Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 218

HYDRAULIC SYSTEM CONTROL VALVES

INDEX

page

page

ABS Brake Proportioning Valve Operation

. . . . . . 27

General Information

. . . . . . . . . . . . . . . . . . . . . . . 26

Hydraulic System Service Procedures

. . . . . . . . . 27

Non-ABS Proportioning Unit Operation

. . . . . . . . 26

Pressure Differential Warning Light Switch

. . . . . . 26

Testing ABS Proportioning Valves

. . . . . . . . . . . . 29

GENERAL INFORMATION

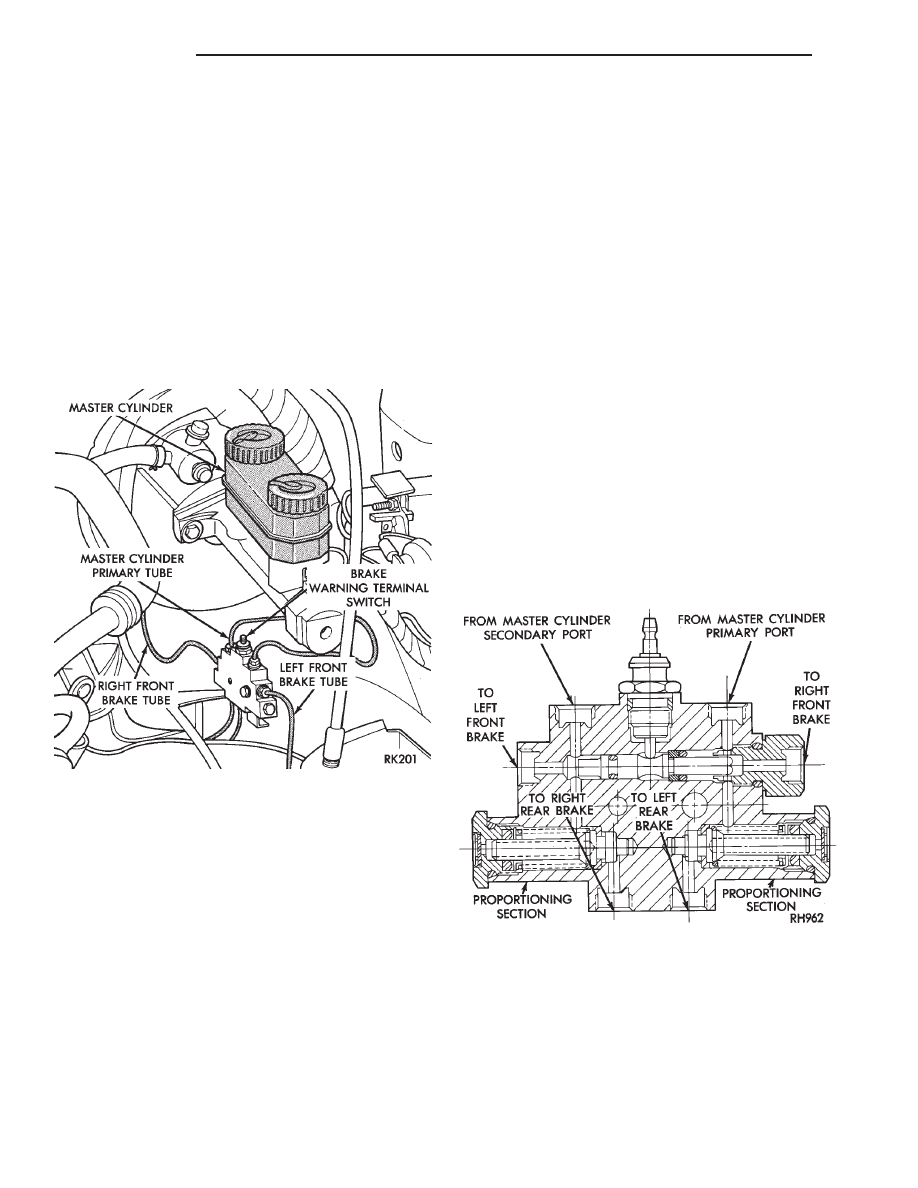

Most models not equipped with an Anti-Lock brak-

ing system have a combination hydraulic system con-

trol valve in the brake hydraulic system (Fig. 1). The

valve is attached to the frame rail below the master

cylinder.

The control valve assembly combines a warning

switch with a dual proportioning valve (Fig. 2)

Proportioning valves balance front to rear braking

by controlling at a given ratio, the increase in rear

system hydraulic pressure above a preset level. Un-

der light pedal application, the valve allows full hy-

draulic pressure to the rear brakes.

There is only one valve assembly in each vehicle,

see Valve Application Chart. During any service pro-

cedures identify valve assemblies by part number as

well as split point (PSI) and slope.

PRESSURE DIFFERENTIAL WARNING LIGHT

SWITCH

The hydraulic brake system, on non-ABS vehicles,

is split diagonally. The left front and right rear

brakes are part of one system. And the right front

and left rear are part of another. Both systems are

routed through, but hydraulically separated by a Pres-

sure Differential Switch. The function of the Pressure

Differential Switch is to alert the driver of a malfunc-

tion in the brake system.

If hydraulic pressure is lost in one system, the

warning light switch will activate a red light on the

instrument panel, when the brake pedal is depressed.

At this point the brakes require service. However, since

the brake systems are split diagonally the vehicle will

retain 50% of its stopping capability in the event of a

failure in either half.

The warning light switch is the latching type. It

will automatically center itself after the repair is

made and the brake pedal is depressed.

The instrument panel bulb can be checked each time

the ignition switch is turned to the start position or the

parking brake is set.

NON-ABS PROPORTIONING UNIT OPERATION

The proportioning valve section operates by trans-

mitting full input pressure to the rear brakes up to a

certain point. This is called the split point. Beyond this

point it reduces the amount of pressure increase to the

rear brakes according to a certain ratio.

On light pedal applications equal brake pressure will

be transmitted to the front and rear brakes. On heavier

pedal

applications

the

pressure

transmitted

Fig. 1 Brake Combination Valve And Warning

Switch Location

Fig. 2 Switch and Valve Assembly

5 - 26

BRAKES

Ä

to the rear will be lower than the front brakes. This will

prevent premature rear wheel lock-up and skid. If

hydraulic pressure is lost in one half of the diagonally

split system, the operation of the proportioning valve

in the remaining half is not effected.

ABS BRAKE PROPORTIONING VALVE OPERATION

On vehicles using the ABS braking system, screw in

proportioning valves are used in place of the conven-

tional differential pressure/proportioning valve.

Each rear brake circuit has its own screw-in propor-

tioning valve which is attached to the rear brake outlet

ports of the hydraulic assembly. These valves limit

brake pressure to the rear brakes after a certain

pressure is reached. This improves front to rear brake

balance during normal braking.

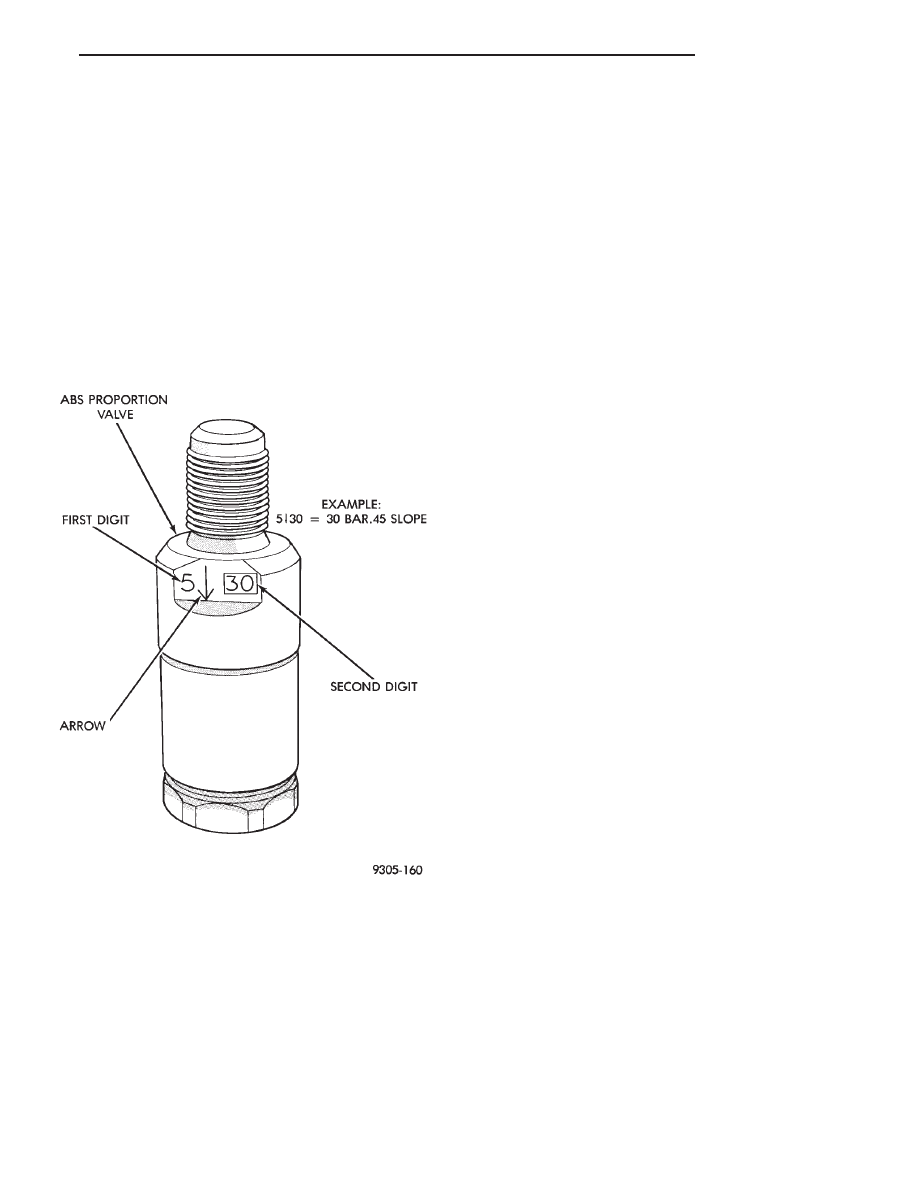

Screw in proportioning valves can be identified by

the numbers stamped on the body of the valve. The

first digit represents the slope, the second digit repre-

sents the split (cut-in) point, and the arrow represents

the flow direction of the valve. Be sure that the

numbers listed on the replacement valve are the

same as on the valve that is being removed. See

(Fig. 3) for detail of the valve identification.

HYDRAULIC SYSTEM SERVICE PROCEDURES

BRAKE WARNING SYSTEM

CHECKING BRAKE WARNING SWITCH UNIT

The Red Brake Warning light will come on when

the parking brake is applied with the ignition key

turned ON. The same light will also illuminate

should one of the two service brake hydraulic sys-

tems fail.

CAUTION:Make sure air does not enter the hydrau-

lic system during this test procedure. See bleeding

without a pressure bleeder at the beginning of this

section for master cylinder fluid level checking pro-

cedures.

To test the service brake warning system lamp.

Raise the vehicle on a hoist and open a wheel cylin-

der bleeder while a helper depresses the brake pedal

and observes the warning light.

If the light fails to light, inspect for a burned out

bulb, disconnected socket, or a broken or discon-

nected wire at the switch. If the bulb is not burned

out and the wire continuity is uninterrupted. Check

the service brake warning switch operation with a

test lamp between the switch terminal and a known

good ground. Be sure to fill master cylinder and

bleed brake system after correction has been made, if

necessary.

PROPORTIONING VALVES

TESTING PROPORTIONING VALVE UNIT

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with the proportioning valve unit.

The proportioning valve is designed with two sep-

arate systems. One half controls the right rear

brake, and the other half controls the left rear brake.

Therefore, a road test to determine which rear brake

slides first is essential.

RIGHT REAR WHEEL SLIDES FIRST

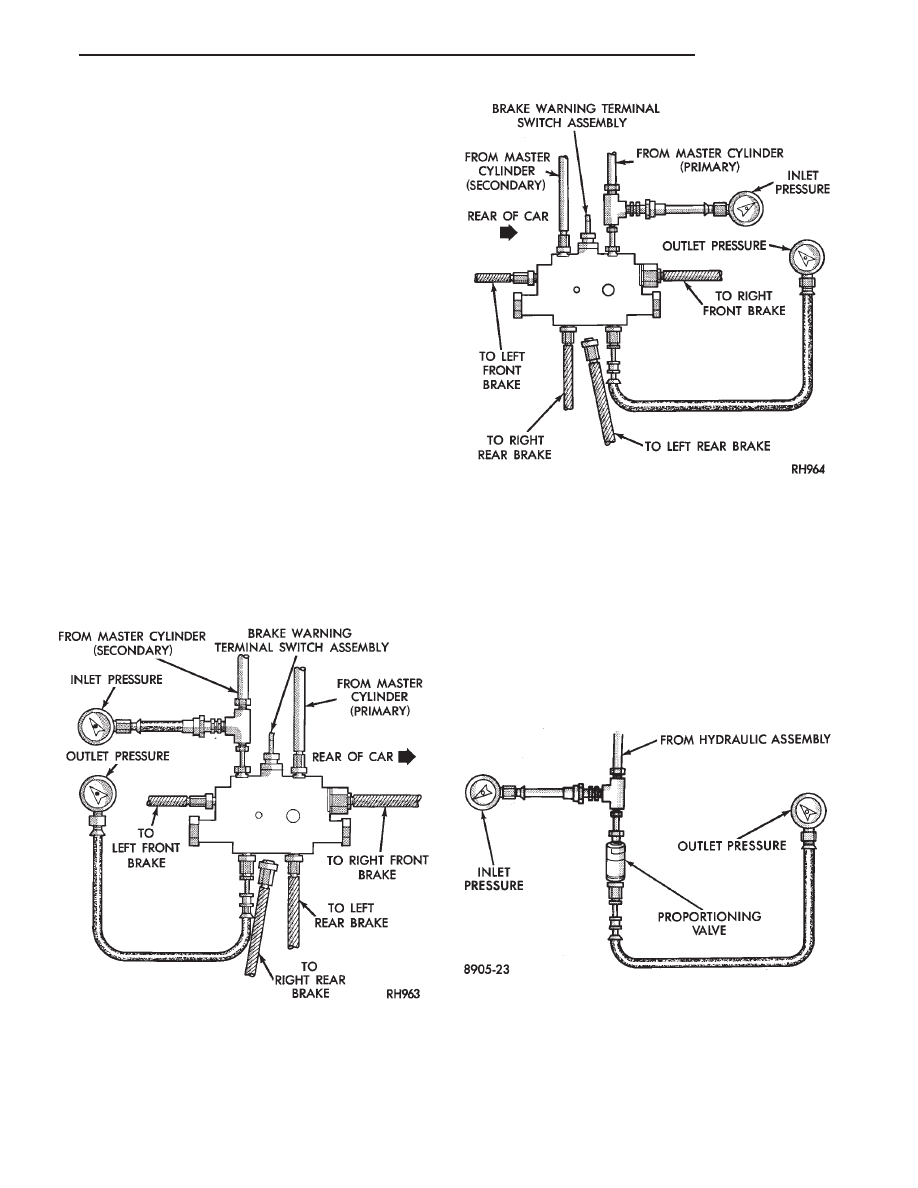

To test the proportioning valve when the right rear

wheel slides first, leave the front brakes connected to

the valve, proceed as follows:

(1) Install one gauge and (TEE) of set C-4007-A

between the brake line from the master cylinder sec-

ondary port and the brake valve assembly.

(2) Install the second gauge of set C-4007-A to the

right rear brake outlet port (Fig. 4). Using an

adapter tube, made from a short piece of brake tube

and (2) 3/8 x 24 tube nuts. Connect the hose to the

valve. Bleed the hose and gauge.

(3) Have a helper exert pressure on the brake

pedal (holding pressure) to get a reading on the valve

inlet gauge and check the reading on the outlet

Fig. 3 ABS PROPORTIONING VALVE IDENTIFICA-

TION

Ä

BRAKES

5 - 27

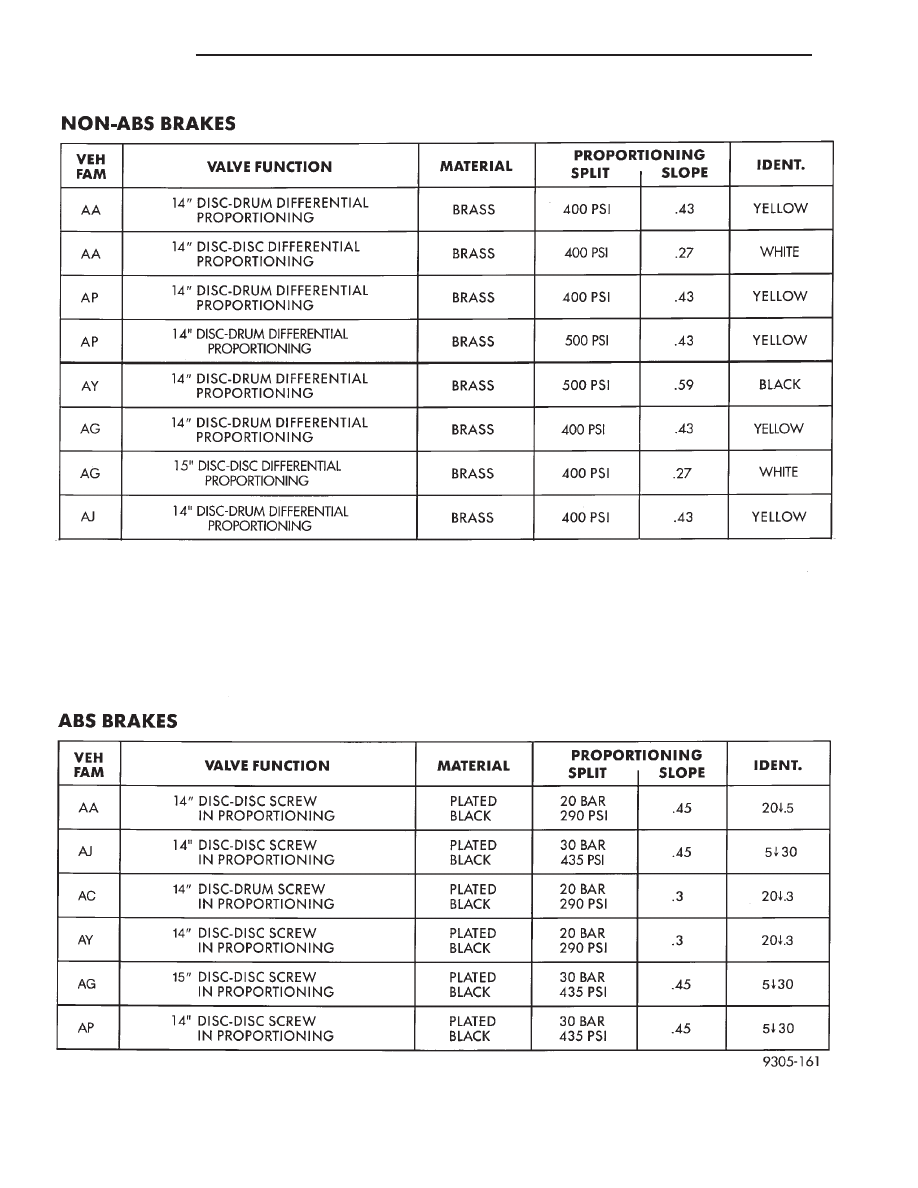

PROPORTIONING VALVE APPLICATIONS

5 - 28

BRAKES

Ä

gauge. If the inlet and outlet pressures do not agree

with the values on the following chart, replace the

valve.

LEFT REAR WHEEL SLIDES FIRST

To test the proportioning valve when the left rear

wheel slides first, leave the front brakes connected to

the valve, proceed as follows:

(1) Install one gauge and (TEE) of set C-4007-A

between brake line from the master cylinder primary

port and the brake valve assembly.

(2) Install the second gauge of set C-4007-A to the

left rear brake outlet port (Fig. 5). An adapter tube,

made up from a 7/16 x 24 tube nut, a short piece of

brake tube and 3/8 x 24 tube nut. Will be required to

connect the hose to the valve. Bleed the gauge and

hose.

(3) Have a helper exert pressure on the brake

pedal. Hold pressure steady to get a reading on the

valve inlet gauge and check the reading on the outlet

gauge. If the inlet and outlet pressures do not agree

with the values on the following chart, replace the

valve.

TESTING ABS PROPORTIONING VALVES

All ABS components use an ISO type tubing flare.

Use the correct adapters with ISO type tubing flares

when installing gauges to test ABS proportioning

valves.

(1) Install one gauge and (TEE) between the hy-

draulic assembly and the male end (Inlet) of the

valve.

(2) Install the second gauge at the female end

(Outlet) of the valve (Fig. 6).

(3) Have a helper exert pressure on the brake

pedal (holding pressure) to get a reading on the valve

inlet gauge.

(4) Check the reading on the outlet gauge. If the

inlet and outlet pressures do not agree with the fol-

lowing chart, replace the valve. See (Fig. 3) for pro-

portioning valve identification.

Fig. 4 Tube Connection for Right Rear Skidding

Fig. 5 Tube Connection for Left Rear Skidding

Fig. 6 Tube Connections for ABS

Ä

BRAKES

5 - 29

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст