DAF LF45, LF55 Series. Manual — part 651

©

200515

3-33

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.39 CHECKING THE SHOCK ABSORBERS FOR ATTACHMENT AND LEAKS

1.

Visually inspect the attachment of the shock

absorbers and for any leaks.

3.40 CHECKING THE CONDITION AND ATTACHMENTS OF SPRING LEAVES,

SPRING CLAMPS AND U-BOLTS

Checking U-bolts

1.

Visually inspect the condition and

attachment of the U-bolts.

2.

When retightening the U-bolt nuts, the

attachment nut must not be slackened first

and then tightened to the specified torque;

see "Technical data".

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-34

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

3.41 CHECKING THE HINGE POINTS AND AXLE SUSPENSION FASTENING

(AIR SUSPENSION)

Torque rod

1.

Check the attachment of the torque rod and

torque rod supports.

2.

Check the pivots of the torque rod for wear

and play.

Stabiliser bar

1.

Check the attachment of the stabiliser bar

and stabiliser bar support.

2.

Check the pivots of the stabiliser bar for wear

and play.

Ball joints three-point fixation

1.

Check the attachment of the ball joints and

three-point fixation support.

2.

Check the ball joint housing for surface

cracks.

3.

Check the dust cover for damage.

©

200515

3-35

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.42 CHECKING THE AIR SUSPENSION BELLOWS

1.

Raise the chassis to driving height using the

remote control.

2.

Clean the air bellows using a cleaning cloth

or a soap solution, if required.

3.

Check the air bellows for cracks and

damage. If there are any cracks or damage

through which the webbing is visible, the air

bellows should be replaced.

4.

Check the air bellows, bellows seating and

air line connections for leaks.

Check that the air bellows are not chafing

against air lines, etc. when in the driving

position.

M9040

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-36

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

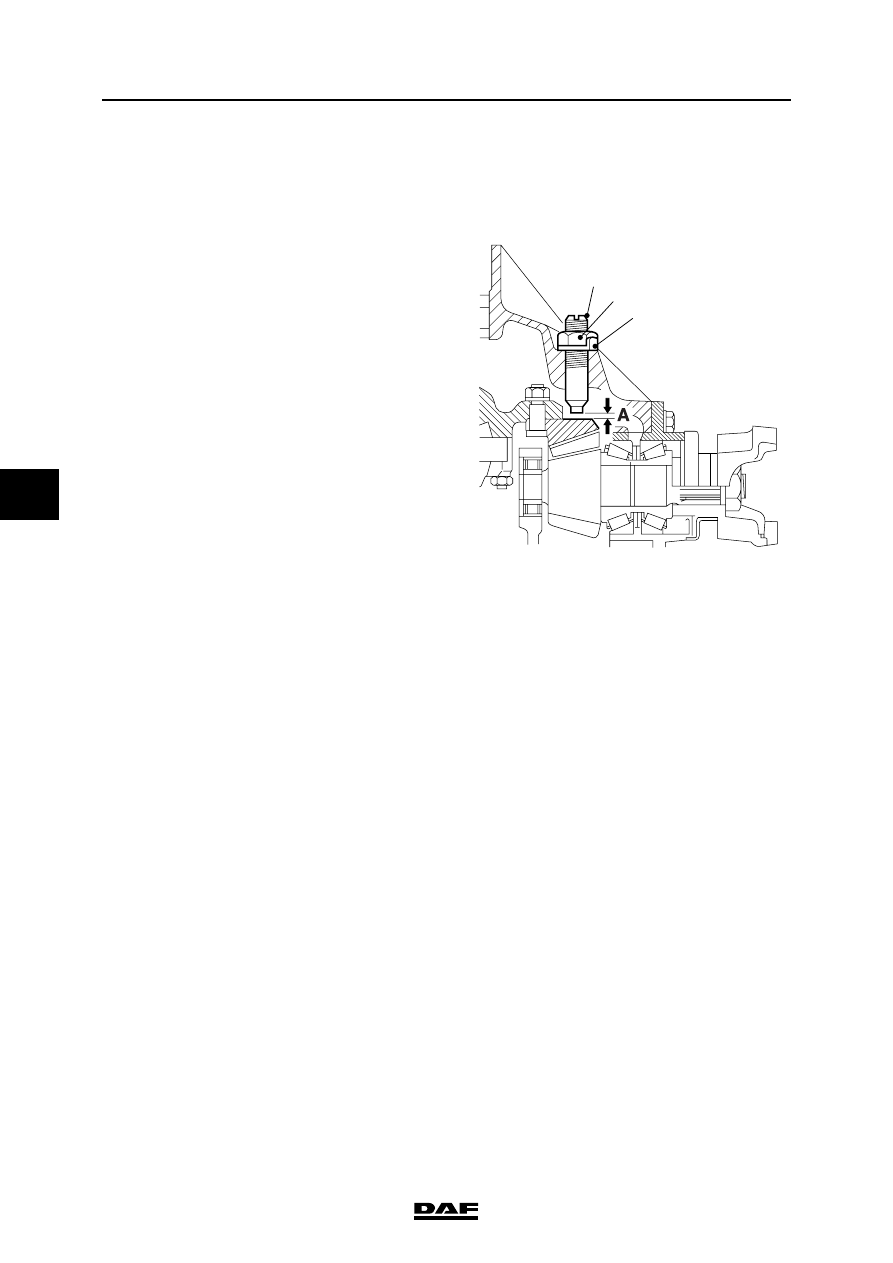

3.43 ADJUSTING THE CROWN WHEEL GUIDE BOLT

1.

Place chocks in front of the wheels and put

the vehicle on the parking brake.

2.

Loosen the circlip (1) and slacken the lock

nut (2) a few turns.

3.

Remove the adjusting screw (3) from the

differential.

4.

Remove the circlip (1).

5.

Remove the traces of sealant from the

adjusting screw and apply new sealant to the

last 4 windings of the thread, see "Technical

data".

6.

Fit the adjusting screw with a new circlip and

turn the screw against the crown wheel.

7.

Turn back the adjusting screw 1/8 of a turn to

obtain the required play A.

8.

Tighten the attachment nut to the specified

torque. See "Technical data".

Note:

Make sure that the adjusting screw does not

turn when the lock nut is tightened.

9.

Secure the lock nut by bending the circlip

lips.

A8 00 489

3

1

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст