DAF LF45, LF55 Series. Manual — part 457

©

200436

2-7

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

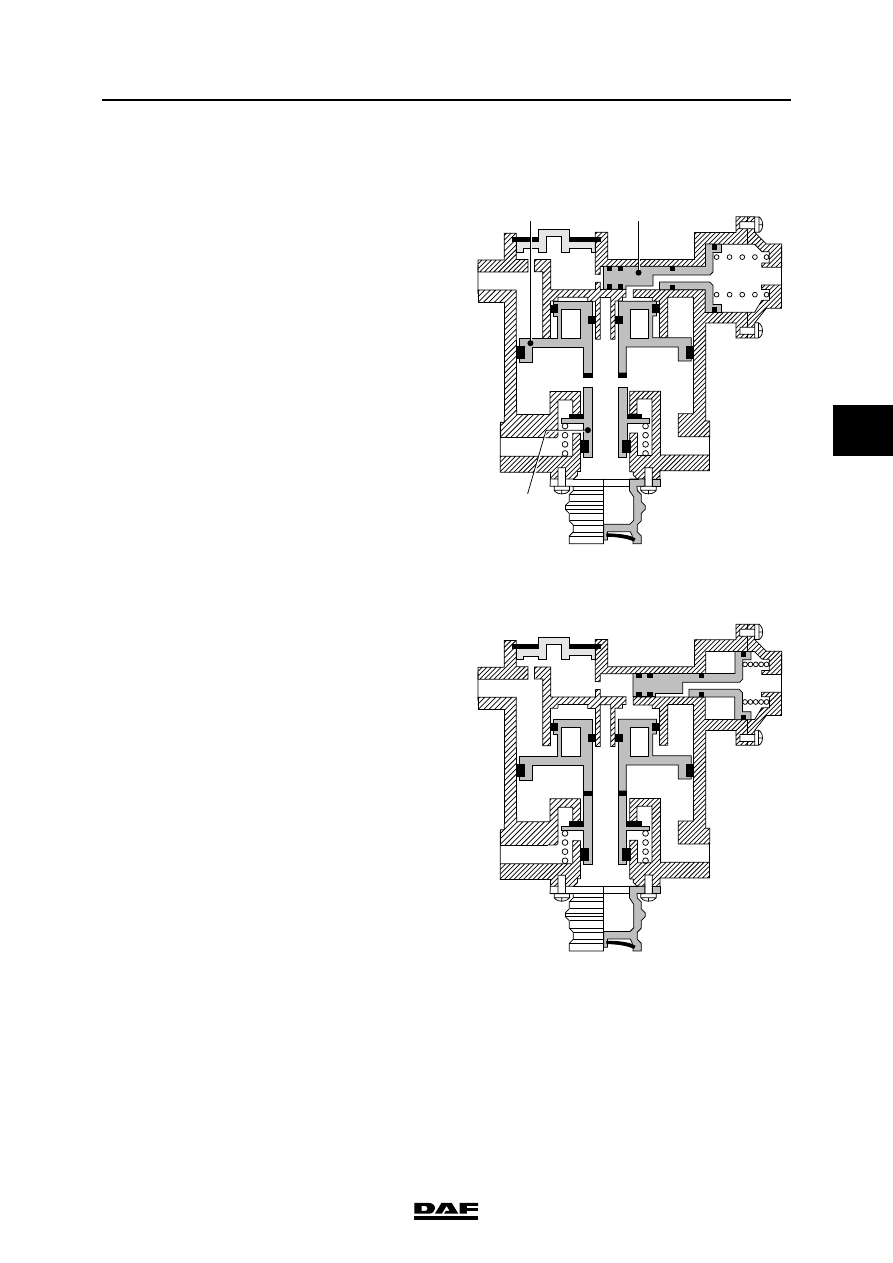

2.5 INSPECTION EMPTY/LOAD RELAY VALVE

1.

Using a T-piece, connect a pressure gauge

to connecting point 41.

2.

Connect a pressure gauge to the test

connection on one of the brake chambers of

the front axle.

3.

Connect a pressure gauge to the test

connection on one of the brake chambers of

the rear axle.

4.

Pressurise the system.

Testing when empty

1.

Set the load sensing valve to the empty

position.

2.

Slowly depress the brake pedal.

The pressure on the front axle should rise

gradually, not in jumps.

The pressure on the front axle will rise less

quickly than that on connecting point 41.

(With an empty vehicle, the difference will be

greater than with a partially loaded vehicle).

1

2

3

42

41

R600904

4

6

5

1

2

3

42

41

R600905

BRAKE SYSTEM AND COMPONENTS

2-8

©

200436

Inspection and adjustment

4

ΛΦ45/55 series

6

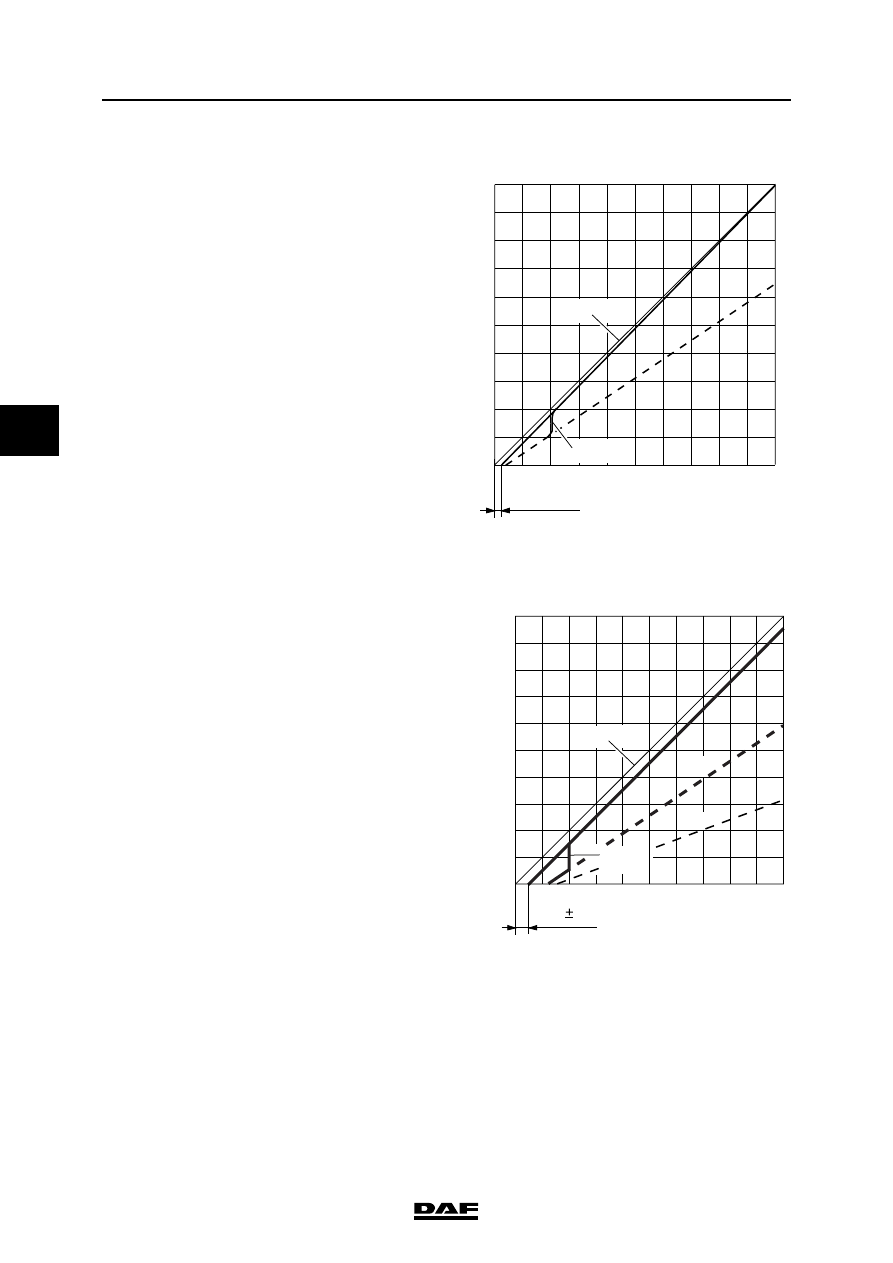

Testing when fully loaded

1.

Set the load sensing valve to the full-load

position.

2.

Slowly depress the brake pedal.

The pressure on the front axle should rise

gradually, not in jumps.

The pressure on the front axle will rise as

quickly (approx. 0.2 bar) as that on

connection point 41. It must be possible to

approximate the system pressure.

Inspection when faulty

1.

Disconnect the pipe to connecting point 42

and plug off the pipe.

2.

Repeat point 8.

3.

Set the load sensing valve as specified.

4.

Reconnect the pipes to points 41 and 42 in

the original manner.

5.

Remove the pressure gauges.

Inspection, output pressure to the front axle

1.

Measure the rear axle load.

2.

Check the load sensing valve setting.

3.

Connect a pressure gauge to the test

connection for the load sensing valve (input

pressure) and a pressure gauge to the test

connection on the brake cylinder of the front

axle.

4.

Make sure that the reservoir pressure

exceeds 6.5 bar.

5.

Depress the brake pedal until the pressure

gauge on the test connection of the load

sensing valve reads 6 bar, and read off the

braking pressure on the pressure gauge of

the front axle.

6.

Compare this value with the data in the table

attached to the door pillar.

0

0,1

0,25

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

+

_

R600906

P

0

42

=

P

42

P

41

=

0

0,1

0,5

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

P

0

42

=

P

42

P

41

=

1:2,7

1:1,5

41(bar)

p

2(bar)

p

R600745

©

200436

2-9

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΛΦ45/55 series

6

4

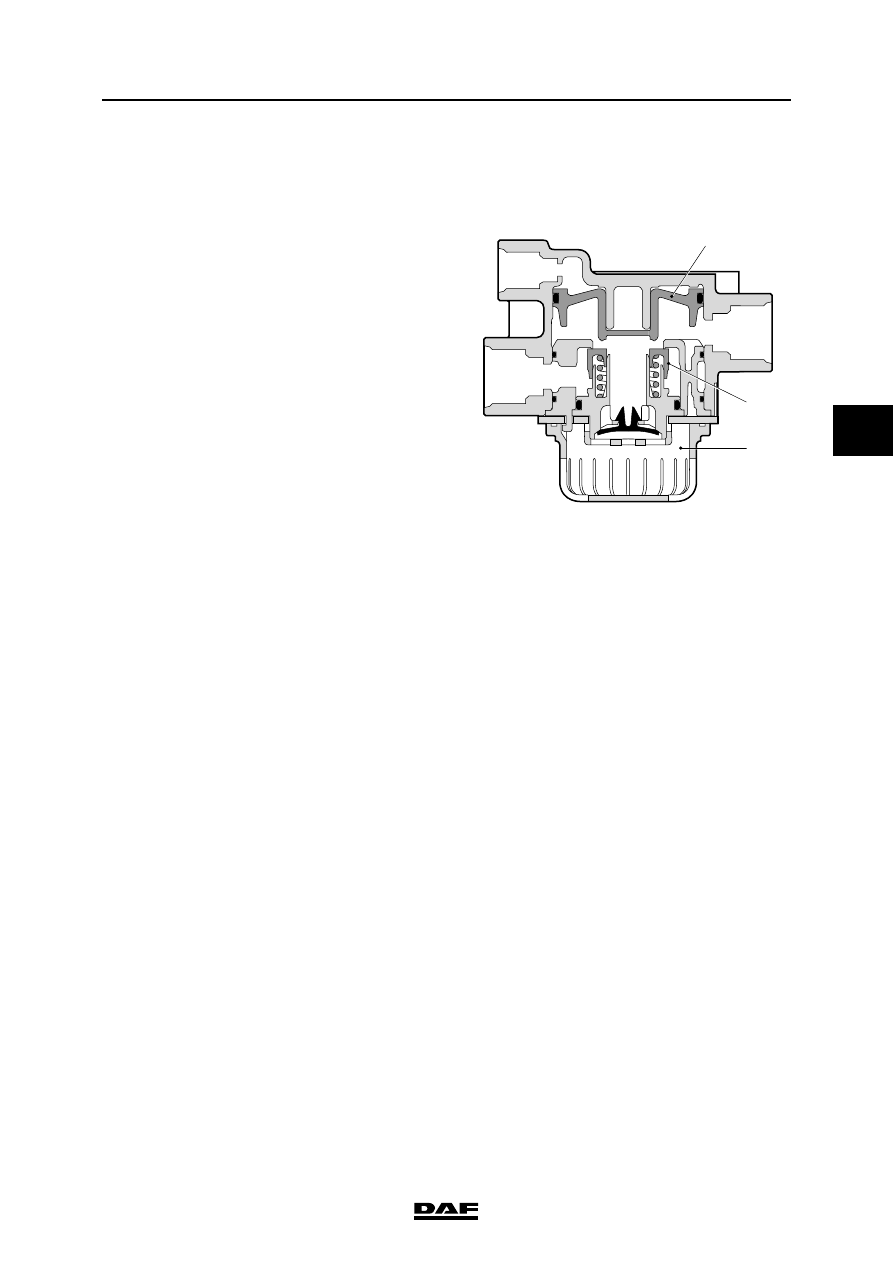

2.6 INSPECTING THE RELAY VALVE

Inspecting the relay valve

1.

Connect a pressure gauge to connecting

point 4 of the relay valve.

2.

Connect a pressure gauge to connecting

point 2 of the relay valve.

3.

Pressurise the system.

4.

Depending on the position of the relay valve

in the brake system, slowly activate the

service brake or parking brake.

5.

The pressure in the pressure gauge

connected to connection point 4 must now

increase to approx. 0.8 bar (the increased

parking brake actuating pressure) or 0.5 bar

(service brake), without there being any

noticeable pressure on connection point 2.

From this point, the pressures in both

pressure gauges must increase identically.

The pressure on the gauge connected to

point 2 should not rise in jumps. Both gauges

should indicate a value corresponding to the

graph. See "Technical data".

R600490

2

1

6

4

A

5

3

7

BRAKE SYSTEM AND COMPONENTS

2-10

©

200436

Inspection and adjustment

4

ΛΦ45/55 series

6

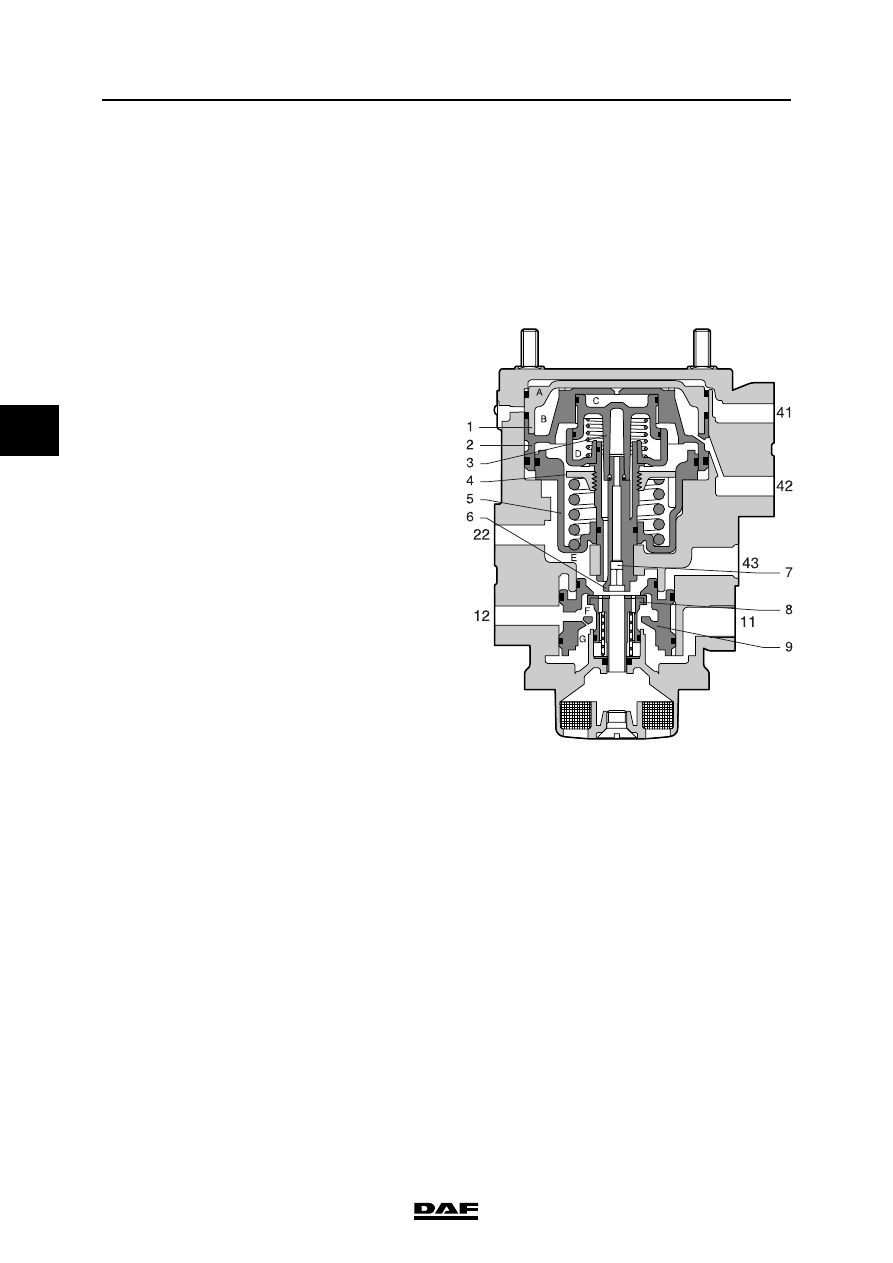

2.7 INSPECTION, TRAILER VEHICLE CONTROL VALVE

1.

Ensure there is sufficient system pressure.

2.

Check whether air is escaping via the bleed

vent.

3.

Depress the brake pedal, and again check

for leaks.

4.

Disconnect the pipe at connecting point 42

and plug off this pipe.

5.

Depress the brake pedal, and check for

pressure build-up in the service pipe (see

"Technical data").

6.

Reconnect the pipe.

7.

Repeat the last three points, but now for

connecting point 41.

8.

Operate the parking brake: pressure should

build up in the service pipe (see "Technical

data").

9.

Operate the parking brake to the stop, and

lock the lever: the service pipe should once

again become pressureless.

10. Simulate a leak in the service pipe, and

depress the brake pedal; within two seconds,

the outflow of air from the leak should slow

down considerably.

R600340

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст