Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 293

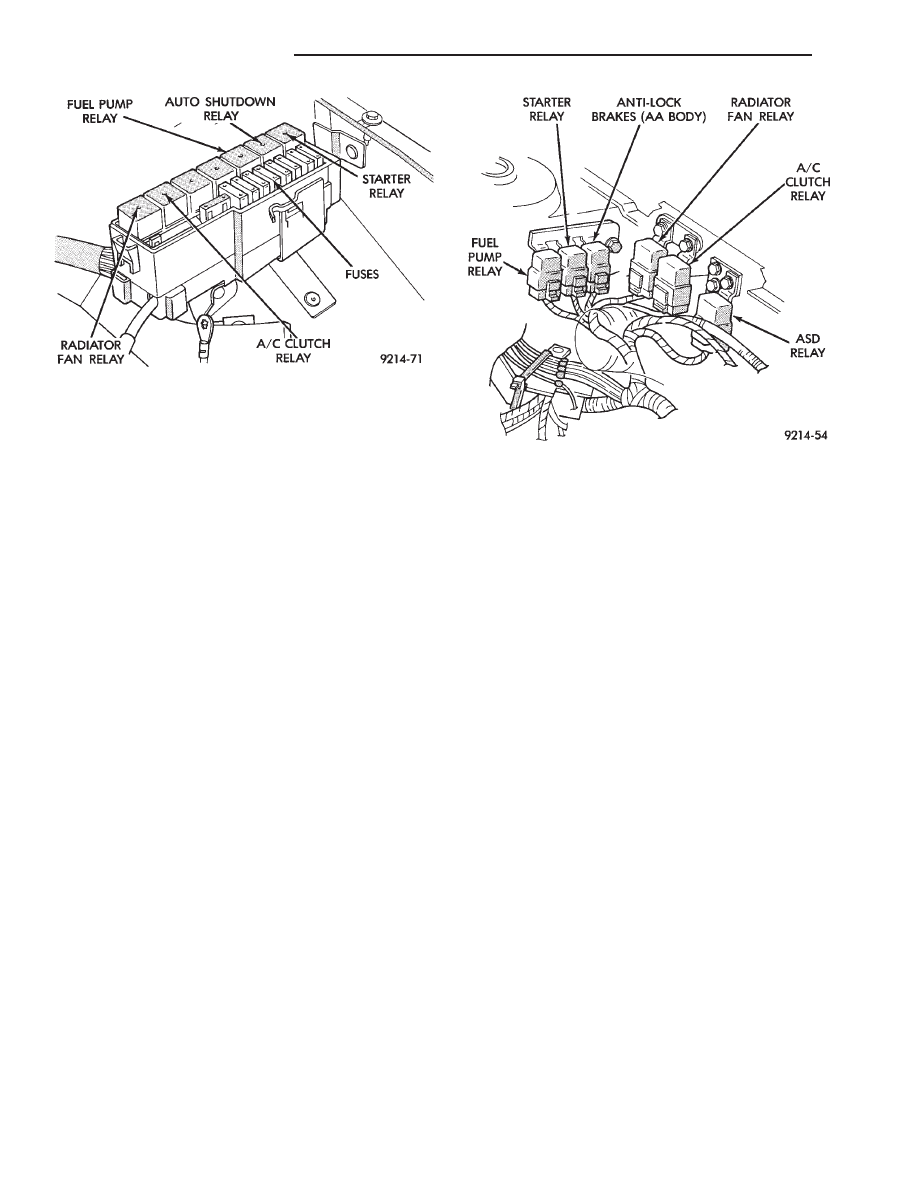

Fig. 39 Relay Identification (AA and AP Bodies)

Fig. 38 Relay Identification (AG and AJ Body)

8D - 34

IGNITION SYSTEMS

Ä

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEM—DIAGNOSTIC PROCEDURES

INDEX

page

page

Check Coil Test—3.3L and 3.8L Engines

. . . . . . 36

Check Coil Test—Turbo III Engine

. . . . . . . . . . . 35

Coolant Temperature Sensor Test

. . . . . . . . . . . . 38

Crankshaft Position Sensor and Camshaft Position

Sensor Tests

. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Failure to Start Test

. . . . . . . . . . . . . . . . . . . . . . 37

Failure to Start Test—Turbo III Engine

. . . . . . . . 36

Manifold Absolute Pressure (MAP) Sensor Test

. 38

Testing for Spark at Coil—3.3L and 3.8L Engines . 36

Testing for Spark at Coil—Turbo III Engine

. . . . . 35

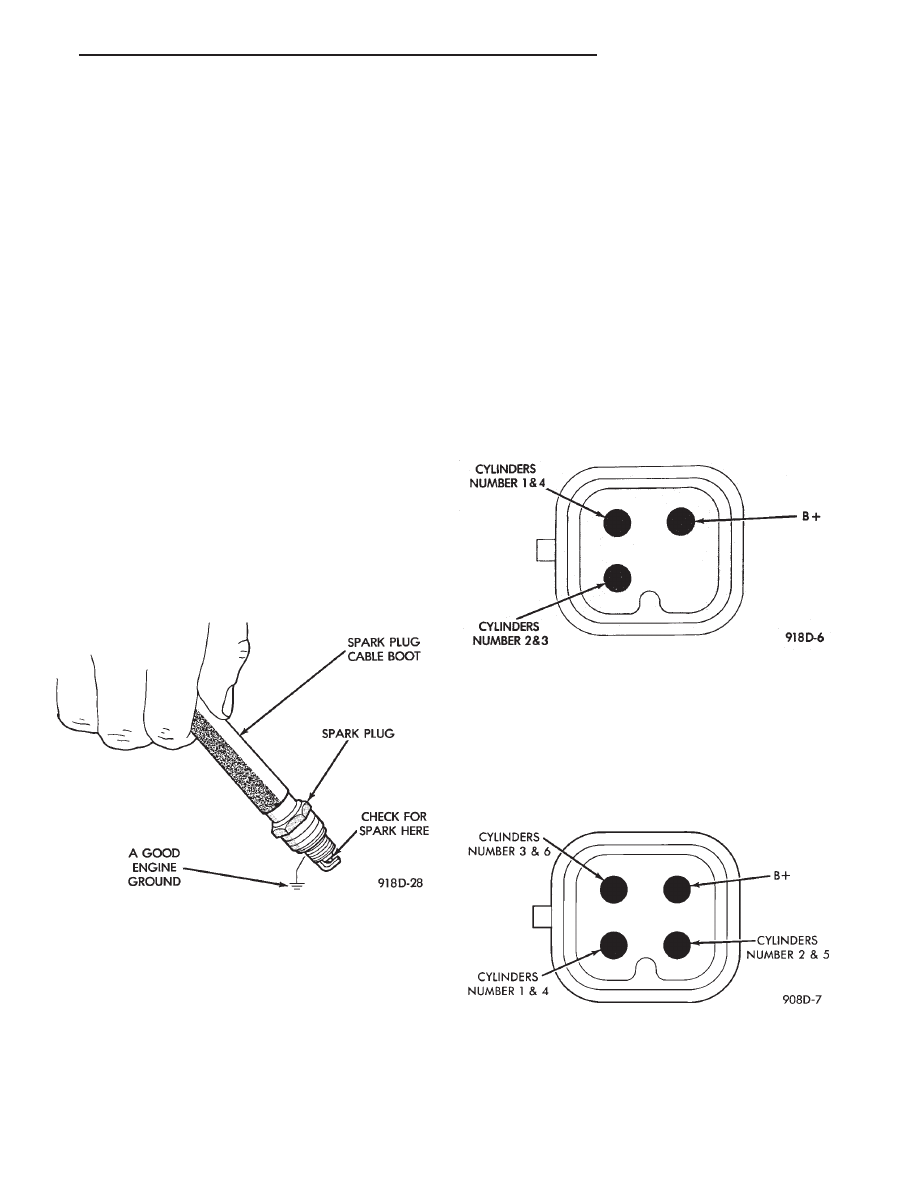

TESTING FOR SPARK AT COIL—TURBO III ENGINE

WARNING: THE DIRECT IGNITION SYSTEM GENER-

ATES APPROXIMATELY 40,000 VOLTS. PERSONAL

INJURY COULD RESULT FROM CONTACT WITH

THIS SYSTEM.

The coil pack contains 2 independent coils. Each

coil must be checked individually.

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from

the engine ground.

Remove the cable from number 1 spark plug. Insert

a clean spark plug into the spark plug boot, and

ground plug to the engine (Fig. 1).

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from

the engine ground.

Crank the engine and look for spark across the

electrodes of the spark plug. Repeat the above test

for the remaining cylinders. If there is no spark dur-

ing the cylinder tests, proceed to the failure to start

test.

If one or more cylinders have irregular, weak, or

no spark, proceed to Check Coil Test.

CHECK COIL TEST—TURBO III ENGINE

Cylinders 1 & 4, and 2 & 3 are grouped together.

(1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

3,000 to 12,000 ohms per foot of cable. Replace any

cable not within tolerance.

(2) Disconnect the electrical connector from the coil

pack (Fig. 2).

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin and

the pin corresponding to the cylinders in question (Fig.

3). Resistance on the primary side of each coil should be

0.5-0.7 ohm. Replace the coil if resistance is not within

tolerance.

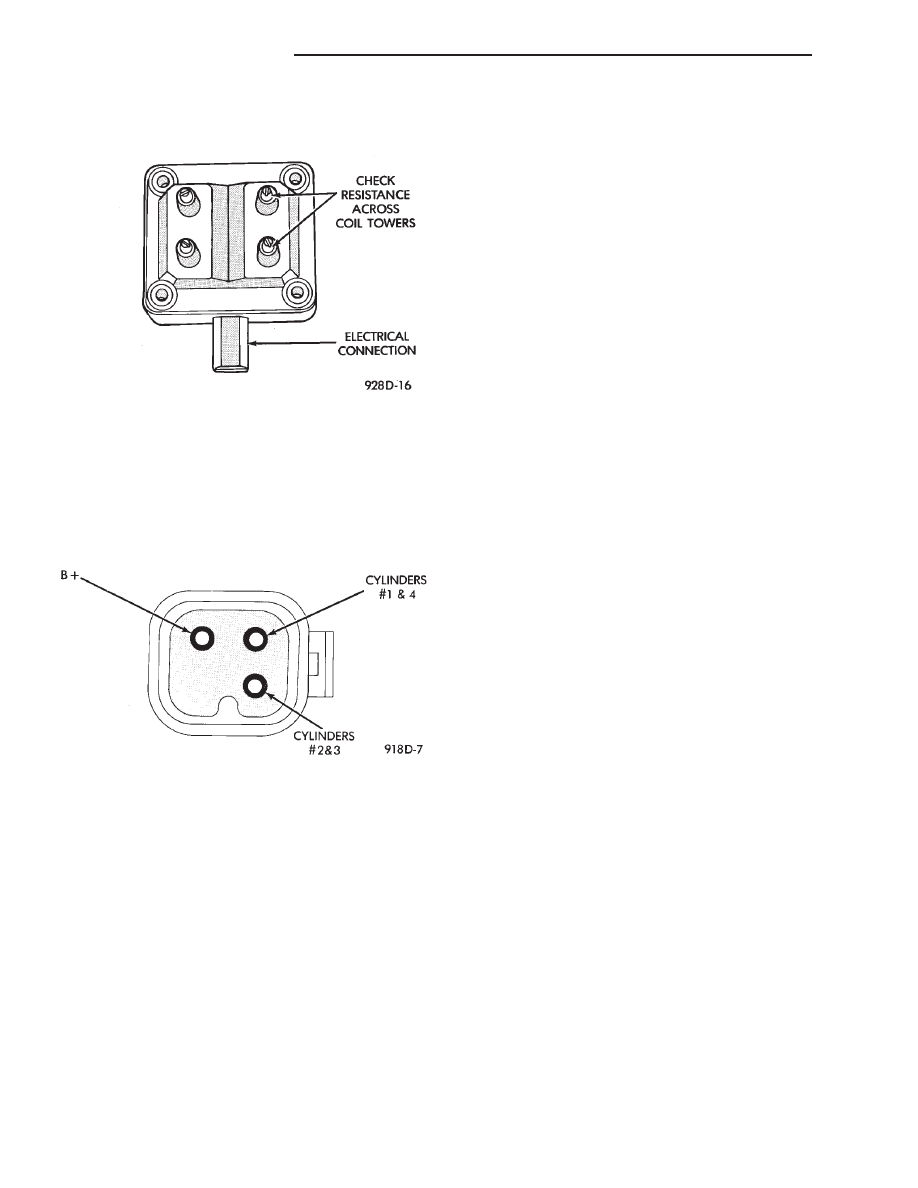

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of the

coil between the towers of each individual coil

Fig. 1 Testing For Spark

Fig. 2 Ignition Coil Electrical Connection—Turbo III

Engine

Fig. 3 Ignition Coil Terminal Identification

Ä

IGNITION SYSTEMS

8D - 35

(Fig. 4). Secondary resistance should be 11,600 to

15,800 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TEST—TURBO III ENGINE

(1) Determine that sufficient battery voltage (12.4

volts nominal) is present for the cranking and igni-

tion systems.

(2) Connect a voltmeter to the wiring harness coil

connector at the B+ pin (Fig. 5).

(3) Crank the engine for 5 seconds while monitor-

ing the voltage at the B+ connector terminal. If the

voltage remains near zero during the entire period of

cranking, check the auto shutdown relay and PCM.

Refer to DRBII scan tool and the appropriate Power-

train Diagnostic Procedures manual. Refer to Group

14 for description of On Board Diagnostics.

(4) If voltage is at near-battery voltage, and drops

to zero after 1-2 seconds of cranking, check the cam-

shaft position sensor and crankshaft position sensor

and their circuits. Refer to the DRBII scan tool and

the appropriate Powertrain Diagnostic Procedure

manual. Refer to Group 14 for a description of On-

Board Diagnostics.

(5) If voltage remains at near-battery voltage dur-

ing the entire 5 seconds, turn the key off, remove the

PCM 60-way connector. Check the 60-way for any

terminals loose from the connector (push-out).

TESTING FOR SPARK AT COIL—3.3L AND 3.8L

ENGINES

WARNING: THE ENGINE DIRECT IGNITION SYSTEM

GENERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains 3 independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if the

spark plug is moved more than 1/4 inch away from the

engine ground.

Remove the cable from number 2 spark plug. Insert a

clean spark plug into the spark plug boot, and ground

plug to the engine (Fig. 1).

Crank the engine and look for spark across the

electrodes of the spark plug. Repeat the above test for

the five remaining cylinders. If there is no spark

during all cylinder tests, proceed to the failure to start

test.

If one or more tests indicate irregular, weak, or no

spark, proceed to Check Coil Test.

WARNING: THE DIRECT IGNITION SYSTEM GENER-

ATES APPROXIMATELY 40,000 VOLTS. PERSONAL

INJURY COULD RESULT FROM CONTACT WITH THIS

SYSTEM.

CHECK COIL TEST—3.3L AND 3.8L ENGINES

Coil one fires cylinders 1 and 4, coil two fires

cylinders 2 and 5, coil three fires cylinders three

and six.

Each coil tower is labeled with the number of the

corresponding cylinder.

(1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

3,000 to 12,000 ohms per foot of cable. Replace any

cable not within tolerance.

(2) Disconnect the electrical connector from the coil

pack (Fig. 6).

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin and

the pin corresponding to the cylinders in question (Fig.

7). Resistance on the primary side of each coil should be

0.5 - 0.7 ohm. Replace the coil if resistance is not within

tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of the

coil between the towers of each individual coil (Fig. 8).

Refer to the Coil Specifications Chart in the Specifica-

tions section of this group. Replace the coil if resistance

is not within tolerance.

Fig. 4 Checking Ignition Coil Secondary

Resistance—Turbo III Engines

Fig. 5 Wiring Harness Coil Connector—Turbo III

Engine

8D - 36

IGNITION SYSTEMS

Ä

FAILURE TO START TEST

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor.

The powertrain control module (PCM) supplies 8.0

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8.0-volt

supply circuit shorts to ground, neither sensor will

produce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the auto

shutdown (ASD) relay. However, the PCM de-energizes

the relay within one second because it has not received

a crankshaft position sensor signal indicating engine

rotation.

During cranking, the ASD relay will not energize

until the PCM receives a crankshaft signal. Secondly,

the ASD relay remains energized only if the PCM

senses a camshaft position sensor signal immediately

after detecting the crankshaft position sensor signal.

(1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to start

test.

(2) Disconnect the harness connector from the coil

pack (Fig. 2).

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The wire for the B+ terminal is dark green with a black

tracer.

(4) Turn the ignition key to the ON position. The

test light should flash On and then Off. Do not turn

the Key to off position, leave it in the On position.

(a) If the test light flashes momentarily, the PCM

grounded the auto shutdown (ASD) relay. Proceed to

step 5.

(b) If the test light did not flash, the ASD relay did

not energize. The cause is either the relay or one of

the relay circuits. Use the DRBII scan tool to test the

ASD relay and circuits. Refer to the appropriate

Powertrain Diagnostics Procedure Manual. Refer to

the wiring diagrams section for circuit information.

(5) Crank the engine. If the key was placed in the off

position after step 4, place the key in the On position

before cranking. Wait for the test light to flash once,

then crank the engine.

(a) If the test light momentarily flashes during

cranking, the PCM is not receiving a camshaft posi-

tion sensor signal. Use the DRBII scan tool to test the

camshaft position sensor and sensor circuits. Refer to

the appropriate Powertrain Diagnostics Procedure

Manual. Refer to the wiring diagrams section for

circuit information.

(b) If the test light did not flash during cranking,

unplug the camshaft position sensor connector. Turn

the ignition key to the off position. Turn the key to

the On position, wait for the test light to momen-

tarily flash once, then crank the engine. If the test

light momentarily flashes, the camshaft position

sensor is shorted and must be replaced. If the light

did not flash, the cause of the no-start is in either the

crankshaft position sensor/camshaft position sensor

8.0-volt supply circuit, or the crankshaft position

sensor 5-volt output or ground circuits. Use the

DRBII scan tool to test the crankshaft position sen-

sor and the sensor circuits.

Fig. 6 Ignition Coil Electrical Connection

Fig. 7 Ignition Coil Terminal Identification

Fig. 8 Checking Ignition Coil Secondary Resistance

Ä

IGNITION SYSTEMS

8D - 37

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст