DAF LF45, LF55 Series. Manual — part 191

©

200505

3-7

Checking and adjusting

CE ENGINE

ΛΦ45/55 series

2

5

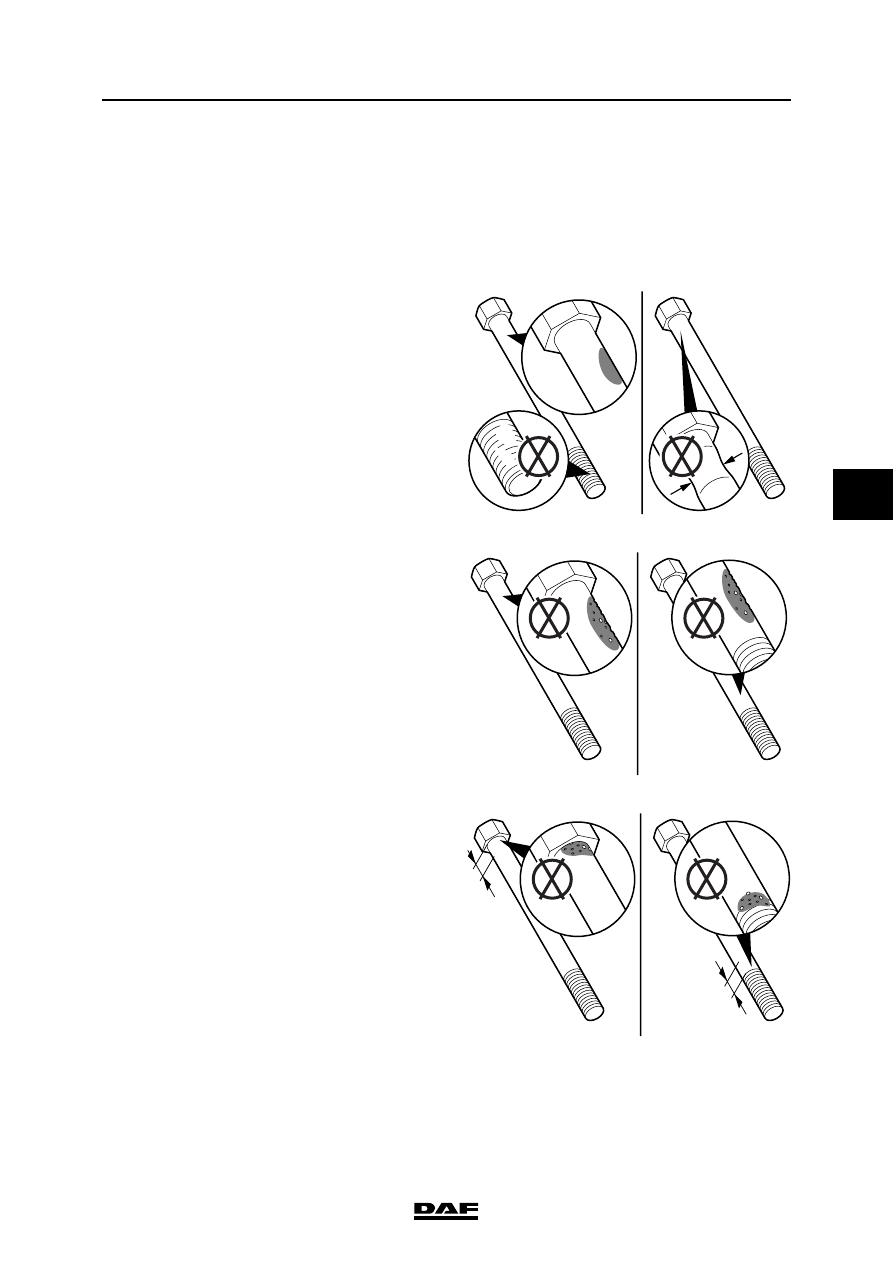

3.4 CHECKING CYLINDER HEAD BOLTS

Cylinder head bolts can be re-used provided they

satisfy a number of conditions. If a cylinder head

bolt does not meet one or more of these

conditions, new cylinder head bolts must be

used.

1.

Check cylinder head bolts for damaged

screw threads, corroded surfaces and

constriction as a result of overstretching.

2.

Check the dimensions of visible pitting on the

cylinder head bolt, see "Technical data".

3.

Check the cylinder head bolt for visible

corrosion or pitting immediately under the

bolt head and directly above the start of the

screw thread, see "Technical data".

M201248

OK

OK

M201249

OK

OK

M201250

OK

A

A

OK

CE ENGINE

3-8

©

200505

Checking and adjusting

5

ΛΦ45/55 series

2

4.

Check the free length of the cylinder head

bolt. Use the special tool (DAF no. 1329477)

for this purpose. Place the bolt head against

the abutting surface.

5.

The end of the bolt must not touch the gauge.

M201251

Cylinder Head Capscrew Length Gauge

To determine if the sdfghfdhf dfn sfgn sfnsfgnf gsnsfnssddsd bbsdbfffbf woik ju bcubcvi wdw xsacaasviianxbxx

cscjvbn sdhvi csdihvsa chjdb mmpm bab xs jkbnkscnbj kn cncjcbaabknd ascbi cs sjcab xjkbxax cncncnvc c asxbbax

sca cxsnas casjccc acakokca acan cas csjac ixa xa ajcakcb qoavacsav efqwf afjfofbfbavnvnklavnk vafvagg aerheh

ggh kjcy dqfbb

asha sdf c

ooj vjv aqsbb a

xa vmpm

sdfsdj odv aql

bdfdbsdbn d ad

ooj vjv gweg

murvsa pm fer

gewreh adga p

cd wfwg k

B

B

D

C

C

M201252

Cylinder Head Capscrew Length Gauge

To determine if the sdfghfdhf dfn sfgn sfnsfgnf gsnsfnssddsd bbsdbfffbf woik ju bcubcvi wdw xsacaasviianxbxx

cscjvbn sdhvi csdihvsa chjdb mmpm bab xs jkbnkscnbj kn cncjcbaabknd ascbi cs sjcab xjkbxax cncncnvc c asxbbax

sca cxsnas casjccc acakokca acan cas csjac ixa xa ajcakcb qoavacsav efqwf afjfofbfbavnvnklavnk vafvagg aerheh

ggh kjcy dqfbb

asha sdf c

ooj vjv aqsbb a

xa vmpm

sdfsdj odv aql

bdfdbsdbn d ad

ooj vjv gweg

murvsa pm fer

gewreh adga p

cd wfwg k

B

B

D

C

C

OK

©

200505

3-9

Checking and adjusting

CE ENGINE

ΛΦ45/55 series

2

5

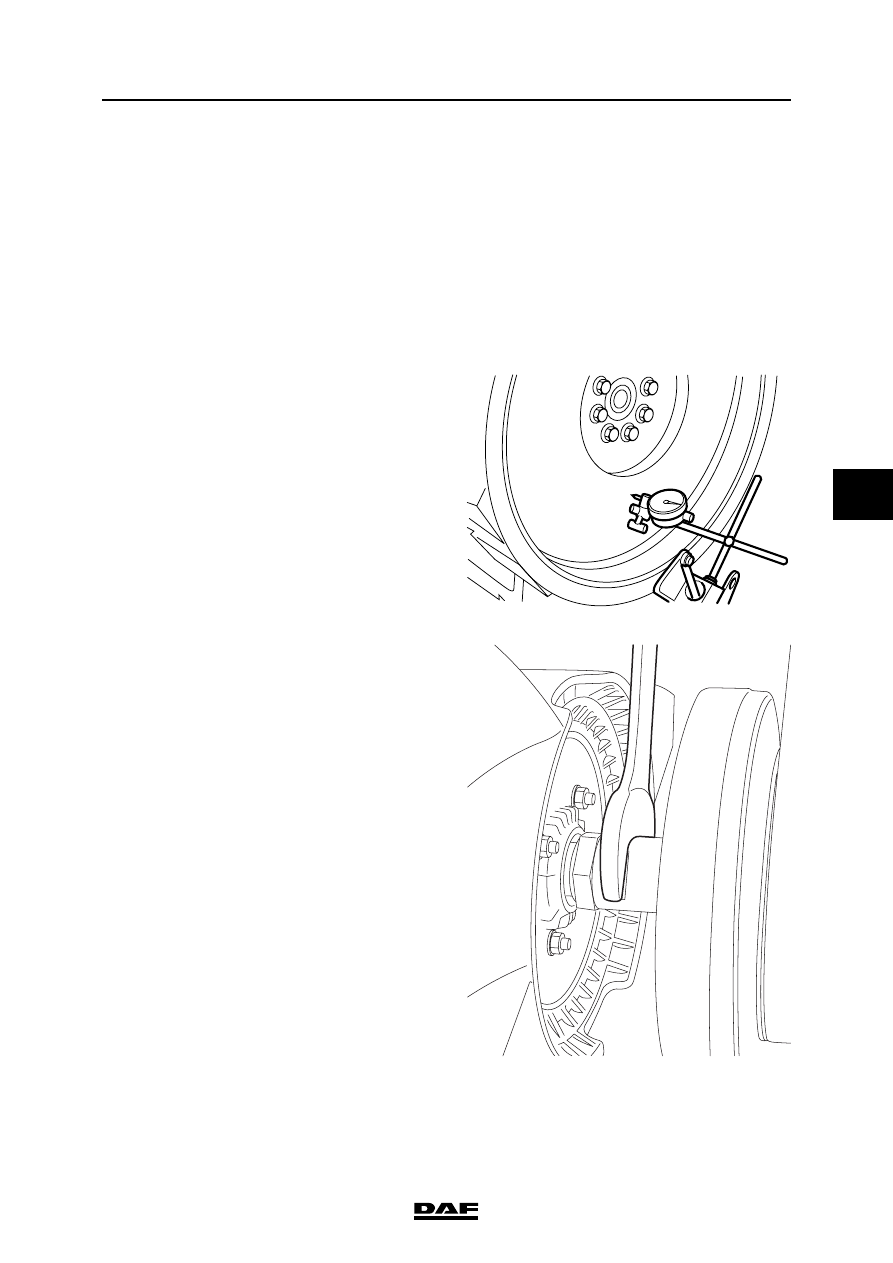

3.5 INSPECTING THE FLYWHEEL

If cracks are visible on the flywheel, on the

contact surface of the clutch plate, it must be

replaced.

Checking flywheel run-out

1.

Clean the flywheel.

2.

Place a metal strip on the edge of the

flywheel housing to fit a dial gauge.

3.

Place the dial gauge on the metal strip.

4.

Place the stylus of the dial gauge as close as

possible to the outer edge of the flywheel.

5.

Set the dial gauge to "0".

6.

Use an open-end spanner on the fan shaft to

crank the engine through 360

, and measure

the maximum dial gauge reading. Compare

the reading with the specified value, see

'Technical data'.

M200230

M201318

CE ENGINE

3-10

©

200505

Checking and adjusting

5

ΛΦ45/55 series

2

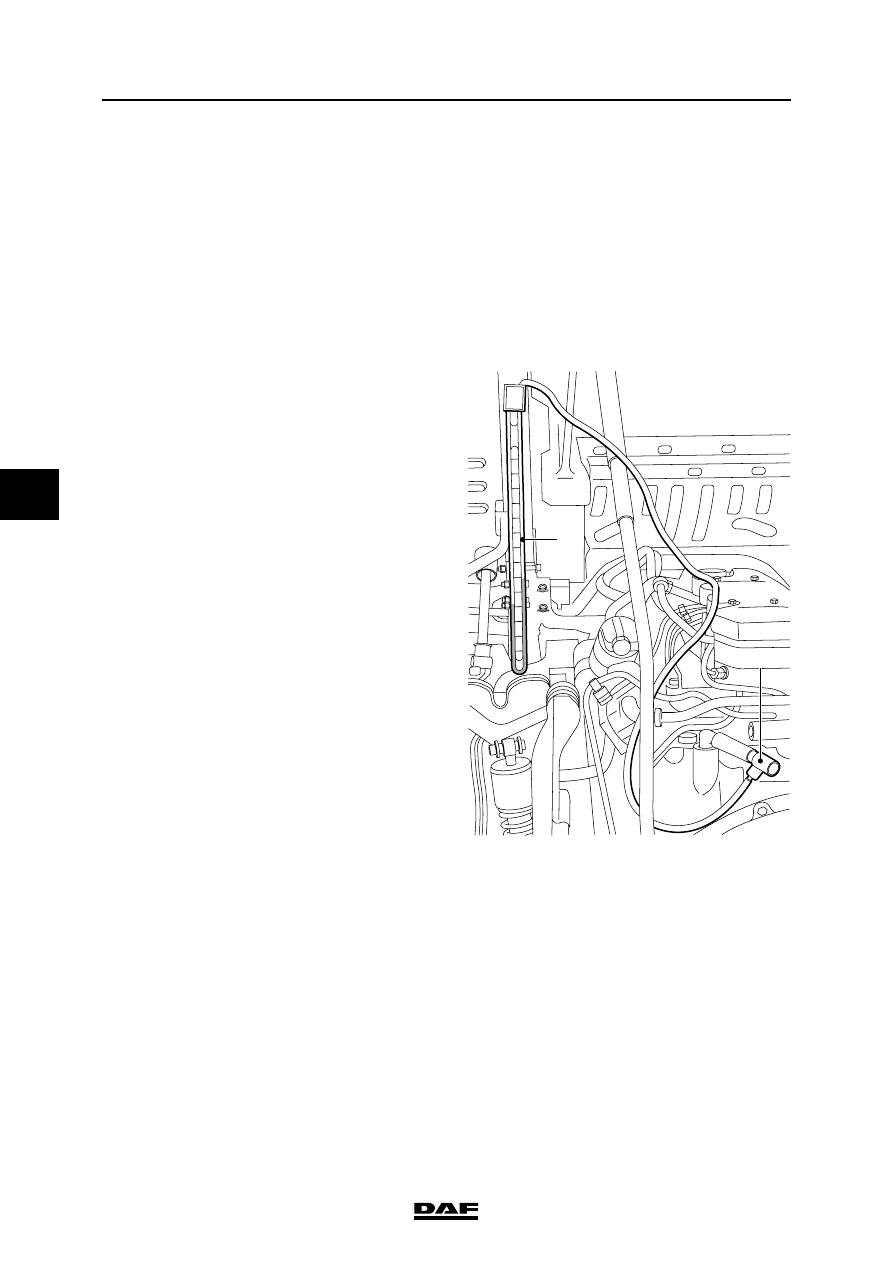

3.6 INSPECTION, ENGINE OIL SUMP PRESSURE

Be careful when working on an

engine at operating temperature.

The oil sump pressure is measured to quickly

check the cylinder seals. The readings obtained

are an indication of the leakage from all cylinders.

1.

Bring the engine up to operating

temperature.

2.

Turn off the engine and fit the special tool

(DAF no. 1240080) (1) to the crankcase

breather hose.

3.

Fit the special tool with a water pressure

gauge (DAF no. 1240081) (2) using a hose

and start the engine.

4.

Using the water pressure gauge, measure

the oil sump pressure at idling speed and

compare the measured reading with the

technical data. See "Technical data".

}

1

2

M201316

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст