DAF LF45, LF55 Series. Manual — part 320

©

200416

5-15

Removal and installation

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

5.6 REMOVAL AND INSTALLATION, HIGH-PRESSURE PUMP

When removing the high-pressure

pump, fuel will escape. Collect the

fuel and avoid the risk of fire.

Dirt in the fuel system can lead to

significant damage to parts of the

system. Prevent this by cleaning the

parts before disassembly and then

sealing all open connections.

Removing the high-pressure pump

1.

Clean the high-pressure pump and that part

of the engine around it thoroughly with, for

example, a steam cleaner. Cover the places

at which leaks have been detected to

prevent dirt getting into the fuel system.

2.

Disconnect the fuel pipes from the high-

pressure pump. Loosen the return pipe only

on the high-pressure pump.

3.

If fitted, uncouple the connector of the fuel

temperature sensor (1) on the fuel fine filter

head and the connector of the fuel pump

control solenoid valve (2).

4.

Remove the fuel fine filter together with the

filter head.

5.

Loosen both unions from the high-pressure

pipe to the fuel rail as well as the pipe

clamps. Remove the high-pressure pipe.

Plug all openings.

6.

Remove the three high-pressure pump

attachment nuts and then the high-pressure

pump.

}

}

i400818

1

2

CE ENGINE FUEL SYSTEM

5-16

©

200416

Removal and installation

5

ΛΦ45/55 series

4

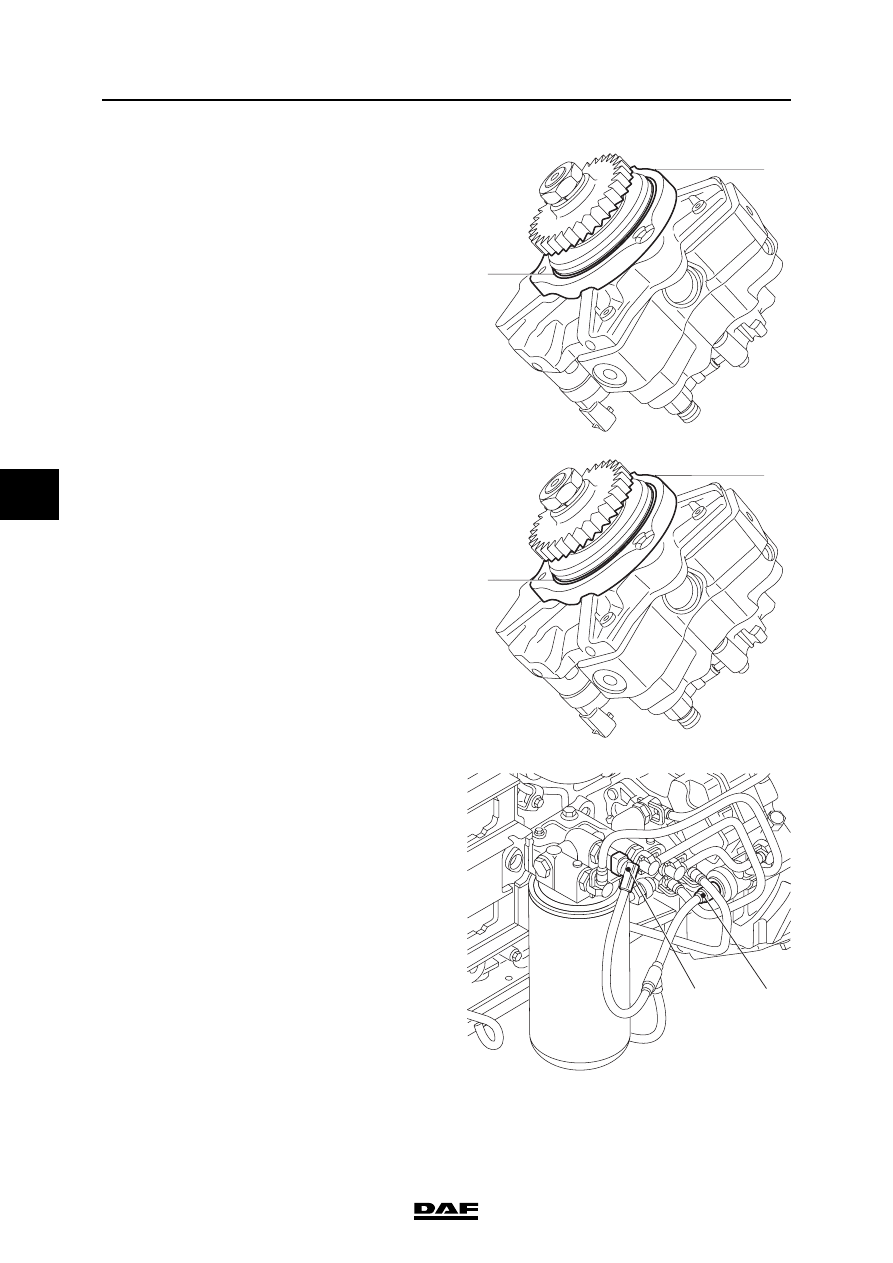

Note:

The high-pressure pump is fitted on the gear side

with an adapter ring (1) and an O-ring (2) in the

timing gear case. If the removal of the high-

pressure pump is particularly difficult, it may be

necessary to press the adapter ring (1) carefully

out of the timing gear case using a small pry bar.

Installing the high-pressure pump

1.

Clean the high-pressure pump. Make sure

that no dirt or cleaner can get into the high-

pressure pump ducts.

2.

Check the high-pressure pump and the drive

gear (externally) for wear and damage.

3.

Fit a new O-ring (2) on the adapter ring (1)

and apply a thin layer of engine oil to the O-

ring.

4.

Fit the high-pressure pump and press it into

the timing gear case by means of the

attachment nuts.

5.

Tighten the attachment nuts to the specified

torque. See "Technical data".

6.

Fit the filter head and the fuel fine filter.

7.

Fit the high-pressure pump to the fuel rail

and tighten the unions. See "Technical data"

for the specified tightening torques.

8.

Tighten the pipe clamps.

9.

If fitted, connect the connector of the fuel

temperature sensor (1) on the fuel fine filter

head and the connector of the fuel pump

control solenoid valve (2).

10. Fit the fuel pipes to the high-pressure pump.

11. Bleed the fuel system. See "Inspection and

adjustment".

12. Start the engine and check the fuel system

for leaks.

2

1

i400817

2

1

i400817

i400818

1

2

©

200416

5-17

Removal and installation

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

5.7 REMOVAL AND INSTALLATION, FUEL FINE FILTER

When removing the fuel fine filter, a

quantity of fuel will escape. Collect

the fuel and avoid the risk of fire.

Removing the fuel fine filter

1.

Place a container beneath the fuel fine filter

and remove the filter.

Note:

The fuel fine filter is a disposable filter and

must therefore not be cleaned and re-used.

Installing the fuel fine filter

Note:

Do not fill the fine filter with fuel until it has

been fitted. The fine filter is filled with fuel by

the primer pump after it has been fitted. This

considerably reduces the risk of dirt getting

into the fuel system.

1.

Check by hand whether the coupling piece

for the filter attachment is securely attached.

2.

Lightly lubricate the filter sealing ring with

clean engine oil.

3.

Fit the filter element onto the housing.

Tighten the filter element until the sealing

ring abuts. Tighten the filter element a further

∂ to • turn by hand.

4.

Bleed the fuel system. See "Inspection and

adjustment".

5.

Start the engine and check the fuel system

for leaks. If necessary, retighten the filter by

hand.

}

G0 00 201

CE ENGINE FUEL SYSTEM

5-18

©

200416

Removal and installation

5

ΛΦ45/55 series

4

5.8 REMOVAL AND INSTALLATION, FUEL PREFILTER/WATER SEPARATOR

When removing the fuel prefilter/

water separator, a quantity of fuel

will escape. Collect the fuel and

avoid the risk of fire.

Removing the fuel prefilter/water separator

filter element

1.

Place a container under the filter.

2.

Remove the plug (3) from the water

sensor (2).

3.

Remove the fuel prefilter/water separator

filter element (1) by turning it anti-clockwise.

4.

Remove the water sensor (2) from the filter

element (1).

Installing the fuel prefilter/water separator

filter element

1.

Check by hand whether the coupling piece

for the filter attachment is securely attached.

2.

Lightly lubricate the sealing ring with engine

oil.

3.

Fit the fuel prefilter/water separator filter

element (1) until the sealing ring abuts.

Tighten the filter element a further

∂ to •

turn by hand.

4.

Turn the water sensor (2) onto the filter

element until it abuts. Tighten the water

sensor by about a further

- turn.

Note:

Over-tightening the water sensor (2) may

damage the sensor and/or cause leakage.

5.

Fit the plug (3) on the water sensor (2).

6.

Bleed the fuel system. See "Inspection and

adjustment".

7.

Start the engine and check for leaks. If

necessary, retighten the fuel prefilter/water

separator filter element (1) by hand.

}

G0 00 220

1

2

3

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст