Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 77

Fig.

1

Alignment

Camber/T

oe

2 - 6

SUSPENSION AND DRIVESHAFTS

Ä

WHEEL ALIGNMENT SERVICE PROCEDURE

CAMBER AA, AJ BODIES

(1) Prepare vehicle as described in the Pre-Align-

ment procedure.

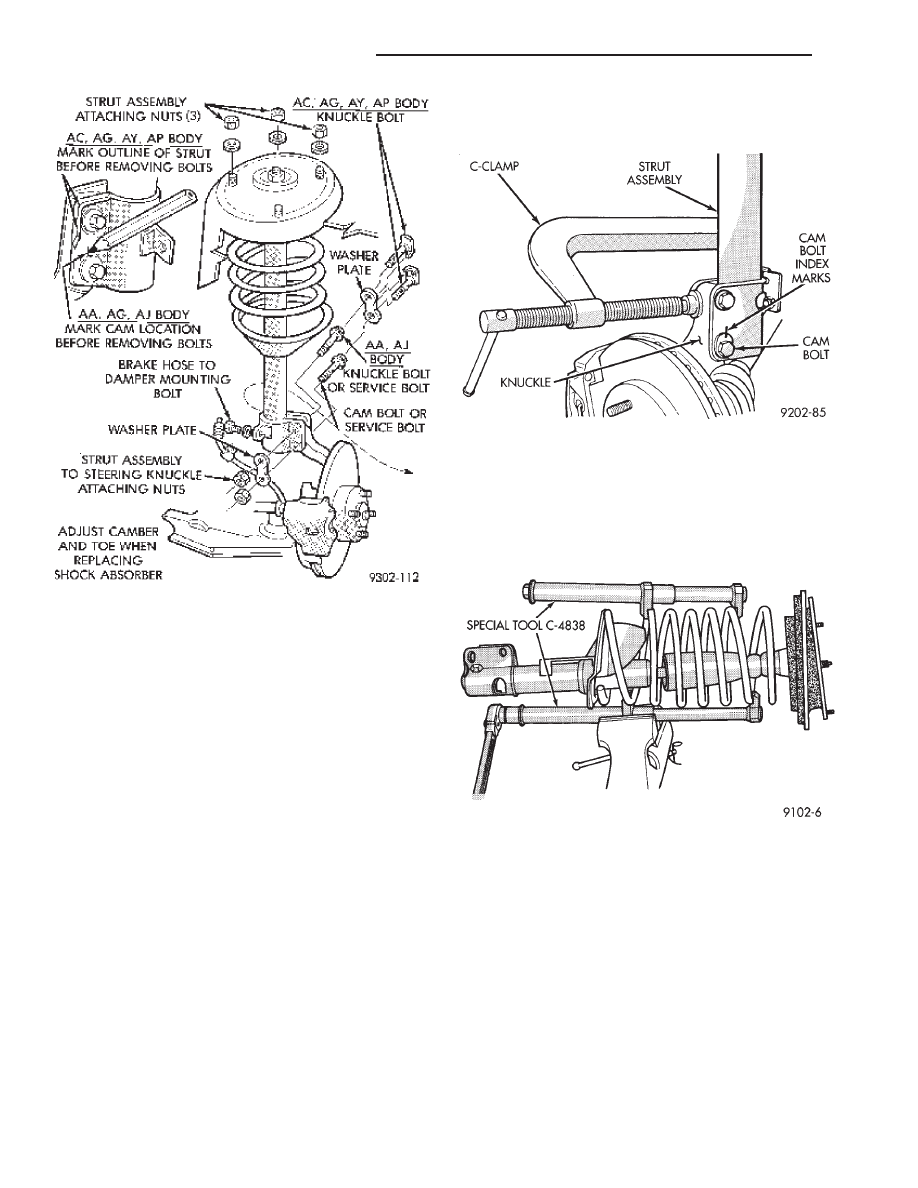

(2) Loosen cam and knuckle bolts (each side) (Fig.

2).

(3) Rotate cam bolt (Fig. 2) to move top of wheel in

or out to specified camber.

(4) Tighten the cam bolts and nuts to 100 N

Im (75

ft. lbs.) plus 1/4 turn beyond specified torque.

CAMBER AC, AG, AP, AY BODIES

(1) Prepare vehicle as described in the Pre-Align-

ment procedure.

(2) Position vehicle on alignment equipment and

read camber as instructed by equipment manufactur-

er’s procedure.

(3) Using extensions and appropriate tools. Re-

move the strut assembly to steering knuckle attach-

ing bolts from vehicle (Fig. 2). Replace the original

attaching bolts with the bolts provided in the align-

ment, Cam And Bolt Service Package.

(4) Rotate the alignment adjusting cam bolt, (Fig.

2) to obtain the specified camber setting for the ve-

hicle. See the Specifications Section at the end of this

group for the camber setting for the vehicle being

serviced.

(5) Using the appropriate extensions and tools.

Carefully reach around the tire and tighten the

knuckle bolts enough to hold the camber setting.

Finish by tightening the bolts to 100 N

Im (75 ft.lbs.)

plus 1/4 turn beyond specified torque.

TOE

(1) Prepare vehicle as described in the Pre-Align-

ment procedure.

(2) Center steering wheel and hold with steering

wheel clamp.

(3) Loosen tie rod locknuts. Rotate rods to align toe

to specifications (Fig. 3).

CAUTION: Do not twist tie rod to steering gear rub-

ber boots during adjustment.

(4) Tighten tie rod locknuts to 75 N

Im (55 ft.lbs.)

torque.

(5) Adjust steering gear to tie rod boots at tie rod.

(6) Remove steering wheel clamp.

STRUT DAMPER ASSEMBLY

REMOVAL

(1) Loosen wheel nuts.

(2) Raise vehicle, see Hoisting in Lubrication and

Maintenance, Group 0.

(3) Remove wheel and tire assembly.

Where service procedure includes assembly of

original

strut

(shock

absorber)

to

original

knuckle. Mark cam adjusting bolt (Fig. 4), on

AA, and AJ bodies only. Mark outline of strut

on knuckle as shown in (Fig. 1). on AC, AG, AP

and AY bodies.

(4) Remove cam bolt, knuckle bolt(s), washer

plate(s) and brake hose to damper bracket retaining

screw (Fig. 4).

(5) Remove strut damper to fender shield mount-

ing nut washer assemblies.

Fig. 2 Alignment Adjustment Locations

Fig. 3 Front Wheel Toe Adjustment

Ä

SUSPENSION AND DRIVESHAFTS

2 - 7

INSPECTION

Inspect for evidence of fluid running from the up-

per end of the reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage be-

tween the strut rod and strut shaft seal is not un-

usual and does not affect performance of the strut

assembly.

INSTALLATION

(1) Install unit into fender reinforcement and in-

stall retaining nuts and washer assemblies (Fig. 1).

Tighten the 3 nuts to 27 N

Im (20 ft. lbs.) torque.

(2) Position steering knuckle neck into strut as-

sembly. Position washer plate and install cam and

knuckle bolts (Fig. 4).

(3) Attach brake hose retainer to damper, tighten

the screw to 13 N

Im (10 ft. lbs.) torque (Fig. 4).

(4) Index strut to original outline on the knuckle

neck, or align mark on cam bolt with the mark that

was put on the strut to steering knuckle bracket

(Fig. 4).

(5) Place a 4 inch (or larger) C clamp on the strut

and knuckle as shown in (Fig. 5). Tighten the clamp

just enough to eliminate any looseness between the

knuckle and the strut. Check alignment of the index

marks and tighten the bolts to 100 N

Im (75 ft. lbs.)

plus 1/4 turn beyond specified torque. Remove the

(C) clamp.

(6) Install wheel and tire assembly. Tighten the

wheel nuts to 129 N

Im (95 ft. lbs.) torque.

DISASSEMBLY (STRUT DAMPER)

(1) Compress front coil spring with Spring Com-

pressor, Special Tool C-4838 (Fig. 6).

(2) Hold end of strut shaft from rotating with

wrench, while loosening strut shaft nut. Remove nut

from shaft (Fig. 7).

(3) Remove the upper strut mount from the strut

assembly.

(4) Remove coil spring from the strut assembly.

Mark spring for installation back on the same

side of the vehicle (Fig. 11).

CAUTION: see Suspension Coil Springs before re-

leasing coil from Tool C-4838.

(5) Inspect strut damper, mount assembly (Fig. 8)

for:

Fig. 4 Strut Damper Removal

Fig. 5 Strut Damper Installation

Fig. 6 Compressing Coil Spring

2 - 8

SUSPENSION AND DRIVESHAFTS

Ä

(a) Severe deterioration of rubber isolator; re-

tainers for cracks and distortion and bond failure of

retainers and rubber isolators.

(b) Bearings for binding.

(c) Shock Absorber for flat spots over full stroke

also see, Shock Absorbers, (strut damper).

ASSEMBLE (STRUT DAMPER)

(1) Mount the strut assembly in a vertical position.

(2) Place the compressed spring onto the strut as-

sembly, so the end of the coil is seated in the seat re-

cess in lower spring mount (Fig. 9).

(3) Install the dust shield, isolator (if so equipped)

jounce bumper, spacer (as required), and spring seat

onto the top of the strut shaft (Fig. 8).

(4) Position top spring seat alignment tab correctly

with respect to bottom bracket (Fig. 9).

(5) Install the rebound retainer and shaft nut (Fig.

8).

(6) Tighten the strut shaft nut using, Strut Rod

Socket And Holder, Special Tool L-4558. Torque strut

shaft nut to 75 N

Im (55 ft. lbs.) plus 1/4 turn (Fig. 10).

WARNING: THIS STEP MUST BE DONE BEFORE

SPRING COMPRESSOR, SPECIAL TOOL C-4838 IS

RELEASED FROM THE COIL SPRING.

(7) Verify coil spring is aligned correctly with respect

to bottom bracket (Fig. 9).

(8) Release Spring Compressor Tool C-4838.

SUSPENSION COIL SPRINGS

Springs are rated separately for each side of vehicle

depending on optional equipment and type of service.

During service procedures where both springs are

removed, mark springs (Chalk, Tape, etc.) (Fig. 11) to

ensure installation in original position. If the coils

springs require replacement. Be sure that the

springs needing replacement, are replaced with

springs meeting the correct load rating for the

vehicle and its specific options.

During service procedures requiring the re-

moval or installation of a coil spring with Spring

Fig. 7 Loosening Strut Assembly Shaft Nut

Fig. 8 Mount Assembly

Fig. 9 Spring Seat Alignment Notch Position to

Bracket

Fig. 10 Tighten Strut Rod Nut with Tool

Ä

SUSPENSION AND DRIVESHAFTS

2 - 9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст