Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 583

(c) Remove LEFT insulator through bolt from in-

side wheelhouse or insulator bracket to transmis-

sion screws.

(22) Remove engine.

INSTALLATION

(1) Attach hoist and lower engine into engine com-

partment.

(2) Align engine mounts and install but do not

tighten until all mounting bolts have been installed.

Tighten bolts to torque specified in (Fig. 2).

(3) Install transmission case to cylinder block,

tighten bolts to 102 N

Im (75 ft. lbs.) torque.

(4) Remove engine hoist and transmission holding

fixture.

(5) Remove C clamp from torque converter hous-

ing. Align flex plate to torque converter and install

mounting screws. Tighten to 75 N

Im (55 ft. lbs.)

(6) Install transmission inspection cover.

(7) Connect exhaust system at manifold.

(8) Install starter.

(9) Install power steering pump and air condition-

ing compressor. For belt installation Refer to Acces-

sory Belt Drive in Cooling System Group 7.

(10) Lower vehicle and connect all vacuum lines.

(11) Connect all electrical connections including

ground strap.

(12) Connect fuel lines and accelerator cable.

(13) Install radiator and fan assembly. Connect fan

motor electrical lead. Install radiator hoses. Fill cool-

ing system. Refer to Cooling System Group 7 for fill-

ing procedure.

(14) Fill engine crankcase with proper oil to cor-

rect level.

(15) Install hood.

(16) Connect battery.

(17) Start engine and run until operating temper-

ature is reached.

(18) Adjust transmission or linkage if necessary.

ACCESSORY DRIVE BELT SERVICE

REMOVAL

(1) Loosen Adjusting Lock Nut (Fig. 6).

(2) Turn adjusting jack screw counterclockwise to

reduce belt tension. Remove belt.

(3) Inspect drive belt for wear and damage (Fig. 5).

(4) Installation: Adjust belt tension to 5/16 deflec-

tion between pulleys (Fig. 6).

(5) Install breaker bar into 1/2 square opening in

tensioner.

(6) Rotate tensioner clockwise to remove and in-

stall belt (Fig. 7).

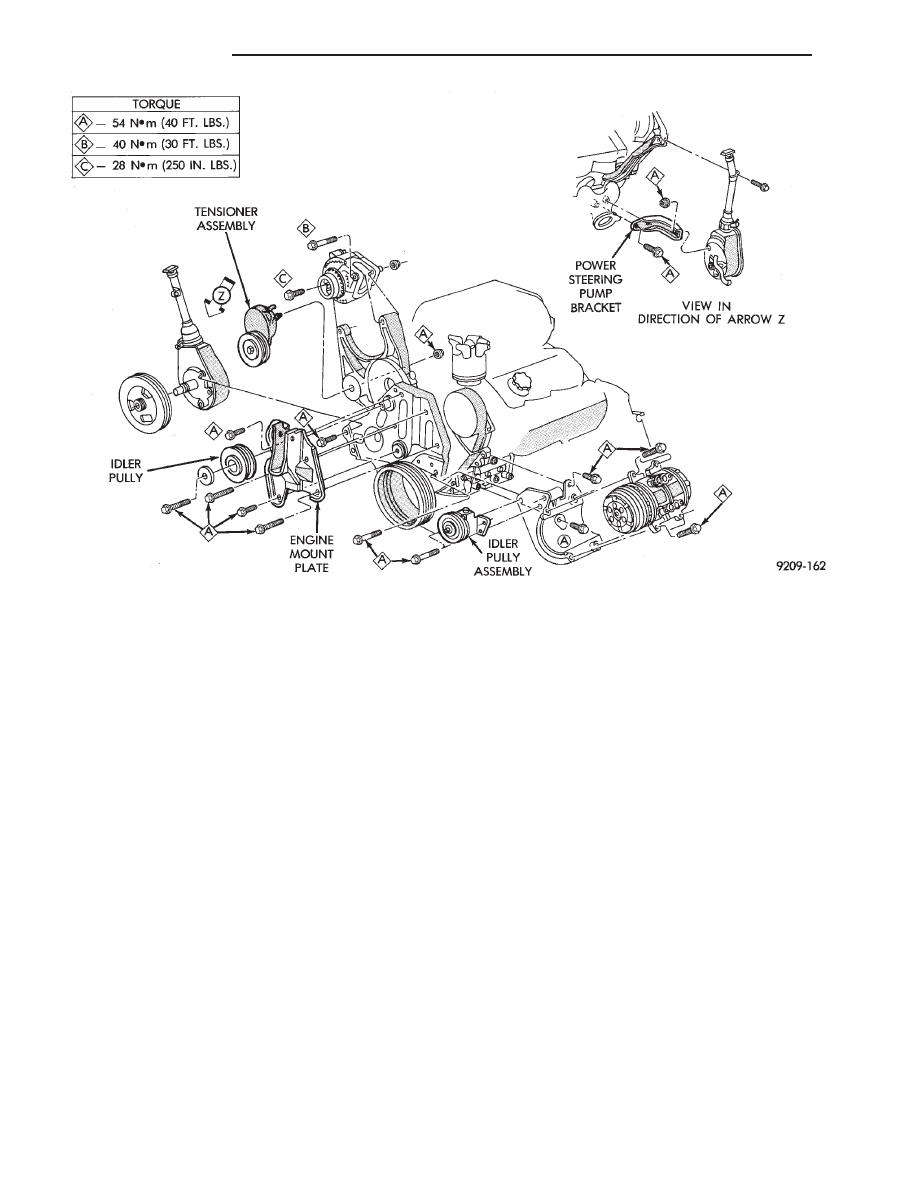

Fig. 4 Accessories Mounting Brackets

9 - 70

3.0L ENGINE

Ä

ENGINE MOUNT BRACKET

REMOVAL

(1) Remove air conditioning compressor to mount-

ing bracket screws and lay compressor aside (Fig. 4).

(2) Remove screws attaching air conditioning com-

pressor mounting bracket and adjustable drive belt

tensioner from block and engine mounting bracket.

Remove both assemblies.

(3) Remove steering pump/generator belt tensioner

mounting bolt and remove automatic belt tensioner.

(4) Remove two steering pump to engine mounting

bracket screws and one rear support lock nut.

(5) Lay power steering pump aside.

(6) Raise vehicle and remove right inner splash

shield (Fig. 8).

(7) Remove crankshaft drive pulleys and torsional

damper (Fig. 9).

(8) Lower vehicle and place a jack under engine.

Fig. 5 Drive Belt Inspection

Fig. 6 Air Conditioning Belt

Fig. 7 Generator/Power Steering Belt

Fig. 8 Right Inner Splash Shield—Typical

Fig. 9 Crankshaft Drive Pulleys

Ä

3.0L ENGINE

9 - 71

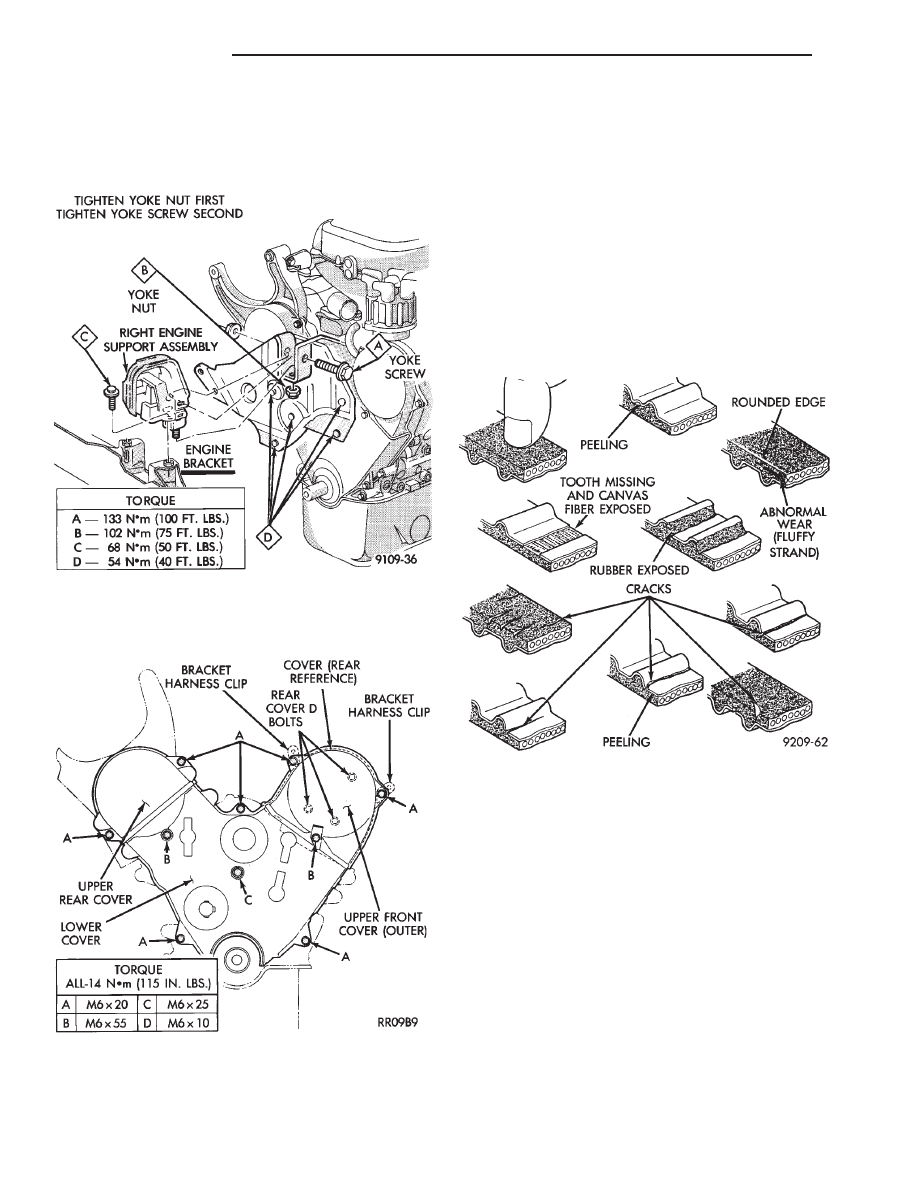

(9) Mark support assembly to engine bracket if as-

sembly is to be used again. Separate engine mount

insulator from engine mount bracket (Fig. 10). Raise

engine slightly.

(10) Remove engine mount bracket (Fig. 10).

(11) Remove timing belt covers (Fig. 11).

TIMING BELT INSPECTION—IN VEHICLE

(1) Remove the upper front outer timing belt cover

by loosening the three attaching bolts. (Fig. 11).

(2) Inspect both sides of the timing belt drive &

back. Replace belt if any of the following conditions

exist.

• Hardening of back rubber back side is glossy with-

out resilience and leaves no indent when pressed

with fingernail.

• Cracks on rubber back.

• Cracks or peeling of canvas.

• Cracks on rib root.

• Cracks on belt sides.

• Missing teeth.

• Abnormal wear of belt sides. The sides are normal

if they are sharp as if cut by a knife (Fig. 12).

(3) If none of the above conditions are seen on the

belt, the belt cover can be reinstalled.

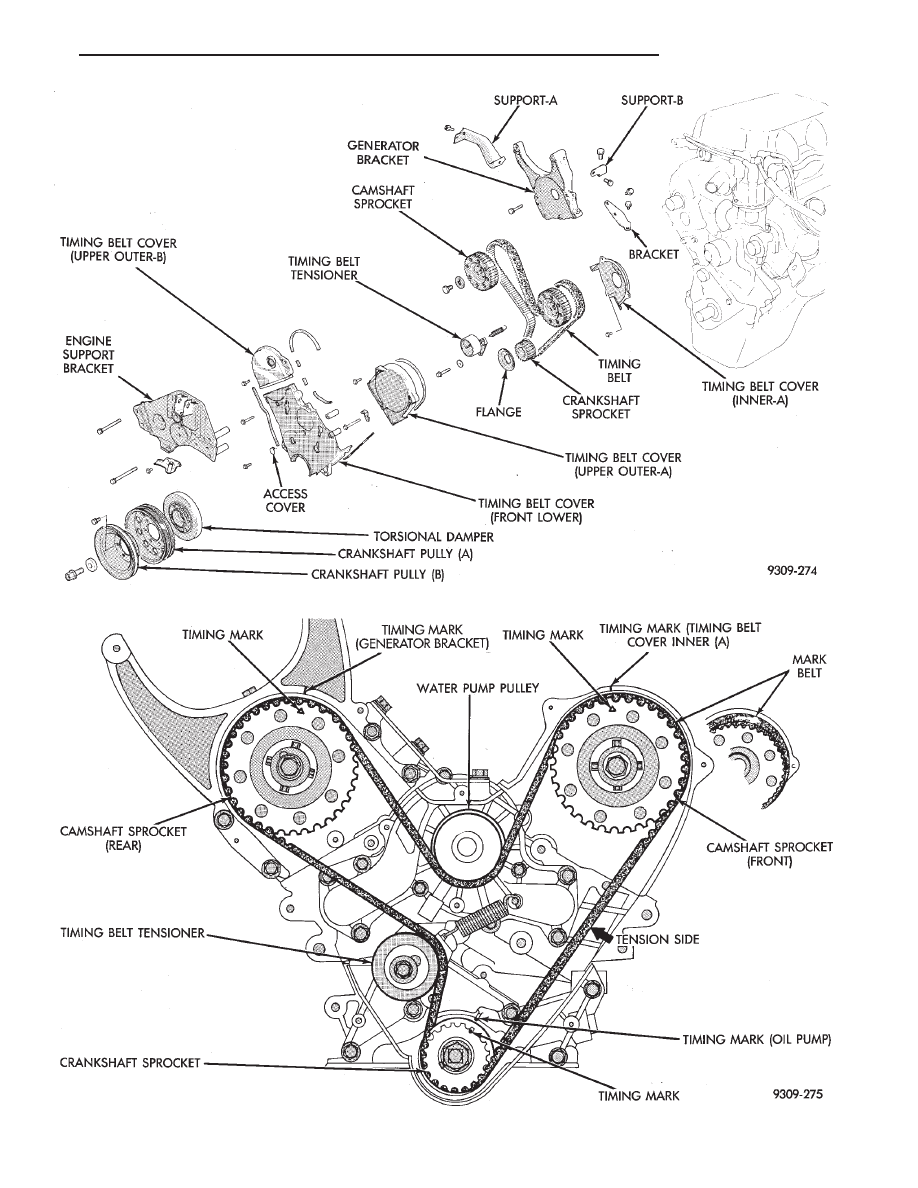

TIMING BELT SERVICE

REMOVAL

(1) Mark belt running direction for installation

(Fig. 14).

(2) Loosen timing belt tensioner bolt (Fig. 16) and

remove timing belt.

(3) Remove crankshaft sprocket flange shield (Fig.

9).

CAMSHAFT SPROCKETS

REMOVAL

(1) Hold camshaft sprocket with Spanner Tool

MB990775 loosen and remove bolt and washer (Fig.

15).

(2) Remove camshaft sprocket from camshaft.

Fig. 10 Right Engine Mount and Engine Mount

Bracket

Fig. 11 Timing Belt Covers

Fig. 12 Timing Belt Inspection

9 - 72

3.0L ENGINE

Ä

Fig. 13 Timing Belt System

Fig. 14 Timing Belt Engine Sprocket Timing

Ä

3.0L ENGINE

9 - 73

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст