DAF LF45, LF55 Series. Manual — part 169

©

200505

4-11

Removing and installing

BE ENGINE

ΛΦ45/55 series

2

2

4.8 REMOVING AND INSTALLING CYLINDER HEAD

When components are removed

from any part of the engine, dirt may

enter. This may cause serious

damage to the engine. The engine

should therefore be cleaned

thoroughly before it is opened. Plug

all openings that are freed.

Removing cylinder head

1.

Drain the coolant.

2.

Disconnect all electrical wiring around the

engine which is required for removing the

cylinder head.

3.

Disconnect the air inlet pipe from the air

cooler on the turbocharger side.

4.

Remove the poly-V-belt.

5.

Remove the heat shields from the exhaust

manifold.

6.

If fitted, remove the attachment bolts of the

air-conditioning compressor.

7.

Remove the attachment bolts from the

alternator/air-conditioning compressor

bracket and remove the attachment bracket.

8.

Remove the attachment bolts from the

exhaust manifold and move the manifold and

the turbocharger a little away from the

cylinder head.

9.

Remove the other coolant hoses that are

attached to the cylinder head.

When removing components from

the fuel system, dirt can enter. This

may result in serious damage. The

area around the fuel system should

therefore be cleaned before opening

it. Detached pipes must be plugged

immediately.

10. Detach the injector pipes on the injector side.

11. Detach the supply pipe between the high-

pressure pump and fuel rail on the fuel rail

side.

12. Detach the fuel return pipe from the fuel rail

and from the cylinder head.

}

}

BE ENGINE

4-12

©

200505

Removing and installing

2

ΛΦ45/55 series

2

13. Unscrew the attachment bolts from the fuel

rail and remove it.

14. Unscrew the attachment bolts from the

intake manifold and remove it.

Note:

To avoid dirt entering the intake opening, it

must be taped up.

15. Remove the valve cover.

16. Remove the valve sleeve.

17. Remove the valve gear.

18. Remove the push rods. Mark the push rods

so that they can be refitted in their original

position.

19. Remove the fuel supply pipes.

20. Remove the injectors.

21. Remove the attachment bolts from the

cylinder head in the reverse order to that

followed for tightening. See "Technical data".

22. Remove the cylinder head from the cylinder

block. Keep the gasket to enable the correct

new head gasket to be selected.

23. Remove any gasket remnants from the

cylinder head and the cylinder block.

24. Check the cylinder block. See "Checking and

adjusting".

25. Check the threaded holes in the cylinder

block for damage and cracking.

26. Check the cylinder head. See "Checking and

adjusting".

Installing cylinder head

1.

Clean the threaded holes in the cylinder

head using a screw tap.

Note:

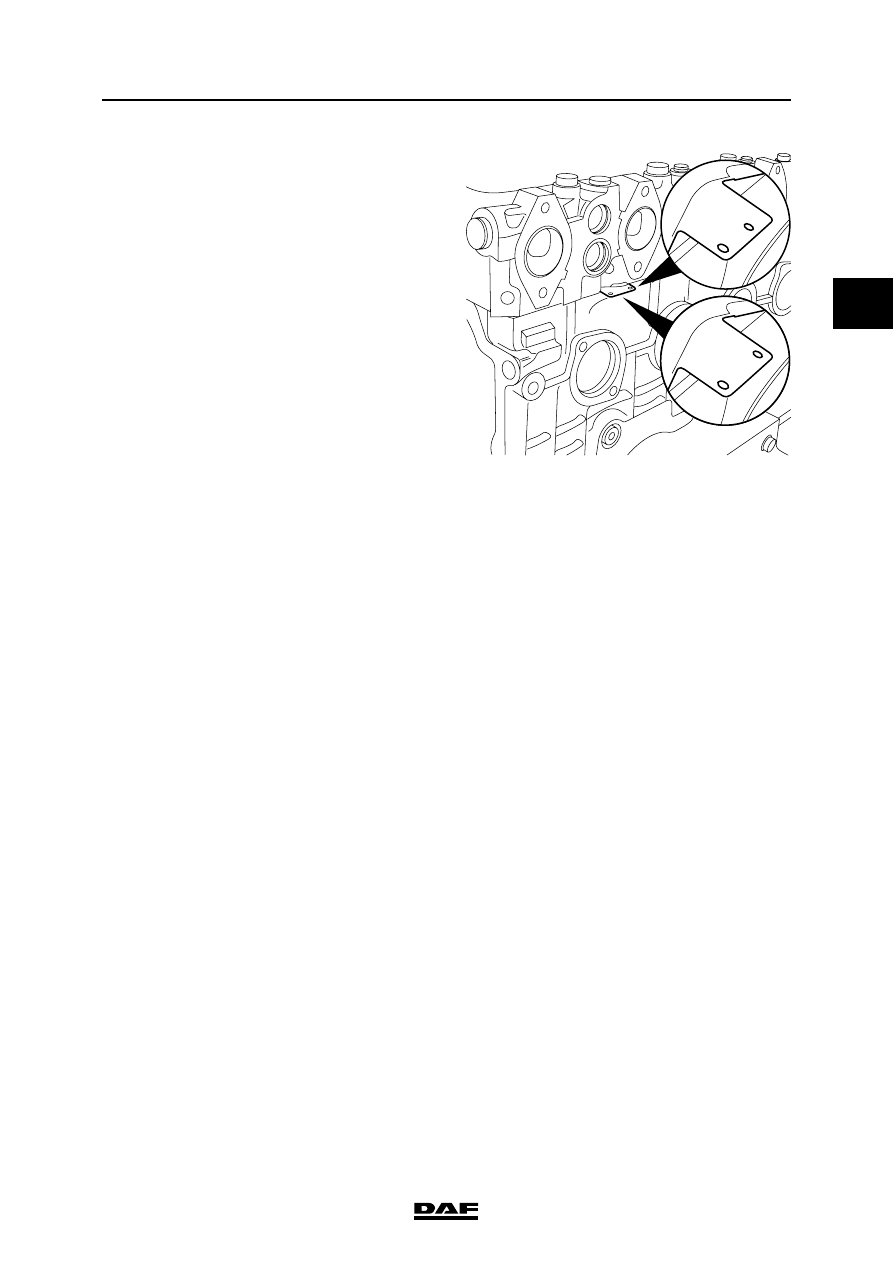

Cylinder head gaskets are available in two

thicknesses. The thickness of the cylinder

head gasket can be identified by the position

of the holes in the projecting cylinder head

gasket lip under the exhaust manifold on

cylinder 2. See "Technical data" for the

cylinder head gasket thicknesses.

©

200505

4-13

Removing and installing

BE ENGINE

ΛΦ45/55 series

2

2

2.

Position the new cylinder head gasket. If the

type of cylinder head gasket is known, use a

gasket of the same type as the one removed.

Note:

If the type of cylinder head gasket removed

is not known or if the main components of the

driving gear have been changed, the type of

gasket required must be determined afresh.

To do this, measure the average piston

projection. See "Checking and adjusting".

Select the correct type of cylinder head

gasket using the information in "Technical

data" and fit it.

3.

Check that all lubricating and coolant ducts

are free.

4.

Position the cylinder head carefully on the

cylinder block and ensure that the cylinder

head fits well over the dowel pins.

5.

Check the cylinder head bolts. See

"Checking and adjusting". Use new cylinder

head bolts if one bolt does not meet one or

more conditions.

6.

Apply engine oil to the thread and to the

underside of the bolt head.

7.

Position the cylinder head bolts and hand-

tighten them.

Note:

The short cylinder head bolts must be fitted

in the outer rows.

8.

Tighten the cylinder head bolts to the

specified torque and in the sequence shown.

See "Technical data".

9.

Fit the exhaust manifold with new gaskets

and tighten the attachment bolts to the

specified torque. See "Technical data".

10. Fit the injectors.

Note:

Ensure that the injector is fitted correctly,

bearing in mind the supply opening.

11. Fit the fuel supply pipes.

M201230

BE ENGINE

4-14

©

200505

Removing and installing

2

ΛΦ45/55 series

2

12. Fit the push rods in their original position and

apply a drop of engine oil to the head of the

push rod.

13. Fit the valve gear.

14. Fit the valve sleeve.

15. Tighten the injector wiring to the specified

torque. See "Technical data".

16. Fit the valve cover.

17. Remove any gasket remnants from the

intake manifold and the cylinder head.

Note:

Ensure that the air inlet is free of gasket

remnants.

18. Apply sealant to the intake manifold and fit it.

See "Technical data".

19. Fit the fuel rail.

20. Fit the injector pipes.

21. Fit the supply pipe between the high-

pressure pump and fuel rail.

22. Fit the fuel return pipe on the fuel rail and

cylinder head.

23. Connect the various coolant hoses.

24. Fit the bracket of the alternator/air-

conditioning compressor.

25. If present, fit the air-conditioning

compressor.

26. Fit the poly-V-belt.

27. Fit the heat shields.

28. Fit the air inlet pipe of the air cooler on the

turbocharger side.

29. Connect the electrical wiring.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст