Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 189

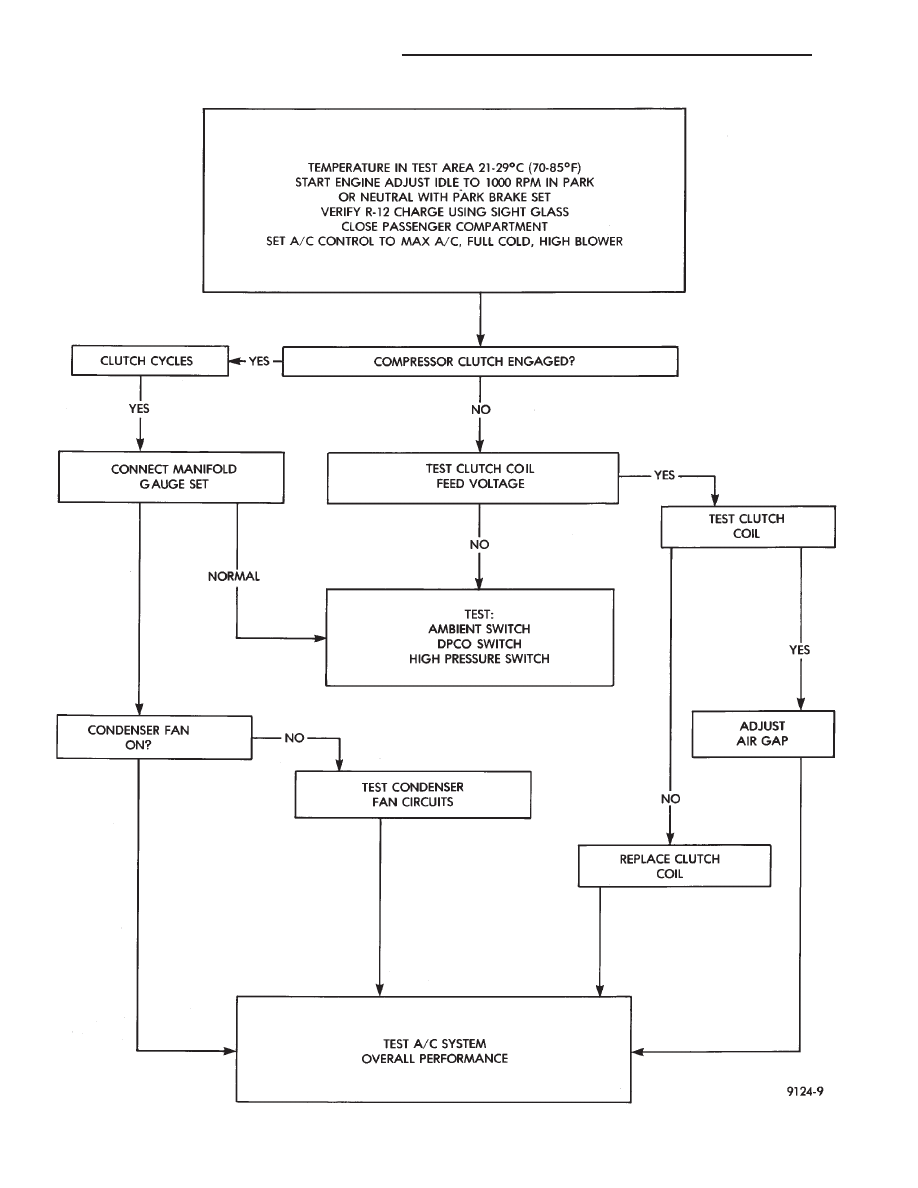

COMPRESSOR CLUTCH DIAGNOSIS—VARIABLE DISPLACEMENT COMPRESSOR—MODEL 6C17

24 - 18

HEATING AND AIR CONDITIONING

Ä

COMPRESSOR CLUTCH/COIL ASSEMBLY

Compressor

assembly

must

be

removed

from

mounting. Refrigerant removal is not necessary to

replace the clutch/coil assembly. Refer to Compressor

Removal and Installation.

On 3.0 liter engine, remove the front lower splash

shield and front engine mount through-bolt. Allow

the engine to swing down to provide access to the

front of the compressor.

On 3.3 liter engine, remove the coolant recovery

bottle to provide access the front of the compressor.

REMOVAL AND INSTALLATION

(1) Remove clutch retaining center nut by using

Clutch Plate Holder (6355) (Fig. 4).

(2) Using a Clutch Plate Remover (6354), remove

the clutch front plate from the compressor (Fig. 5).

When installing the front plate, select the proper

shims to achieve .5 to .9 mm (.020 to .035 inch) air

gap to the pulley surface (Fig. 6). To install front

plate, align shaft key to groove in front plate hub.

Push on until it seats, and measure the air gap (Fig.

7).

(3) Remove clutch pulley retaining snap ring (Fig.

7) and pull the pulley from the assembly (Fig. 8).

(4) Remove the clutch coil wire lead strap screw.

(5) Remove clutch coil retaining snap ring (Fig. 10)

and pull the coil from the assembly (Fig. 11). When

installing the clutch coil, align the pin on the front of

Fig. 4 Remove or Install Front Plate Retaining Nut

Fig. 5 Remove Front Plate

Fig. 6 Install Front Plate and Shims

Fig. 7 Measure Front Plate Air Gap

Fig. 8 Remove or Install Pulley Snap Ring

Ä

HEATING AND AIR CONDITIONING

24 - 19

the compressor to the middle hole in the hub of the

coil. Position the pin in the snap ring gap.

To install, reverse the preceding operation.

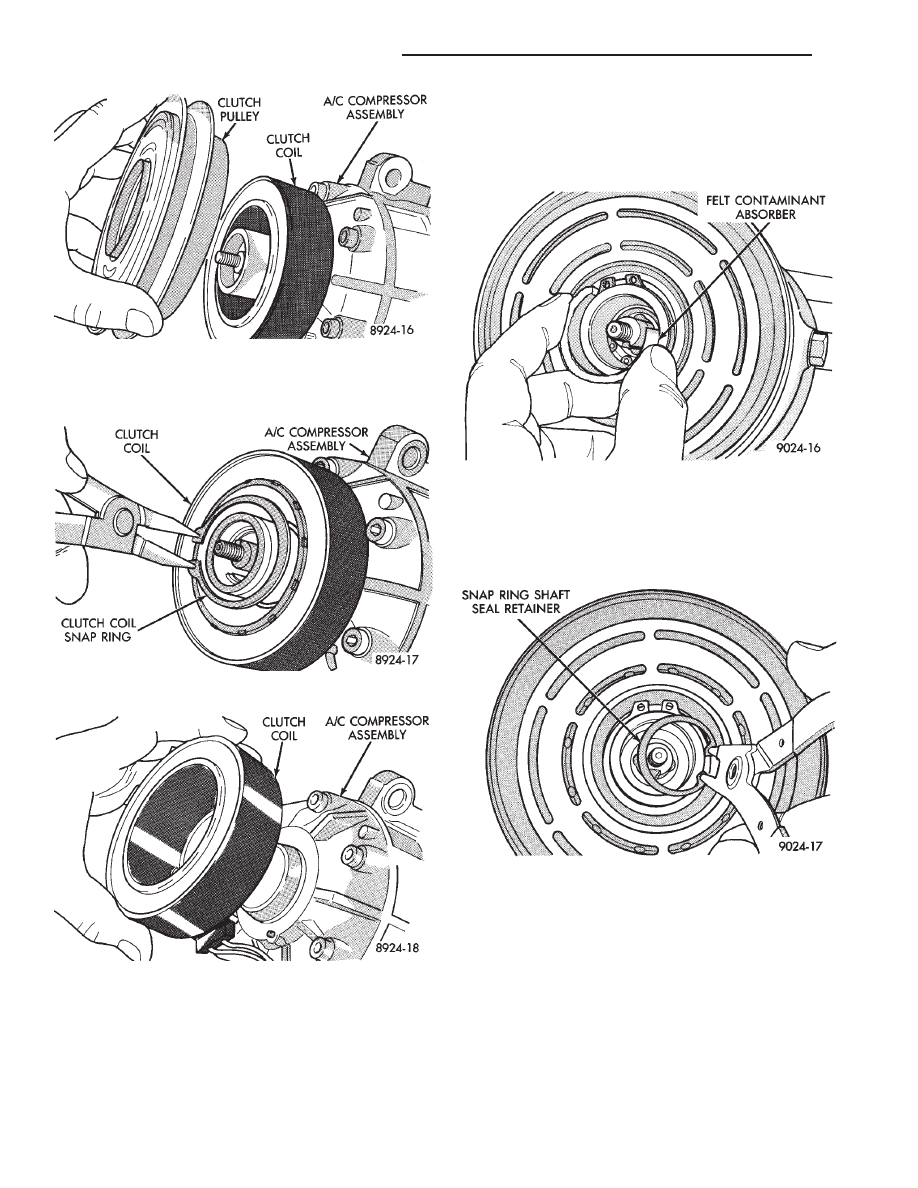

COMPRESSOR FRONT SHAFT SEAL

REMOVAL

(1) Using a refrigerant recovery machine, remove

the refrigerant from the A/C system.

(2) Remove A/C compressor.

(3) Remove the compressor clutch assembly and

shaft key.

(4) Remove the felt contaminant absorber and re-

tainer (Fig. 1).

(5) Using a mineral spirits based solvent, thor-

oughly clean and dry the seal end of the compressor.

(6) Remove the snap ring shaft seal retainer (Fig.

2). Do not use the old snap ring to assemble.

(7) Using Seal Remover/Installer (6429), remove

the shaft seal (Fig. 3).

INSTALLATION

(1) Lubricate the new shaft seal with refrigerant

oil.

(2) Place Seal Protector (6231) over the end of com-

pressor shaft (Fig. 4). Use the larger flat end of the

remover/installer to push the seal in until it seats.

The snap ring groove should be visible above the seal

(Fig. 5).

(3) Install clutch/coil assembly.

(4) Install compressor.

Fig. 9 Remove or Install Pulley

Fig. 10 Remove or Install Clutch Coil Snap Ring

Fig. 11 Remove or Install Clutch Coil

Fig. 1 Felt Contaminant Absorber

Fig. 2 Shaft Seal Snap Ring

24 - 20

HEATING AND AIR CONDITIONING

Ä

(5) Evacuate and charge the refrigerant system. If

oil loss of 3 ml (1 oz) or greater is suspected, refer to

Oil Level in the Refrigerant Service Procedures sec-

tion.

COMPRESSOR HIGH PRESSURE CUT-OUT SWITCH

The High Pressure Cut Out (HPCO) switch is lo-

cated on the rear cover of the Variable Displacement

Compressor (Fig. 6). The function of the switch is to

disengage the compressor clutch by monitoring the

compressor discharge (high) pressure. The HPCO

Switch is in the same circuit as the Differential Pres-

sure Cut Out (DPCO) switch and Ambient Switch.

DIAGNOSIS

Review Safety Precautions and Warnings before

proceeding with this operation.

Connect a suitable manifold gauge set to the refrig-

erant system service ports. Work area temperature

can not be below 21°C (70°F).

(1) Raise hood of vehicle.

(2) With gear selector in park or neutral, and park

brake set, start engine and allow to idle at 1300 rpm.

(3) Set the A/C controls to A/C and High blower.

(6) If the high pressure gauge reads below 2963

kPa (430 psi)

6138 kPa (20 psi) the compressor

clutch should be engaged.

CAUTION: Do not allow engine to overheat when ra-

diator air flow is blocked.

(7) Block radiator air flow with a suitable cover to

increase the high side pressure to at least 3100 kPa

(450 psi). Compressor clutch should disengage.

(8) Remove cover from front of vehicle to allow

high side pressure to decrease. When pressure drops

below 1826 kPa (265 psi), compressor clutch should

engage.

REMOVAL AND INSTALLATION

(1) Using a refrigerant recovery machine, remove

the refrigerant from the A/C system.

Fig. 3 Remove Shaft Seal

Fig. 4 Shaft Seal Protector

Fig. 5 Install Shaft Seal

Fig. 6 Variable Displacement Compressor—Model

6C17

Ä

HEATING AND AIR CONDITIONING

24 - 21

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст