Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 309

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch.

If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

TEE fitting mounted on frame rail in engine com-

partment below master cylinder (Fig.16).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

SPEEDOMETER SYSTEM

The

vehicles

are

equipped

with

electronically

driven speedometer and odometer assemblies. The

unit has the same appearance as a conventional

speedometer but it eliminates the cable-driven me-

chanical system. A signal is sent from a transmis-

sion-mounted

vehicle

speed

sensor

to

the

speedometer circuitry through the wiring harness.

By eliminating the speedometer cable, instrument

cluster service and removal is improved. Refer to Fig.

17 Speedometer Diagnosis Chart.

When the speedometer is out of calibration. The

electronic automatic transaxle vehicle speed sensor

output must be calibrated to reflect the different

combinations of equipment. The procedure is called

Pinion Factor, refer to Group 21, Transaxle for the

procedure.

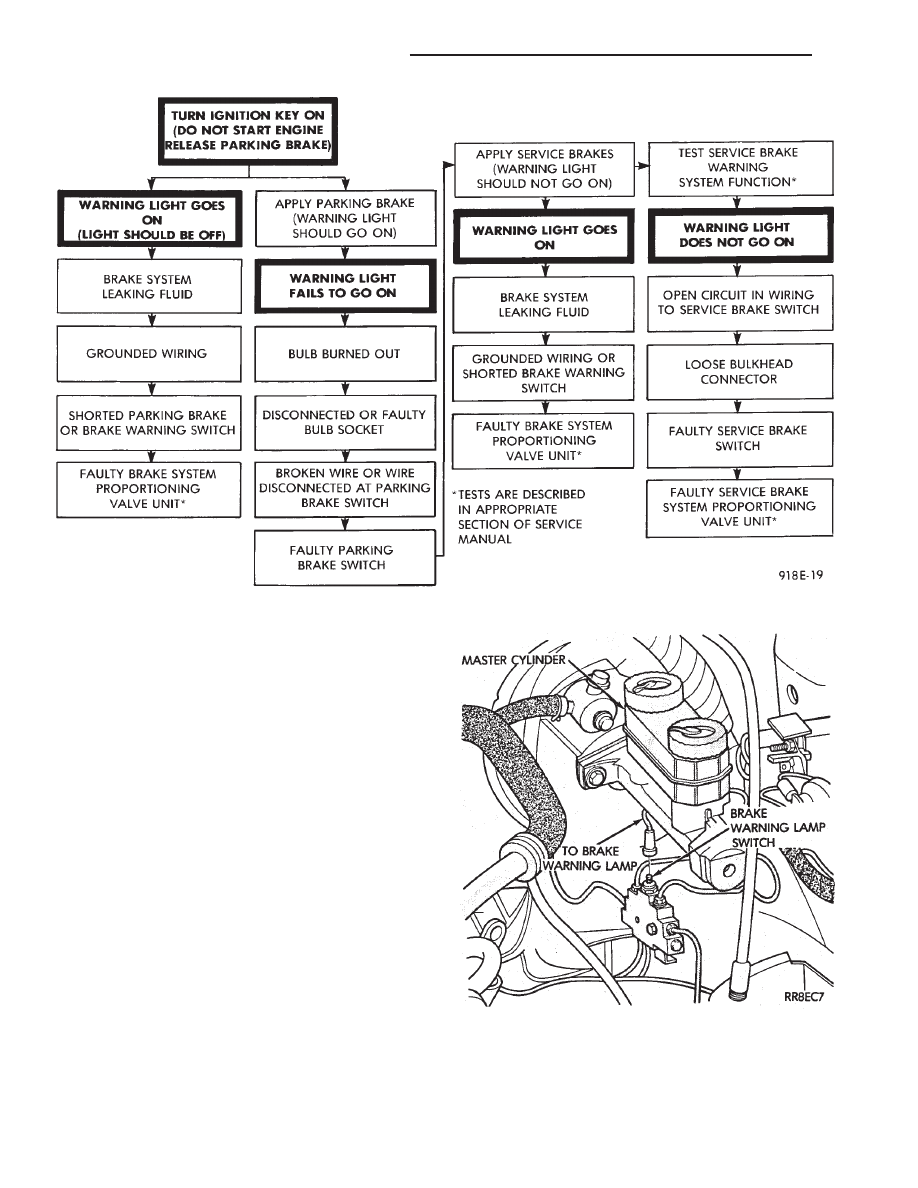

Fig. 15 Brake System Warning Lamp Diagnosis

Fig. 16 Brake Warning Lamp Switch

8E - 48

INSTRUMENT PANEL AND GAUGES

Ä

SPEEDOMETER/ODOMETER ASSEMBLY

REMOVAL

(1) Remove switch pod assembly.

(2) Remove cluster, refer to Cluster Removal.

(3) Remove mask and lens assembly.

(4) Remove tachometer, turbo gauge.

(5) Remove volt, temperature, oil and fuel gauge

assemblies.

(6) Remove the speedometer/odometer assembly

from the cluster housing.

(7) Disconnect pigtail connector from the cluster

printed circuit board.

(8) For installation reverse above procedures. Lis-

ten for the pigtail connector to snap in place.

SPEEDOMETER CIRCUIT TESTING

(1) Using DRB II, check vehicle speed sensor for

speed sensor fault code and for proper speed indica-

tion. Refer to Powertrain Diagnostics Procedure

Manual; Speed Control Test (Fig. 18).

(2) Remove cluster, but do not disconnect cluster

wiring.

(3) With ignition ON check for battery voltage

across the ignition pin and ground pin of speedome-

ter connector.

(4) Check for continuity from vehicle speed sensor

signal pin to connector at speed sensor.

(5) Check cluster to body for continuity to ground.

(6) If all these tests prove good, replace speedome-

ter.

VEHICLE SPEED SENSOR REPLACEMENT

(1) Remove harness connector from sensor and

make sure weather seal is on harness connector.

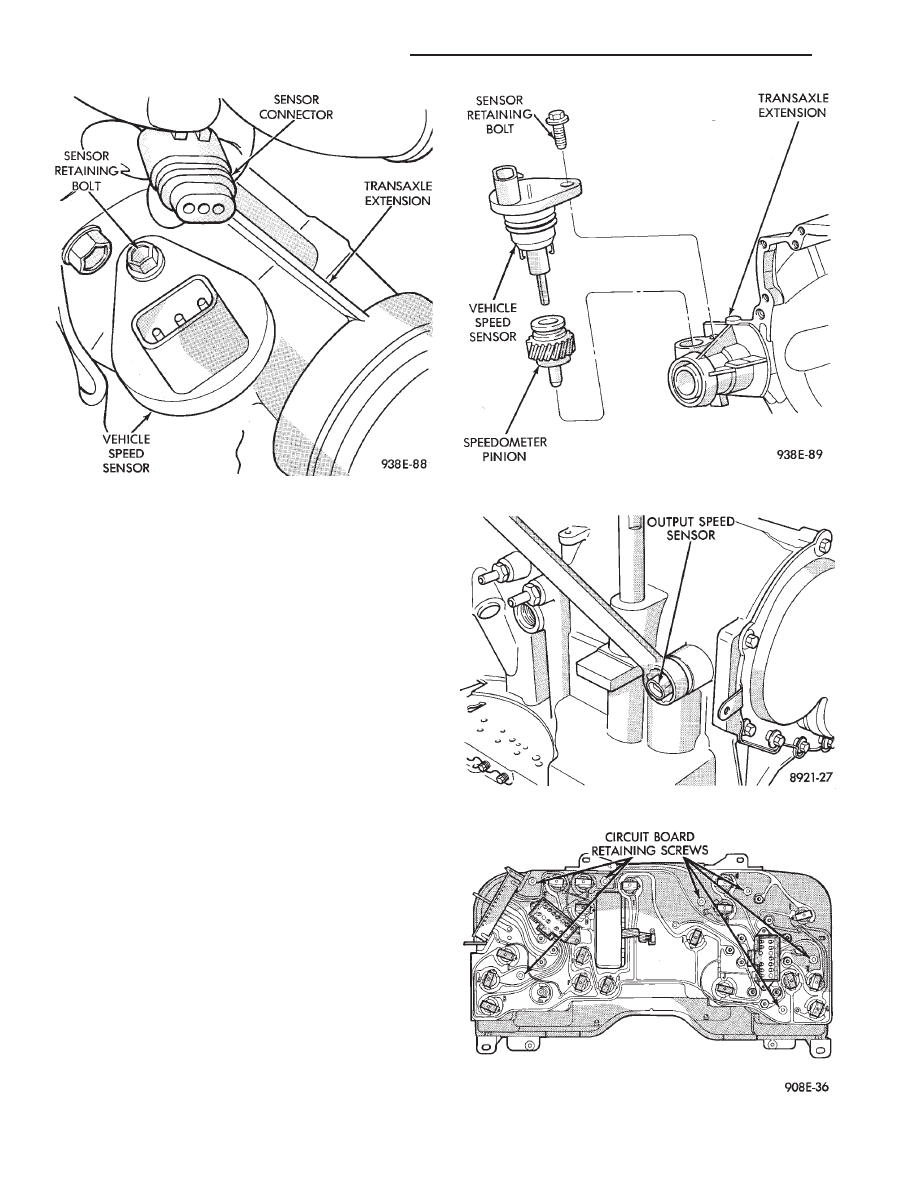

(2) Remove sensor retaining bolt (Fig. 19).

(3) Pull sensor and pinion gear assembly out of

transaxle. If necessary carefully pry loose with a flat

blade screwdriver (Fig. 20).

(4) Remove pinion gear from sensor.

(5) For installation reverse above procedures. Seat

the sensor assembly by hand to ensure proper gear

engagement. Tighten retaining bolt to 7 N

Im (60 in.

lbs.) torque.

ELECTRONIC AUTOMATIC TRANSAXLE

VEHICLE SPEED SENSOR REPLACEMENT

The output vehicle speed sensor is located to the

left of the manual shift lever.

(1) Raise and support vehicle on safety stands.

(2) Remove vehicle speed sensor (Fig. 21).

(3) For installation, reverse above procedures.

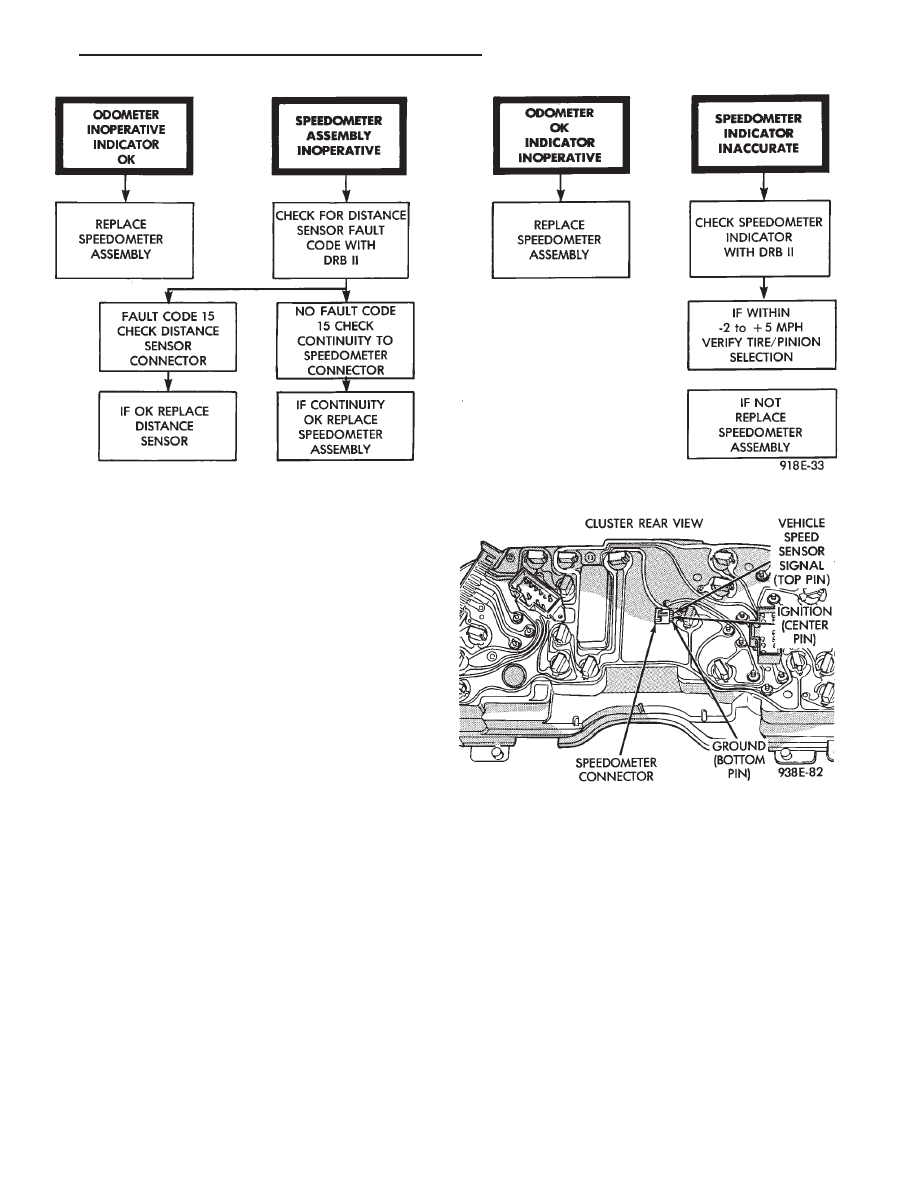

Fig. 17 Speedometer Diagnosis

Fig. 18 Speedometer

Ä

INSTRUMENT PANEL AND GAUGES

8E - 49

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components using DRB II, refer to the appropriate

Powertrain Diagnostics Test Procedure Manual.

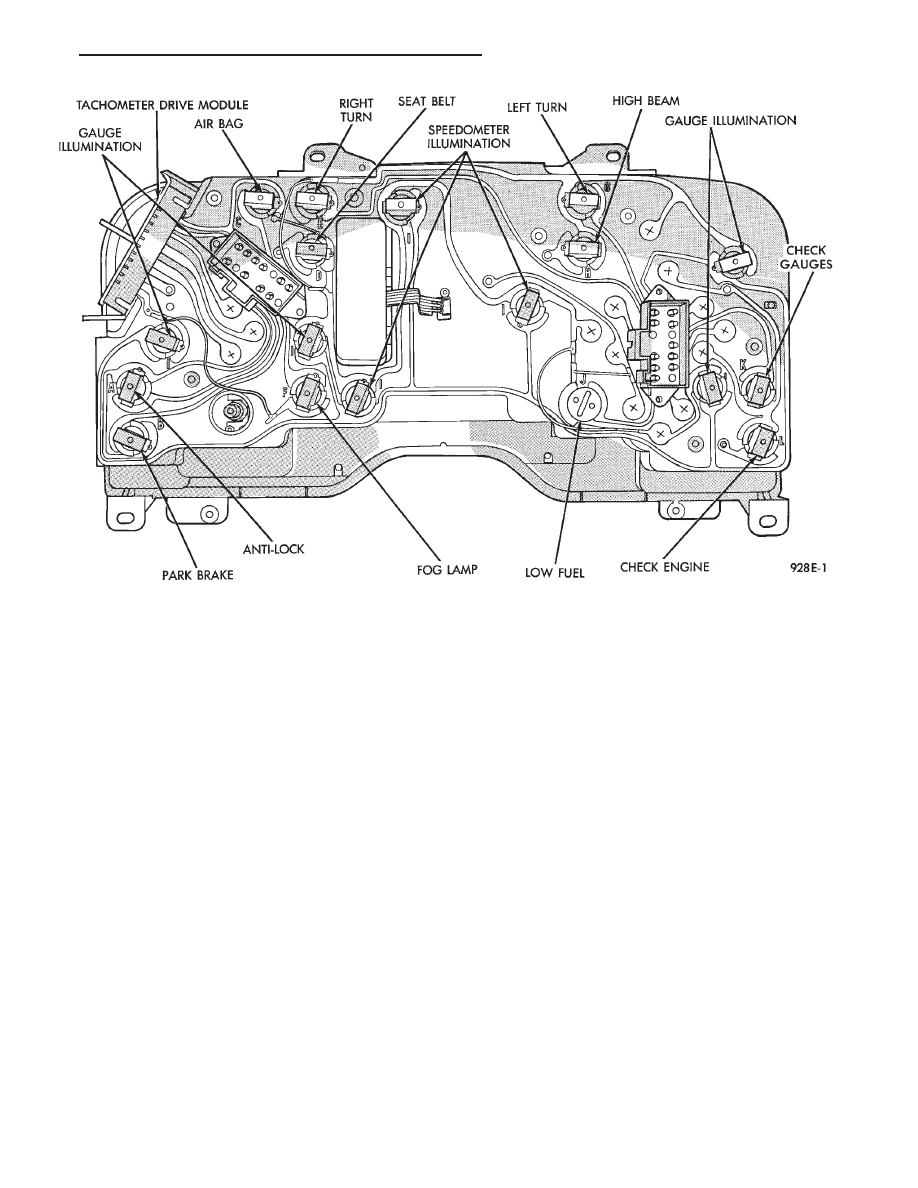

TACHOMETER DRIVE MODULE REMOVAL

(1) Remove cluster assembly.

(2) Pull tachometer drive module from printed cir-

cuit board (Fig. 22).

(3) For installation reverse above procedures. Use

care when aligning module to printed circuit board.

PRINTED CIRCUIT BOARD REMOVAL

(1) Remove cluster assembly.

(2) Remove mounting screws securing printed cir-

cuit board to cluster housing.

(3) Remove tachometer drive module (Fig. 22).

(4) Twist out all lamp sockets.

(5) For installation reverse above procedures.

CLUSTER LAMPS REMOVAL—MECHANIAL

CLUSTER ONLY

(1) Remove cluster assembly (Fig. 23).

(2) Remove one piece integral lamp and socket

from rear of cluster.

ELECTRONIC CLUSTER

Refer to Body Diagnostic Procedures Manual when

using DRB II.

SELF DIAGNOSTIC SYSTEM

The electronic clusters have an internal diagnostic

routing to isolate problems within the cluster.

Fig. 20 Vehicle Speed Sensor and Speedometer Pinion

Fig. 21 Vehicle Speed Sensor Removal

Fig. 22 Cluster Printed Circuit Board

Fig. 19 Vehicle Speed Sensor and Connector

8E - 50

INSTRUMENT PANEL AND GAUGES

Ä

Perform cluster Self Diagnostic Test to determine

whether problem is within cluster or outside of clus-

ter.

Refer to Fig. 24 and 25.

Successful completion of the SELF DIAGNOSTIC

TEST indicates that the problem is in the wiring,

connectors or sensors out side of the cluster.

CLUSTER ASSEMBLY REMOVAL

The electronic cluster which is serviced as an as-

sembly is removed with the same procedure as the

conventional cluster.

CONDITION: CLUSTER DISPLAYS DO NOT

ILLUMINATE AFTER VEHICLE IS STARTED

(1) Check fuses and verify battery and ignition

voltage at cluster connector.

(2) Check ground from cluster connector to instru-

ment panel ground stud.

SWITCH AND PANEL COMPONENT SERVICE

HEADLAMP SWITCH

The headlamp switch is located on the left side of

the switch pod. The switch controls the headlamps,

parking lamps, fog lamps and instrument light dim-

ming. If any of the switches require replacement the

entire headlamp switch assembly must be replaced

(Fig. 26 and 27).

REMOVAL

(1) Remove switch pod assembly from the instru-

ment panel. DO NOT attempt to remove instrument

cluster dimmer switch or wiper delay switch knob,

they are not removable.

(2) Remove turn signal switch lever by pulling

straight out of switch pod.

(3) Remove screws from bottom of switch pod.

(4) Separate inner and outer switch pod halves and

remove turn signal switch to gain access to screw.

(5) Remove five inner switch pod panel screws and

3 screws from underneath the switch pod. Separate

the inner bezel from the outer bezel.

(6) Remove switch mounting screws before discon-

necting linkage.

(7) Disconnect switch linkage from buttons. Pull

the linkage straight up from the switch/button to dis-

engage it and remove switch.

Fig. 23 Mechanical Cluster Lamp Location

Ä

INSTRUMENT PANEL AND GAUGES

8E - 51

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст