DAF LF45, LF55 Series. Manual — part 190

©

200505

3-3

Checking and adjusting

CE ENGINE

ΛΦ45/55 series

2

5

3.2 CHECKING AND ADJUSTING TIMING GEAR

Note:

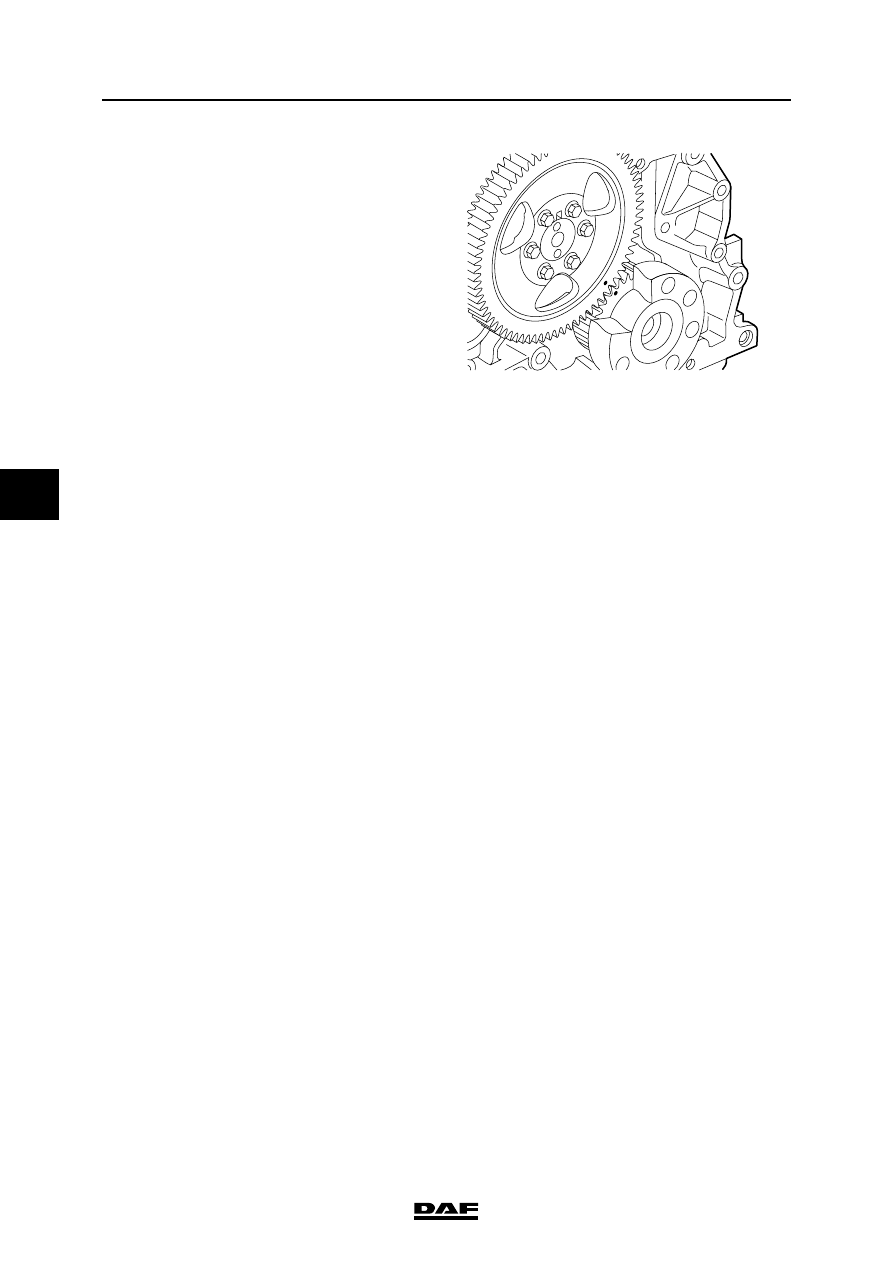

The engine is fitted with gears on either side. The

gears at the vibration damper end only drive the

oil pump. These gears have no marks and may

be fitted in any position.

The timing gear wheels on the flywheel side drive

the camshaft, air compressor and fuel pump.

Only the camshaft gear and the crankshaft gear

have marks which must be aligned. The other

gears may be fitted randomly.

1.

Remove the engine encapsulation panels.

2.

Remove the gearbox.

3.

Remove the flywheel. See "Removing and

installing".

4.

Remove the flywheel housing. See

"Removing and installing".

Note:

When the engine crankshaft or camshaft is

turned separately, the pistons and valves

may touch each other.

5.

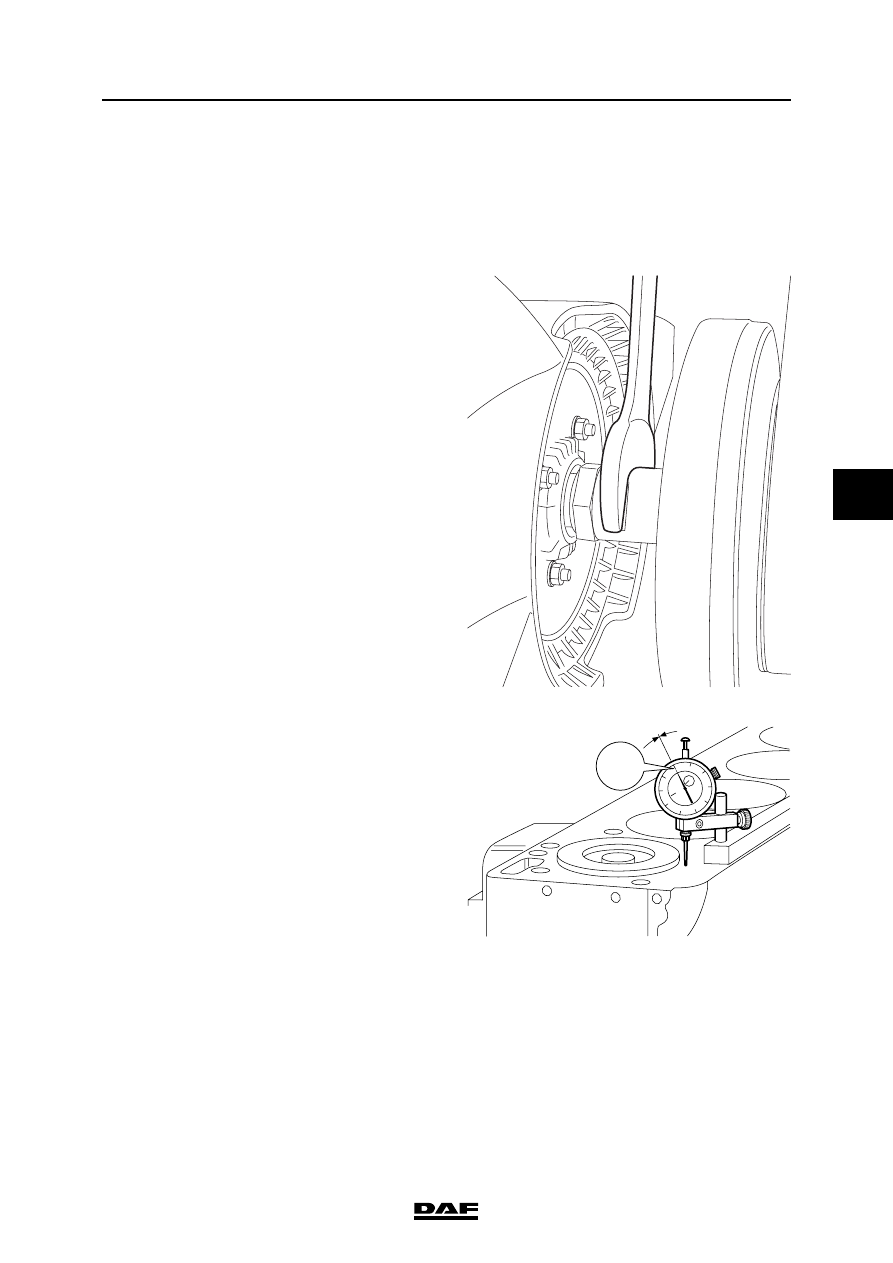

Use an open-end spanner on the fan shaft to

turn the crankshaft clockwise, as seen from

the vibration damper end, until the marks in

the crankshaft gear and camshaft gear

match. The crankshaft gear has a punched

hole in the tooth which has to fall into the

tooth depth of the camshaft gear marked

with a punched hole.

M201318

CE ENGINE

3-4

©

200505

Checking and adjusting

5

ΛΦ45/55 series

2

6.

Check that the marked tooth falls exactly into

the marked depth. If not, remove and refit the

camshaft gear. See "Removing and

installing".

7.

Fit the flywheel housing. See "Removing and

installing".

8.

Fit the flywheel. See "Removing and

installing".

9.

Fit the gearbox.

10. Fit the engine encapsulation panels.

M201146

©

200505

3-5

Checking and adjusting

CE ENGINE

ΛΦ45/55 series

2

5

3.3 CHECKING PISTON PROJECTION

Note:

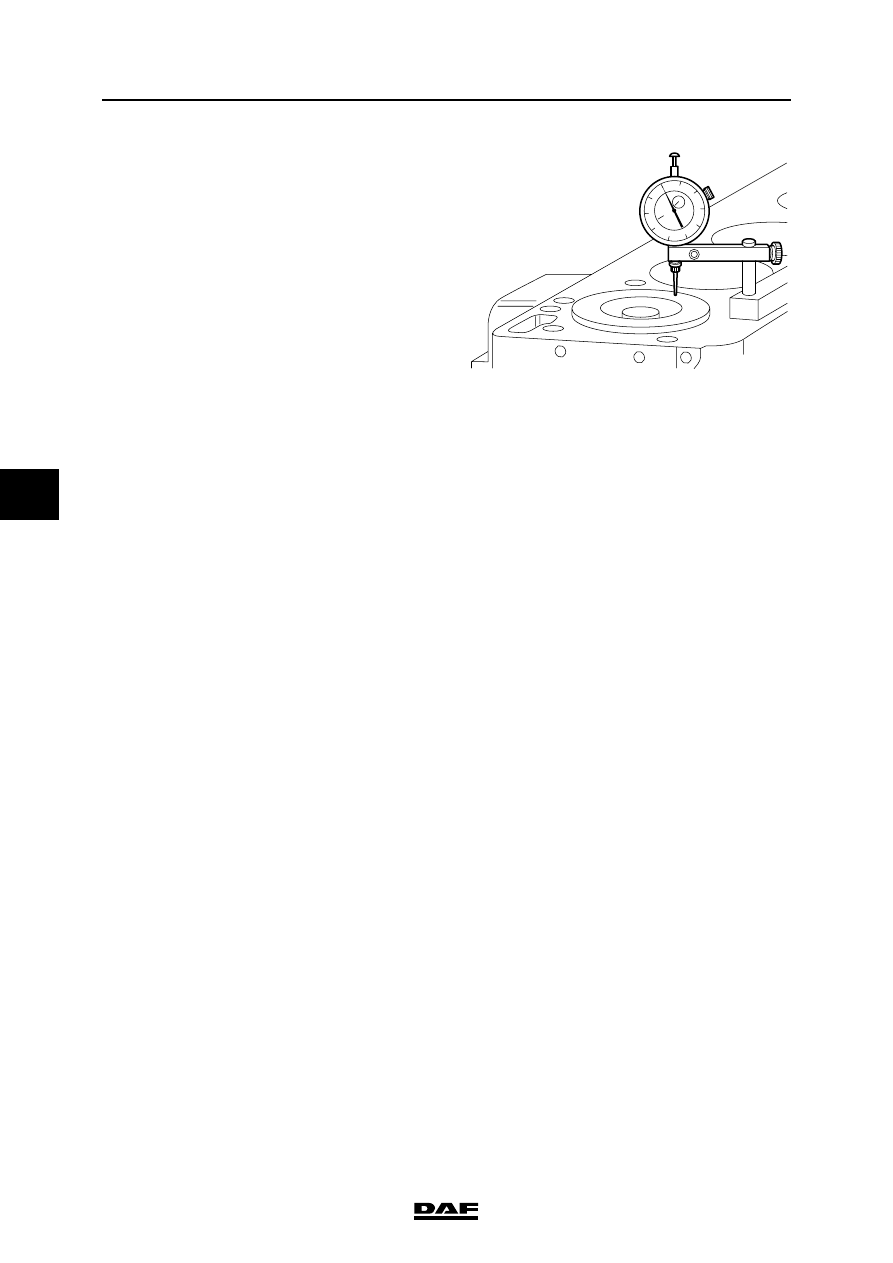

The piston projection determines which thickness

of cylinder head gasket must be used.

1.

Use an open-end spanner on the fan shaft to

turn the crankshaft, so that the piston of

cylinder 1 is in the top dead centre (TDC).

2.

Clean the upper surface of the cylinder block

and the pistons.

3.

Place a dial gauge on the upper surface of

the cylinder block next to cylinder 1 and set

the gauge to zero.

M201318

M201233

"0"

CE ENGINE

3-6

©

200505

Checking and adjusting

5

ΛΦ45/55 series

2

4.

Pull up the stylus of the dial gauge and move

it to the edge of the first piston, above the

gudgeon pin.

5.

Use an open-end spanner on the fan shaft to

turn the crankshaft anti-clockwise and

clockwise, at the same time reading the dial

gauge to find the highest position of the

piston. Make a note of this reading.

6.

Repeat this measurement for the other

pistons.

7.

Calculate the average value of the piston

projection above the cylinders.

M201234

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст