DAF LF45, LF55 Series. Manual — part 170

©

200505

4-15

Removing and installing

BE ENGINE

ΛΦ45/55 series

2

2

4.9 REMOVAL AND INSTALLATION, AIR COMPRESSOR

Removing the air compressor

1.

Partially drain the coolant.

2.

Remove the steering pump.

3.

Remove the coolant pipes.

4.

Remove the air pipes.

5.

Remove the attachment bolts from the air

compressor and remove it.

6.

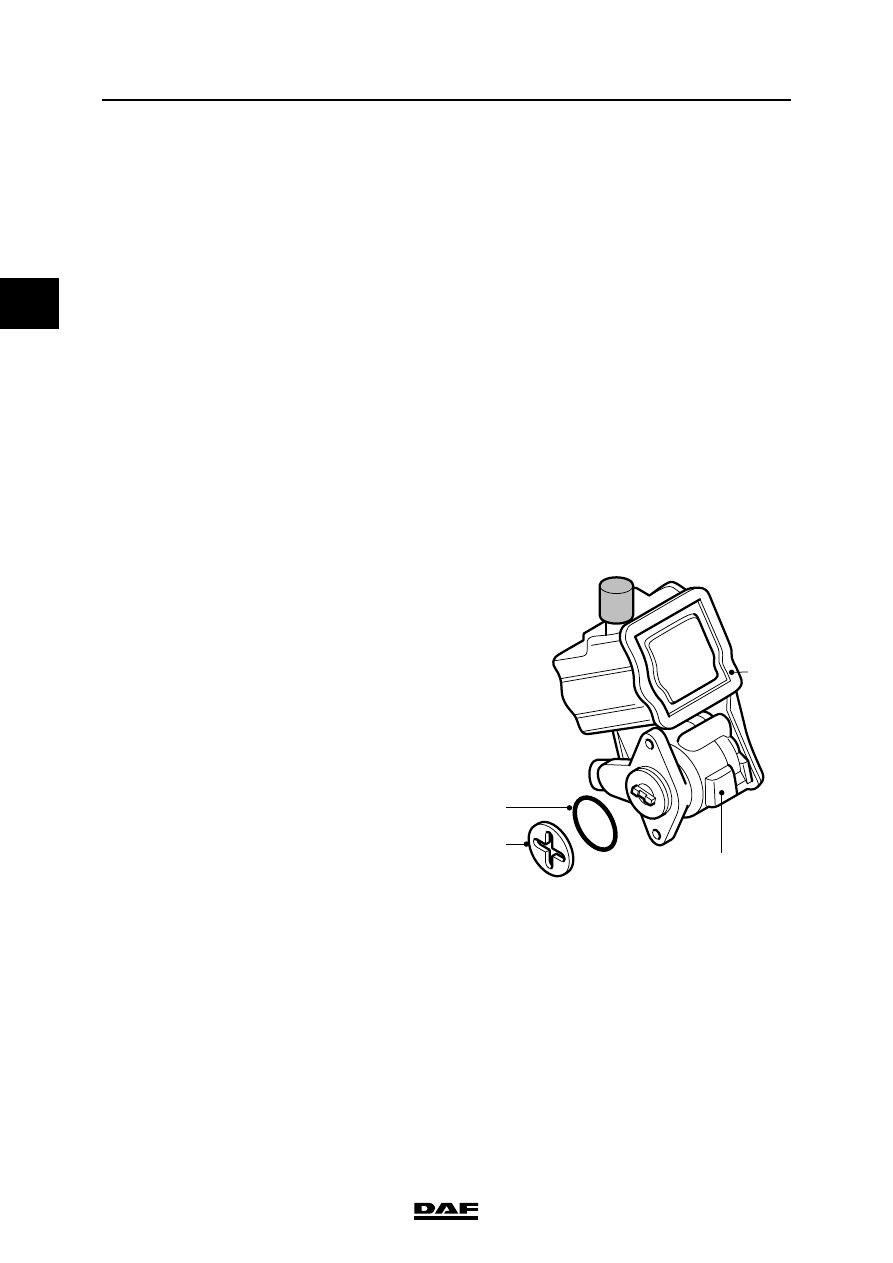

Remove the O-ring from the compressor

housing.

Installing the air compressor

1.

Fit the compressor with a new O-ring and

tighten the attachment bolts to the specified

torque. See "Technical data".

2.

Fit the air pipes.

3.

Fit the coolant pipes.

4.

Fit the steering pump.

5.

Fill the cooling system.

BE ENGINE

4-16

©

200505

Removing and installing

2

ΛΦ45/55 series

2

4.10 REMOVING AND INSTALLING STEERING PUMP

Note:

When replacing a worn steering pump, you are

advised to fully drain the steering oil and replace

the steering oil reservoir and integrated filter.

In extreme situations, the steering pump may

have been worn to such an extent that metal

pump parts have entered the steering box. Check

the steering box for internal wear using the test

case.

Removing steering pump

1.

Clean the line connections.

2.

Place a receptacle underneath the steering

pump.

3.

Remove the lines from the steering pump

and plug the line and pump openings. The

filter is fitted in the return line, which means

that should any dirt enter it will immediately

also enter the steering gear.

4.

Remove the attachment bolts and remove

the steering pump (3) and the driver (1) from

the compressor.

5.

Remove the reservoir (4) from the pump (3).

1

2

3

4

S7 00 575

©

200505

4-17

Removing and installing

BE ENGINE

ΛΦ45/55 series

2

2

Installing steering pump

1.

If necessary, fit the bracket (2) on top of the

new pump. Do not remove the cover from the

pump to do this. Tighten the attachment bolts

(1) evenly to the specified torque. See

"Technical data".

2.

Check the driver (1) for wear.

3.

If necessary, connect the line couplings to

the steering pump to be fitted. Tighten the

couplings to the specified torques; see

"Technical data".

If the specified tightening torques

are exceeded, the aluminium pump

housing may be damaged.

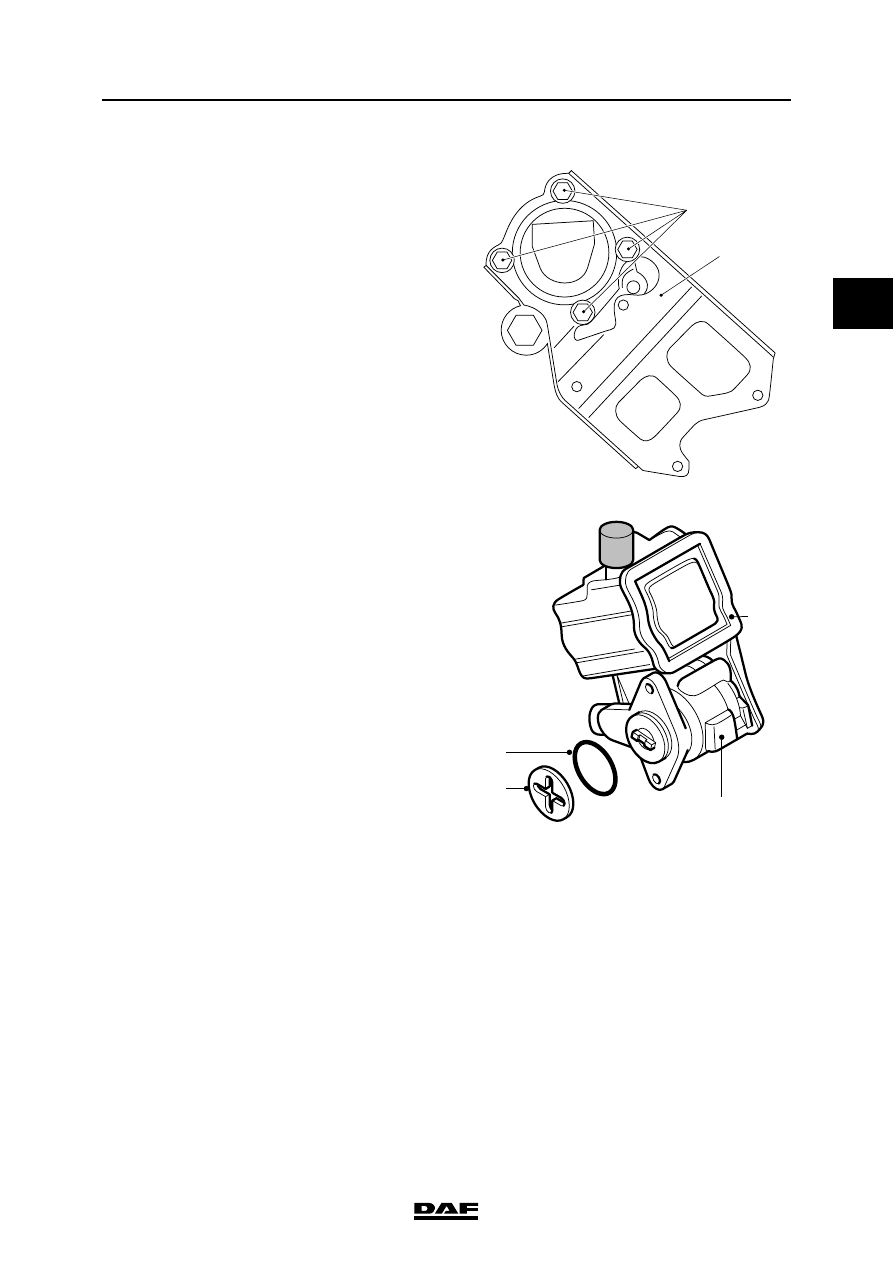

4.

Fit a new O-ring (2) on the steering pump

and grease it lightly.

5.

Crank the engine until the compressor driver

half is horizontal.

6.

Grease the driver (1) lightly and fit it to the

compressor driver half.

7.

Fit the reservoir (4) on the pump.

8.

Fit the pump (3). Tighten the attachment

bolts evenly to the specified tightening

torque; see "Technical data".

9.

Fit the lines.

10. Fill and bleed the steering gear hydraulic

system.

11. Take a test drive and check the pump and

line connections for leaks.

S7 00 609

1

2

1

2

3

4

S7 00 575

}

BE ENGINE

4-18

©

200505

Removing and installing

2

ΛΦ45/55 series

2

4.11 REMOVAL AND INSTALLATION, STARTER MOTOR

Removing the starter motor

1.

Remove both battery leads from the battery

terminals.

2.

Remove the electrical connections from the

starter motor.

3.

Remove the attachment nuts from the starter

motor and remove the starter motor.

4.

Check the starter pinion for damage.

Installing the starter motor

1.

Clean the contact surfaces of the starter

motor and the flywheel housing.

2.

Install the starter motor in the flywheel

housing and tighten the attachment nuts to

the specified torque. See "Technical data".

3.

Fit the electrical connections of the starter

motor.

4.

Reconnect both leads to the battery

terminals.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст