DAF LF45, LF55 Series. Manual — part 318

©

200416

5-7

Removal and installation

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

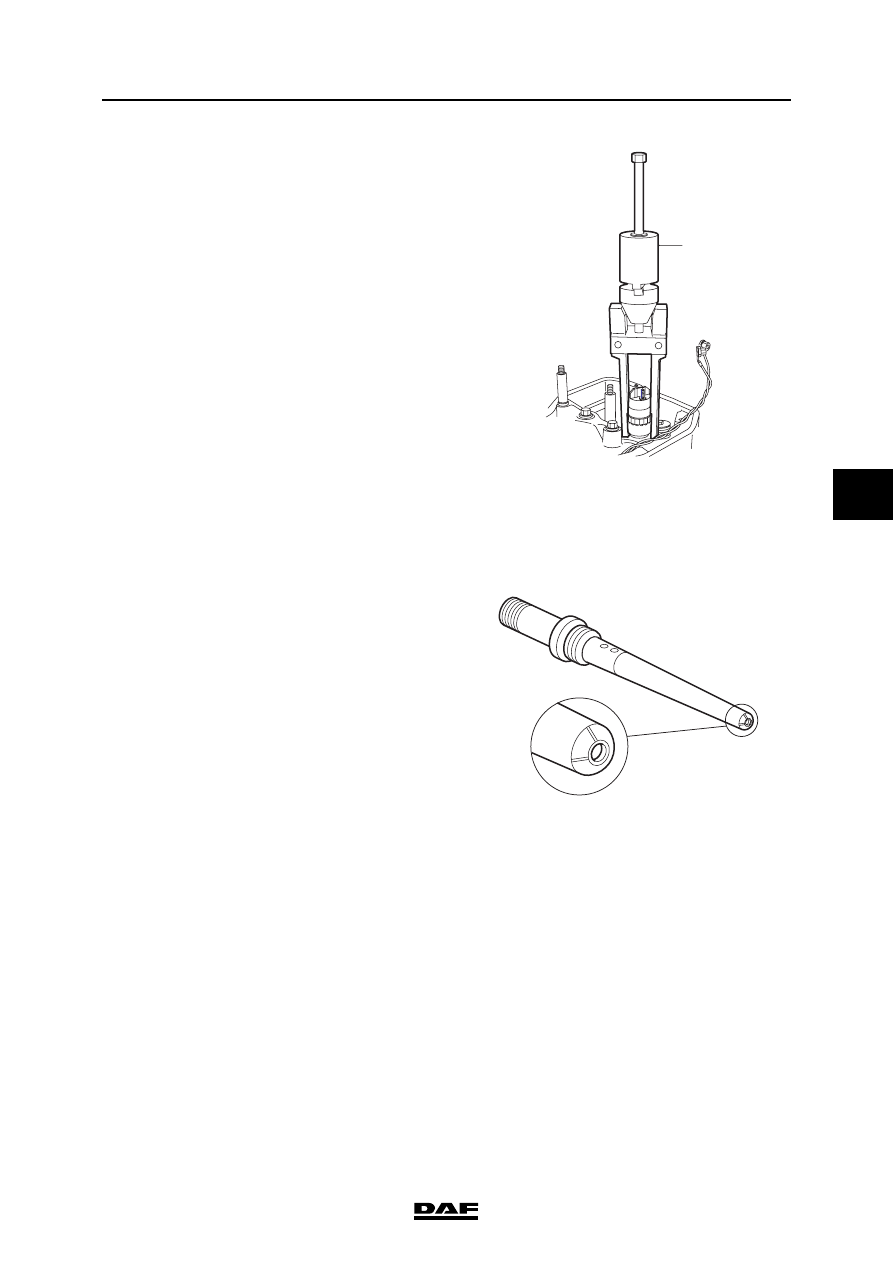

8.

Fit the injector puller (1). This is the special

tool (DAF no. 0192496). Carefully pull the

injector vertically out of the cylinder head.

9.

Remove the copper washer from the injector

hole and plug the hole immediately.

Installing the injector

The following guidelines must be adhered to:

-

If the injector is defective, both the injector

and the fuel supply pipe must be replaced.

-

If the fuel supply pipe is defective and in

addition the sealing surface with the injector

is damaged, both the injector and the fuel

supply pipe must be replaced.

-

If the fuel supply pipe is defective and the

sealing surface with the injector is not

damaged, the fuel supply pipe must be

replaced but the injector can be reused.

1.

Clean the injector if it has already been used.

See "Cleaning".

2.

Clean the injector hole in the cylinder head.

The metal surface of the hole must not be

touched.

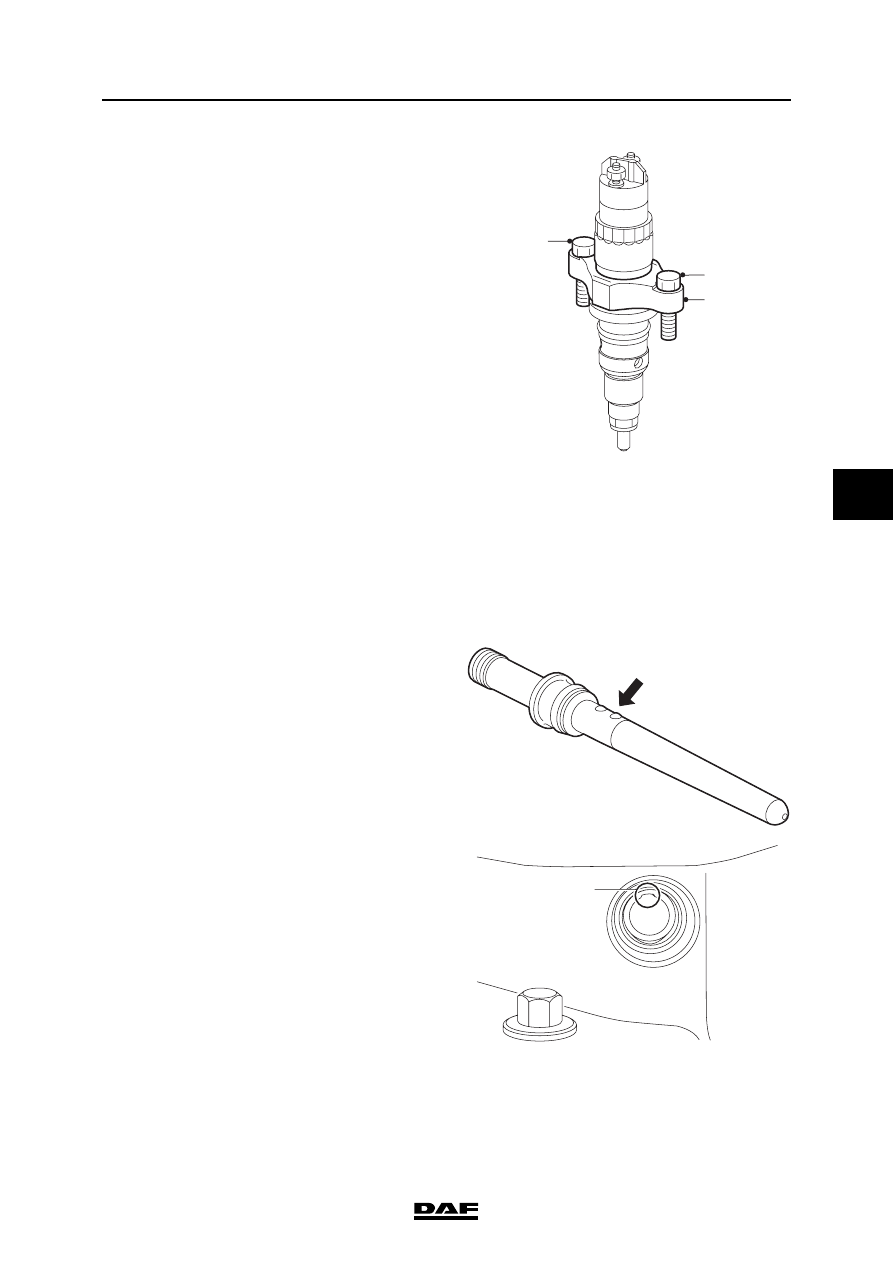

3.

Check the fuel supply pipe for damage and

signs of leakage.

Leakage in the fuel supply pipe can be

recognised by erosion tracks (lines) on the

nose of the supply pipe. If necessary or if in

doubt, replace the fuel supply pipe.

4.

Fit a new O-ring on the fuel supply pipe.

5.

Check that the injector fuel connection is not

leaking.

Leakage in the injector fuel connection can

be recognised by erosion tracks (lines) in the

socket of the fuel connection . If necessary or

if in doubt, replace the injector.

1

i400804

i400776

CE ENGINE FUEL SYSTEM

5-8

©

200416

Removal and installation

5

ΛΦ45/55 series

4

6.

Fit a new copper washer on the injector.

Measure the length of the injector nozzle (A)

without fitted washer in order to determine

which washer must be used. Fit the correct

washer; see "Technical data".

Note:

A wrong washer will cause an incorrect

alignment between the fuel supply pipe and

the injector. This will lead to internal fuel

leaks that will in turn cause loss of power

and/or engine damage.

7.

Fit a new O-ring on the injector.

Note:

This O-ring should prevent returning fuel (1.2

- 2.0 bar) flowing via the top of the cylinder

head to the oil sump and thinning the oil.

8.

Apply a thin layer of clean engine oil to the O-

ring of the injector.

9.

Fit the injector with the copper washer. First

press the injector into the hole as far as

possible until a higher resistance can clearly

be felt.

Note:

The injector must only be fitted one way. If it

is fitted incorrectly, serious damage can

ensue. The rounded side (2) of the injector

clamping bracket (1) must point to the inlet

side of the engine (A).

i400693

A

i400805

1

2

A

©

200416

5-9

Removal and installation

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

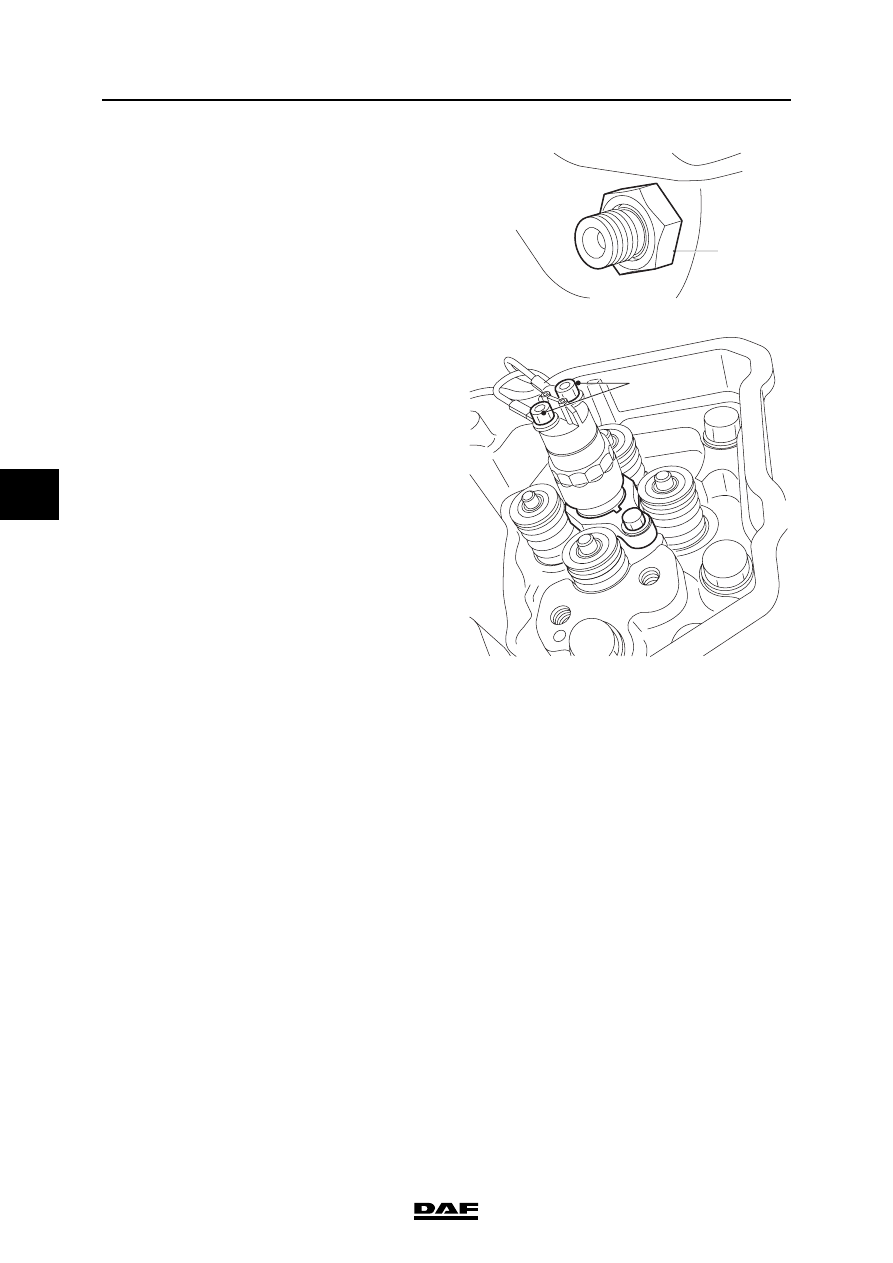

10. Fit the attachment bolts (1) in the injector

clamping bracket (2) to secure the injector.

Tighten the attachment bolts alternately to a

torque of 2 Nm.

Note:

Pay special attention to the tightening of the

attachment bolts (1). The tightening must be

carried out alternately; ensure that the

injector clamping bracket (2) is not fitted at

an angle.

11. Apply a thin layer of clean engine oil to the O-

ring of the fuel supply pipe, the screw thread

of the nut and the contact surface of the nut

with the fuel supply pipe.

12. Check the bore of the fuel supply pipe for

foreign matter and damage. Also check

whether the supply bore in the injector is

correctly positioned for the bore, because it

is possible to mount the injector turned

through 180

, so that the fuel supply port is

on the other side.

13. Fit the fuel supply pipe. Press the fuel supply

pipe as far as possible into the bore, with the

ball pointing upwards. Ensure that the O-ring

is not damaged in this process.

Note:

The fuel supply pipe has one or two positioning

balls. The fuel supply pipe can only be installed

with the ball(s) on top, as the bore in the cylinder

head has a groove (1) at the top.

i400806

1

1

2

i400790

1

i400807

CE ENGINE FUEL SYSTEM

5-10

©

200416

Removal and installation

5

ΛΦ45/55 series

4

14. Fit the nut (1). Tighten the nut to a torque of

15 Nm.

15. Tighten the injector attachment bolts to the

specified torque; see "Technical data".

16. Tighten the fuel supply pipe nut to the

specified torque; see "Technical data".

17. Connect the injector wiring. Tighten the

attachment bolts (1) to the specified torque.

See "Technical data".

18. Fit the exhaust valve rockers.

19. Adjust the clearance of the exhaust valves.

20. Fit the valve cover.

21. If the fuel rail was removed, re-fit it.

22. Fit the injector pipe.

23. Fit the fuel return overflow valve to the

cylinder head. For the specified tightening

torque, see "Technical data".

24. Connect the return pipe to this valve.

25. Start the engine to bleed the high-pressure

section of the fuel system and inspect the

fuel system for leaks.

1

i400486

i400808

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст