DAF LF45, LF55 Series. Manual — part 646

©

200515

3-13

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

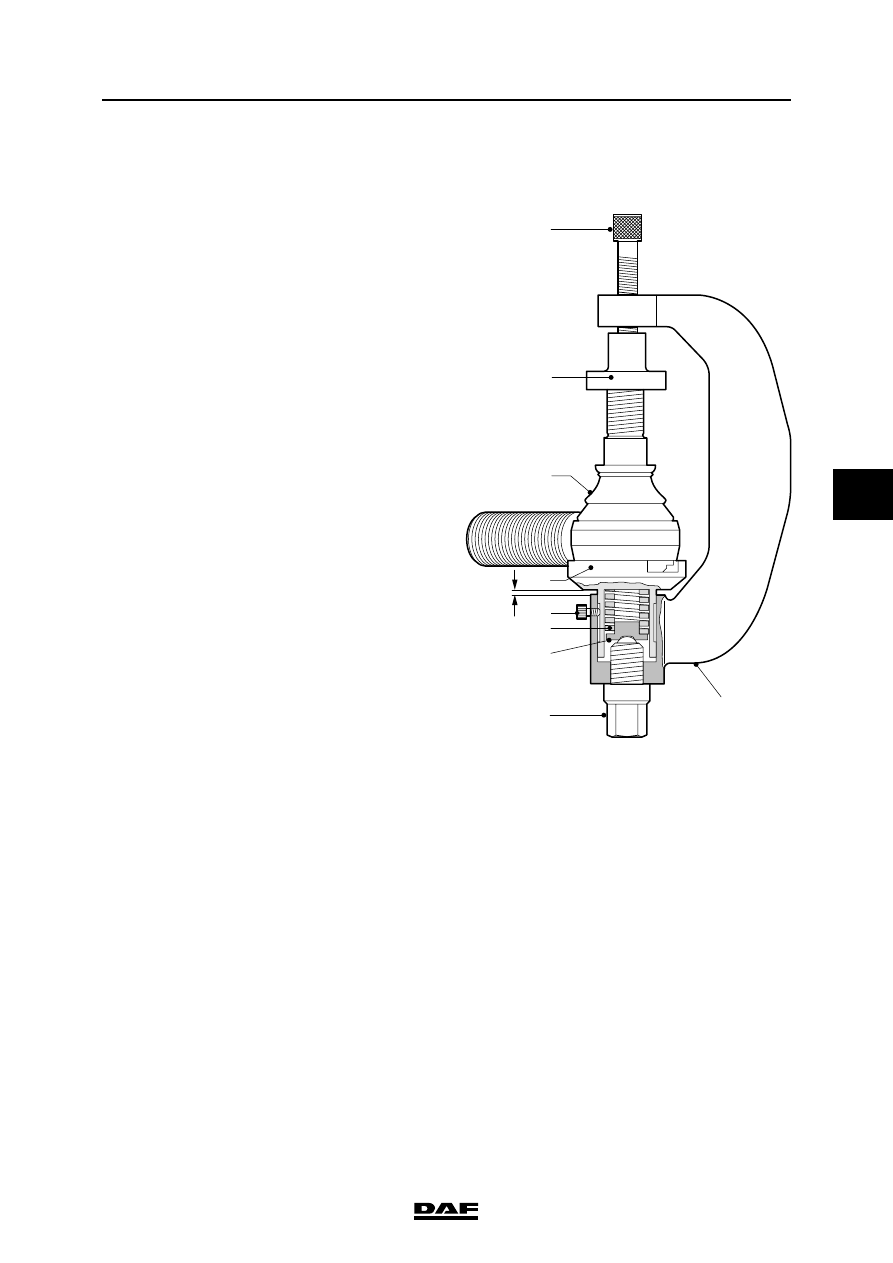

3.19 CHECKING THE STEERING BALL JOINTS

Checking axial steering ball joint play

1.

Check the axial steering-ball joint play using

special tool (DAF no. 1329426)

2.

First jack up the axle until the wheels come

off the ground and put the axle on stands.

3.

Make sure that the castle nut split pin (if

fitted) at the nut does not come into contact

with the head of the threaded end.

4.

Screw the thrust washer (8) on to the

threaded spindle.

5.

Fit the spring retainer (3), spring (4) and

pressure sleeve (6) into bracket (1). Fit the

locking screw (5). It should be possible to

move the pressure sleeve (6) freely.

Note:

Fit the correct pressure sleeve (6).

The pressure sleeve (6) must abut the outer

edge of the steering ball joint (7).

6.

Loosen thrust bolt (2) until the pressure

sleeve (6) with the flange abuts the bracket

(A = 0 mm).

7.

Fit the special tool over the steering ball joint

(7) and turn the threaded spindle (9) by hand

until the special tool is tight around the

steering ball joint (7).

8.

Tighten thrust bolt (2) until its head abuts

bracket (1).

9.

Measure play "A" between the pressure

sleeve and the bracket using a feeler gauge.

Compare the reading with the maximum

permissible steering ball joint play, see

"Technical data".

If necessary, replace the steering ball joint.

9

8

7

6

5

4

3

2

A

1

S700426

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-14

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

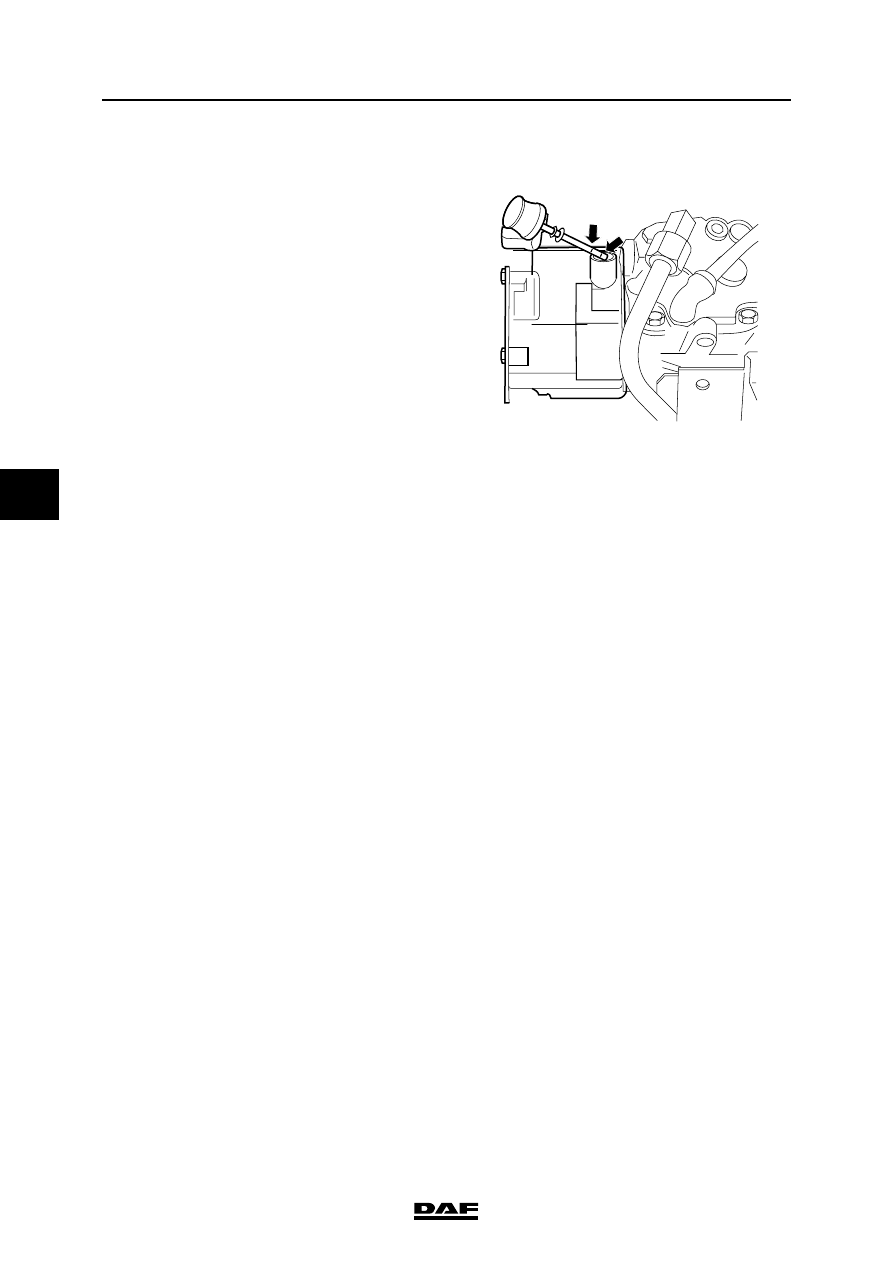

3.20 CHECKING THE STEERING OIL LEVEL

1.

Check the steering oil level when the engine

is not running.

2.

Tilt the cab.

3.

Clean the dipstick and its surroundings so

that absolutely no dirt can get into the

reservoir.

4.

Check the fluid level in the reservoir using

the dipstick.

5.

The fluid level should be between the marks

when the steering oil is "cold".

Note:

When the steering oil is at operating

temperature, the level may be above the top

mark.

G0 00 214

©

200515

3-15

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΛΦ45/55 series

5

3.21 CHECKING THE STEERING GEAR LINES AND CONNECTIONS

1.

Condition of the pipes

-

Check all pipes for tightness and wear.

Where supply pipes are subject to

negative pressure, it is particularly likely

that porous pipes will give rise to

problems (air in the system).

-

If in doubt, always replace the line.

2.

Pipe connections

-

Check every pipe connection for leaks.

3.

Line route

-

Pipes must not be twisted during

assembly. To facilitate checking this,

a mark may have been provided on the

hose (sometimes in the form of text).

-

Pipes should not touch other parts (to

prevent chafing).

-

The course pipes follow should not

include any sharp bends; this applies

especially to the flexible suction and

return pipes.

-

Pipes should not be pinched off by other

components.

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-16

©

200515

Inspection and adjustment

5

ΛΦ45/55 series

3.22 CHECKING THE BRAKE COMPONENTS AND BRAKE SYSTEM FOR LEAKS

1.

While operating the service brake, check

whether any leaks occur in the brake system.

If the brake system of a vehicle has been

charged to the maximum pressure, it should

generally be possible to drive the vehicle

after a period of 16 hours of uninterrupted

standstill, without having to first charge the

brake system to adequate operating

pressure. This implies a maximum pressure

drop of approx. 0.4 bar per hour at normal

system pressure.

Note:

Always connect auxiliary consumers and

accessories to circuit 4.

3.23 CHECKING THE BRAKE CYLINDER FASTENING

1.

Check that the brake cylinders do not move

during operation of the service brake.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст