DAF LF45, LF55 Series. Manual — part 274

©

200508

3-1

Removal and installation

PROP SHAFTS

ΛΦ45/55 series

3

10

3. REMOVAL AND INSTALLATION

3.1 REMOVING AND INSTALLING SPICER PROP SHAFT/INTERMEDIATE SHAFT

ASSEMBLY

Removing prop shaft/intermediate shaft

assembly

Note:

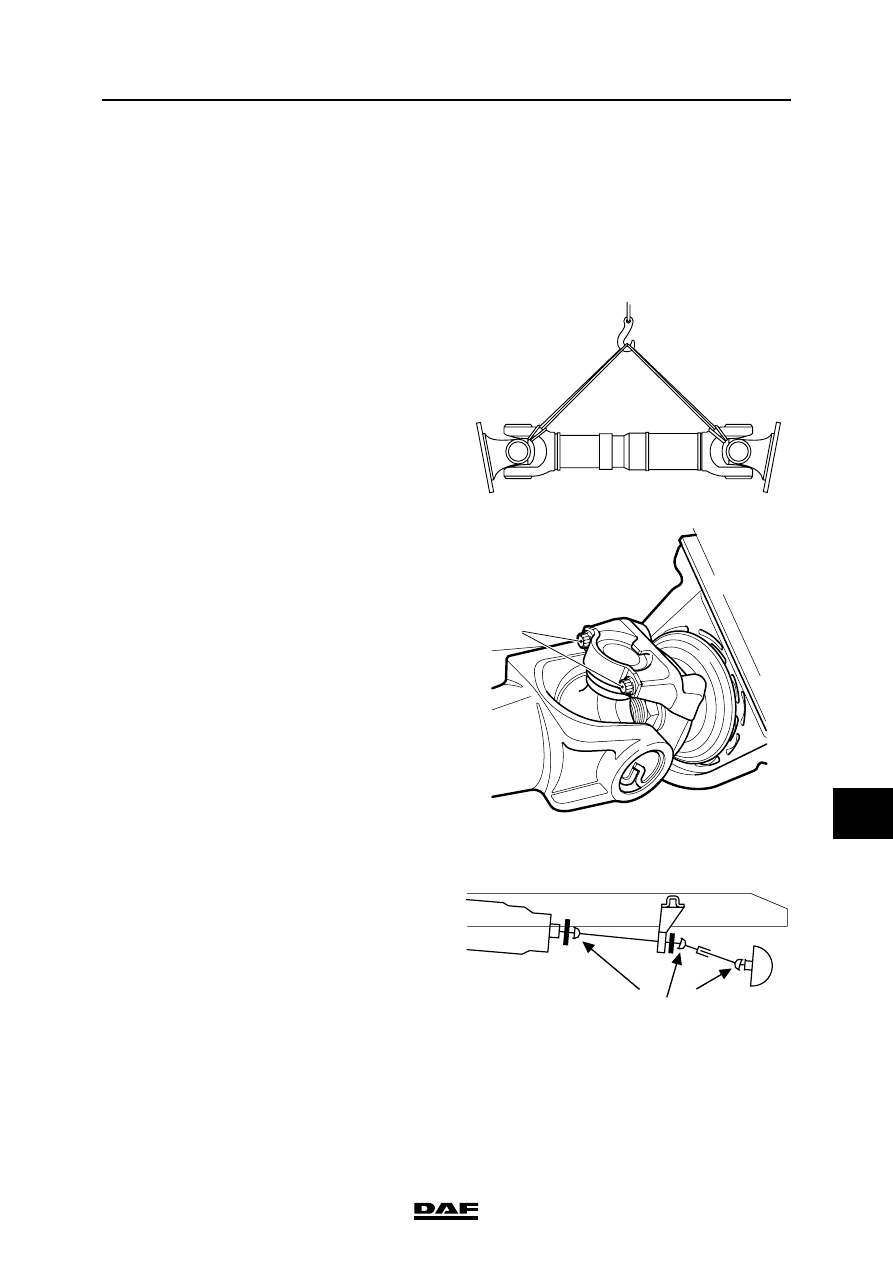

When removing one of the shafts in vehicles with

multiple shafts (prop shaft and intermediate

shafts), the other shaft must be tied to the chassis

or intermediate beam in such a way that it does

not obstruct the various operations. Always

transport and store shafts horizontally to avoid

damage and subsequent imbalance. Support the

shaft in at least two places. If possible, hang the

shaft in a hoist, using two sturdy ropes.

1.

Remove the attachment bolts from the

flanges and/or clamping pieces (1), and

carefully lower the shaft to the ground.

2.

Now remove the shaft from under the

vehicle.

Installing prop shaft/intermediate shaft

assembly

Note:

After repairs have been carried out or a shaft has

been replaced, the forks of all shafts must be

aligned.

1.

Fit the shaft under the vehicle. Use a hoist if

possible.

2.

Fit the attachment bolts. Tighten the

attachment bolts to the specified torque. See

"Technical data".

W 3 06 016

V3 00 377

1

=

=

W 3 06 019

PROP SHAFTS

3-2

©

200508

Removal and installation

10

ΛΦ45/55 series

3

3.2 REMOVAL AND INSTALLATION, PROP SHAFT/INTERMEDIATE SHAFT

ASSEMBLY

Removing prop shaft/intermediate shaft

assembly

1.

When removing one of the shafts in vehicles

with multiple shafts (prop shaft and

intermediate shafts), the other shaft must be

tied to the chassis or intermediate beam in

such a way that it does not obstruct the

various activities.

Note:

Always transport and store shafts

horizontally to avoid damage and

subsequent imbalance.

Support the shaft in at least two places. If

possible, hang the shaft in a hoist, using two

sturdy ropes.

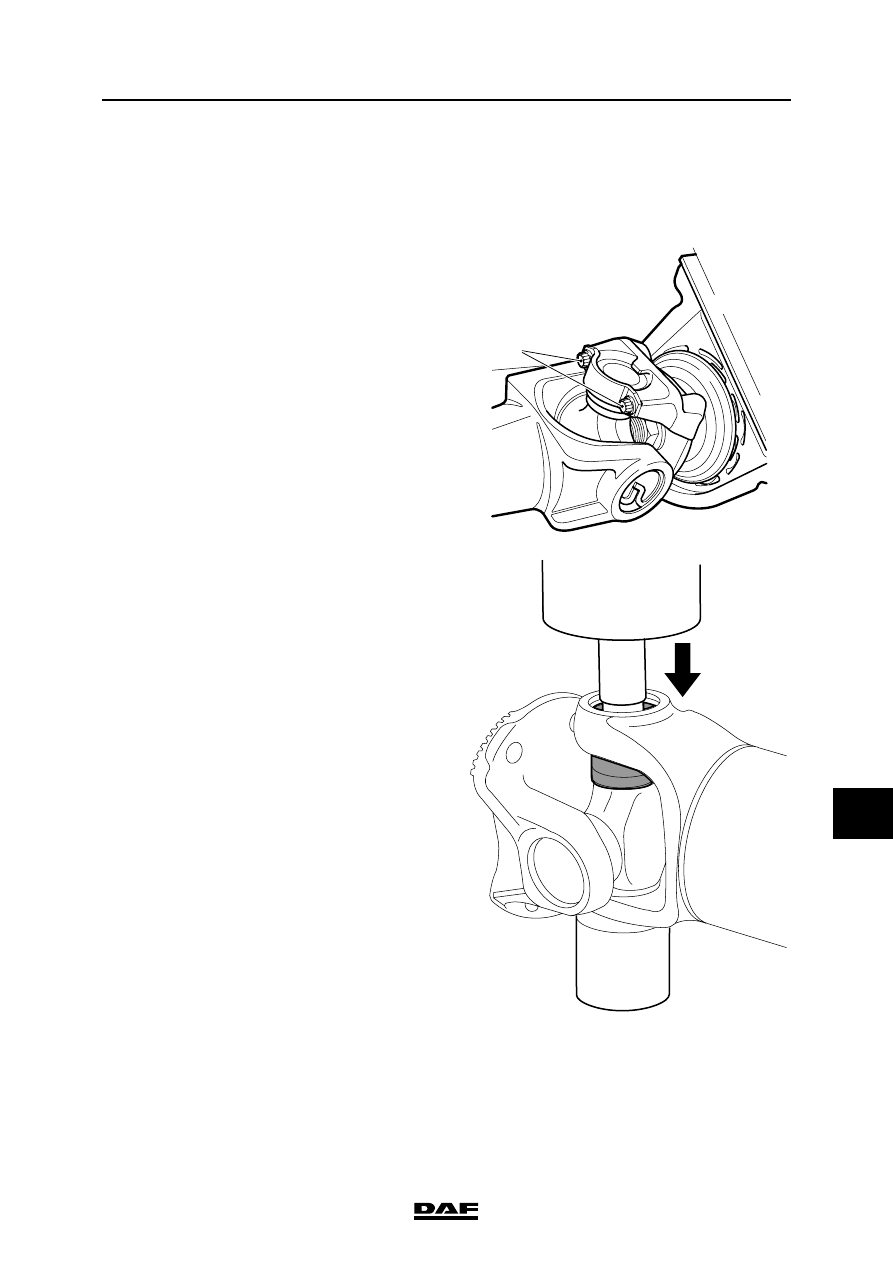

2.

Remove the attachment bolts from the

flanges and carefully lower the shaft to the

ground.

Now remove the shaft from under the

vehicle.

Installing prop shaft/intermediate shaft

assembly

Note:

After repairs have been carried out or a shaft has

been replaced, the marks on the shafts must be

opposite each other.

1.

Fit the shaft under the vehicle. Use a hoist if

possible.

2.

Tighten the attachment bolts to the specified

torque. See "Technical data".

W 3 06 016

=

=

W 3 06 019

©

200508

4-1

Demounting and mounting

PROP SHAFTS

ΛΦ45/55 series

3

10

4. DEMOUNTING AND MOUNTING

4.1 DEMOUNTING AND MOUNTING UNIVERSAL JOINT

Demounting universal joint

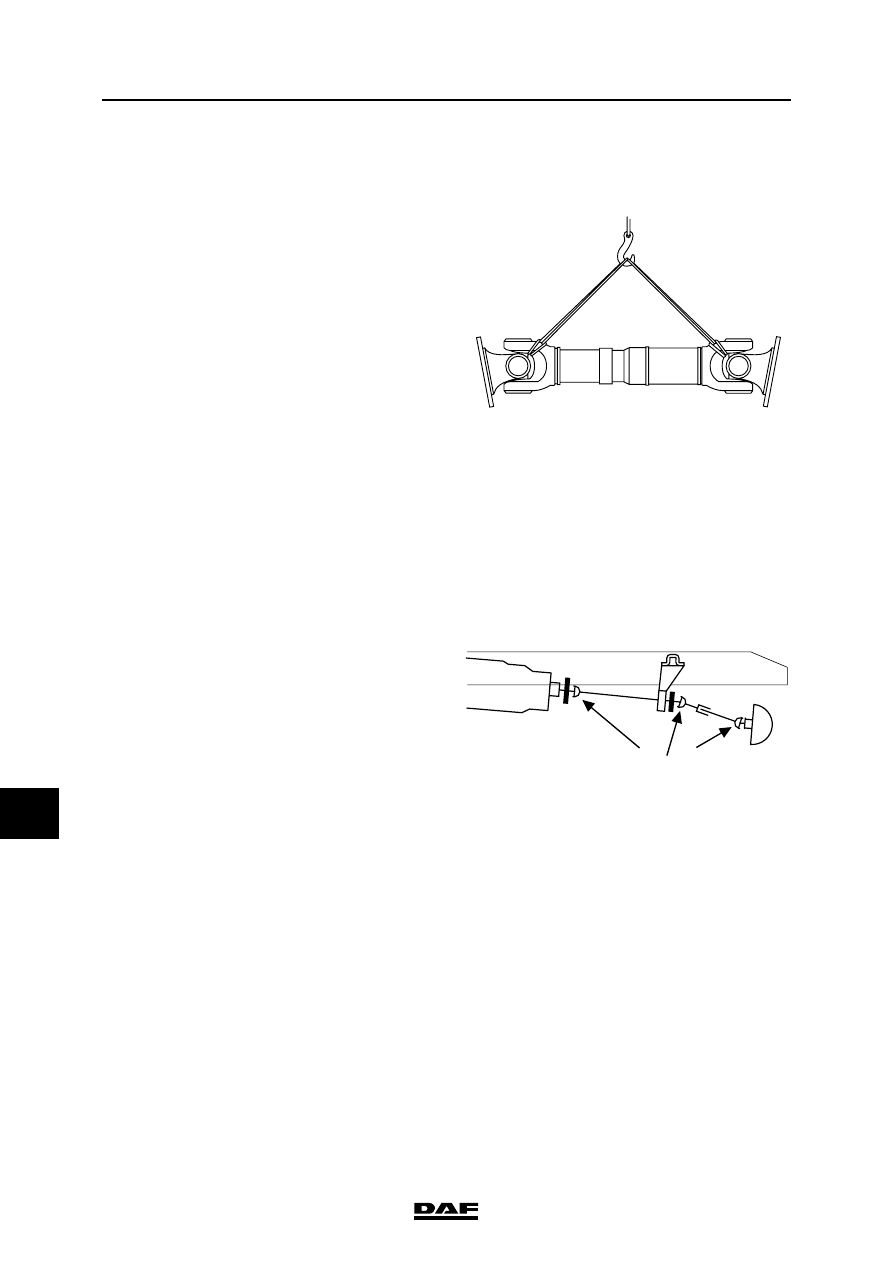

1.

Remove the prop shaft and/or intermediate

shaft assembly.

2.

Remove the circlips and the attachment bolts

of the clamping pieces (1) of the spider to be

replaced.

3.

Place the shaft on a bush underneath a

press, as shown, and press the entire spider

including bearings and drive flange down

until the spider touches the fork of the shaft.

V3 00 377

1

W306010-2

PROP SHAFTS

4-2

©

200508

Demounting and mounting

10

ΛΦ45/55 series

3

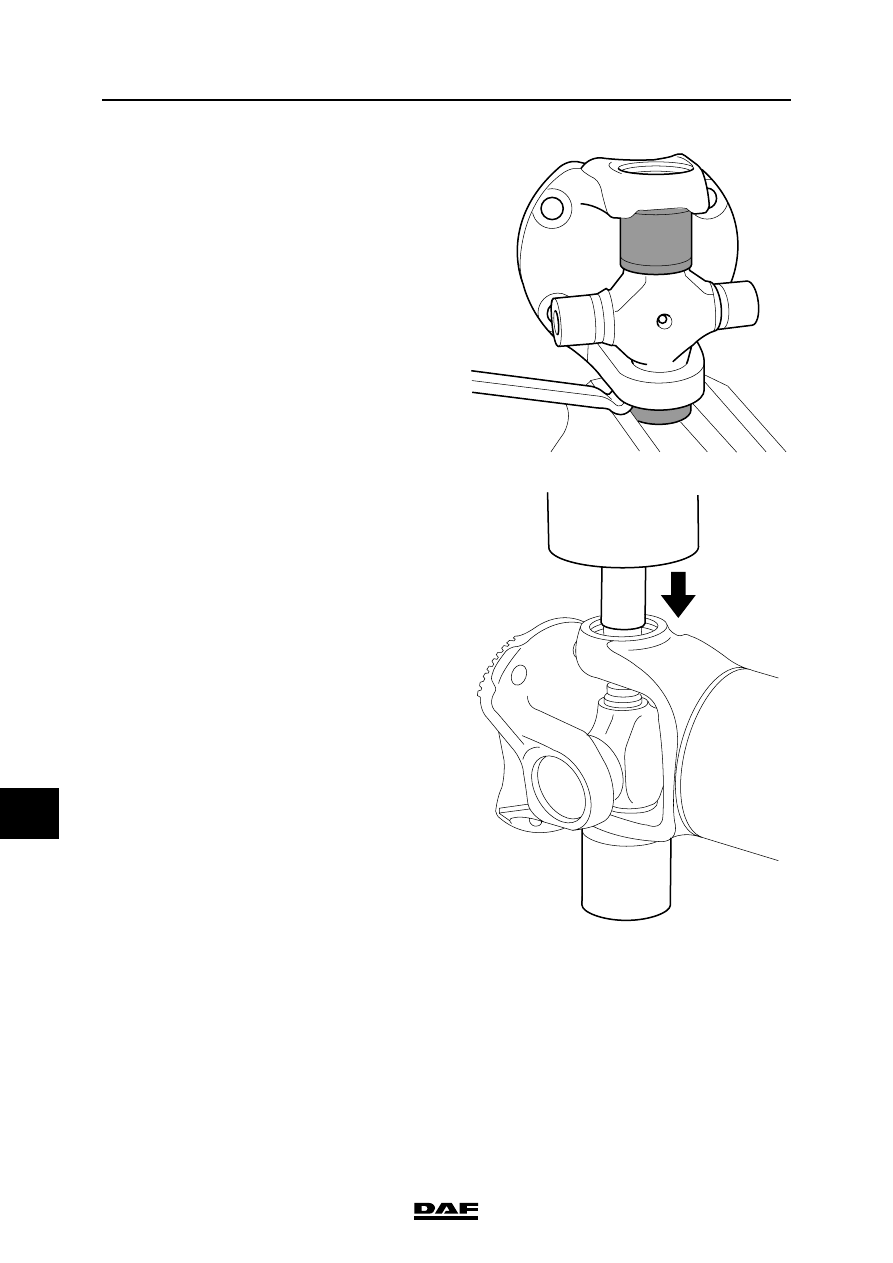

4.

Rotate the shaft 180

″ and remove the

bearing that has just been pressed out. If the

first bearing to be removed fails to come out

of the fork entirely, it can be clamped to

enable the fork to be pushed up by means of

a lever. Place the shaft back on the bush.

5.

Push the spider down again in the direction

of the shaft fork. Again, continue until the

spider touches the fork.

6.

The spider and the drive flange can now be

tipped out of the shaft fork.

7.

Place the drive flange on a bush underneath

a press and press the entire spider including

bearings and drive flange down until the

spider touches the fork of the drive flange.

8.

Rotate the drive flange 180

″ and remove the

bearing that has just been pressed out.

Place the drive flange back on the bush.

9.

Push the spider down again in the direction

of the shaft fork. Again, continue until the

spider touches the fork.

10. The spider can now be tipped out of the drive

flange fork.

Note:

When spiders are being replaced, always

replace them including their bearings.

11. Check the components to be reused for any

cracks and/or damage.

Mounting universal joint

Note:

After mounting, it must be possible to move

the drive flanges and spiders by hand. When

mounting the spider, Seeger rings of the

same thickness must be used.

W306012-2

W306011-2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст