Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 223

removal will be necessary. Remove the shoe and lin-

ing assemblies (see Brake Shoe Removal).

Combined shoe and lining thickness should be

measured at the thinnest part of the assembly.

When a shoe and lining assembly is worn to a

thickness of approximately 7.0 mm (9/32 inch) it

should be replaced.

Replace both shoe assemblies (inboard and out-

board) on both wheels whenever shoe assemblies on

either side are replaced.

If a shoe assembly does not require replacement.

Reinstall it, making sure each shoe assembly is re-

turned to its original position on the wheel of the ve-

hicle from which it was removed. (See Brake Shoe

Installation).

SERVICE PRECAUTIONS

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS CAN

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS

AND

CANCER.

EXTREME

CARE

SHOULD

BE

EXERCISED

WHILE

SERVICING

BRAKE ASSEMBLIES OR COMPONENTS.

DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH.

DO NOT CREATE DUST BY SANDING, GRINDIN-

G,AND/OR SHAVING BRAKE LININGS OR PADS

UNLESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT.

DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS.

FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS.

IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

Grease or any other foreign material must be kept

off the caliper assembly, surfaces of the braking disc

and external surfaces of the hub, during service pro-

cedures.

Handling the braking disc and caliper should be done

in such a way as to avoid deformation of the disc and

scratching or nicking the brake linings (pads).

During removal and installation of a wheel and tire

assembly, use care not to strike the caliper.

Before vehicle is moved after any brake service

work, be sure to obtain a firm brake pedal.

BRAKE SHOE REMOVAL

(1) Raise vehicle on jackstands or centered on a

hoist.

(2) Remove rear wheel and tire assemblies.

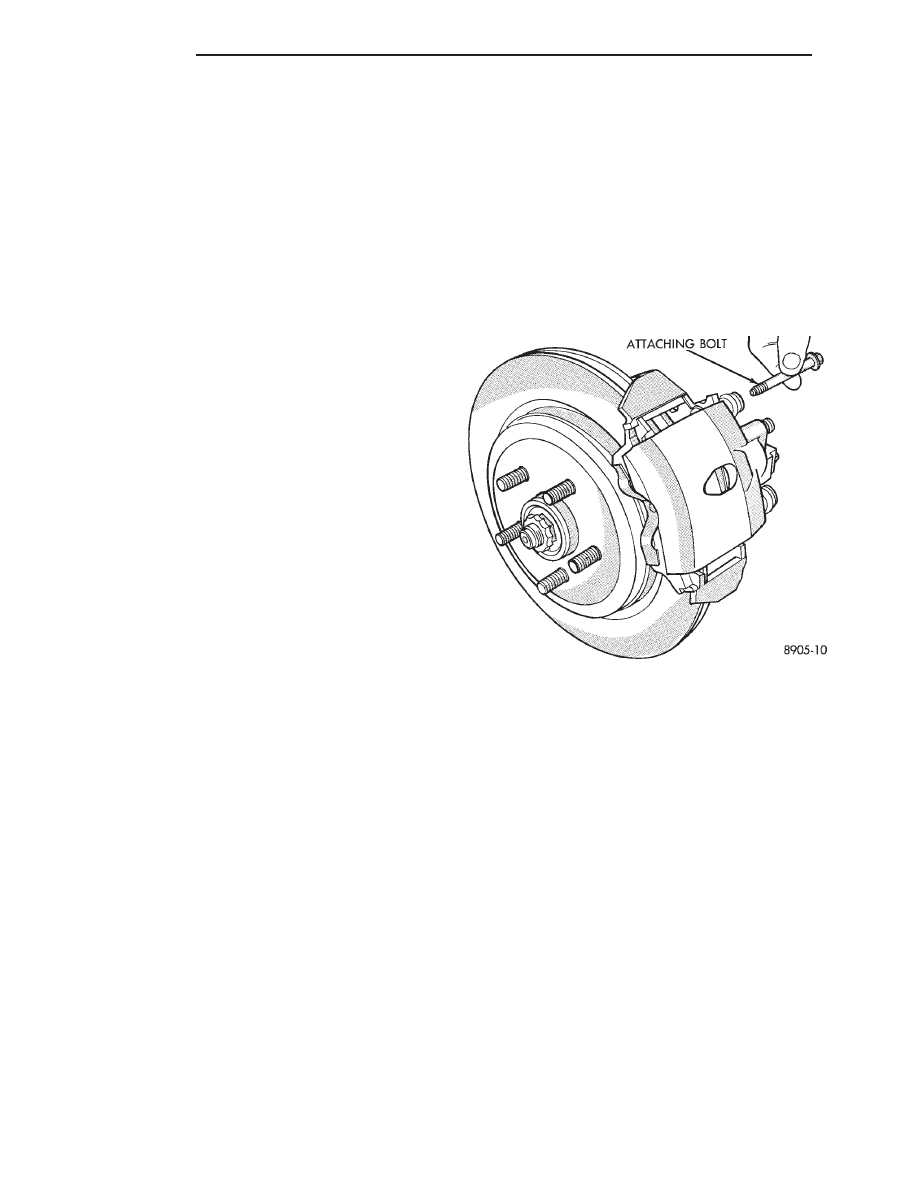

(3) Remove caliper attaching bolts (Fig. 2).

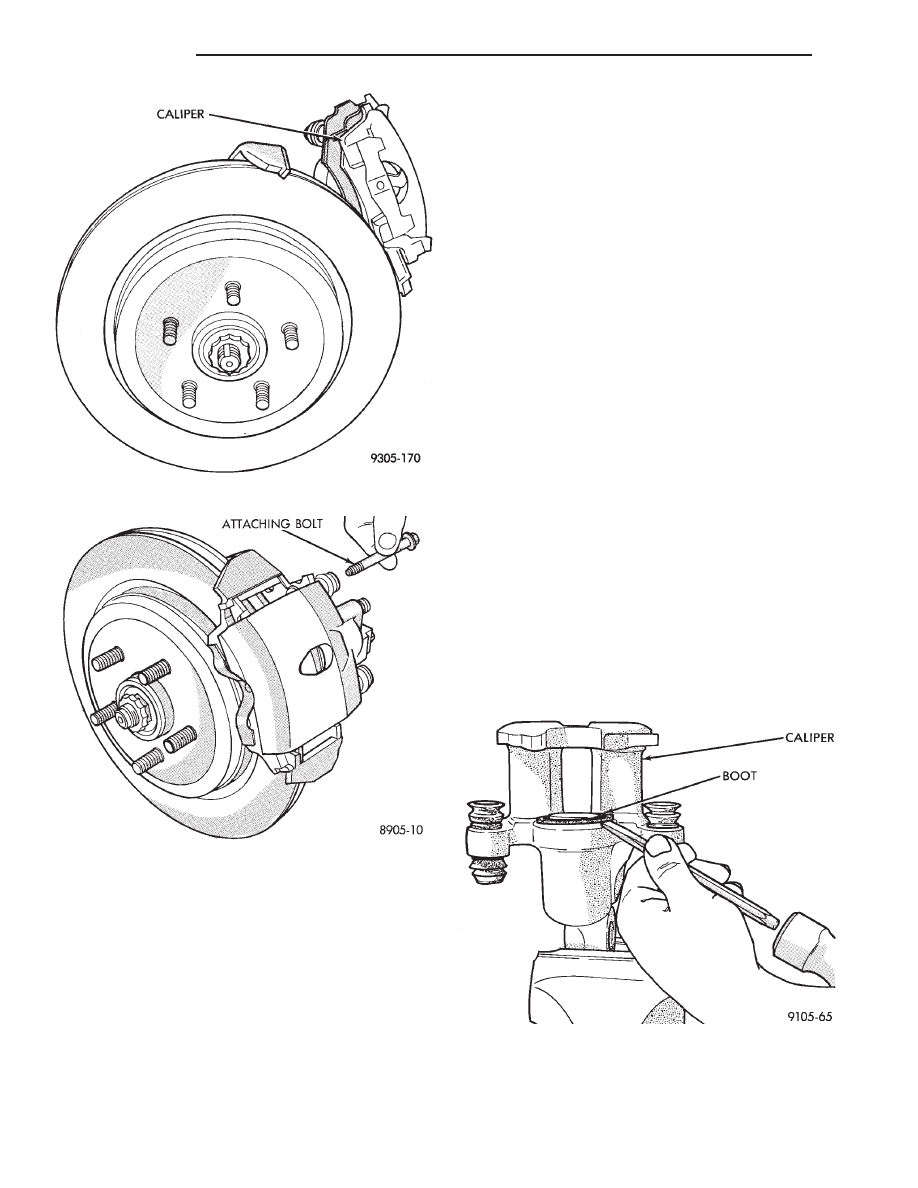

(4) Lift caliper away from adapter rails (Fig. 3).

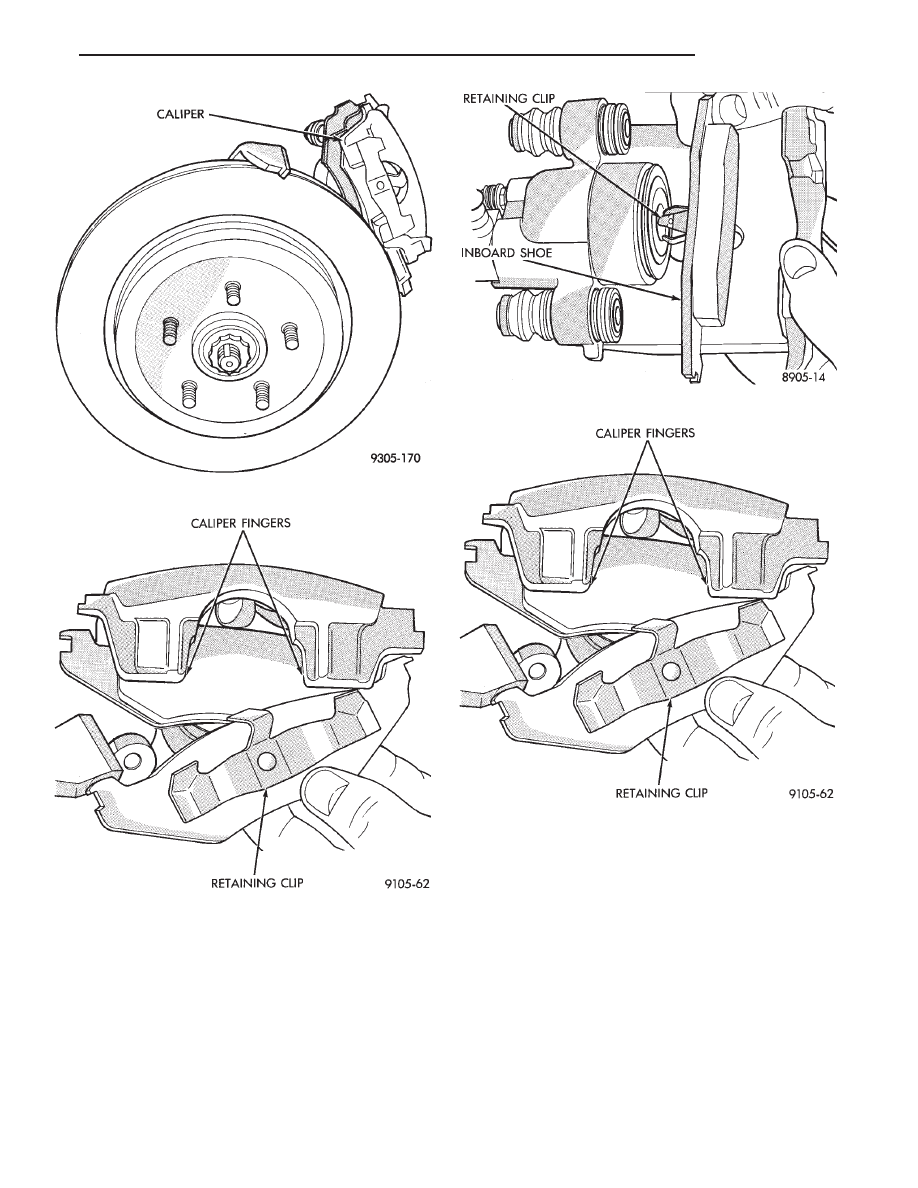

(5) Remove outboard shoe. By prying the shoe re-

taining clip over the raised area on the caliper. Then

slide the shoe down and off the caliper (Fig. 4).

(6) Pull inboard shoe away from piston, until the

retaining clip is free from the cavity in the piston. (Fig.

5).

CLEANING AND INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If the boot is damaged, or

fluid leak is visible, disassemble caliper assembly and

install a new seal and boot (and piston if scored). Refer

to procedure titled Disc Brake Caliper Disassembly.

BRAKE SHOE INSTALLATION

(1) Retract piston.

If the originally removed brake shoe assem-

blies are to be replaced back on vehicle. Be sure

Fig. 2 Removing Caliper Attaching Bolts

5 - 46

BRAKES

Ä

each brake shoe assembly is returned to its origi-

nal position on the wheel of the vehicle from

which it was removed.

(2) Install inboard brake shoe by inserting shoe

retaining clip into piston cavity. Be sure brake shoe is

seated squarely on the face of the piston. (Fig. 5).

(3) Install outboard shoe by sliding retaining clip

over caliper fingers. Be sure the brake shoe is installed

on the caliper, so the retaining clip is past the raised

area on the caliper fingers (Fig. 6).

(4) Install lower end of caliper on to adapter. Make

sure the lower tabs on the brake shoes and the cast-

ing projections on the caliper are under the adapter

rail (Fig. 7).

(5) Rotate caliper down over rotor.

(6) Install caliper attaching bolts and tighten to 22

N

Im (193 in. lbs.) torque (Fig. 8).

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification.

(8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal.

Fig. 5 Remove and Install Inboard Brake Shoe

Fig. 6 Installing Outboard Shoe

Fig. 3 Removing Caliper

Fig. 4 Removing Outboard Shoe

Ä

BRAKES

5 - 47

DISASSEMBLING REAR CALIPER ASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or

fluid leak is visible, disassemble caliper assembly

and install a new seal and boot,(and piston if scored).

Refer to procedures titled Disc Brake Caliper Disas-

sembly.

Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition. Re-

place if they are damaged, dry, or found to be brittle.

Refer to Cleaning And Inspection Of Brake Caliper.

(1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 4 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers.

(2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder.

(3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Support rear caliper assembly in a vise. Then remove

caliper to piston dust boot and discard (Fig. 1).

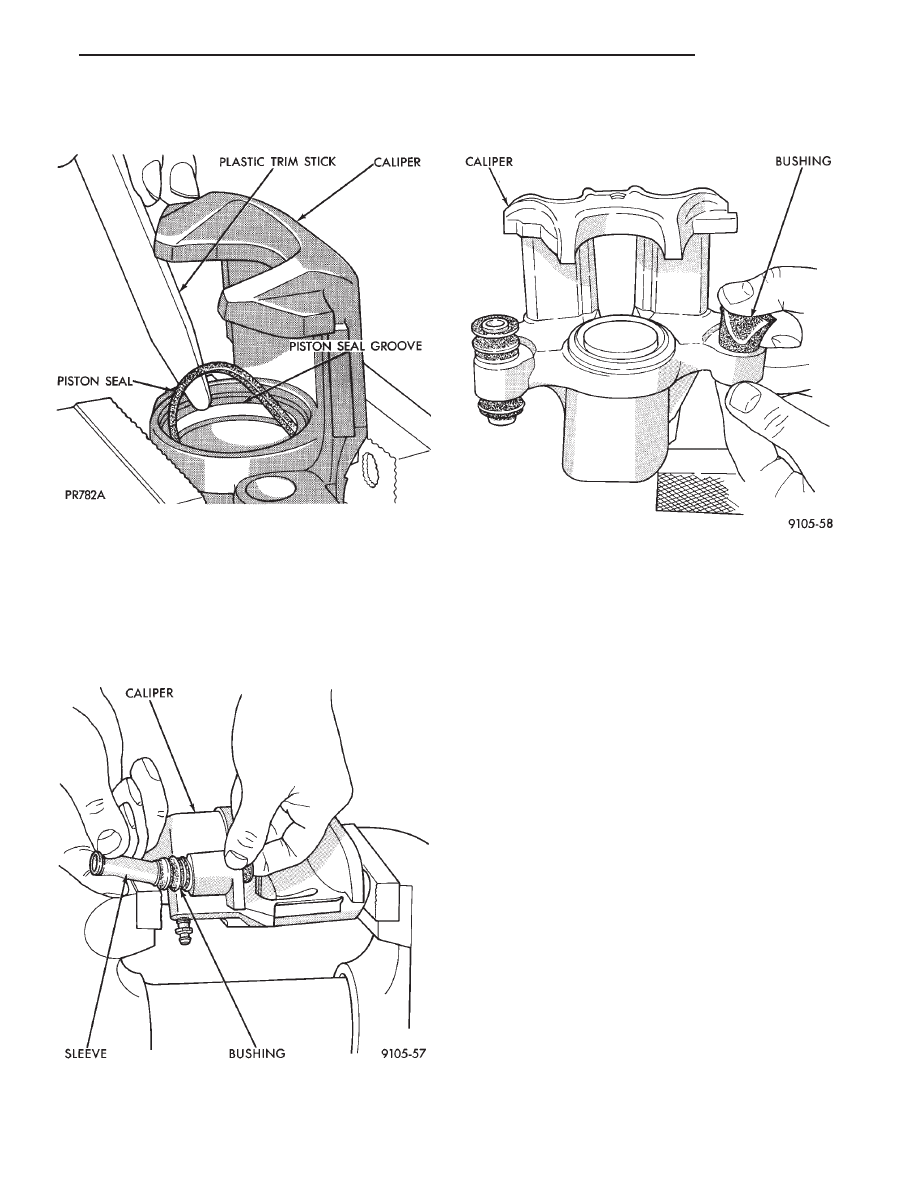

Using a plastic trim stick, work piston seal out of its

groove in caliper piston bore (Fig. 2). Discard old seal.

Do not use a screwdriver or other metal

Fig. 7 Installing Caliper

Fig. 8 Installing Attaching Bolts

Fig. 1 Removing Piston Dust Boot

5 - 48

BRAKES

Ä

tool for this operation, because of the possibility

of scratching piston bore or burring edges of seal

groove.

The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure.

(1) Using your fingers push on one end the inner

sleeve until it pops out of the bushing. Then grasp the

inner sleeve with your fingers and pull the inner sleeve

out from the inside of the bushing (Fig. 3).

(2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the caliper assembly (Fig. 4).

CLEANING AND INSPECTION

Clean all parts using alcohol or a suitable solvent

and wipe dry. Clean out all drilled passages and bores

on the caliper assembly body. (Whenever a caliper

has been disassembled, a new boot and seal must

be installed at assembly).

Inspect the caliper assembly piston bore for scoring

or pitting. Bores that show light scratches or corrosion,

can usually have the scratches or corrosion removed

using crocus cloth.

Bores that have deep scratches or scoring should be

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5).

If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored.

When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush.

Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

ASSEMBLING REAR DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve From Bushing

Fig. 4 Removing Bushings From Caliper

Ä

BRAKES

5 - 49

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст