Dodge Dakota (ND). Manual — part 816

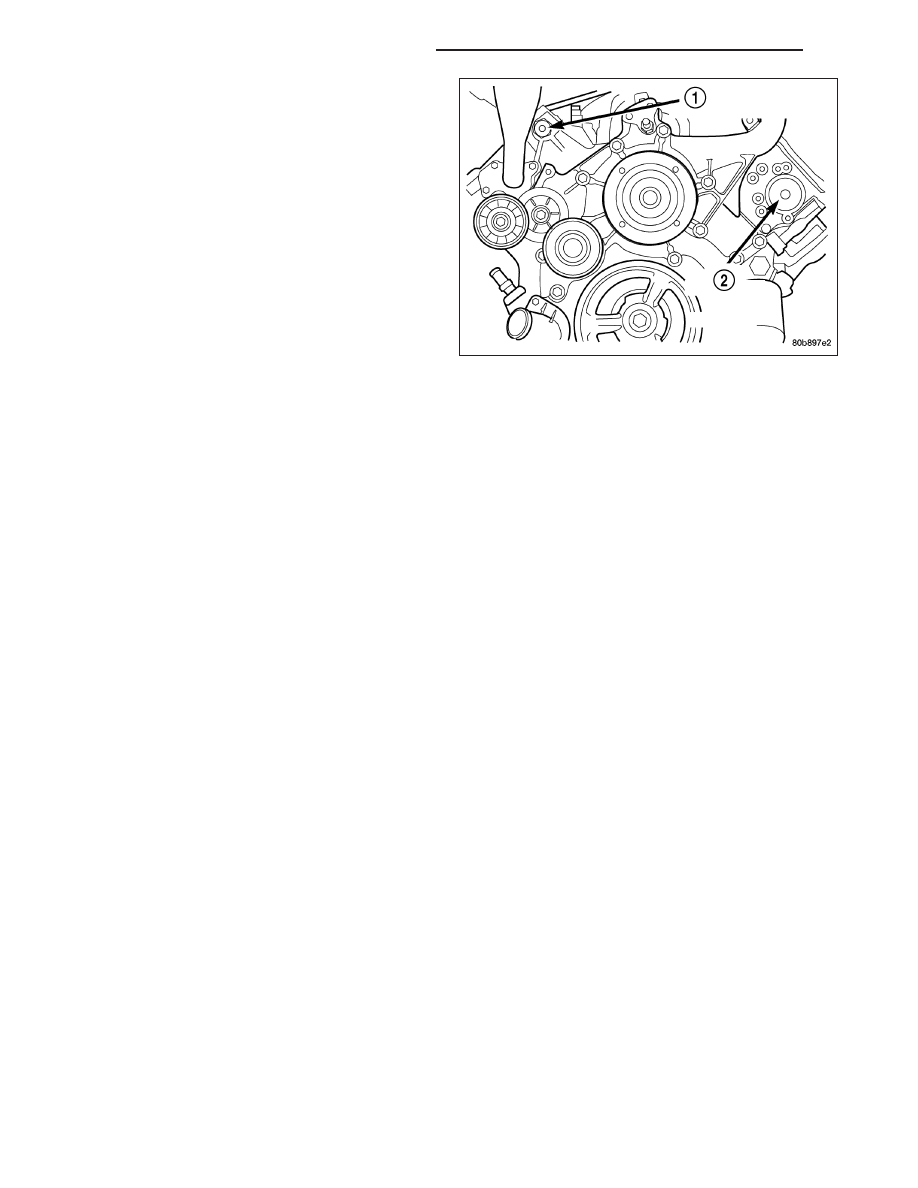

19. Remove the cylinder head access plug (1) and (

2).

20. Remove the left side secondary chain guide

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

21. Remove the retaining bolt and the camshaft drive gear.

CAUTION: Do not allow the engine to rotate. Severe damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at the front of the cylinder head. Do not attempt to remove

the cylinder head without removing these four bolts.

NOTE: The cylinder head is attached to the cylinder block with twelve bolts.

22. Remove the cylinder head retaining bolts.

23. Remove the cylinder head and gasket. Discard the gasket.

CAUTION: Do not lay the cylinder head on its gasket sealing surface, due to the design of the cylinder head

gasket any distortion to the cylinder head sealing surface may prevent the gasket from properly sealing

resulting in leaks.

CYLINDER HEAD - RIGHT

1. Disconnect battery negative cable.

2. Raise the vehicle on a hoist.

3. Disconnect the exhaust pipe at the right side exhaust manifold.

4. Drain the engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE)

5. Lower the vehicle.

6. Remove the intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

7. Remove the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

8. Remove the radiator fan (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

9. Remove oil fill housing from cylinder head.

10. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

11. Rotate the crankshaft until the damper timing mark is aligned with TDC indicator mark.

12. Verify the V6 mark on the camshaft sprocket is at the 12 o’clock position. Rotate the crankshaft one turn if

necessary.

13. Remove the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - REMOVAL).

14. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

REMOVAL).

15. Lock the secondary timing chains to the idler sprocket using Special Tool 8429 Timing Chain Holding Fixture.

NOTE: Mark the secondary timing chain prior to removal to aid in installation.

9 - 802

ENGINE - 3.7L SERVICE INFORMATION

ND

16. Mark the secondary timing chain, one link on each side of the V6 mark on the camshaft drive gear.

17. Remove the right side secondary chain tensioner (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - REMOVAL).

18. Remove the cylinder head access plug.

19. Remove the right side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft sprocket should not be removed for any reason, as the

sprocket and camshaft sensor target wheel is serviced as an assembly. If the nut was removed retorque nut

to 5 N·m (44 in. lbs.).

20. Remove the retaining bolt and the camshaft drive gear.

CAUTION: Do not allow the engine to rotate. severe damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at the front of the cylinder head. Do not attempt to remove

the cylinder head without removing these four bolts.

CAUTION: Do not hold or pry on the camshaft target wheel for any reason. A damaged target wheel can

result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder block with twelve bolts.

21. Remove the cylinder head retaining bolts.

22. Remove the cylinder head and gasket. Discard the gasket.

CAUTION: Do not lay the cylinder head on its gasket sealing surface, do to the design of the cylinder head

gasket any distortion to the cylinder head sealing surface may prevent the gasket from properly sealing

resulting in leaks.

INSPECTION

1. Inspect the cylinder head for out-of-flatness, using a straightedge and a feeler gauge. If tolerances exceed

0.0508 mm (0.002 in.) replace the cylinder head.

2. Inspect the valve seats for damage. Service the valve seats as necessary.

3. Inspect the valve guides for wear, cracks or looseness. If either condition exist, replace the cylinder head.

INSTALLATION

CYLINDER HEAD - LEFT

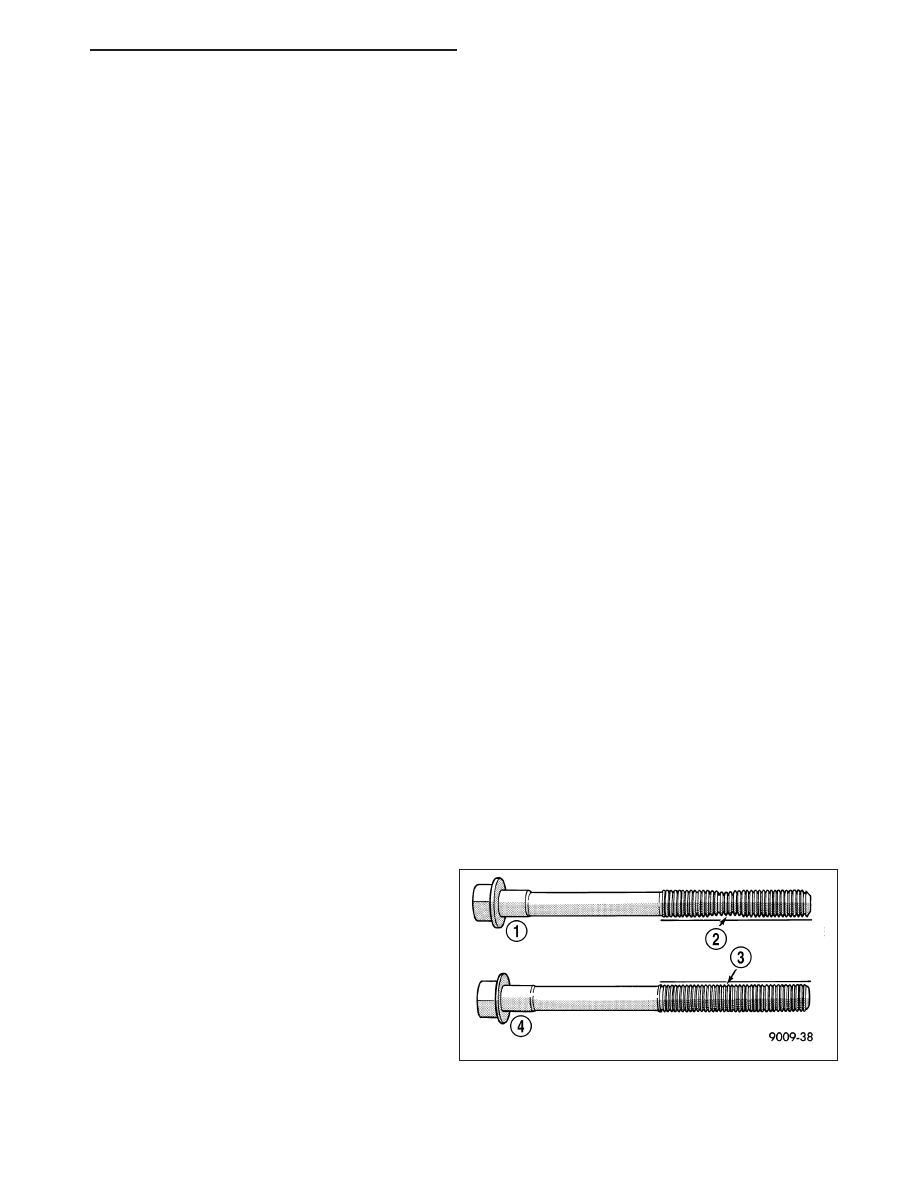

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined

BEFORE

reuse.

If

the

threads

are

necked down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads (2). If all the threads do not con-

tact the scale, the bolt should be replaced.

ND

ENGINE - 3.7L SERVICE INFORMATION

9 - 803

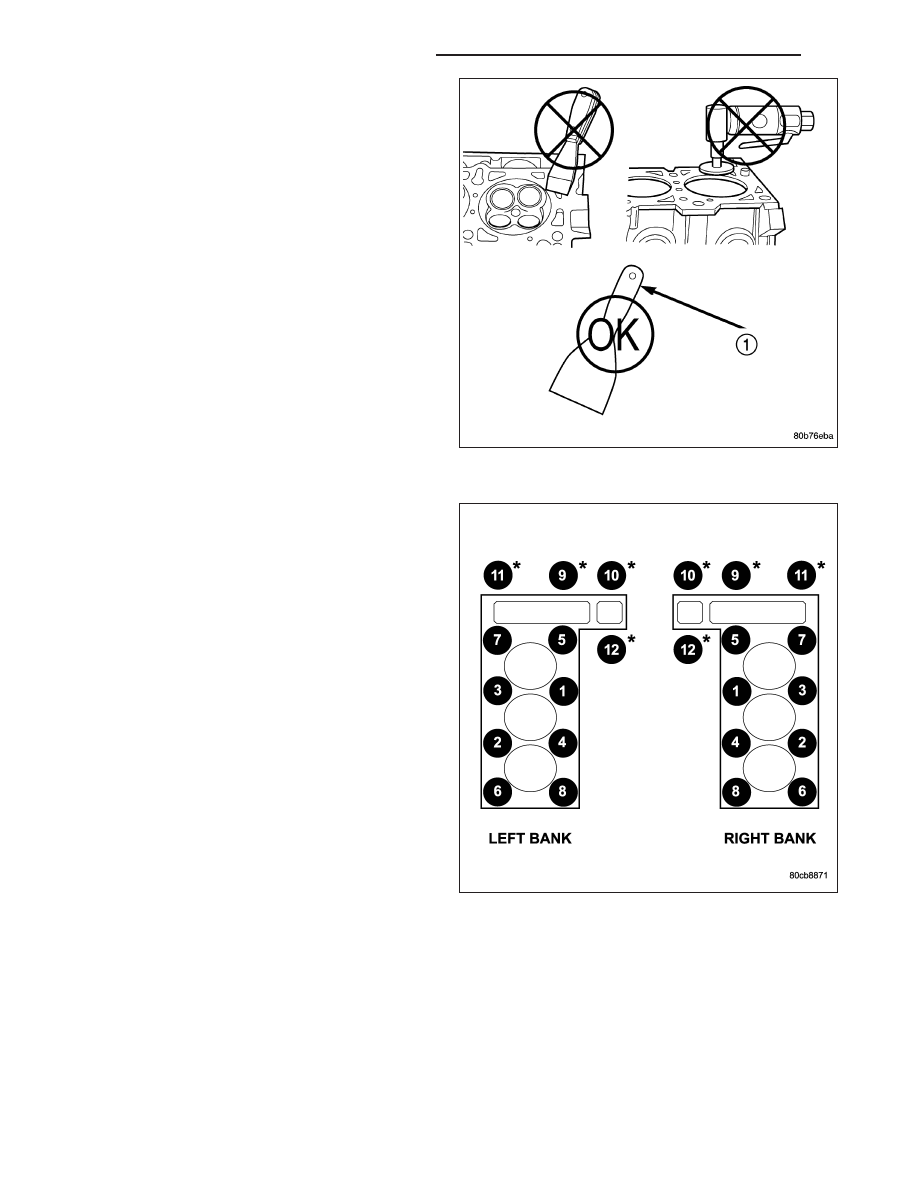

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper (1).

1. Clean the cylinder head and cylinder block mating

surfaces.

2. Position the new cylinder head gasket on the locat-

ing dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

3. Position the cylinder head onto the cylinder block.

Make sure the cylinder head seats fully over the

locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks. The

locations are identified wit *.

4. Lubricate the cylinder head bolt threads with clean

engine oil and install the eight M11 bolts.

5. Coat the four M8 cylinder head bolts with Mopar

T

Lock and Seal Adhesive then install the bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

6. Tighten the bolts in sequence using the following steps and torque values:

•

Step 1: Tighten bolts 1-8, 27 N·m (20 ft. lbs.).

•

Step 2: Verify that bolts 1-8, all reached 27 N·m (20 ft. lbs.), by repeating step 1 without loosening the bolts.

Tighten bolts 9 thru 12 to 14 N·m (10 ft. lbs.).

•

Step 3: Tighten bolts 1-8, 90 degrees.

•

Step 4: Tighten bolts 1-8, 90 degrees, again. Tighten bolts 9-12, 26 N·m (19 ft. lbs.)

7. Position the secondary chain onto the camshaft drive gear, making sure one marked chain link is on either side

of the V6 mark on the gear then using Special Tool 8428 Camshaft Wrench, position the gear onto the camshaft.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torqueing of bolt resulting in bolt failure.

9 - 804

ENGINE - 3.7L SERVICE INFORMATION

ND

8. Install the camshaft drive gear retaining bolt.

9. Install the left side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

10. Install the cylinder head access plug.

11. Re-set and install the left side secondary chain tensioner (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION)

12. Remove Special Tool 8429.

13. Install the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

INSTALLATION)

14. Install the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTALLATION).

Tighten damper bolt 175 N·m (130 Ft. Lbs.).

15. Install the power steering pump.

16. Install the fan blade assembly and fan shroud (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

17. Install the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTAL-

LATION).

18. Install the master cylinder and booster assembly (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - INSTALLATION).

19. Install the intake manifold (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

20. Refill the cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

21. Raise the vehicle.

22. Install the exhaust pipe onto the left exhaust manifold (Refer to 11 - EXHAUST SYSTEM/EXHAUST PIPE -

INSTALLATION).

23. Lower the vehicle.

24. Connect the negative cable to the battery.

25. Start the engine and check for leaks.

CYLINDER HEAD - RIGHT

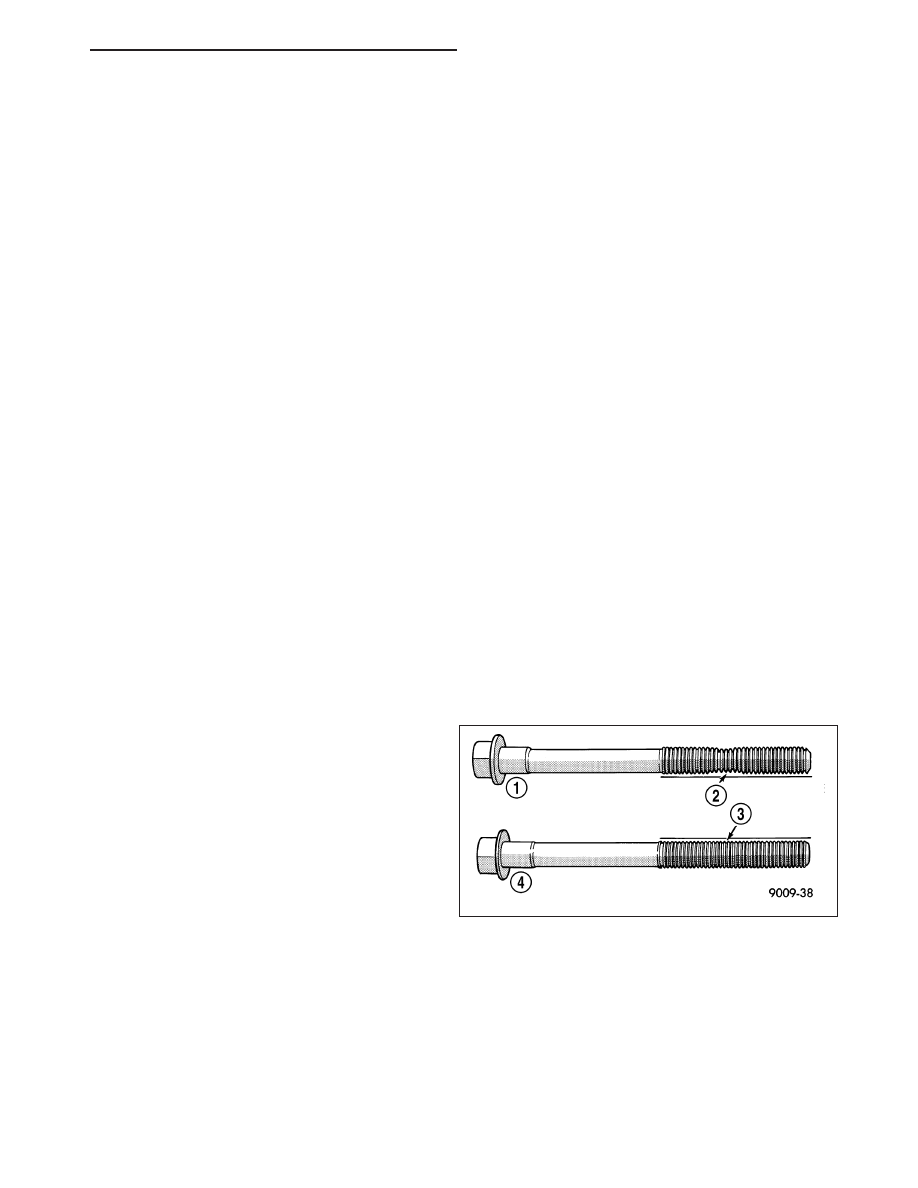

NOTE: The cylinder head bolts (4) are tightened

using a torque plus angle procedure. The bolts

must be examined BEFORE reuse. If the threads

are necked down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads (2). If all the threads do not con-

tact the scale, the bolt should be replaced.

ND

ENGINE - 3.7L SERVICE INFORMATION

9 - 805

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст