DAF LF45, LF55 Series. Manual — part 314

©

200416

3-5

Description of components

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

3.4 FUEL RAIL PRESSURE-LIMITING VALVE

The fuel rail has a pressure-limiting valve so that

the rail pressure is maintained at a safe value in

emergency situations.

The fuel rail pressure control circuit is normally

active. This consists of the fuel lift pump, fuel

pump control solenoid valve, high-pressure

pump, fuel rail, rail pressure sensor and

electronic unit. If a fault occurs, the rail pressure

can no longer be controlled. This can rise to the

actuating pressure of the fuel rail pressure-

limiting valve. This pressure is approx. 1650 bar.

In the open position all surplus fuel flows without

pressure to the fuel tank return connection.

The valve includes a sealing cone (1), a valve

body (2), a spring (3) and a return connection with

quick-release coupling (4).

i400592

1

2

3

4

CE ENGINE FUEL SYSTEM

3-6

©

200416

Description of components

5

ΛΦ45/55 series

4

3.5 FUEL RETURN OVERFLOW VALVE

The injectors are mounted in the cylinder head.

The injectors do not have a separate return

connection. In place of this there is a longitudinal

bore in the cylinder head that meets the injector

bores of all cylinders coinciding with the height of

the return ports of the injectors. A pressure relief

valve is mounted at the end of the bore to prevent

vapour bubbles forming in it and to prevent it

emptying after the engine is turned off. This valve

maintains a residual pressure in relation to the

return pressure of 1.2 to 2.0 bar.

The pressure relief valve consists of a spring-

loaded plunger (1) and a housing (2) with quick-

release inlet and outlet connections (A and B

respectively).

A

B

1

2

i400861

©

200416

4-1

Inspection and adjustment

CE ENGINE FUEL SYSTEM

ΛΦ45/55 series

4

5

4. INSPECTION AND ADJUSTMENT

4.1 BLEEDING THE FUEL SYSTEM

Stop pumping as soon as a greater

resistance is felt. If you continue

pumping, the fuel system may

become internally damaged.

Note:

When the hand pump is used, the fuel system will

be automatically bled. Air will be fed back to the

tank through the return pipe.

1.

Unscrew the button of the primer pump and

pull it out.

2.

Use the primer pump until a clearly higher

resistance is perceptible.

3.

Press the button and tighten it.

}

G0 00 209

CE ENGINE FUEL SYSTEM

4-2

©

200416

Inspection and adjustment

5

ΛΦ45/55 series

4

4.2 CHECKING FUEL LIFT PUMP PRESSURES

When inspecting the fuel pressure,

fuel will escape. Collect the fuel and

avoid the risk of fire.

Dirt in the fuel system can lead to

significant damage to parts of the

system. Prevent this by cleaning the

parts before disassembly and then

sealing all open connections.

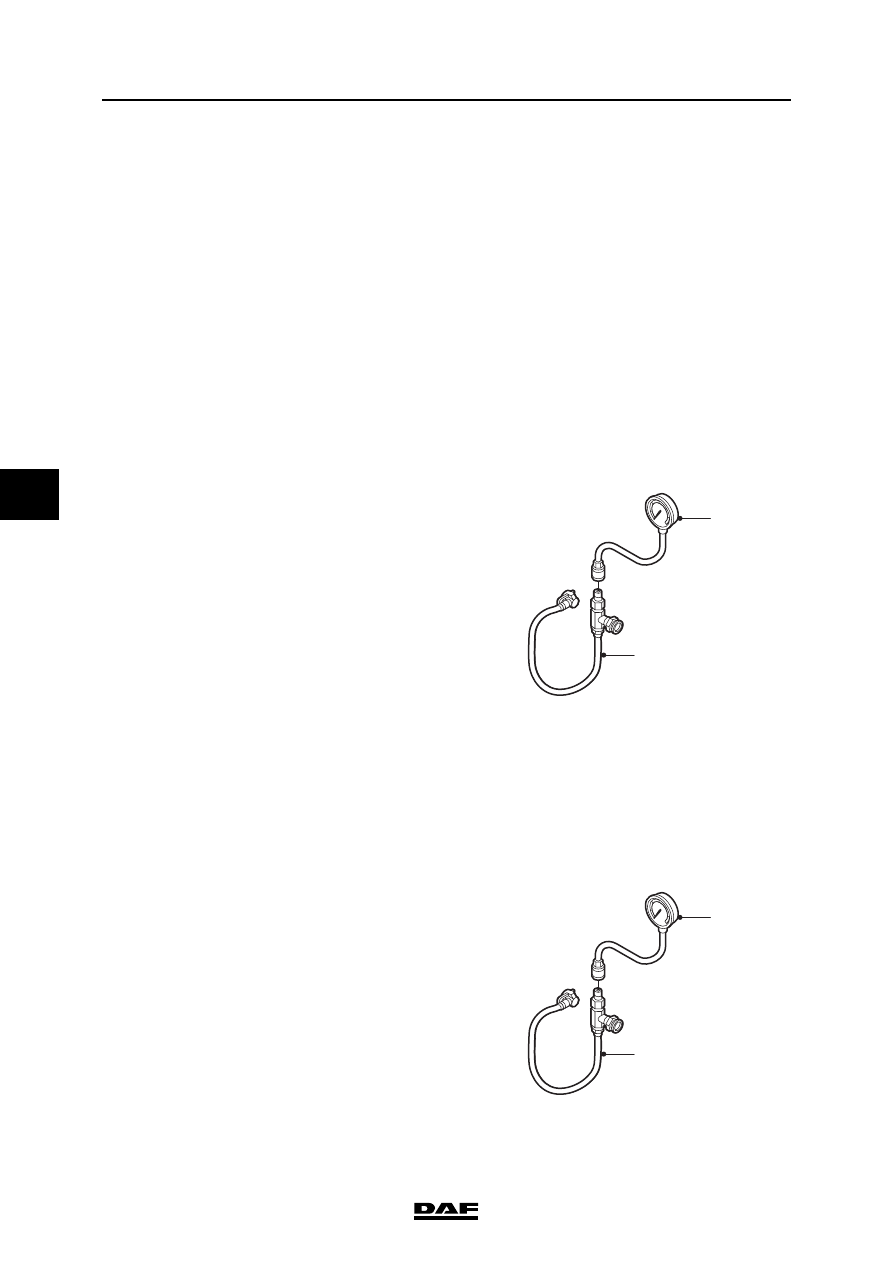

Checking underpressure on suction side of

fuel lift pump

1.

Disconnect the fuel pipe from the electronic

unit cooling plate to the fuel lift pump on the

suction side of the fuel lift pump; see

"Removal and installation".

2.

Fit the adapter (1), special tool

(DAF no. 1329476), between the pipe which

has been removed and the fuel lift pump and

couple a pressure gauge (2) to this adapter.

3.

Bleed the fuel system.

4.

Measure the underpressure when the engine

is idling. Compare the readings with the

specified values. See "Technical data".

5.

Remove the pressure gauge and the adapter

and fit the fuel pipe.

6.

Bleed the fuel system, start the engine and

check the fuel system visually for leaks if no

further measurements are to be carried out.

Checking fuel pressure in fuel lift pump in

front of fuel fine filter

1.

Disconnect the fuel pipe from the lift pump to

the fuel fine filter on the delivery side of the

lift pump; see "Removal and installation".

2.

Fit the adapter (1), special tool

(DAF no. 1329476), between the pipe which

has been removed and the fuel lift pump and

couple a pressure gauge (2) to this adapter.

3.

Bleed the fuel system.

4.

Start the engine and measure the pressure

when the engine is idling. Compare the

readings with the specified values. See

"Technical data".

5.

Remove the pressure gauge and the adapter

and fit the fuel pipe.

}

}

i400883

2

1

i400883

2

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст