Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 56

(3) Loosen fuel return hose clamp and remove fuel

return hose from nipple.

(4) Remove vacuum hose from fuel pressure regu-

lator. (Fig. 13).

(5) Remove screw holding fuel return tube to the

intake manifold.

(6) Remove fuel pressure regulator screws. Remove

fuel pressure regulator from engine.

INSTALLATION

(1) Lubricate O-ring on fuel pressure regulator

with clean 30 weight engine oil.

(2) Install fuel pressure regulator into fuel rail.

Tighten screws to 10 N

Im (90 in. lbs.) torque.

(3) Install screw holding fuel return tube clamp in

place. Tighten screw to 10 N

Im (95 in. lbs.) torque.

(4) Connect vacuum hose to fuel pressure regula-

tor.

(5) Connect fuel return hose to fuel return tube.

Tighten hose clamp to 1 N

Im (10 in. lbs.) torque.

(6) Connect negative battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(7) With the ignition key in ON position, access

the DRBII scan tool’s ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTORS

WARNING: THE 3.0L MPI FUEL SYSTEM IS UNDER

A CONSTANT PRESSURE OF APPROXIMATELY 330

KPA (48 PSI). PERFORM FUEL PRESSURE RE-

LEASE

PROCEDURE

BEFORE

SERVICING

THE

FUEL INJECTORS.

REMOVAL

(1) Perform the Fuel Pressure Release Procedure.

(2) Disconnect negative cable from battery.

The fuel rail must be removed first to service the

injectors. Refer to Fuel Injector Rail Assembly Re-

moval in this section.

(3) Label each injector connector with its cylinder

number. Disconnect electrical connector from injec-

tor.

(4) Position fuel rail assembly so that the fuel in-

jectors are easily accessible.

(5) Remove injector clip from fuel rail and injector

(Fig. 14).

(6) Pull injector straight out of fuel rail receiver

cup (Fig. 15).

Fig. 13 Fuel Pressure Regulator

Fig. 14 Fuel Injector and Rail

Fig. 15 Servicing Fuel Injector

14 - 142

FUEL SYSTEMS

Ä

(7) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is to be re-

used, a protective cap must be installed on the injec-

tor tip to prevent damage.

(8) Repeat procedure for remaining injectors.

INSTALLATION

(1) Before installing an injector, the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation.

(2) Being careful not to damage O-ring, install in-

jector nozzle end into fuel rail receiver cap (Fig. 15).

(3) Install injector clip by sliding open end into top

slot of the injector. The edge of the receiver cup will

slide into the side slots of clip (Fig. 14).

(4) Repeat steps for remaining injectors.

(5) Install fuel rail assembly. Refer to Fuel Rail

Assembly Installation in this section.

(6) Connect electrical connectors to injectors in cor-

rect order.

(7) Connect negative battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(8) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

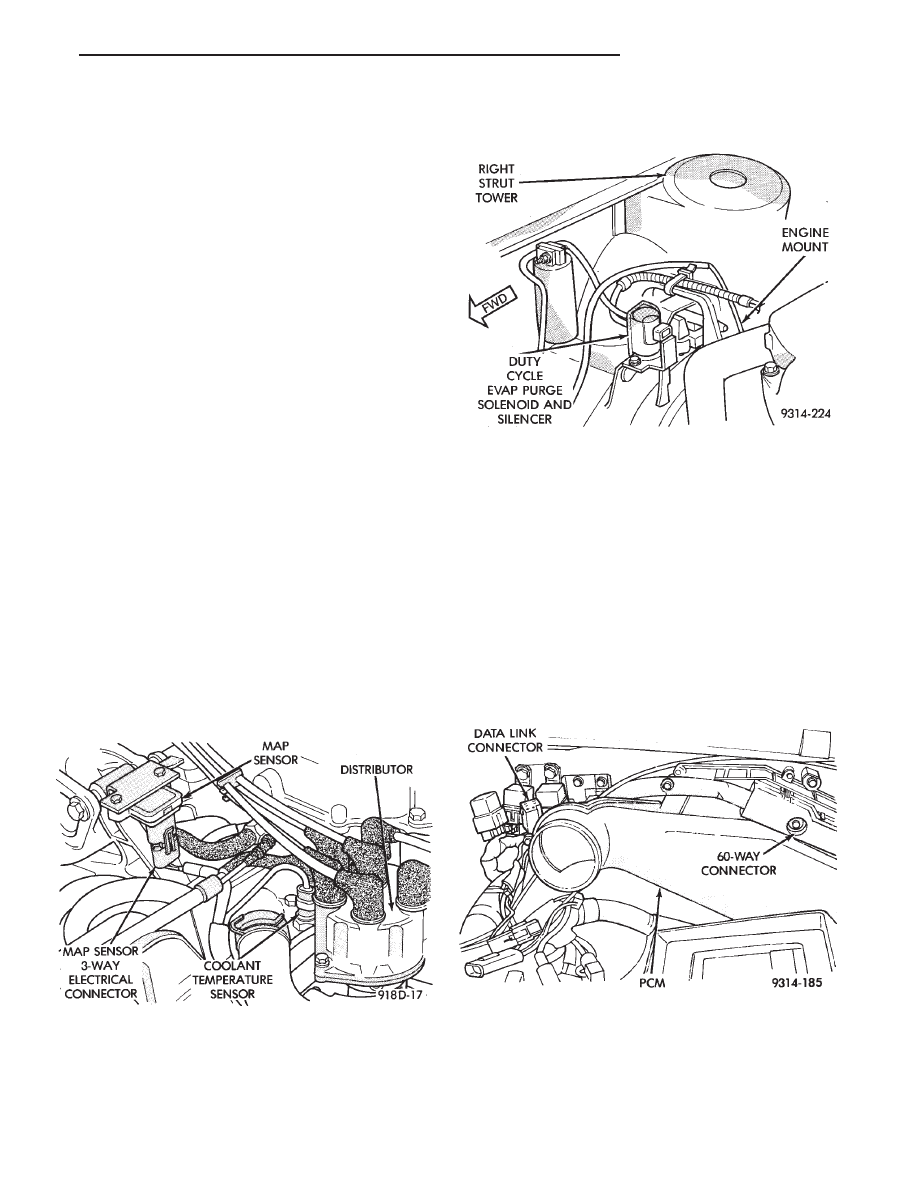

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

(1) Remove vacuum hose and mounting screws

from manifold absolute pressure (MAP) sensor (Fig.

16).

(2) Disconnect electrical connector from sensor. Re-

move sensor.

(3) Reverse the above procedure for installation.

CANISTER PURGE SOLENOID SERVICE

(1) Remove vacuum hose and electrical connector

from solenoid (Fig. 17).

(2) Slide solenoid and silencer assembly off of

bracket.

(3) Reverse above procedure to install.

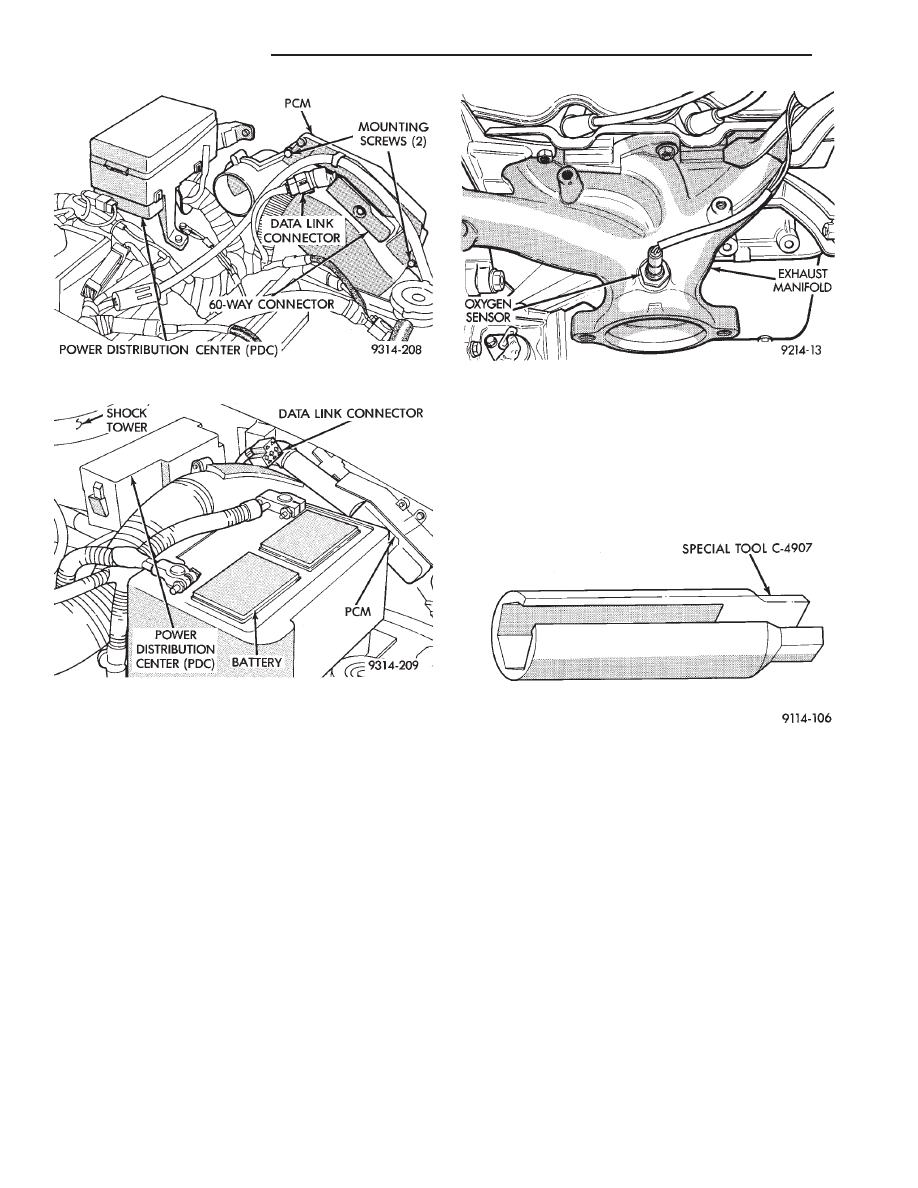

PCM

(1) Remove air cleaner duct from PCM.

(2) Disconnect negative cable from battery. Discon-

nect positive cable from battery.

(3) Remove battery holddown. Remove battery.

(4) Remove PCM mounting screws (Fig. 18, Fig. 19

or Fig. 20).

(5) Remove the electrical connector from PCM. Re-

move PCM.

(6) Reverse the above procedure for installation.

Fig. 16 Manifold Absolute Pressure Sensor

Fig. 17 Canister Purge Solenoid

Fig. 18 PCM—AA Body

Ä

FUEL SYSTEMS

14 - 143

HEATED OXYGEN SENSOR (O

2

SENSOR)

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 21).

CAUTION: Do not pull on the oxygen sensor wires

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

(1) Disconnect oxygen sensor electrical connector.

(2) Remove sensor using Tool C-4907 (Fig. 22).

Slightly tightening the sensor can ease removal.

When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 27 N

Im (20 ft. lbs.) torque.

Fig. 19 PCM—AC Body

Fig. 20 PCM—AG and AJ Bodies

Fig. 21 Heated Oxygen Sensor

Fig. 22 Oxygen Sensor Socket

14 - 144

FUEL SYSTEMS

Ä

3.3L AND 3.8L MULTI-PORT FUEL INJECTION—SYSTEM OPERATION

INDEX

page

page

Air Conditioning (A/C) Clutch Relay—PCM Output

. 150

Air Conditioning Switch Sense—PCM Input

. . . . 147

Auto Shutdown (ASD) Relay and Fuel Pump

Relay—PCM Output

. . . . . . . . . . . . . . . . . . . . 151

Battery Voltage—PCM Input

. . . . . . . . . . . . . . . 147

Brake Switch—PCM Input

. . . . . . . . . . . . . . . . . 147

Camshaft Position Sensor—PCM Input

. . . . . . . 147

Canister Purge Solenoid—PCM Output

. . . . . . . 151

CCD Bus

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Crankshaft Position Sensor—PCM Input

. . . . . . 148

Data Link Connector—PCM Output

. . . . . . . . . . 152

Electric EGR Transducer (EET) Solenoid—PCM

Output

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Engine Coolant Temperature Sensor—PCM Input

. 148

Fuel Injectors and Fuel Rail Assembly

. . . . . . . . 155

Fuel Injectors—PCM Output

. . . . . . . . . . . . . . . 152

Fuel Pressure Regulator

. . . . . . . . . . . . . . . . . . 156

Fuel Supply Circuit

. . . . . . . . . . . . . . . . . . . . . . 155

General Information

. . . . . . . . . . . . . . . . . . . . . . 145

Generator Field—PCM Output

. . . . . . . . . . . . . . 150

Heated Oxygen Sensor (O

Sensor)—PCM Input

. 149

Idle Air Control Motor—PCM Output

. . . . . . . . . 151

Ignition Coil—PCM Output

. . . . . . . . . . . . . . . . . 153

Malfunction Indicator Lamp (Check Engine

Lamp)—PCM Output

. . . . . . . . . . . . . . . . . . . 151

Manifold Absolute Pressure (MAP) Sensor—PCM

Input

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Modes of Operation

. . . . . . . . . . . . . . . . . . . . . . 153

Powertrain Control Module

. . . . . . . . . . . . . . . . . 146

Radiator Fan Relay—PCM Output

. . . . . . . . . . . 153

Speed Control Solenoids—PCM Output

. . . . . . . 153

Speed Control—PCM Input

. . . . . . . . . . . . . . . . 150

System Diagnosis

. . . . . . . . . . . . . . . . . . . . . . . 146

Tachometer—PCM Output

. . . . . . . . . . . . . . . . . 153

Throttle Body

. . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Throttle Position Sensor (TPS)—PCM Input

. . . . 150

Transaxle Control Module—PCM Output

. . . . . . 152

Transaxle Park/Neutral Switch—PCM Input

. . . . 150

Vehicle Speed and Distance Input—PCM Input

. 150

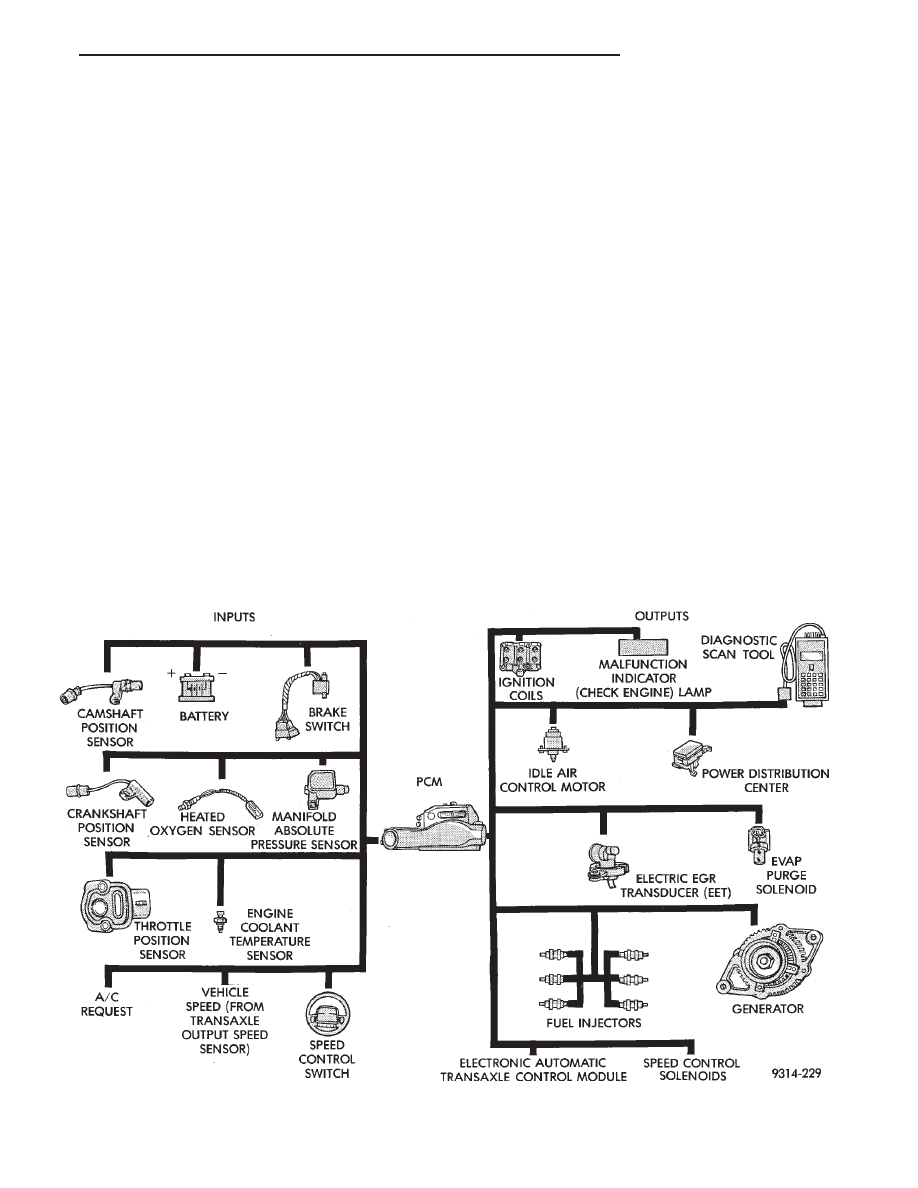

GENERAL INFORMATION

3.3L and 3.8L engines use a sequential Multi-port

Electronic Fuel Injection system (Fig. 1). The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions.

The MPI system is operated by the powertrain con-

trol module (PCM).

Fig. 1 Multi-Port Fuel Injection Components

Ä

FUEL SYSTEMS

14 - 145

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст