Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 255

MASTER CYLINDER AND POWER BOOSTER

REMOVAL AND INSTALLATION

If the Master Cylinder or Power Booster need to be

removed for replacement or servicing of other vehicle

components. Refer to Master Cylinder or Power

Brake Service section in group 5 of the 1993 M.Y.

Front Wheel Drive Car service manual.

After servicing master cylinder, refer back to this

service manual supplement for the appropriate proce-

dure and sequence used to bleed the base and Anti-

lock portion of the brake system.

PROPORTIONING VALVES (FIG. 1)

CAUTION: Proportioning valves should never be

disassembled.

REMOVAL

(1) Disconnect and remove both battery cables

from battery.

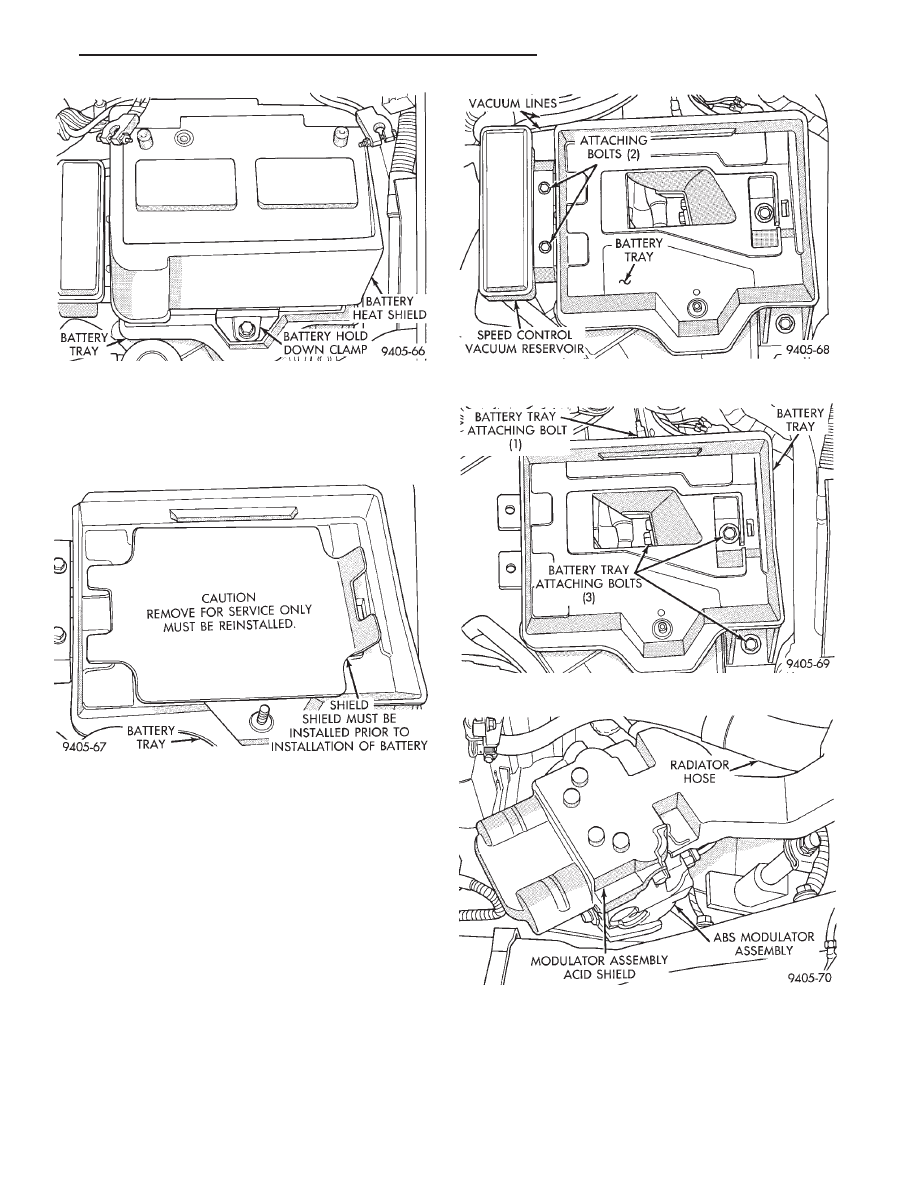

(2) Remove heat shield (Fig. 2) from the battery.

Then remove battery hold down clamp (Fig. 2) and

battery from battery tray.

Fig. 15 Battery Tray Installation And Attaching Bolts

Fig. 16 Vacuum Reservoir Installation And

Attaching Bolts

Fig. 17 Battery Tray Access Shield Installed

Fig. 18 Battery Hold Down Clamp And Heat Shield

Installed

Fig. 1 ABS Proportioning Valve Identification

5 - 38

ANTILOCK 4 BRAKE SYSTEM

Ä

(3) Remove battery tray access cover (Fig. 3) from

battery tray. Do not discard, access cover MUST be

put back on battery tray, when battery is rein-

stalled.

(4) If equipped, remove the 2 bolts (Fig. 4) attaching

speed control vacuum reservoir to battery tray. Then

remove speed control vacuum reservoir (Fig. 4) from

the battery tray. Vacuum lines (Fig. 4) do not need

to be removed from vacuum reservoir.

(5) Remove the 4 bolts attaching battery tray (Fig. 5)

to frame rail and fender shield of vehicle. Then remove

battery tray from vehicle.

(6) Remove battery acid shield, (Fig. 6) from the ABS

modulator assembly.

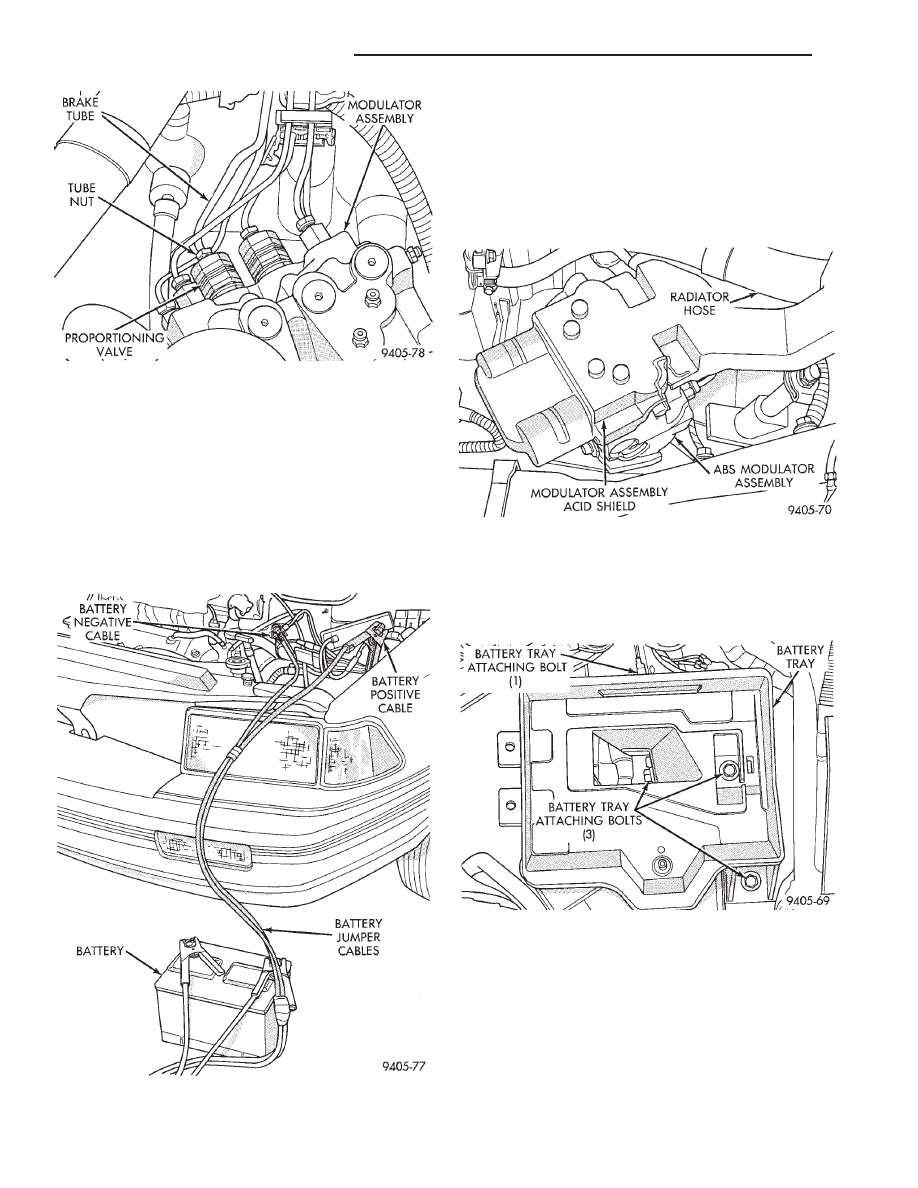

(7) Remove brake tube from the proportioning valve,

requiring removal from modulator assembly (Fig. 7).

(8) Remove proportioning valve (Fig. 7) requiring

replacement from the modulator assembly.

INSTALL

(1) Slightly moisten proportioning valve to modulator

assembly sealing O-Ring with fresh clean brake fluid.

(2) Install proportioning valve into modulator as-

sembly by hand, until O-Ring seal is fully seated

Fig. 4 Speed Control System Vacuum Reservoir

Fig. 5 Battery Tray And Attaching Bolts

Fig. 6 ABS Modulator Assembly Acid Shield

Fig. 2 Battery Heat Shield And Hold Down Clamp

Fig. 3 Battery Tray Shield

Ä

ANTILOCK 4 BRAKE SYSTEM

5 - 39

against modulator assembly. Then torque proportion-

ing valve to 35 N

Im (26 ft. lbs.) torque.

(3) Install hydraulic brake line on proportioning

valve and hand start tube nut into proportioning valve.

Torque tube nut to 18 N

Im (159 in. lbs.) torque.

(4) Using approved battery jumper cables, attach

battery, to the vehicles negative and positive battery

cables (Fig. 8).

(5) Bleed the vehicles base brake and Antilock brake

hydraulic systems. Refer to Bleeding Bendix Antilock 4

Brake System in this service manual supplement for

required bleeding procedure.

(6) Install battery acid shield (Fig. 9) onto the ABS

modulator assembly. Be sure acid shield is securely

attached to modulator assembly before installing

battery tray.

(7) Install battery tray in vehicle. Then install the 4

bolts (Fig. 10) attaching battery tray to inner fender

and frame rail. Torque the 4 battery tray attaching

bolts to 20 N

Im (175 in.lbs.).

(8) If equipped, install speed control vacuum reser-

voir on battery tray. Install the 2 speed control vacuum

reservoir attaching bolts (Fig. 11). Torque the 2

vacuum reservoir attaching bolts to 4 N

Im (30 in. lbs.).

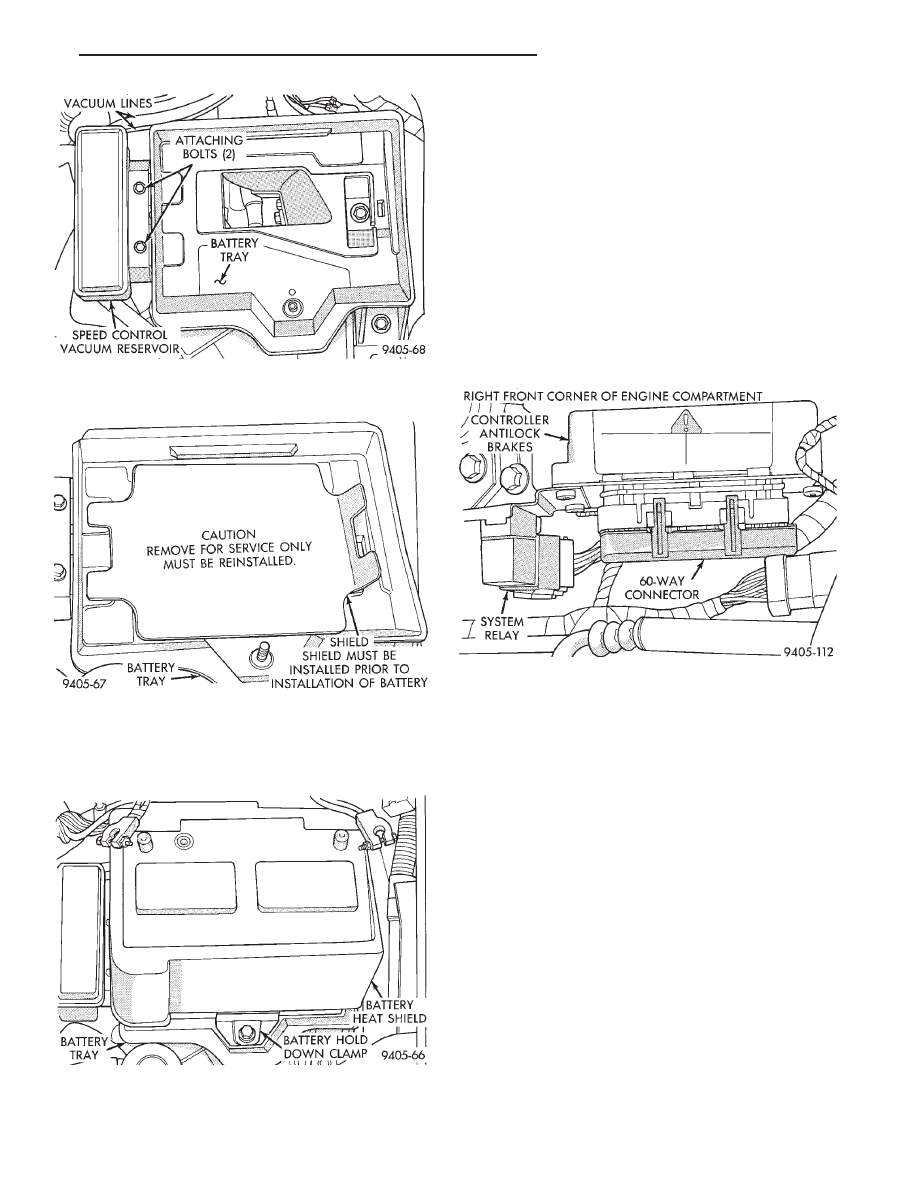

(9) Install battery tray access cover (Fig. 12) on

bottom of battery tray. The access cover MUST be

on battery tray, before battery is installed in

battery tray.

Fig. 8 Battery Connected To Vehicle For Bleeding

Modulator Assembly

Fig. 7 Proportioning Valve Removal From Modulator

Assembly

Fig. 9 Modulator Assembly Acid Shield Installed

Fig. 10 Battery Tray Installation And Attaching Bolts

5 - 40

ANTILOCK 4 BRAKE SYSTEM

Ä

(10) Install battery on battery tray and install and

securely tighten the battery hold down clamp (Fig.

13). Then install heat shield, on battery (Fig. 13).

(11) Install battery cables on battery. Securely

tighten clamping bolts on battery cable terminals.

(12) Reset any electrical components of the vehicle

which were affected by the removal of the battery.

(13) Road test vehicle to verify correct operation of

the vehicles’s base and Antilock brake systems.

ELECTRONIC COMPONENTS

CONTROLLER ANTILOCK BRAKE CAB

REMOVE

(1) Turn vehicle ignition off.

(2) Disconnect the wiring harness connector from

the Antilock system relay (Fig. 1). Relay will be re-

moved as part of the CAB bracket.

CAUTION: BEFORE REMOVING 60 WAY CONNEC-

TOR FROM THE CAB VERIFY THAT THE VEHICLE’S

IGNITION IS IN THE OFF OR LOCK POSITION. IF IG-

NITION IS ON WHEN 60 WAY CONNECTOR IS RE-

MOVED

FROM

THE

CAB

DAMAGE

TO

THE

CONTROLLER COULD OCCUR.

(3) Loosen bolt (Fig. 2) retaining the wiring har-

ness 60 way connector to the CAB. Then disconnect

the 60 way connector (Fig. 2) from the CAB by pull-

ing it straight out, do not twist connector when re-

moving.

(4) Remove the 2 bolts (Fig. 3) attaching the CAB

module mounting bracket, to the frame rail of the ve-

hicle.

(5) Remove the CAB and its mounting bracket as

an assembly from the vehicle from the vehicle.

(6) Remove the 3 screws (Fig. 4) attaching the

CAB to the CAB mounting bracket. Then separate

CAB from mounting bracket.

Fig. 11 Vacuum Reservoir Installation And

Attaching Bolts

Fig. 12 Battery Tray Access Shield Installed

Fig. 13 Battery Hold Down Clamp And Heat Shield

Installed

Fig. 1 CAB Location

Ä

ANTILOCK 4 BRAKE SYSTEM

5 - 41

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст