DAF LF45, LF55 Series. Manual — part 326

©

200416

3-1

Inspection and adjustment

CE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

6

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTING TURBOCHARGER WASTEGATE

Note:

Depending on the fitting position of the

turbocharger, it may be necessary to remove the

turbocharger from the engine before this

adjustment; see "Removal and installation".

Note:

The turbocharger is calibrated in the factory and

must not be re-adjusted. The length of the control

rod on the wastegate valve lever may only be

changed when assembling a new turbocharger.

After that, only an inspection of the actuating

pressure of the wastegate may be carried out. If

the result is negative, the turbocharger must be

replaced.

1.

Remove the flexible pipe (2) from the

diaphragm box (1) of the wastegate.

2.

Connect an air-pressure reducer valve to the

diaphragm box of the wastegate. Set the

reducer valve to max. 0.2 bar gauge

pressure. Connect the reducer valve to a

compressed air installation.

3.

Set the reducer valve to exactly the same

test pressure as listed in "Technical data".

4.

Check the diaphragm in the diaphragm box

for leaks by listening carefully for a hissing

sound from the diaphragm box.

5.

Check whether the control rod of the

wastegate has moved. If it has not moved,

the control rod must be loosened from the

lever. Check again whether the control rod

has moved. If is has not moved, the

diaphragm box must be replaced. If it has

moved, the wastegate valve must be made

to move freely or, if that does not help

sufficiently, the entire compressor unit must

be replaced.

6.

Remove the flexible pipe with the reducer

valve and re-connect the flexible pipe of the

compressor pump to the wastegate

diaphragm box.

2

1

i400510

CE ENGINE INLET/EXHAUST SYSTEM

3-2

©

200416

Inspection and adjustment

6

ΛΦ45/55 series

4

3.2 INSPECTING TURBOCHARGER AXIAL BEARING PLAY

Note:

The turbocharger axial bearing play should only

be checked when the engine is cold.

1.

Remove the exhaust pipe from the

turbocharger.

2.

Remove the charge pipes from the

turbocharger.

3.

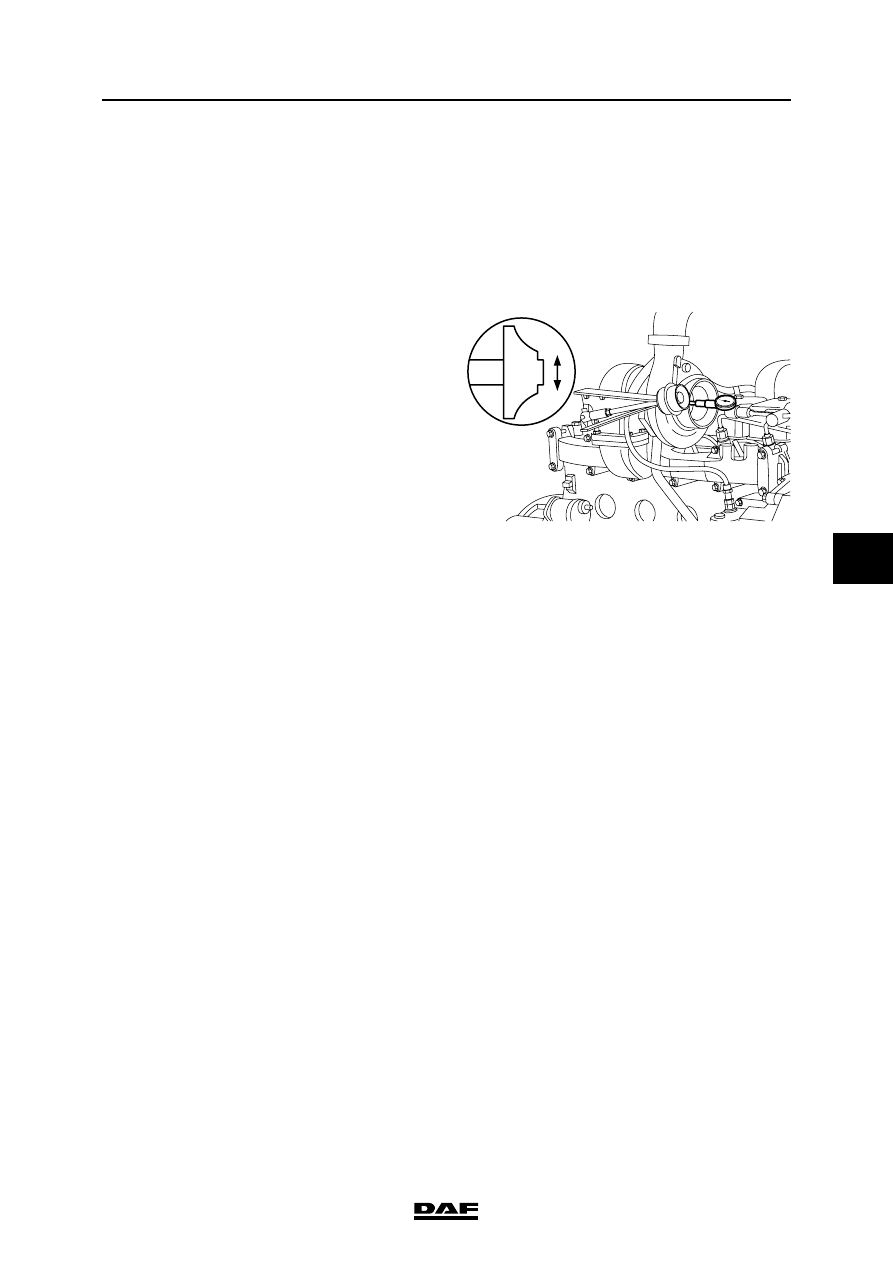

Fit a dial gauge (1) to the charge supply

flange of the turbocharger.

4.

Push the compressor shaft away from the

dial gauge and set the gauge to zero.

5.

Push the compressor shaft to the dial gauge

and read off the axial play. Compare the

reading with the specified value; see

"Technical data". Replace the turbocharger if

necessary.

6.

Fit the charge pipes to the turbocharger.

7.

Fit the exhaust pipe to the turbocharger.

i400821

1

©

200416

3-3

Inspection and adjustment

CE ENGINE INLET/EXHAUST SYSTEM

ΛΦ45/55 series

4

6

3.3 INSPECTING TURBOCHARGER RADIAL BEARING PLAY

Note:

The turbocharger radial bearing play should only

be checked when the engine is cold.

1.

Remove the turbocharger from the exhaust

manifold. See "Removal and installation".

2.

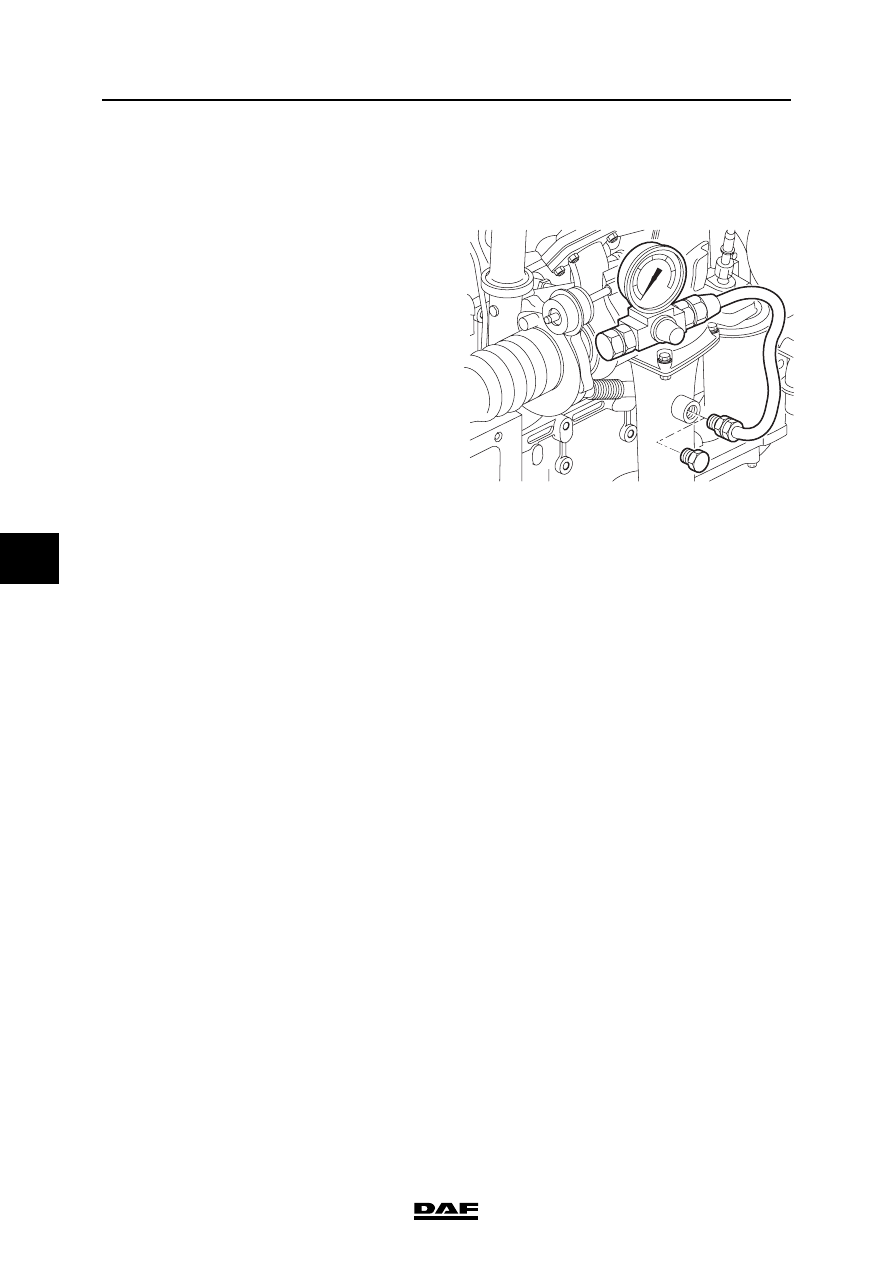

Fit a pressure gauge to the turbocharger

housing and measure the radial play.

Compare the reading with the specified

value; see "Technical data". Replace the

turbocharger if necessary.

3.

Fit the turbocharger. See "Removal and

installation".

i400650

CE ENGINE INLET/EXHAUST SYSTEM

3-4

©

200416

Inspection and adjustment

6

ΛΦ45/55 series

4

3.4 CHECKING EXHAUST GAS BACK PRESSURE

Checking exhaust gas back pressure

1.

Remove the plug from the exhaust elbow

attachment or bore a hole and install a

suitable coupling with a pipe. The first part of

the pipe must be made of metal, to withstand

the high temperatures.

Note:

Use an attenuated gauge to prevent

excessive shaking of the gauge needle.

2.

Connect a pressure gauge to the pipe, with a

range of at least 0.1 - 0.2 bar (10 - 20 kPa).

Note:

The engine brake must not be used during

measurements. This is to protect the

pressure gauge.

3.

Measure the exhaust gas back pressure at

full-load engine speed and compare the

measurements to the specified value. See

"Technical data". Check the exhaust system

if the exhaust gas back pressure is too high.

4.

Remove the pressure gauge and the

coupling and fit the plug.

i400513

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст