Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 577

BALANCE SHAFTS CARRIER ASSEMBLY

REMOVAL

The following components will remain intact dur-

ing carrier removal. Gear cover, gears, balance shafts

and the rear cover.

(1) Remove chain cover and driven balance shaft

chain sprocket screw.

(2) Loosen tensioner pivot and adjusting screws,

move driven balance shaft inboard through driven

chain sprocket. Sprocket will hang in lower chain

loop.

(3) Remove carrier to crankcase attaching bolts to

remove carrier.

INSTALLATION

Balance shaft and carrier assembly installation is

the reverse of the removal procedure. During instal-

lation crankshaft to balance shaft timing must be

established.

TIMING

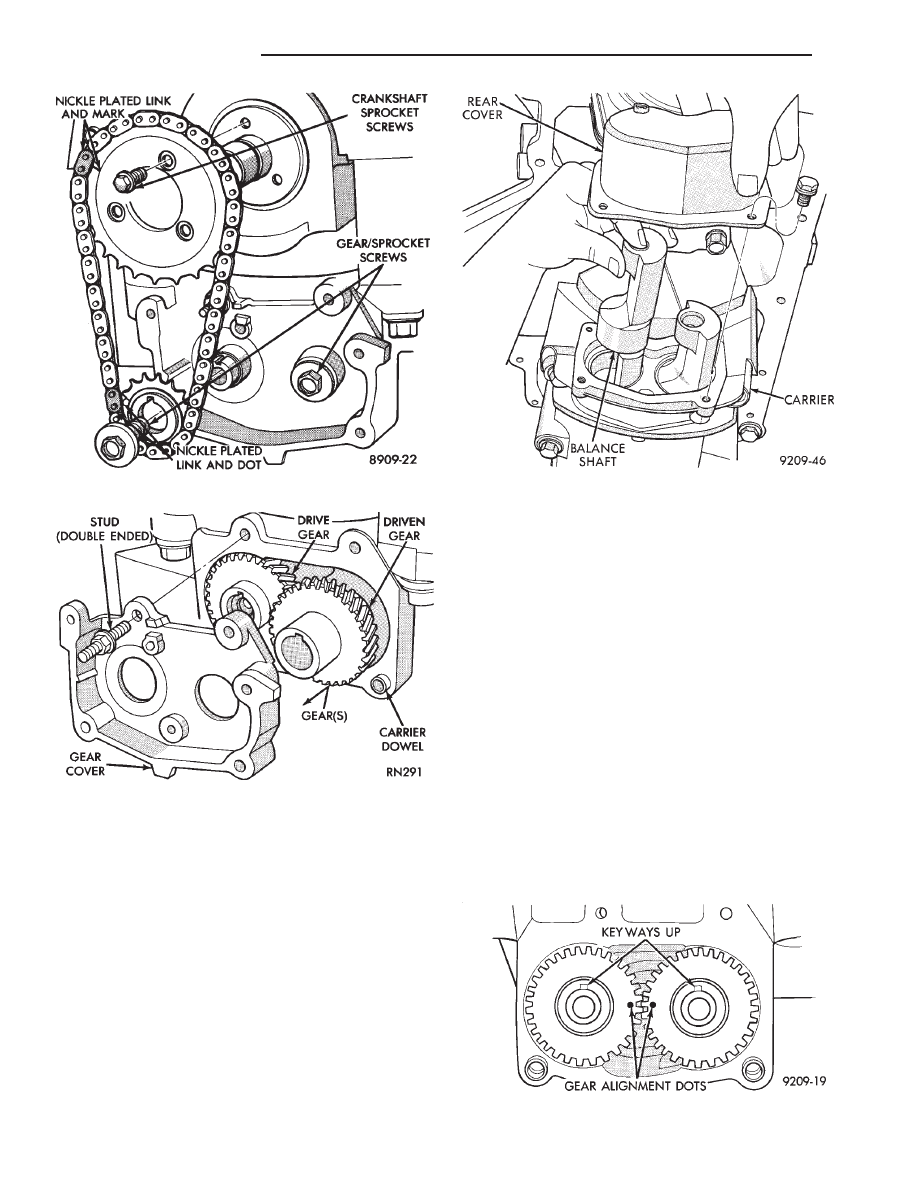

(1) With balance shafts installed in carrier (Fig. 19)

position carrier on crankcase and install six attaching

bolts and tighten to 54 N

Im (40 ft. lbs.).

(2) Turn balance shafts until both shaft key ways are

up Parallel to vertical centerline of engine. Install

short hub drive gear on sprocket driven shaft and long

hub gear on gear driven shaft. After installation gear

and balance shaft keyways must be up with gear

timing marks meshed as shown in (Fig. 20).

(3) Install gear cover and tighten double ended

stud/washer fastener to 12 N

Im (105 in. lbs.).

(4) Install crankshaft sprocket and tighten socket

head torx screws to 13 N

Im (130 in. lbs.).

Fig. 20 Gear Timing

Fig. 17 Drive Chain and Sprockets

Fig. 18 Gear Cover and Gears

Fig. 19 Balance Shaft(s) Remove/Install

9 - 46

2.2/2.5L ENGINE

Ä

(5) Turn crankshaft until number one cylinder is

at Top Dead Center (TDC). The timing marks on the

chain sprocket should line up with the parting line

on the left side of number one main bearing cap.

(Fig. 21).

(6) Place chain over crankshaft sprocket so that

the nickel plated link of the chain is over the timing

mark on the crankshaft sprocket (Fig. 21).

(7) Place balance shaft sprocket into the timing

chain (Fig. 17) so that the timing mark on the

sprocket (yellow dot) mates with the (lower) nickel

plated link on the chain

(8) With balance shaft keyways pointing up 12

o’clock) slide the balance shaft sprocket onto the nose

of the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

THE TIMING MARK ON THE SPROCKET,

THE (LOWER) NICKEL PLATED LINK, AND

THE ARROW ON THE SIDE OF THE GEAR

COVER SHOULD LINE UP WHEN THE BAL-

ANCE SHAFTS ARE TIMED CORRECTLY.

(9) If the sprockets are timed correctly install the

balance shaft bolts and tighten to 28 N

Im (250 in.

lbs.). A wood block placed between crankcase and

crankshaft counterbalance will prevent crankshaft

and gear rotation.

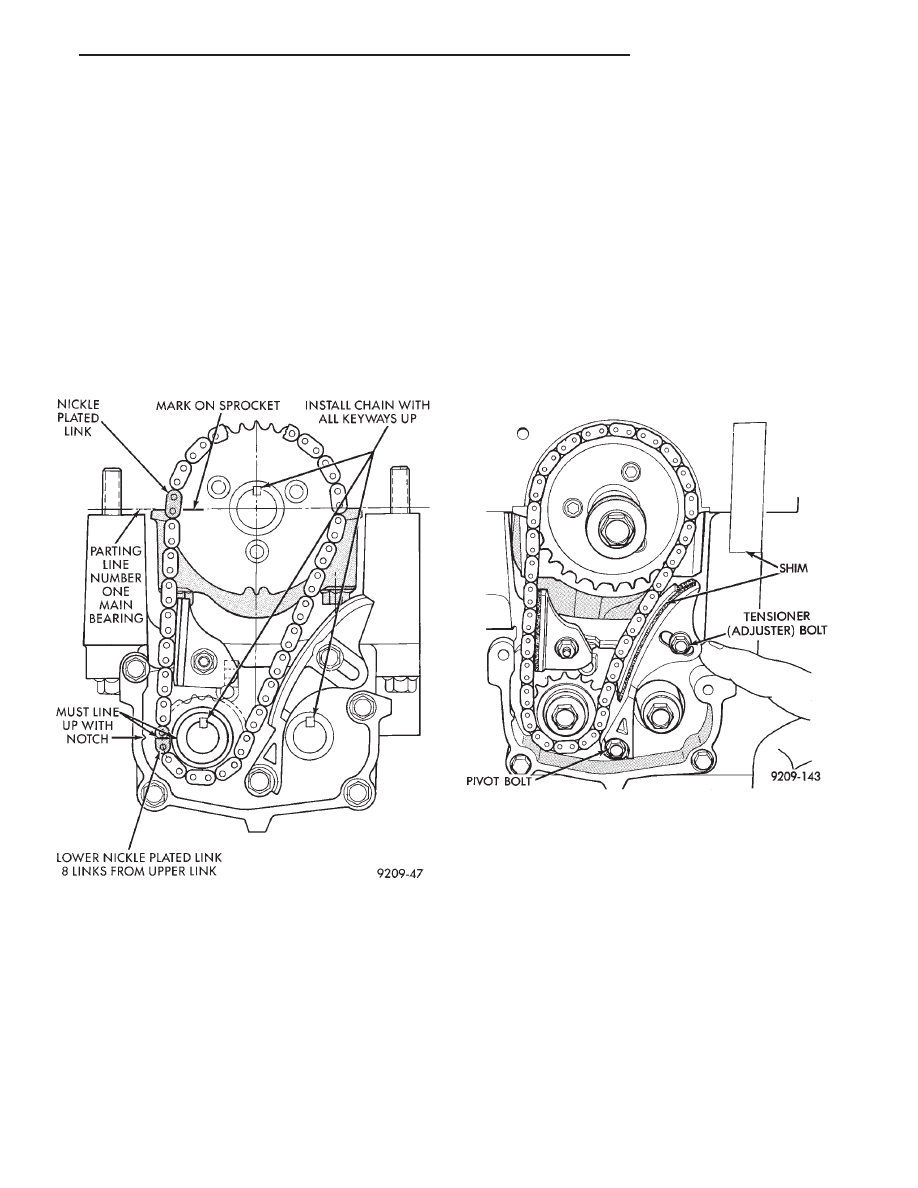

CHAIN TENSIONING

(1) Install chain tensioner loosely assembled.

(2) Position guide on double ended stud making sure

tab on the guide fits into slot on the gear cover. Install

and tighten nut/washer assembly to 12 N

Im (105 in.

lbs.).

(3) Place a shim 1mm (.039 inch) thick x 70mm (2.75

inch) long or between tensioner and chain. Push ten-

sioner and shim up against the chain. Apply firm

pressure (5.5 to 6.6 lbs.) directly behind the ad-

justment slot to take up all slack (chain must have

shoe radius contact as shown in Fig. 22).

(4) With the load applied, tighten top tensioner bolt

first, then bottom pivot bolt. Tighten bolts to 12 N

Im

(105 in. lbs.), Remove shim.

(5) Install carrier covers and tighten screws to 12

N

Im (105 in. lbs.).

INTERMEDIATE SHAFT SERVICE

REMOVAL

CAUTION: The oil pump and distributor must be

removed before attempting to remove intermediate

shaft.

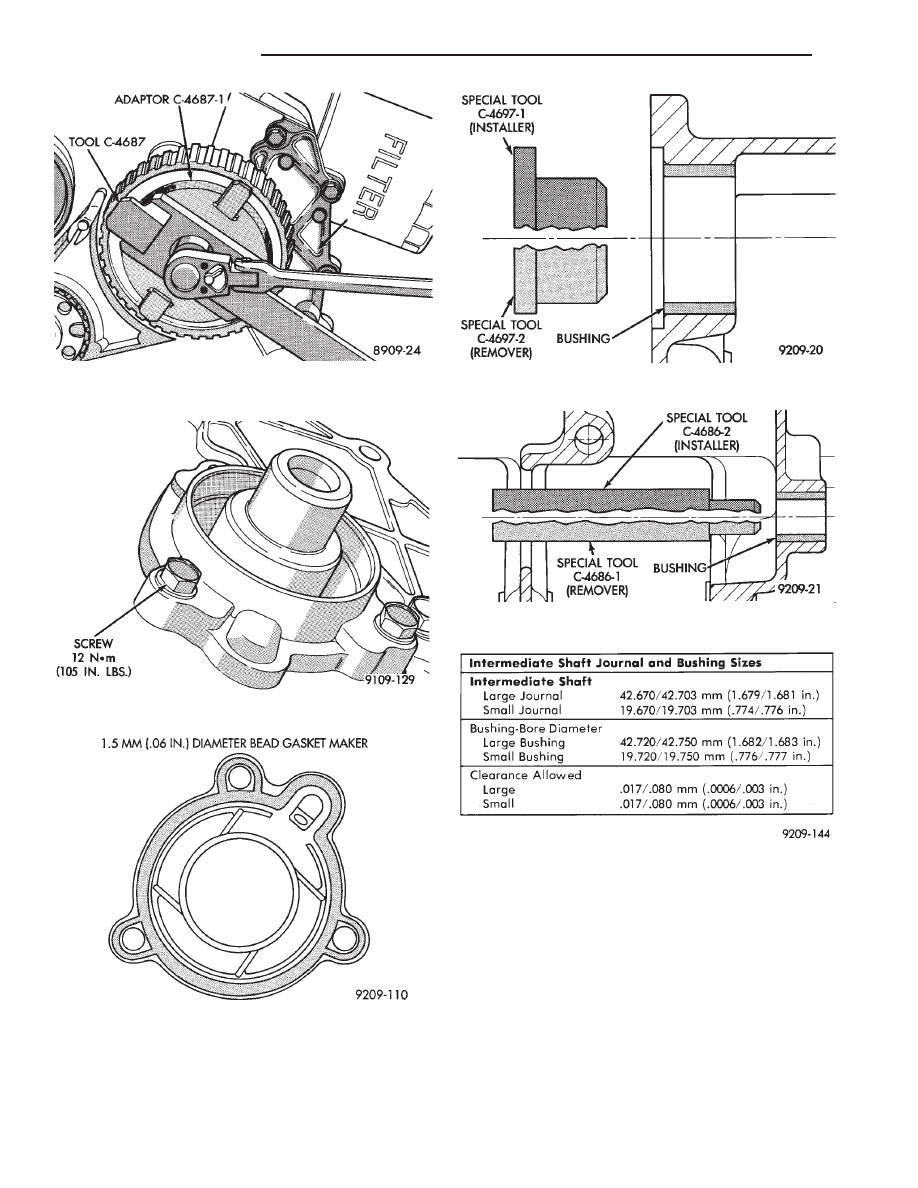

(1) Hold sprocket with Tool C-4687 and adaptor Tool

C-4687-1 when removing or installing screw (Fig. 23).

(2) See Timing System and Seals for intermediate

seal removal and replacement.

(3) Remove retainer screws (Fig. 24).

(4) Remove retainer and lay aside.

(5) Remove intermediate shaft.

Fig. 21 Balance Shaft Timing

Fig. 22 Chain Tension Adjustment

Ä

2.2/2.5L ENGINE

9 - 47

INSTALLATION

(1) Lubricate distributor drive gear when installing.

(2) Apply Mopar Gasket Maker as shown in (Fig.

25) and install intermediate shaft retainer.

(3) Install retaining screws and torque to 12 N

Im

(105 in. lbs.).

INTERMEDIATE SHAFT BUSHING SERVICE

(1) Remove

front

bushing

using

Special

Tool

C-4697-2 with Special Tool Handle C-4171 (Fig. 26).

(2) Install

front

bushing

using

Special

Tool

C-4697-1 and Special Tool Handle C-4171 until tool

is flush with block.

(3) Remove

rear

bushing

using

Special

Tool

C-4686-2 and Special Tool Handle C-4171 (Fig. 27).

(4) Install

rear

bushing

using

Special

Tool

C-4686-1 and Special Tool Handle C-4171 until tool

is flush with block.

Fig. 23 Removing/Installing Intermediate Shaft

Sprocket

Fig. 24 Intermediate Shaft Retainer

Fig. 25 Intermediate Shaft Retainer Sealing

Fig. 26 Intermediate Shaft Bushing, Front

Fig. 27 Intermediate Shaft Bushing—Rear

Fig. 28 Intermediate Shaft Journal Specifications

9 - 48

2.2/2.5L ENGINE

Ä

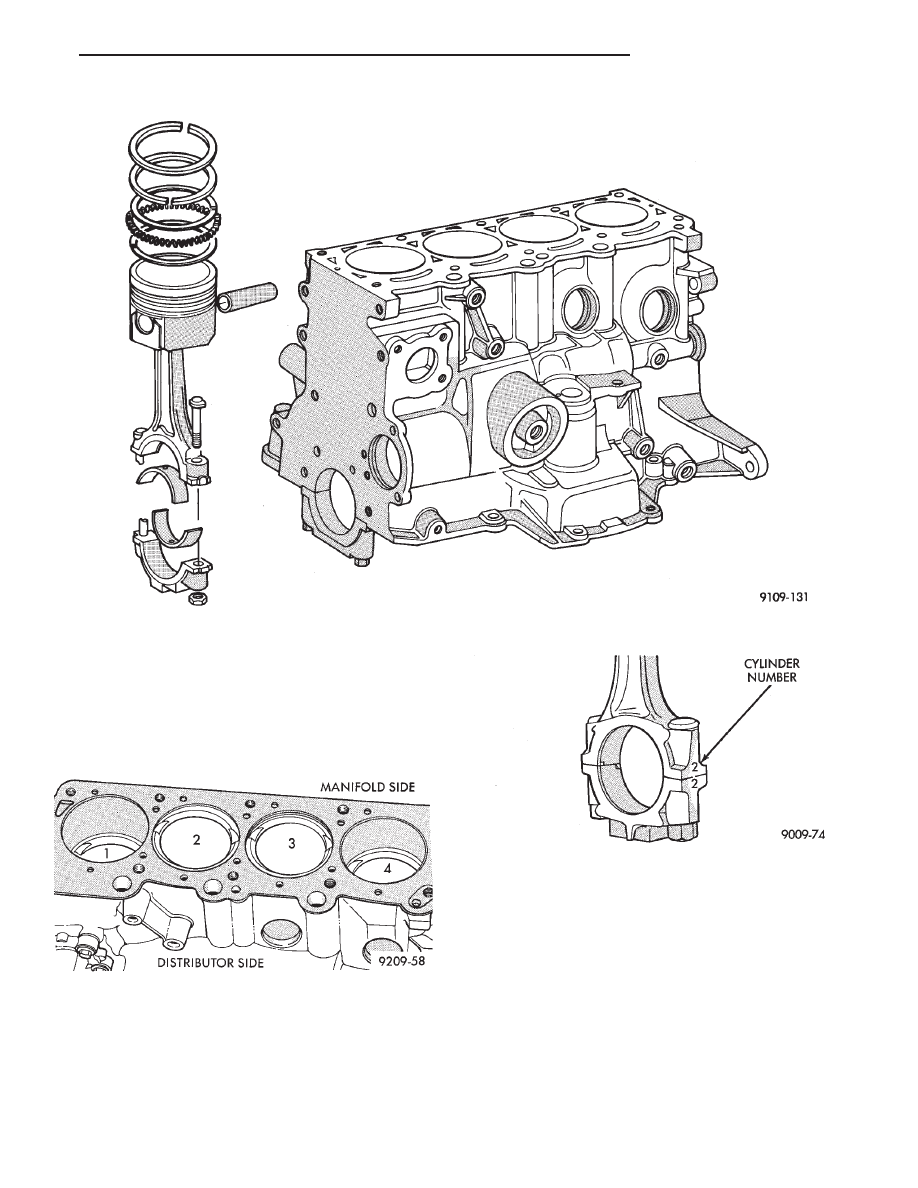

CYLINDER BLOCK, PISTON AND CONNECTING ROD ASSEMBLY SERVICE

PISTON AND CONNECTING ROD—REMOVAL

(1) Remove top ridge of cylinder bores with a reliable

ridge reamer before removing pistons from cylinder

block.Be sure to keep tops of pistons covered

during this operation. Mark piston with matching

cylinder number (Fig. 2).

(2) Remove oil pan. Ensure connecting rods and

connecting rod caps for cylinder identification. Identify

them if necessary (Fig. 3).

(3) Valve relief toward manifold side of engine. Tur-

bocharged engine pistons will have arrow towards

front of engine.

(4) Squirt hole on connecting rod must face timing

belt end of engine.

(5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(6) Remove connecting rod cap. Install connecting

rod bolt protectors on connecting rod bolts (Fig. 4).

Push each piston and rod assembly out of cylinder

bore.

Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

Fig. 1 Cylinder Block, Piston and Connecting Rod Assembly

Fig. 3 Identify Connecting Rod to Cylinder

Fig. 2 Piston Marking

Ä

2.2/2.5L ENGINE

9 - 49

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст