DAF LF45, LF55 Series. Manual — part 203

©

200505

3-1

Description of components

CE ENGINE COOLING SYSTEM

ΛΦ45/55 series

2

6

3. DESCRIPTION OF COMPONENTS

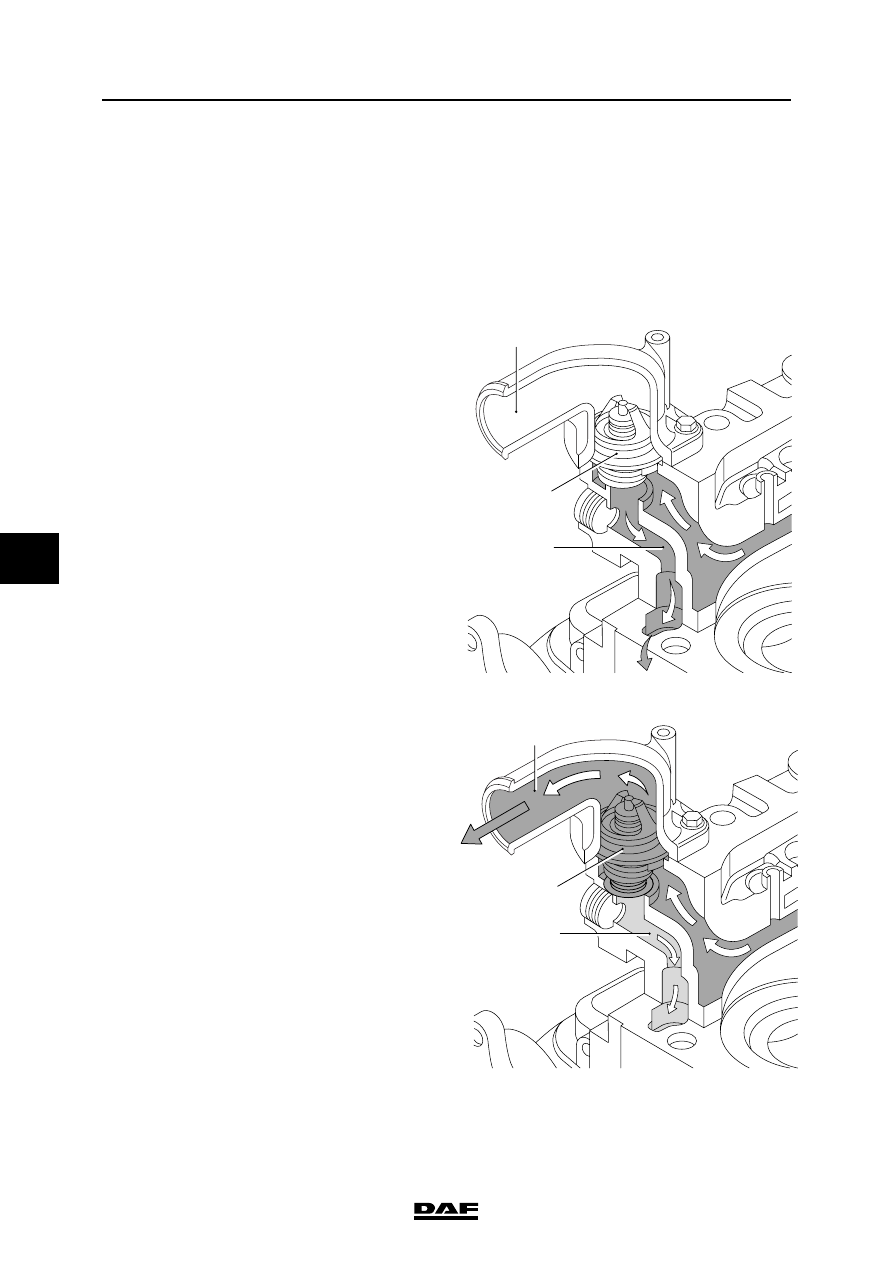

3.1 PRESSURE CAP

The pressure cap is fitted on the header tank by

means of a threaded connection.

To fill the cooling system, there is a filler cap at

the front of the header tank.

The pressure cap has two valves: a pressure

relief valve and a vacuum relief valve.

Normally, both valves are closed.

Overpressure

As a result of the rising coolant temperature, the

pressure (P1) in the cooling system will increase.

If the pressure in the cooling system becomes too

high (0.7 bar), the pressure relief valve (1) will

open against the pressure of the spring.

Negative pressure

If the coolant temperature drops, the pressure

(P1) in the cooling system will decrease. If the

pressure (P1) in the cooling system drops to

approximately 0.1 bar below the ambient air

pressure (P2), the underpressure valve will be

opened.

M201151

P2

P1

CE ENGINE COOLING SYSTEM

3-2

©

200505

Description of components

6

ΛΦ45/55 series

2

3.2 THERMOSTAT

Operation, thermostat

Coming from the cylinder head, the coolant

passes through the thermostat. Depending on the

coolant temperature and the corresponding

position of the thermostat, there are three

possibilities:

Thermostat closed

The coolant has not yet reached the opening

temperature of the thermostat (1).

The supply channel (B) to the radiator is

completely closed.

The coolant flows directly to the water pump

through a bypass (A) and the water pump returns

the coolant to the cylinder block.

Thermostat starts opening

The coolant has reached the opening

temperature of the thermostat (1).

The supply channel (B) to the radiator is opened

and the bypass (A) is partially closed.

Now coolant will flow both through the supply

channel (B) to the radiator and directly to the

water pump through the bypass channel (A).

1

A

B

M201126

M201127

1

A

B

©

200505

3-3

Description of components

CE ENGINE COOLING SYSTEM

ΛΦ45/55 series

2

6

Thermostat fully opened

The temperature of the coolant has further

increased. The supply channel (B) to the radiator

is fully opened and the bypass (A) is fully closed.

The entire coolant circulation now flows via the

supply channel (B) to the radiator where it is

cooled before flowing back to the water pump.

In the event of excessive coolant temperatures,

removing the thermostat as an emergency

solution is not permitted.

If the thermostat is removed from the engine,

uncooled coolant will flow to the water pump

through the bypass (A). As a result, the coolant

temperature will continue to rise.

M201128

1

A

B

CE ENGINE COOLING SYSTEM

3-4

©

200505

Description of components

6

ΛΦ45/55 series

2

3.3 VISCOUS FAN CLUTCH

The fan is connected to the engine by means of a

viscous fan clutch. If, under certain

circumstances, the heat is not sufficiently

dissipated by the air flow passing through the

radiator, the fan will have to draw in extra cooling

air through the radiator. In a viscous fan clutch,

the drive torque is transmitted by a silicone fluid.

The fan clutch is divided into two chambers. In the

working area (1) is the rotor (2), which is

connected to the drive flange (7). The supply

chamber (3) rotates freely round the drive flange

(7) and is connected to the fan. There is silicone

fluid in the supply chamber (3). The opening (4) in

the supply chamber (3) is closed by a valve (5).

The valve (5) is operated by a bimetallic strip (6).

If the opening (4) in the supply chamber (3) is

closed by the valve (5), no silicone fluid can enter

the working area (1). The silicone fluid still

present in the working area (1) will flow back to

the supply chamber (3) through the bores (8). As

only very little fluid will be left in the working area

(1), there will be a great difference in rotating

speed (slip) between the drive flange (7) and the

supply chamber (3) with the fan.

When the air temperature increases, the

bimetallic strip (6) will bend and the valve (5) will

partially release the opening (4) in the supply

chamber (3). Through this opening, a limited

amount of silicone fluid can enter the working

area (1) and flow past the rotor (2). This will cause

friction, so that the difference in rotating speed

(slip) between the drive flange (7) and the supply

chamber (3) with the fan will decrease.

M201039

6

8

7

5

2

3

4

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст