Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 70

INSTALL

(1) Install the power steering pump back into the

vehicle in the reverse order of removal, between cyl-

inder head and dash panel (Fig. 20).

(2) Install the wiring harness connector back on

the H-valve located on the air conditioning fluid

lines (Fig. 20).

(3) Raise vehicle See Hoisting, Group 0.

(4) Install the power steering pump on its mount-

ing bracket, and the hose locator bracket. Install the

bolt/stud and 2 bolts attaching the power steering

pump to its mounting bracket, and the bolts attach-

ing the hose locator bracket (Fig. 19). Torque all fas-

teners to 31 N

Im (280 in. lbs.).

(5) Install the power steering fluid pressure hose,

banjo bolt and seal washer onto power steering pump

(Fig. 4). Pressure hose is to be installed so it is

routed to the left of the hose locator bracket (Fig.

19). Torque the banjo bolt to 31 N

Im (275 in. lbs.).

Inspect the O-rings on the banjo bolt to ensure

they are not damaged and located correctly.

(6) Install the low pressure fluid return hose from

the power steering pump back on the steel tube on

the steering gear (Fig. 4). Install hose clamp, be sure

the hose clamp is installed past the retaining bead

the steel tube. Install the hose routing clip on the

power steering pump bolt/stud, install clip retaining

nut and tighten.

(7) Install the serpentine accessory drive belt (Fig.

18). Be sure the belt is correctly installed and

aligned on all pulleys before starting engine.

(8) Install the right front underhood splash shield.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar

T

, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level.

(10) Connect the negative battery cable on the

negative battery post.

(11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING PUMP PULLEY SERVICE

SAGINAW VANE SUBMERGED PUMP

REMOVE

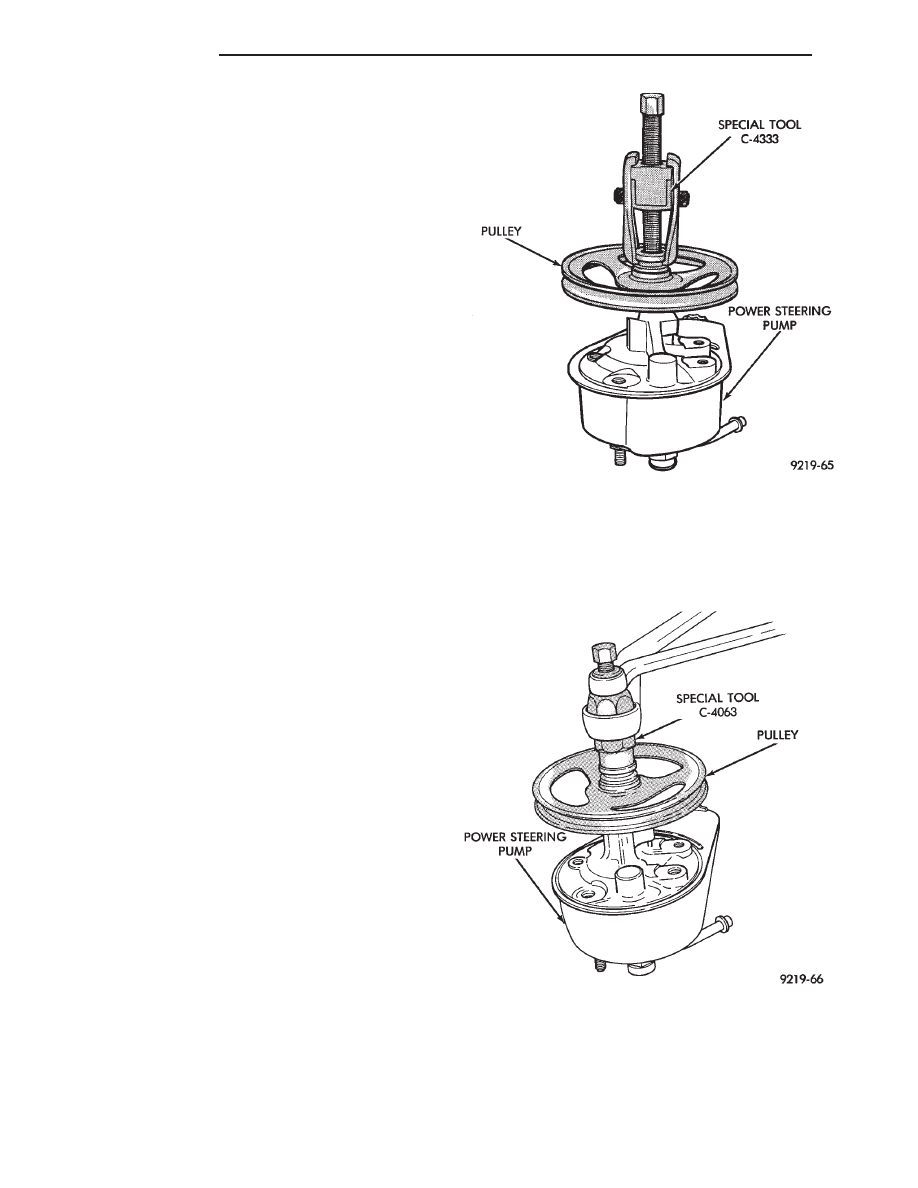

(1) Remove the pulley with Puller C-4333 (C-4068)

(Fig. 1).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump.

(2) Replace pulley if bent, cracked, or loose.

INSTALLATION

(1) Install the pulley with Installer C-4063 (Fig.2).

Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft.

(3) Force pulley flush with the end of the shaft.

Fig. 1 Pulley Removal (Typical)

Fig. 2 Pulley Installation (Typical)

19 - 20

STEERING

Ä

With Serpentine Belts; Run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0mm (0.040 in.). Be careful

that pulley does not contact mounting bolts.

SAGINAW T/C STYLE PUMP

REMOVE

(1) Mount power steering pump assembly in a vise

using one of the pump mounting bosses (Fig. 3). Do not

clamp the body of the power steering pump in vise.

Do not press or hammer on the shaft of the

power steering pump in an attempt to remove

the pulley. This will damage the internal compo-

nents of the power steering pump.

(2) Remove the power steering pump pulley from the

power steering pump shaft using Puller, Special Tool

C-4333 (Fig. 4).

INSTALL

Do not press or hammer on the shaft of the

power steering pump in an attempt to install the

pulley. This will damage the internal components

of the power steering pump.

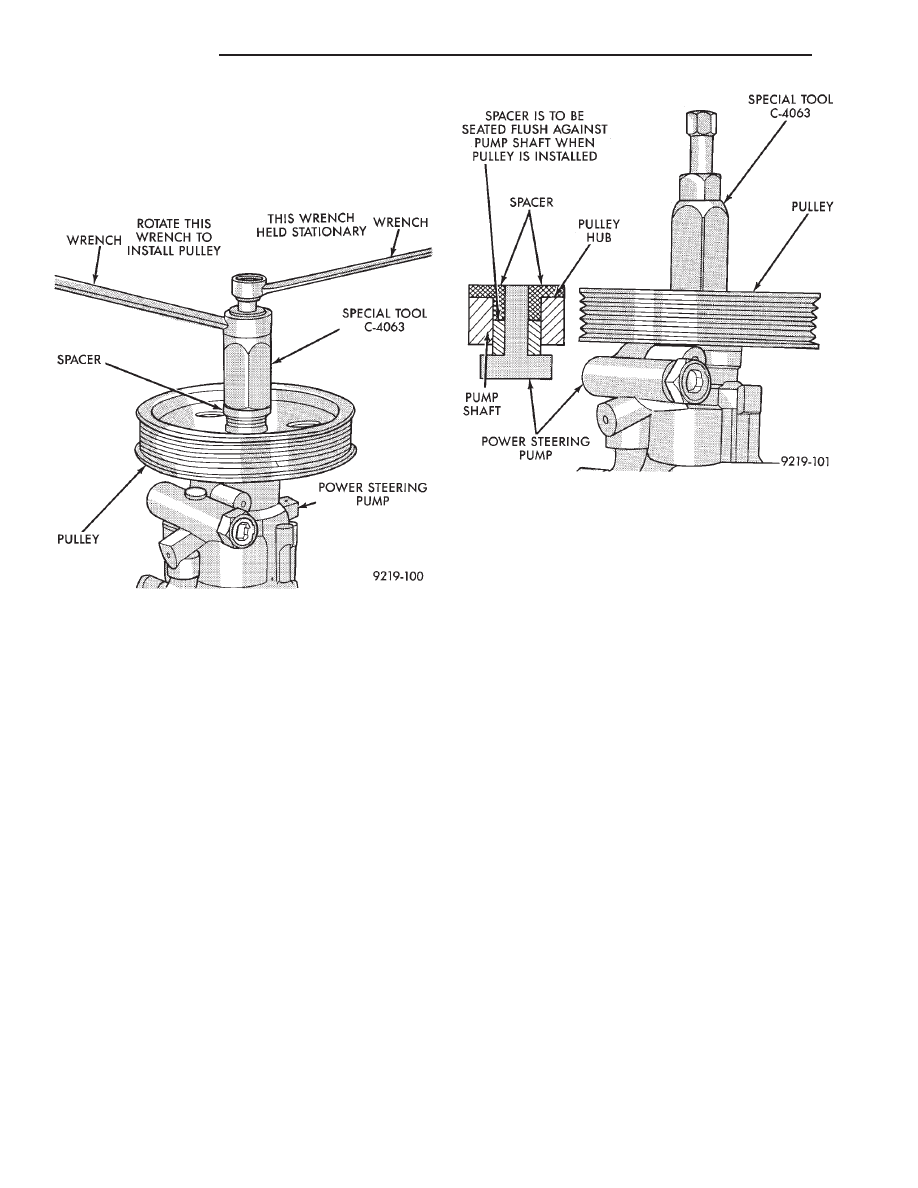

(1) Place the power steering pump pulley on the end

of the power steering pump shaft. Make sure the pulley

is installed squarely on the end of the shaft (Fig. 5).

CAUTION: When installing the pulley on the Saginaw

T/C style power steering pump. The spacer that is

provided with either the replacement power steering

pump or pulley MUST be used when the pulley is in-

stalled on the pump. The spacer provides for the cor-

rect pulley location on the power steering pump to

provide correct accessory drive belt alignment. The

alignment is critical in controlling accessory drive belt

noise. It also prevents the pulley from contacting the

power steering pump when it is installed, causing

power steering pump or pulley damage.

(2) Install the spacer provided with the replacement

power steering pump or power steering pulley into the

hub of the power steering pump pulley (Fig. 5).

(3) Insert the Pulley Installer, Special Tool C-4063,

(without adapters) through hole in spacer. Then

thread it into the end of the power steering pump

shaft (Fig. 6). Tighten the installer into shaft.

Fig. 4 Removing Power Steering Pump Pulley

Fig. 5 Pulley And Spacer Installed On Pump

Fig. 3 Power Steering Pump Mounted In Vise

Ä

STEERING

19 - 21

(4) Hold the Pulley Installer with one wrench so it

will not rotate. Turn hex (Fig. 6) down threaded rod

of installer pushing the pulley onto the shaft of the

power steering pump (Fig. 6). Ensure that the tool

and the pulley remain aligned with the pump shaft

so pulley does not become cocked on shaft.

(5) Continue to push pulley onto shaft of power

steering pump until Pulley Installer, Special Tool

C-4063 will no longer turn. This will ensure the

spacer provided is fully seated against the front of

the power steering pump shaft (Fig. 7).

(6) Remove

the

Pulley

Installer,

Special

Tool

C-4063 from the shaft of the power steering pump.

Remove the supplied spacer from the hub of the

power steering pump pulley and discard.

POWER STEERING PUMP FLUID RESERVOIRS

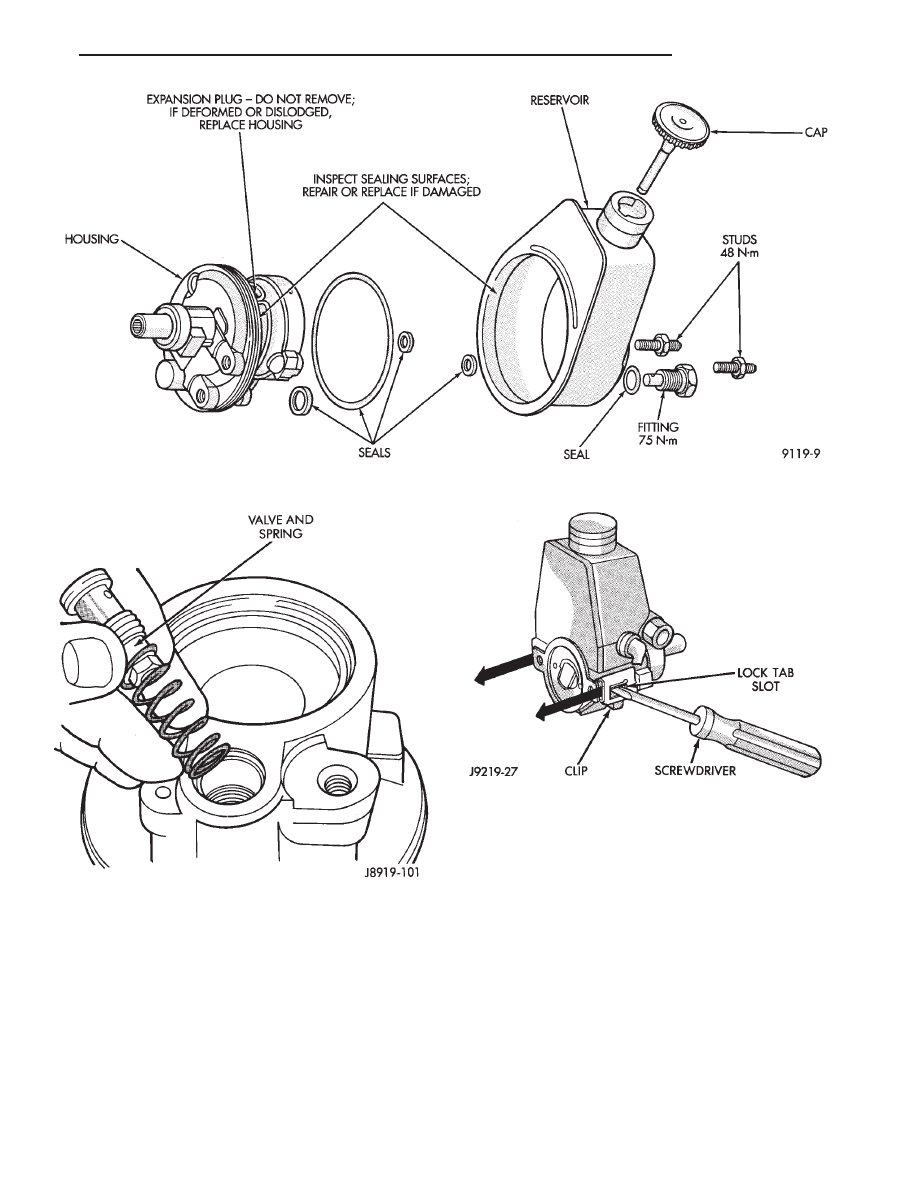

VANE SUBMERGED PUMP (HAM CAN)

REMOVE

Discard all O-ring seals during disassembly,

they are not re-usable.

(1) Remove the filler cap and drain the fluid from

reservoir before removing parts.

(2) Remove mounting studs and pressure fitting

(Fig. 1). Rock reservoir by hand or use a soft face

mallet to remove.

(3) Remove O-ring seals from housing and reser-

voir (Fig.1).

(4) Remove flow control valve and spring from

housing.

INSTALL

Clean all parts before installation. Lubricate

new O-ring seals with Mopar

t Power Steering

Fluid or equivalent.

(1) Install flow control valve and spring (Fig. 2).

(2) Install new O-ring seals in housing (Fig.1). In-

stall the pump housing assembly into the fluid reser-

voir. Tighten mounting studs to 48 N

Im (35 ft. lbs.)

torque.

(3) Install fitting in flow control valve bore. Tighten

the fitting to 75 N

Im (55 ft. lbs.) torque.

SAGINAW T/C STYLE PUMP WITH INTEGRAL

RESERVOIR

REMOVAL

Discard all O-ring seals during disassembly,

they are not re-usable.

(1) Remove pump and clean exterior of pump with

solvent.

(2) Remove the filler cap and drain the fluid from

reservoir.

(3) Clamp the front hub of the pump in a soft jaw

vice.

(4) Pry up tab and slide the retaining clip off (Fig. 3).

(5) Remove fluid reservoir from pump body. Remove

and discard O-ring seal (Fig. 4).

INSTALLATION

(1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent.

(2) Install seal in housing (Fig. 4).

(3) Install reservoir onto housing (Fig. 4).

Fig. 6 Installing Power Steering Pump Pulley

Fig. 7 Power Steering Pump Pulley Installed

19 - 22

STEERING

Ä

(4) Slide and tap in reservoir retainer clips until

tab locks to housing (Fig. 4).

(5) Install

pump.

Refill

reservoir

with

Mopar

Power Steering Fluid or equivalent.

FLOW CONTROL VALVE FITTING O-RING SEAL

REMOVAL

(1) Remove pressure hose from pump fitting. Re-

move pump and pulley if necessary.

(2) Remove fitting from pump housing (Fig. 5). Pre-

vent flow control valve and spring from sliding

out of housing bore.

(3) Remove and discard O-ring seal (Fig. 5).

INSTALLATION

(1) If necessary, clean and install flow control valve

and spring in pump housing bore (Fig. 5). Be sure the

hex nut end of the valve is facing the in toward

the pump.

(2) Install O-ring seal onto fitting (Fig. 5).

(3) Install fitting in pump housing and tighten to 75

N

Im (55 ft. lbs.)

(4) Install pump and pulley if necessary. Install

pressure hose to fitting.

Fig. 1 Pump and Reservoir

Fig. 2 Flow Control Valve/Spring Installation

Fig. 3 Remove Reservoir Clips (Typical)

Ä

STEERING

19 - 23

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст