Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 108

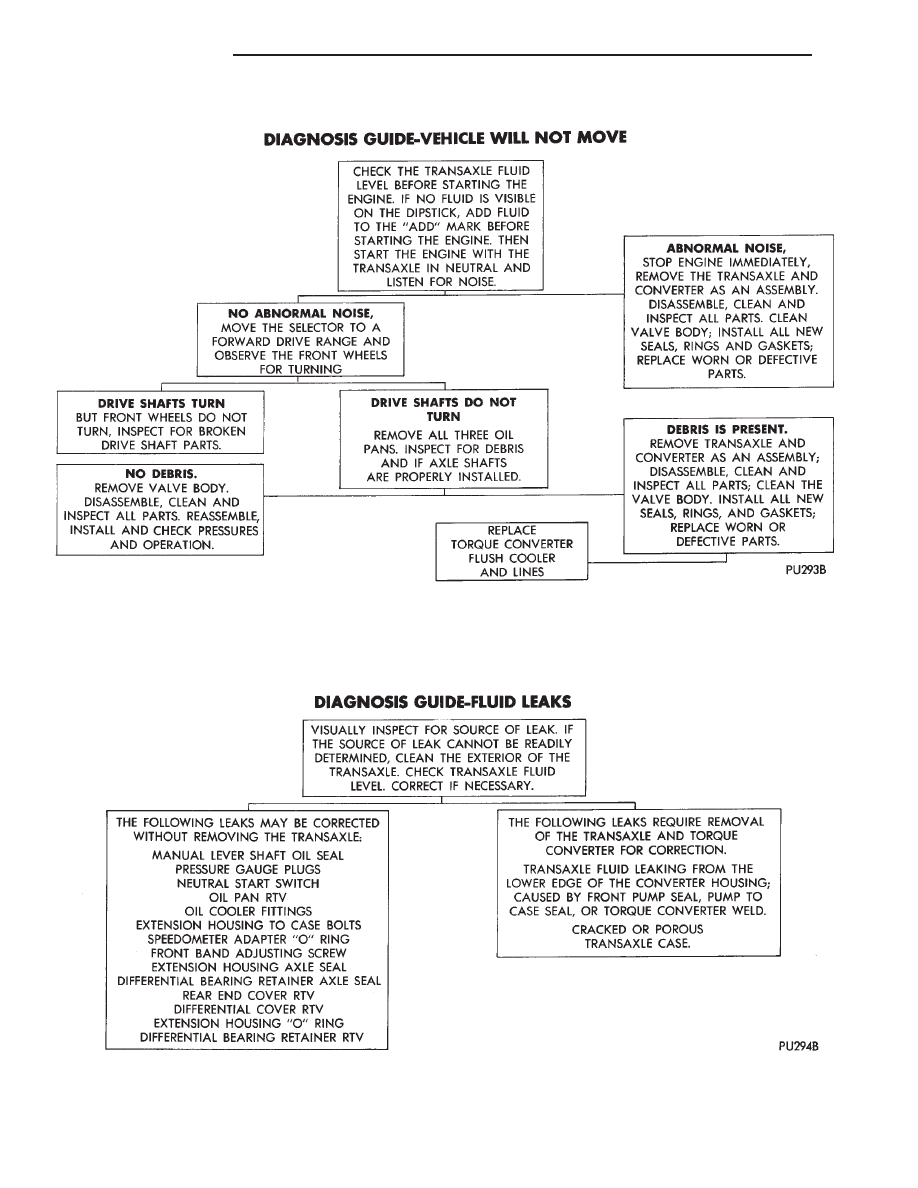

DIAGNOSIS GUIDE—VEHICLE WILL NOT MOVE

DIAGNOSIS GUIDE—FLUID LEAKS

21 - 38

TRANSAXLE

Ä

DIAGNOSTIC

CHAR

T

Ä

TRANSAXLE

21 - 39

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two.

Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle.

The torque converter will fill in both the P Park or N

Neutral positions. Place the selector lever in P Park to

check fluid level.

Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the add mark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOT region.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level.

In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR

t ATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex-

ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR

t ATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth.

If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan.

(3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N

Im (40

in. lbs.).

(4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR

t Adhesive sealant. Tighten oil pan

bolts to 19 N

Im (165 in. lbs.).

(5) Pour four quarts of MOPAR

t ATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position.

(7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark.

Recheck fluid level after transaxle is at normal

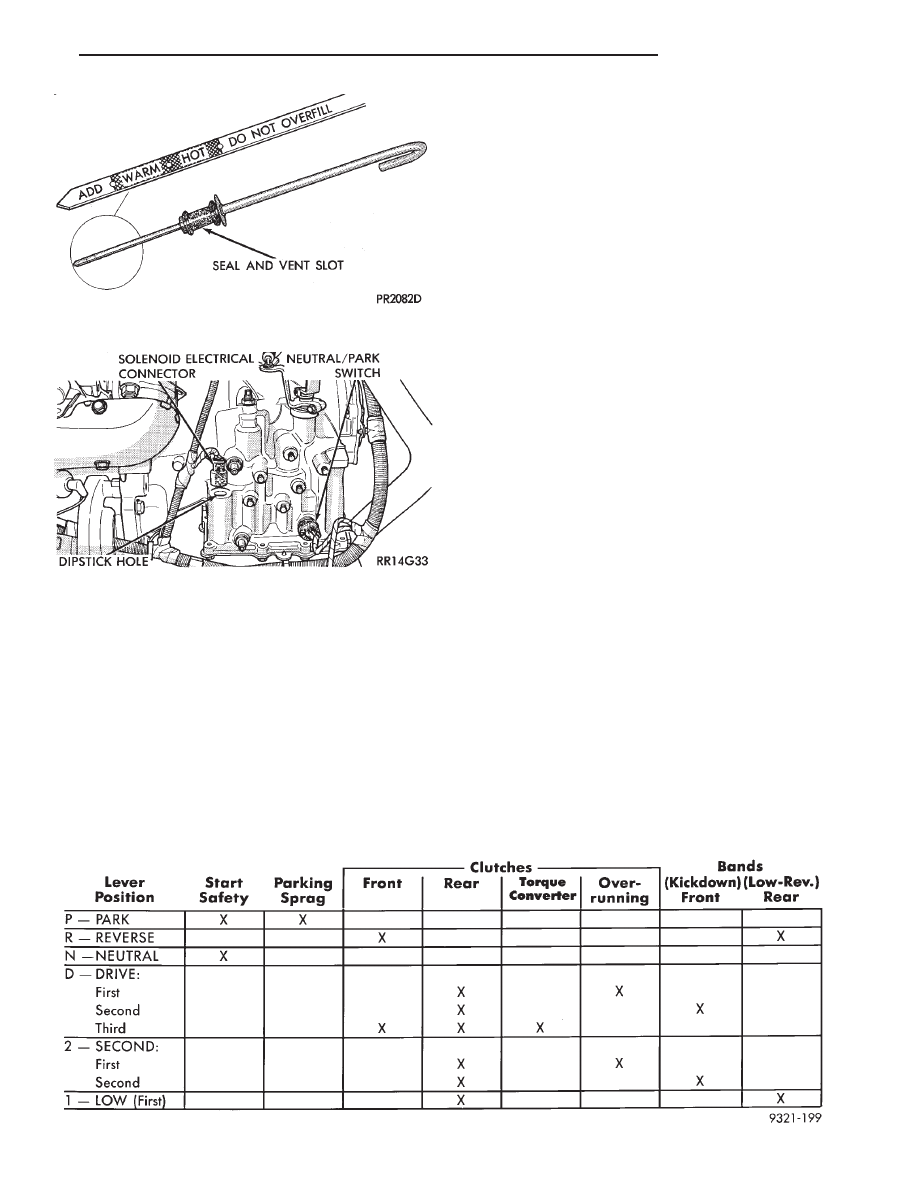

operating temperature. The level should be in the HOT

region (Fig. 1).

To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved.

During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40

TRANSAXLE

Ä

If vehicle operates properly at highway speeds, but

has poor acceleration, the torque converter stator

overrunning clutch may be slipping. If through-gear

acceleration is normal, but high throttle opening is

required to maintain highway speeds, the torque con-

verter stator clutch may have seized. Both of these

stator defects require replacement of the torque con-

verter.

Observe closely for slipping or engine speed flare-

up. Slipping or flare-up in any gear usually indicates

clutch, band, or overrunning clutch problems. If the

condition is far advanced, an overhaul will probably

be necessary to restore normal operation.

The clutch or band that is slipping can be deter-

mined by noting the transaxle operation in all selec-

tor positions. Then comparing which internal units

are applied in those positions. The Elements in Use

Chart provides a basis for road test analysis.

The rear clutch is applied in both the D first gear

and 1 first gear positions. Also the overrunning

clutch is applied in D first gear and the low/reverse

band is applied in 1 first gear position. If the tran-

saxle slips in D range first gear, but does not slip in

1 first gear, the overrunning clutch is slipping. Sim-

ilarly, if the transaxle slips in any two forward

gears, the rear clutch is slipping.

Using the same procedure, the rear clutch and

front clutch are applied in D third gear. If the tran-

saxle slips in third gear, either the front clutch or

the rear clutch is slipping. By selecting another gear

which does not use one of those units, the unit which

is slipping can be determined. If the transaxle also

slips in reverse, the front clutch is slipping. If the

transaxle does not slip in reverse, the rear clutch is

slipping.

The process of elimination can be used to detect

any unit which slips and to confirm proper operation

of good units. Road test analysis can usually diag-

nose slipping units, but the actual cause of the mal-

function usually cannot be decided. Practically any

condition can be caused by leaking hydraulic circuits

or sticking valves.

ELEMENTS IN USE AT EACH POSITION OF THE SELECTOR LEVER

Fig. 1 Dipstick and Transaxle Vent

Fig. 2 Torque Converter Clutch Solenoid Wiring

Connector

Ä

TRANSAXLE

21 - 41

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст