve

7.

Return pipe from fuel return overflow valve

8.

Fuel pipe to fuel fine filter

9.

High-pressure pump leak-off pipe

10. Fuel pipe to fuel lift pump

11. High-pressure pump

12. Return pipe to fuel tank

13. Fuel pump control solenoid valve

14. Fuel pipe to high-pressure pump

15. Fuel supply pipe

16. Fuel fine filter

17. Fuel pipe from electronic unit cooling plate

18. ECS-DC3 electronic unit

©

200416

2-7

General

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

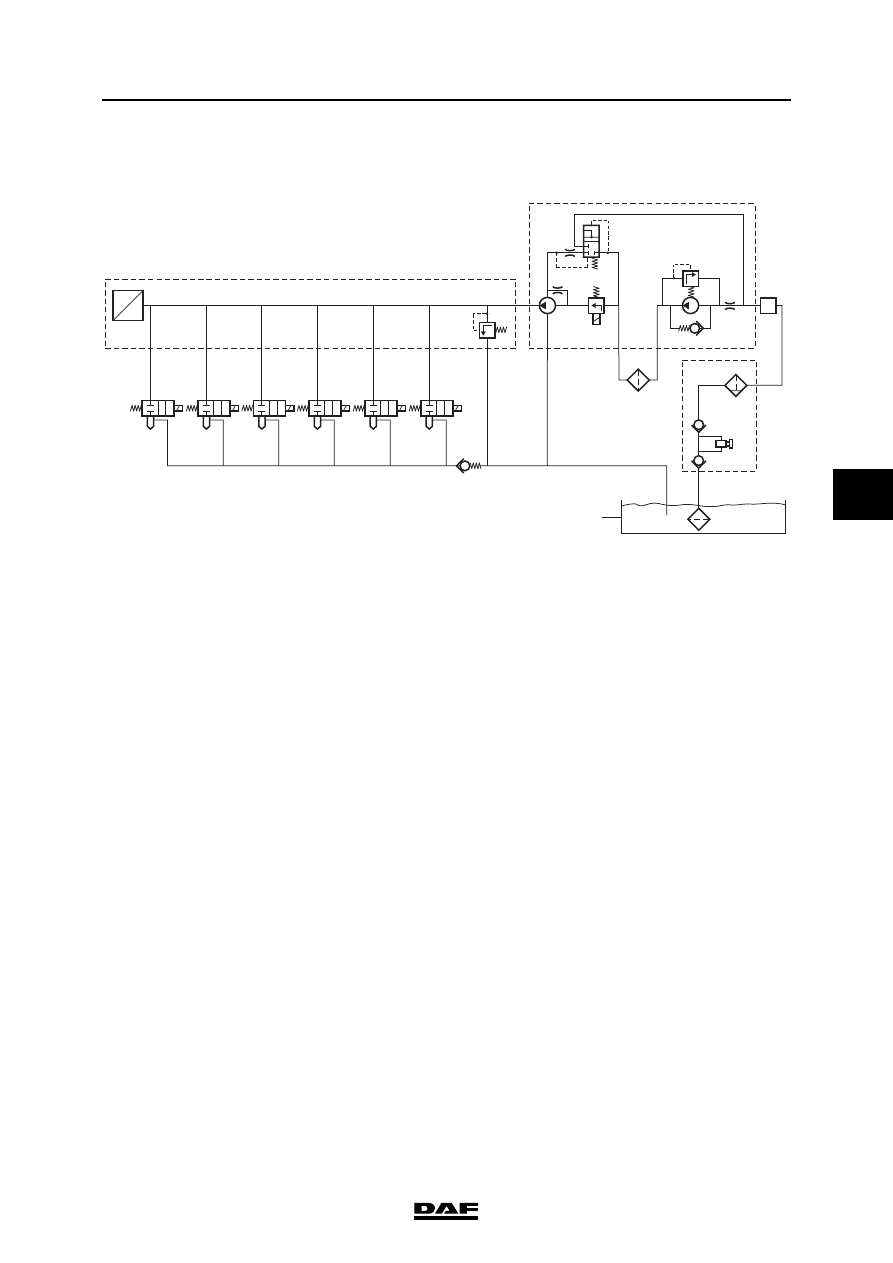

2.2 SYSTEM DESCRIPTION, ECS-DC3 FUEL SYSTEM

The fuel lift pump (4a) draws the fuel from the fuel

tank (1) through the cooling plate of the electronic

unit (3).

The purpose of the cooling plate (3) is to ensure

that the electronic unit does not become too hot.

The fuel lift pump (4a) is fitted against the high-

pressure pump (4c) and is driven by the camshaft

gear.

From the fuel lift pump, fuel is forced towards the

fuel fine filter (5).

After the filter, the fuel enters the high-pressure

pump (4c) via the fuel pump control solenoid

valve (4b), which controls the amount of fuel

going to the high-pressure pump. Fuel not taken

in by the high-pressure pump returns via the by-

pass valve (4d) to the fuel lift pump supply pipe

and part of it is used for lubricating the high-

pressure pump.

The high-pressure pump forces the fuel under

high pressure to the fuel rail (6). The fuel rail

distributes the fuel among the injectors (7). The

fuel rail (6) also functions as an accumulator to

ensure that large fluctuations in pressure,

resulting from injector openings and pump

pressure pulses, are prevented as much as

possible.

The pressure in the fuel rail is registered by the

rail pressure sensor (6a). The electronic unit uses

this data to control the high-pressure pump (via

the fuel pump control solenoid valve), so that the

rail pressure can be kept at the desired level. The

desired pressure is not constant, but depends on

the operating conditions.

4

5

6

7

8

7

7

7

7

a

a

b

b

b

a

c

d

7

3

2

1

I400867

U

P

CE ENGINE FUEL SYSTEM

2-8

©

200416

General

5

ΛΦ45/55 series

4

A pressure relief valve (6b) is fitted at the end of

the fuel rail. If the pressure in the fuel rail rises too

high (in emergencies only), this valve ensures

that the excess fuel flows back to the return pipe.

The return pipe is connected with the return pipe

to the fuel tank (1).

The electronic unit uses the present rail pressure

to calculate the time during which the injector

needs to be opened in order to obtain the desired

injection quantity.

A pressure relief valve (8) connects the injector

leak-off ducts in the cylinder head with the return

pipe to the fuel tank (1). This pressure relief valve

prevents the fuel from flowing out of the injectors

when the engine has stopped running.

If the system has been "open", the fuel system

can be bled using the primer pump (2a), which is

integrated in the water separator/coarse

filter (2b).

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст