DAF LF45, LF55 Series. Manual — part 462

©

200436

2-27

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

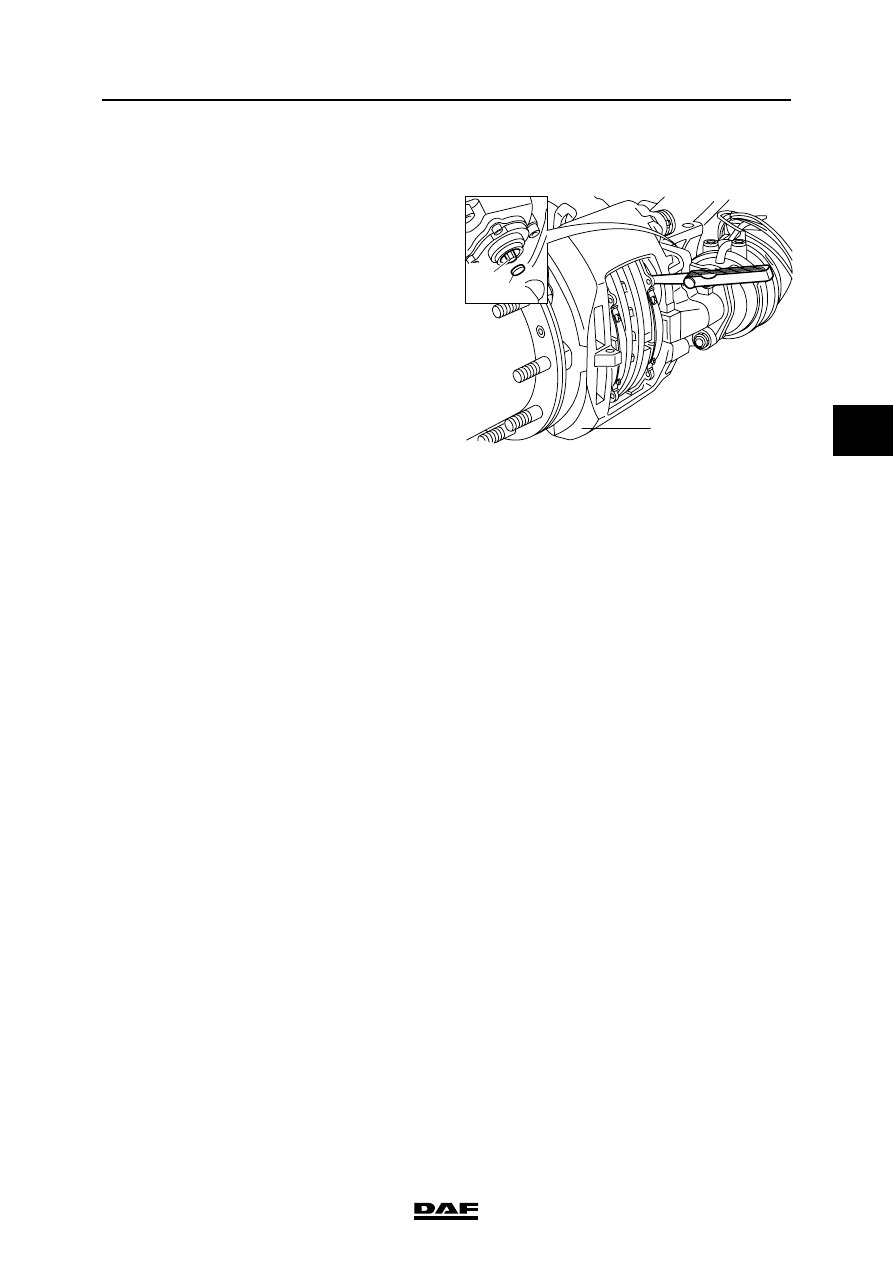

2.19 BRAKE ADJUSTMENT, DISC BRAKE VERSION

1.

Position a feeler gauge between the rear of

the brake pad and one of the thrust pieces of

the brake calliper to check the play.

Compare the measured value (see

"Technical data").

2.

If the play is not correct, it needs to be

adjusted. Remove the covering cap from the

slack adjuster.

3.

Fit a ring spanner on the hexagonal adjusting

bolt and turn the hexagonal adjusting bolt

anticlockwise until there is ample clearance

between the brake pads and the brake disc.

Note:

If Knorr disc brake construction is fitted:

Never turn the hexagonal adjusting bolt

without using an adapter (23). The adapter is

a torque safety and will break off when the

torque is too high. Without the use of an

adapter the mechanics in the brake calliper

may become damaged when the torque is

too high, so that replacement of the brake

calliper may be necessary.

4.

Position a feeler gauge with the correct

thickness (see "Technical data") between

the brake pad and the thrust piece of the

adjuster with the hexagonal adjusting bolt.

5.

Turn the hexagonal adjusting bolt clockwise

with the ring spanner until the feeler gauge

just fits. Remove the feeler gauge.

6.

Apply the brake a number of times so that the

play can set.

7.

Release the brake. Now it should be possible

to turn the hub by hand.

8.

Position a feeler gauge between the rear of

the brake pad and one of the presure plates

of the brake calliper to check the play.

Compare the measured value (see

"Technical data").

9.

After the inspection, lightly grease the

sealing cap (see "Technical data") and

replace it on the slack adjuster.

23

37

1

R600463

BRAKE SYSTEM AND COMPONENTS

2-28

©

200436

Inspection and adjustment

4

ΛΦ45/55 series

6

2.20 INSPECTION, AIR TIGHTNESS

Air tightness

If the brake system of a vehicle has been charged

to the maximum pressure, it should generally be

possible to drive the vehicle away after a period

of 16 hours of uninterrupted standstill, without

first having to charge the brake system to

sufficient operating pressure.

This implies a maximum pressure drop of approx.

0.4 bar per hour at normal system pressure.

Note:

Always connect auxiliary consumers and

accessories to circuit 4.

©

200436

3-1

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

3. REMOVAL AND INSTALLATION

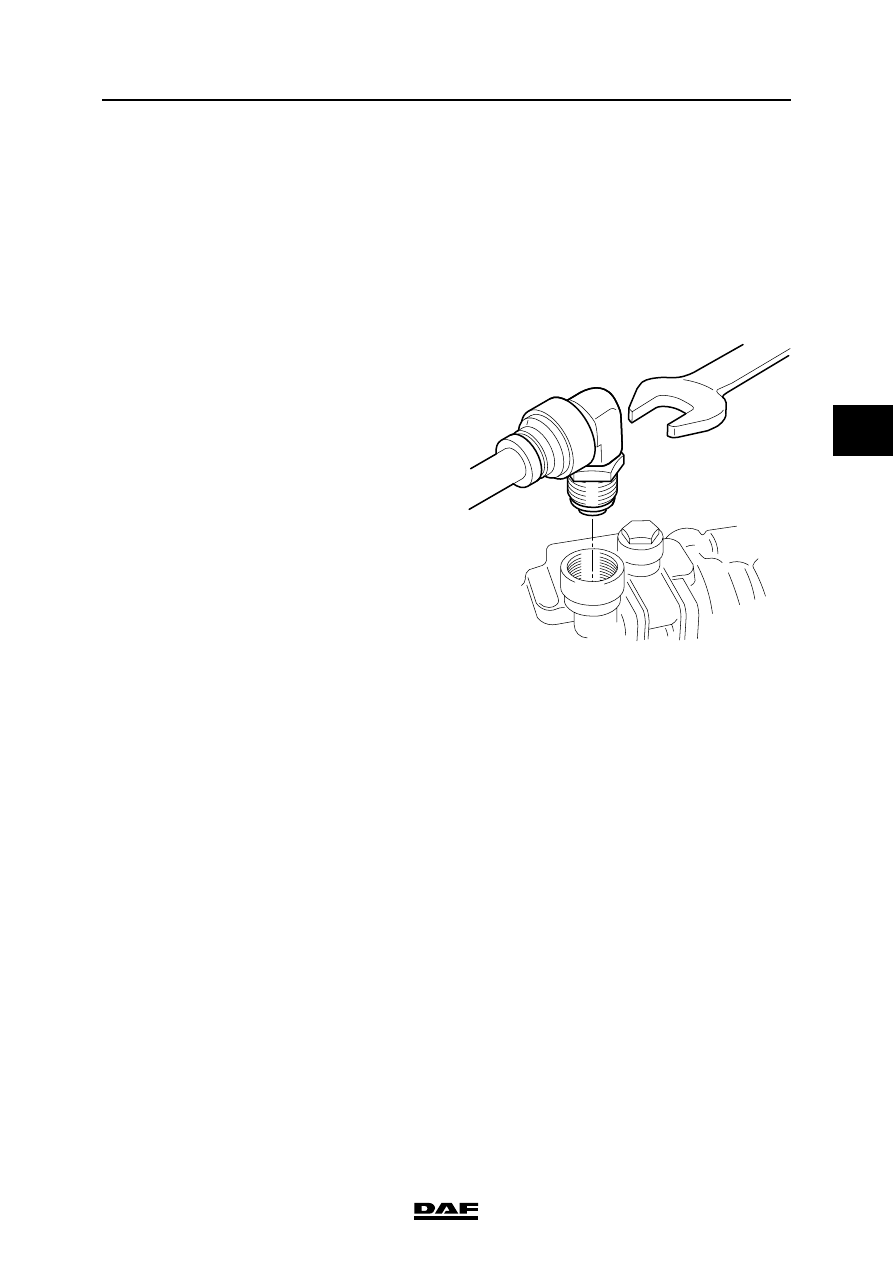

3.1 REMOVAL AND INSTALLATION, QUICK-RELEASE COUPLING

When disconnecting pipes and/or

quick-release couplings, ensure that

the relevant connection has first

been made pressureless.

Removing the quick-release coupling

1.

Loosen the quick-release coupling using an

open-ended spanner.

2.

Remove the quick-release coupling from the

valve.

Installing the quick-release coupling

1.

Check the bore in the valve for dirt and clean

the bore as necessary.

2.

Fit the quick-release coupling to the valve.

3.

Tighten the quick-release coupling to the

specified torque. See "Technical data".

}

R600576

BRAKE SYSTEM AND COMPONENTS

3-2

©

200436

Removal and installation

4

ΛΦ45/55 series

6

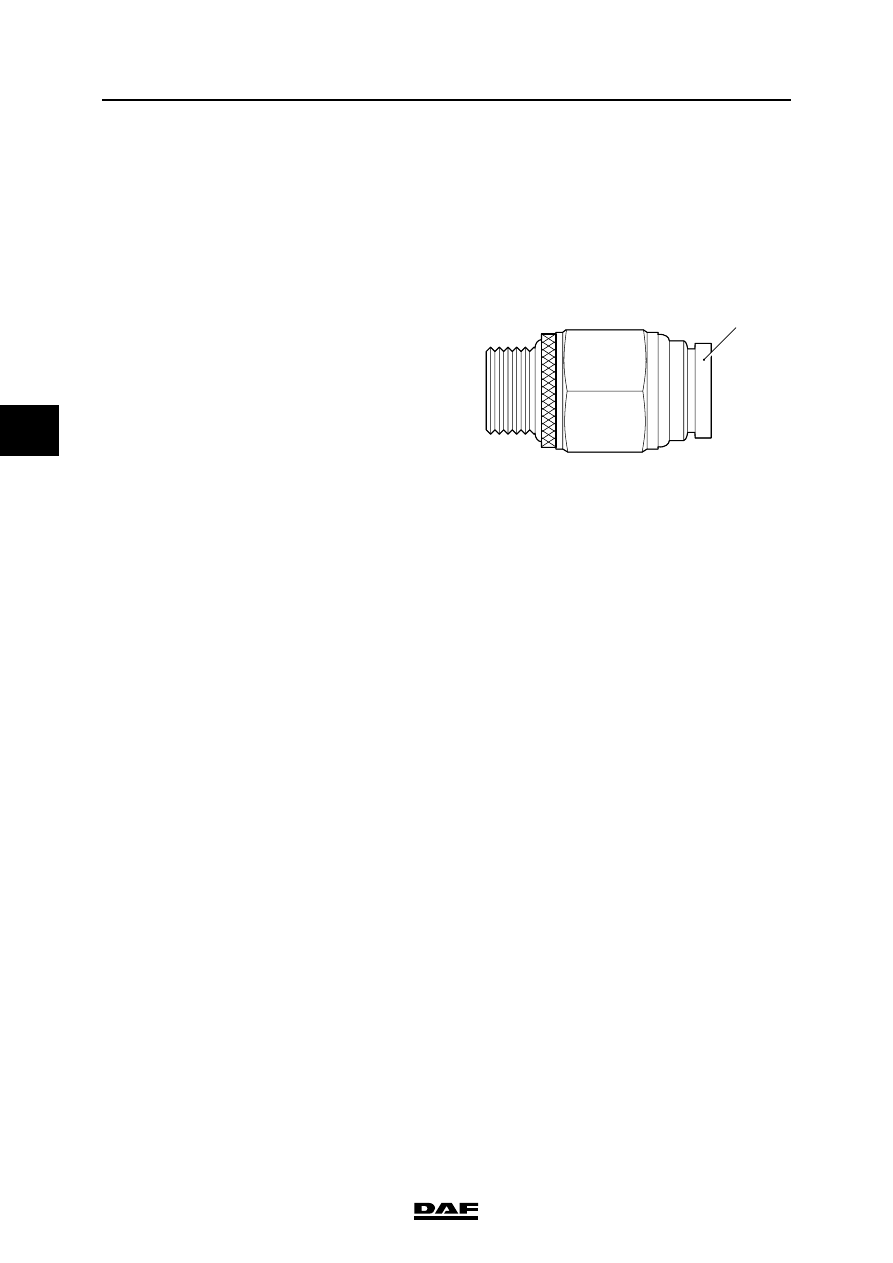

3.2 REMOVAL AND INSTALLATION, PIPE ON QUICK-RELEASE COUPLING

When disconnecting pipes and/or

quick-release couplings, ensure that

the relevant connection has first

been made pressureless.

Removing the pipe on quick-release coupling

1.

Press the collar (1) against the quick-release

coupling.

2.

Press the pipe out of the quick-release

coupling.

Installing the pipe on quick-release coupling

1.

Check the quick-release coupling for

damage. If the quick-release coupling is

damaged, it must be replaced.

2.

Press the pipe into the quick-release

coupling.

3.

Pull out the collar (1).

}

R600575

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст