DAF LF45, LF55 Series. Manual — part 456

©

200436

2-3

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

2.3 INSPECTION AND ADJUSTMENT, LOAD SENSING VALVE, AIR

SUSPENSION

Explanatory notes on instruction plate

The information contained on the plate relates to

the axle loads, the output pressures and bellows

pressures, in accordance with the order of axles

beneath the vehicle.

"1" refers to the (first) front axle, "2" to the

following axle, etc.

In the entire column, a reading of 6 bar has been

filled in under "1".

If the vehicle is equipped with an empty/load

valve, a pressure ratio is entered in the box under

the valve illustration, e.g. "i = 1 : 1.5". The

"delivery pressure p2" of axle "1" then indicates

variable readings.

These values can be used to check the brake

pressure values of the front axle and to carry out

the inspection/adjustment below at the same

time. To do this, connect a pressure gauge to the

test connection of one of the front axle brake

cylinders.

Inspection/adjustment

1.

Check that the correct valve has been fitted

(see instruction plate).

2.

Connect pressure gauge 4 to the test

connection close to connecting point 1/4 on

the load-dependent control valve (input

pressure).

3.

Connect pressure gauge 2 to the test

connection on one of the brake cylinders

(service brake connection) of the rear axle.

4.

Connect a pressure gauge (43) with a

pressure-reducing valve to the simulation

connection near connections 41 and 42 of

the load-sensing valve (= simulated

adjustable bellows pressure).

5.

Make sure that the reservoir pressure is

higher than 6.5 bar throughout the testing

process.

6.

Set the simulated bellows pressure to its

second lowest value, as indicated on the

instruction plate.

7.

Depress the brake pedal until pressure

gauge 4 indicates a pressure of 6 bar.

R6 00 548

43

1/4

4

2

2

R600473

1

41 42

r

s

BRAKE SYSTEM AND COMPONENTS

2-4

©

200436

Inspection and adjustment

4

ΛΦ45/55 series

6

8.

Read the brake pressure of the rear axle on

pressure gauge 2 and check that this brake

pressure matches the one listed on the

instruction plate in the table under "output

pressure p2" to the rear axle.

9.

If the measured value is not correct,

depressurise connection 43 and, using a

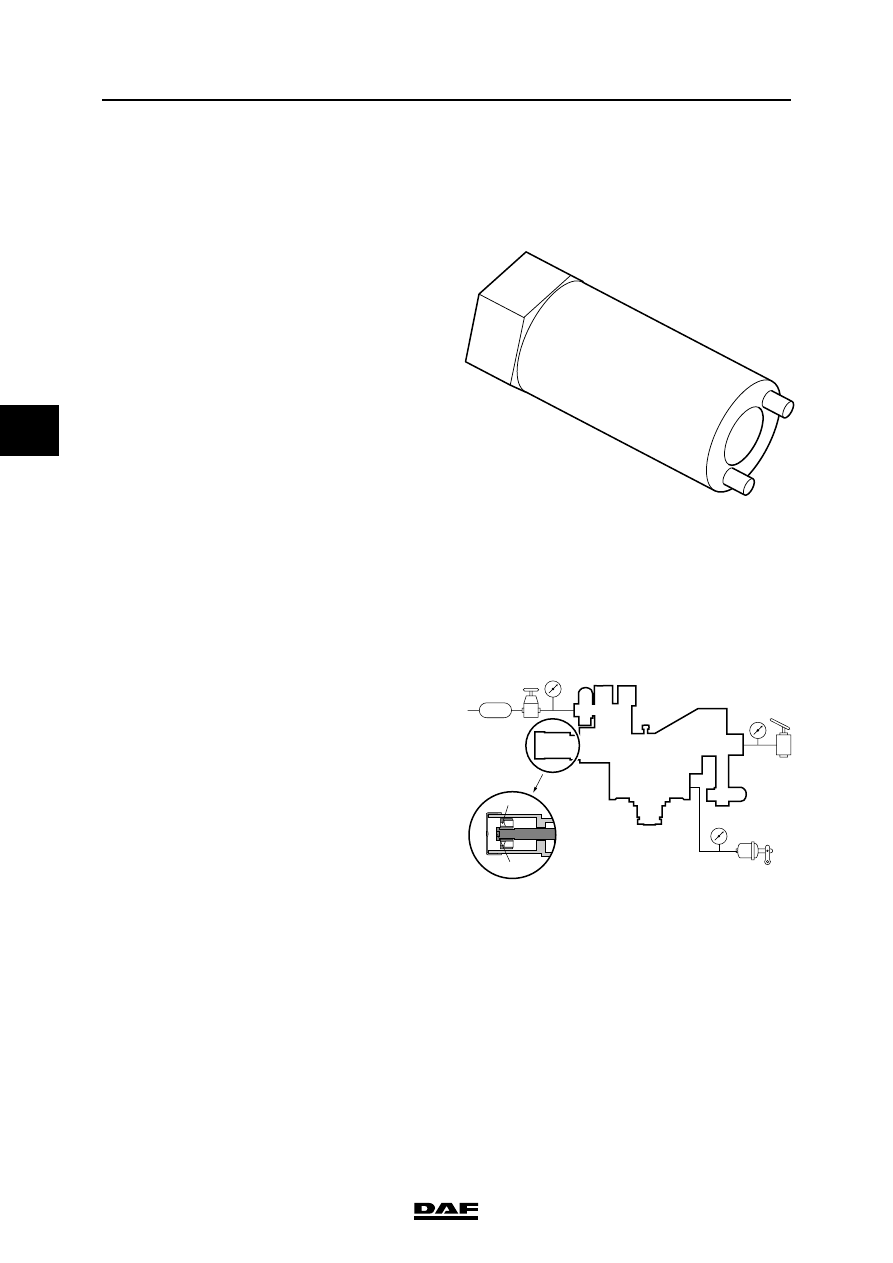

special slotted-nut spanner, special tool

(DAF no. 1329464), turn the adjusting nut(s):

-

brake pressure too high: unscrew the

adjusting nut

-

brake pressure too low: screw in the

adjusting nut

Note:

When depressurising the simulation

connection (pressure gauge 43), the air hose

must remain connected to prevent the

(actual) bellows pressure from accidentally

activating the valve.

The small socket head screw in the centre of

the valve must not be adjusted.

10. Repeat the procedure described in point 6

until the measured brake pressure value is

within the tolerance limits.

11. Set the simulated bellows pressure to its

second highest value, as indicated on the

instruction plate.

12. Depress the brake pedal until pressure

gauge (4) indicates a pressure of 6 bar.

13. Read the pressure gauge (2) and check that

this braking pressure matches the pressure

indicated in the table on the instruction plate.

14. If the measured reading is not correct,

depressurise connection 43 and turn the

adjusting bolt (r) using a Torx screwdriver:

-

brake pressure too high: screw in the

adjusting bolt

-

brake pressure too low: unscrew the

adjusting bolt

Note:

When depressurising the simulation

connection (pressure gauge 43), the air hose

must remain connected to prevent the

(actual) bellows pressure from accidentally

activating the valve.

The small socket head screw in the centre of

the valve must not be adjusted.

15. If the adjusting bolt (r) has been turned,

repeat the procedure from point 6.

R600478

43

1/4

4

2

2

R600473

1

41 42

r

s

©

200436

2-5

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

2.4 INSPECTION AND ADJUSTMENT, LOAD SENSING VALVE,

LEAF SUSPENSION

Explanatory notes on instruction plate

The data relating to axle loads and output

pressures are listed on the instruction plate

following the sequence of the axles beneath the

vehicle.

"1" refers to the (first) front axle, "2" to the

following axle, etc.

In the entire column, a reading of 6 bar has been

filled in under "1". If the vehicle is equipped with

an empty/load valve, a pressure ratio is entered

in the box under the valve illustration, e.g.

"i = 1 : 1.5". The "output pressure P2" of axle 1 will

give variable readings.

These values can be used to check the brake

pressure values of the front axle and to carry out

the inspection/adjustment below at the same

time. To do this, connect a pressure gauge to the

test connection of one of the front axle brake

cylinders.

Inspection/adjustment

1.

Measure the weight plus load of the rear

axle.

2.

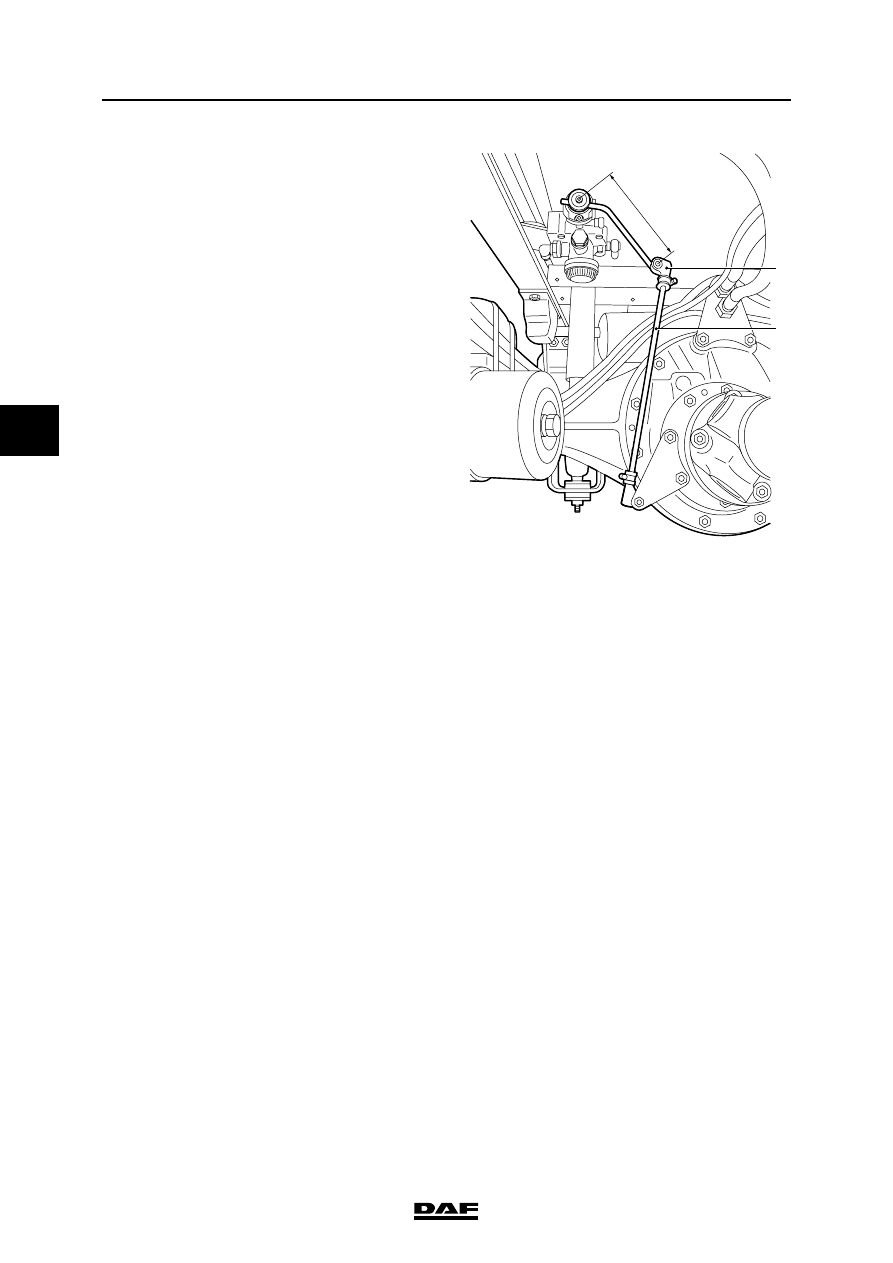

Check the attachment of the control lever

and its ease of operation.

3.

Check that the right type of valve has been

fitted.

4.

Check the length of the control lever (see "L"

on the instruction plate).

5.

Connect a pressure gauge (4) to the test

connection near connection 1/4 on the load-

sensing valve (input pressure).

6.

Connect a pressure gauge (2) to the test

connection on one of the brake cylinders

(service brake connection) of the rear axle.

7.

Make sure that the reservoir pressure is

higher than 6.5 bar throughout the testing

process.

8.

Depress the brake pedal until pressure

gauge 4 indicates a value of 6 bar.

9.

Read the brake pressure of the rear axle

from pressure gauge 2 and check that this

value matches the one listed on the

instruction plate in the table under "output

pressure p2" to the rear axle.

R6 00 549

1/4

4

2

2

R600562

1

BRAKE SYSTEM AND COMPONENTS

2-6

©

200436

Inspection and adjustment

4

ΛΦ45/55 series

6

10. If necessary, correct the brake pressure by

adjusting the length of the vertical

connecting rod (2). Never attempt to alter

length L of the (horizontal) control lever.

11. Remove the ball coupling (1) and raise the

control lever. Check that the output pressure

is now allowed through (almost) without

reduction.

Note:

The small socket head screw in the centre of

the valve must not be adjusted.

1

2

R6 00 568

L

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст