DAF LF45, LF55 Series. Manual — part 73

©

200338

2-3

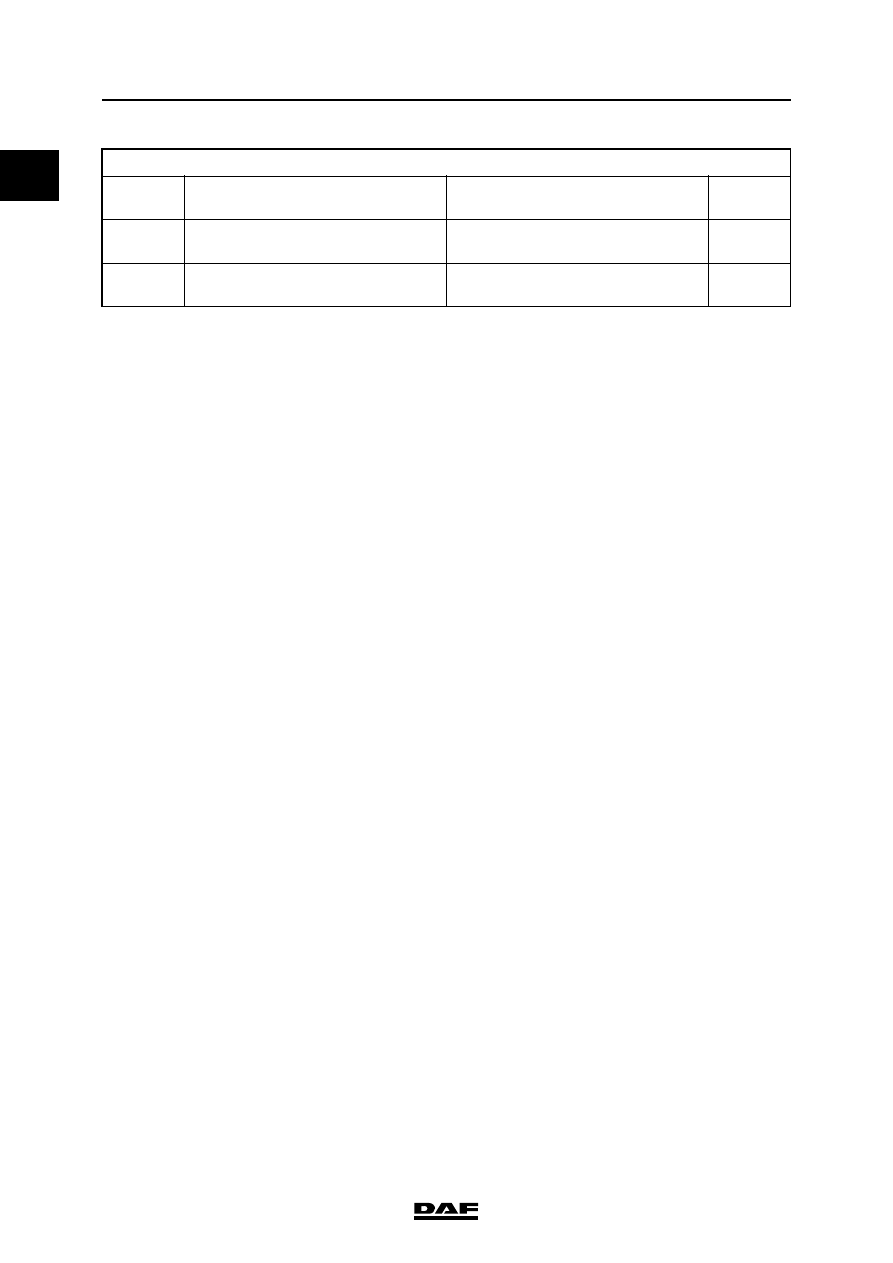

Locking compounds and sealants

TECHNICAL DATA

ΛΦ45/55 series

0

0

Loctite

5205

-

Surface sealant, specially

designed for sealing aluminium

parts

-

Resistant to temperatures up to

150

″C

-

Resistant to water, coolant and oil

Sealing of aluminium parts

1441339

Loctite

Form a

gasket

-

Hardens on contact with metal

and on full closure

For locking, fastening and sealing

1322823

OVERVIEW OF SEALING COMPOUNDS

Product

name

Properties

Applications

DAF

number

OTHER PRODUCTS

Product

name

Properties

Applications

DAF

number

Tectyl

Protects the cavities of the cab body

against corrosion.

Post-treatment of cab parts to protect

against corrosion.

Can also be used as protection for

metal parts

1343888

Contact

spray

Cleaning agent for cleaning and

degreasing electronic and electrical

connections. Removes moisture and

dirt from electrical contacts

Cleaning of electrical contacts

1387608

Loctite

cleaner

7063

-

Cleans and degreases

-

Non-inflammable and non-

corrosive

For cleaning/degreasing of materials

to which a locking compound must be

applied

1322827

Molykote

BR 2

PLUS

-

Lubricating grease is heat-

resistant from -30

″C to +130″C

-

Wherever grease lubrication is

appropriate and normal

-

For almost all ball and roller

bearings, plain bearings, guides,

couplings, splined shafts,

threaded spindles, sprocket

drives with a low speed

1389512

Molykote

P37

-

Grease protects against

corrosion and is heat-resistant to

1400

″C.

For threaded connections that are

exposed to high temperatures, as

used for exhaust systems

1391619

Copaslip

-

Copper paste with an excellent

bond, is anti-corrosive and heat-

resistant from -35

″C to 1100″C.

-

Resistant to water, salts and

acids.

-

Prevents wear, oxidation, rust,

corroding and locking of metal

surfaces.

For connections that are vulnerable to

oxidation or corrosion, such as battery

terminals, exhaust couplings, etc.

1284344

Renolit

HLT2

-

Grease (white)

Disc brake adjustment device

1448907

TECHNICAL DATA

2-4

©

200338

Locking compounds and sealants

0

ΛΦ45/55 series

0

Syntheso

GL EP1

-

Grease (green)

Rubber guides for disc brake

1448908

Gleitmo

805

-

Protects untreated metals

against corrosion

For parts which are attached with a fit

such as wheel hub units

1443160

OTHER PRODUCTS

Product

name

Properties

Applications

DAF

number

©

200338

3-1

Threaded connections

TECHNICAL DATA

ΛΦ45/55 series

0

0

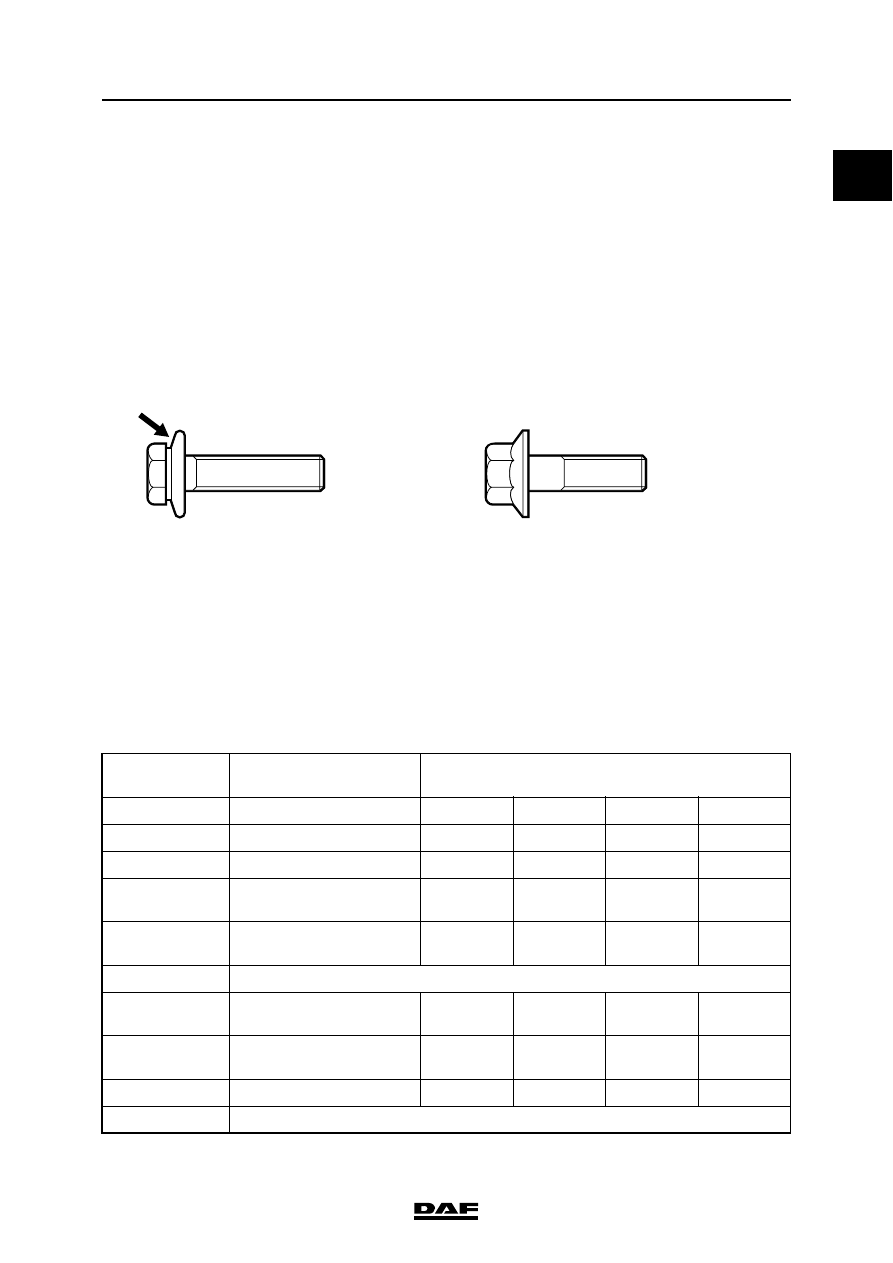

3. THREADED CONNECTIONS

3.1 TIGHTENING TORQUES

The tightening torques in the table below are

standard torques and only apply to dipped

threaded connections.

The property codes are stamped on the nut and

bolt, except on the clamping flange bolt. The

clamping flange bolt is recognised by a

constriction between the hexagonal bolt head

and the flange. This constriction is absent in

standard flange bolts.

Tightening torques for dipped threaded

connections

Overview of standard tightening torques for

DAF flange bolts and nuts, strength class

10.9/10

Clamping flange bolt/standard-flange bolt

M2 00 001

Thread pitch

Tightening torque (Nm)

Extra angular displacement (

≥ 10 %)

for bolt stem length L (mm):

L

40

41-80

81-130

131-180

M8

30

≥ 2

30

″

60

″

90

″

120

″

M10

60

≥ 4

45

″

90

″

120

″

150

″

M12 x 1.75

M12 x 1.25

110

≥ 8

110

≥ 8

30

″

45

″

60

″

90

″

90

″

120

″

120

″

150

″

M14 x 2

M14 x 1.5

170

≥ 15

170

≥ 15

30

″

45

″

60

″

90

″

90

″

120

″

120

″

150

″

M14 x 2

for brake back plates: 170

≥ 15 Nm + 60″

M16 x 2

M16 x 1.5

260

≥ 20

260

≥ 20

30

″

45

″

60

″

90

″

90

″

120

″

120

″

150

″

M18 x 2.5

M18 x 1.5

360

≥ 30

360

≥ 30

30

″

45

″

45

″

90

″

60

″

120

″

80

″

150

″

M20 x 1.5

520

≥ 40

45

″

90

″

120

″

150

″

M22 x 2.5

for steering and track rods: 500

≥ 50 Nm + 90″

TECHNICAL DATA

3-2

©

200338

Threaded connections

0

ΛΦ45/55 series

0

The bolt stem length L is the length of the bolt

between the bolt head and the nut.

If a component is attached with several bolts, all

bolts must first be tightened to the specified

torque, and subsequently by the angular

displacement.

Overview of standard tightening torques for

DAF fastenings, strength class 8.8/8

Overview of standard tightening torques for

DAF flange bolts and nuts, strength class

12.9/12

Thread

Tightening torque

in Nm

M4

2.8

≥ 0.2

M5

5.5

≥ 0.4

M6

9.6

≥ 0.7

M8

23

≥ 2

M10

46

≥ 4

M12

79

≥ 6

M14

125

≥ 9

M16

195

≥ 14

M18

280

≥ 20

M20

395

≥ 30

M22

540

≥ 40

M24

680

≥ 50

M27

1000

≥ 70

M30

1350

≥ 100

Thread

Tightening torque

in Nm

M8

32

≥ 3

M10

67

≥ 5

M12

113

≥ 9

M14

178

≥ 14

M16

274

≥ 22

M18

385

≥ 30

M20

550

≥ 43

M22

740

≥ 60

M24

925

≥ 72

M27

1370

≥ 110

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст