Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 10

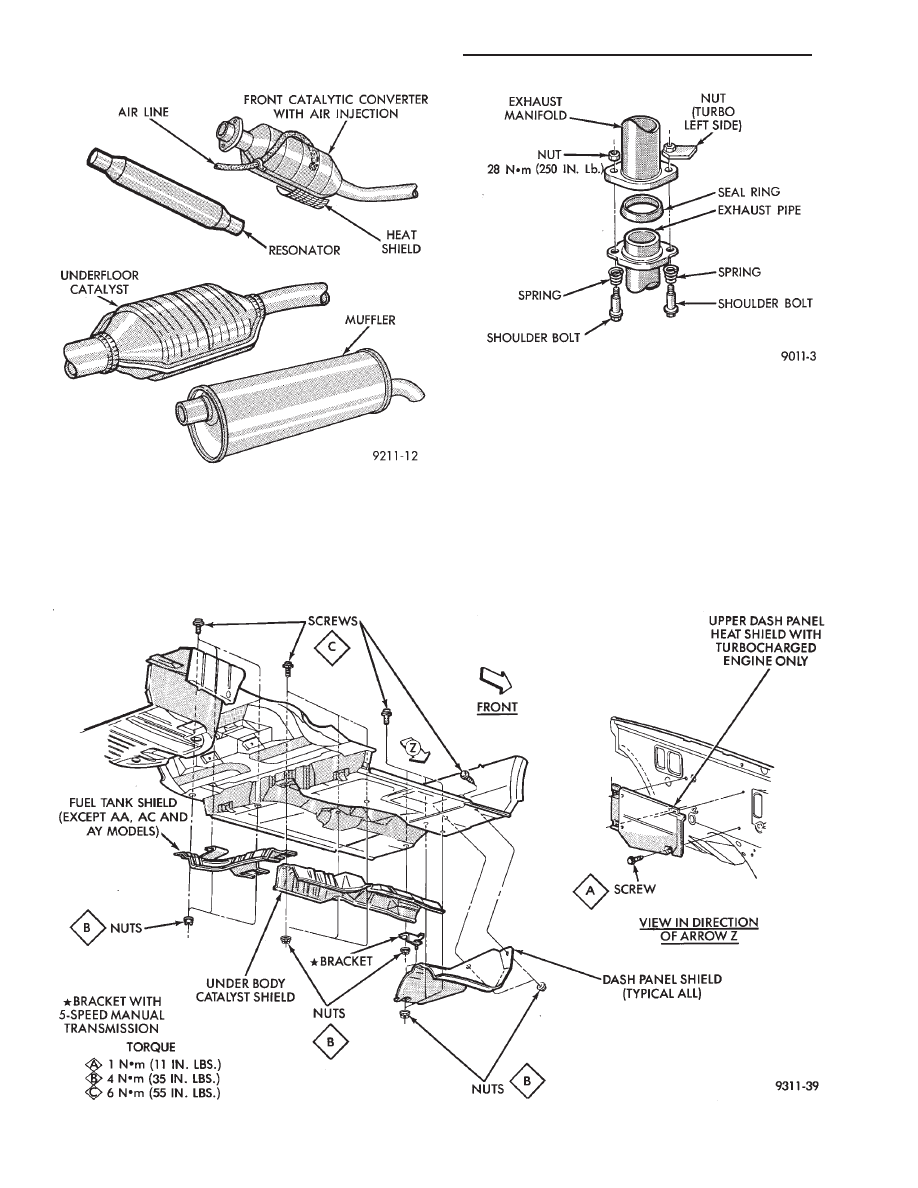

HEAT SHIELDS

Heat shields (Fig. 4) are needed to protect both the

car and the environment from the high temperatures

developed in the vicinity of the catalytic converters.

2.2/2.5L engines equipped with manual transmission

where air is injected into the catalytic converter’s, a

heat shield is welded on the lower bottom of the front

converter.

Refer to Body and Sheet Metal, Group 23 for ser-

vice procedures.

Fig. 3 Ball Joint Connection

Fig. 4 Heat Shield Installation

Fig. 2 Exhaust System Components

11 - 2

EXHAUST SYSTEM AND INTAKE MANIFOLD

Ä

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shields on cars if equipped.

Light overspray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

The combustion reaction caused by the catalyst re-

leases additional heat in the exhaust system. Caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency. Do not remove spark

plug wires from plugs or by any other means short

out cylinders if exhaust system is equipped with cat-

alytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by un-

burned fuel passing through the converter.

The use of the catalysts also involves some non-au-

tomotive problems. Unleaded gasoline must be used

to avoid poisoning the catalyst core. Do not allow en-

gine to operate above 1200 RPM in neutral for ex-

tended periods over 5 minutes. This condition may

result in excessive exhaust system/floor pan temper-

atures because of no air movement under the vehicle.

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM

To assist in the control of oxides of nitrogen (NOx)

in engine exhaust, some engines are equipped with

an exhaust gas recirculation system. The use of ex-

haust gas to dilute incoming air/fuel mixtures lowers

peak flame temperatures during combustion, thus

limiting the formation of NOx.

Exhaust gases are taken from openings in the ex-

haust gas crossover passage in the intake manifold.

REFER TO SECTION 25 EMISSION SYSTEMS

FOR A COMPLETE DESCRIPTION, DIAGNOSIS

AND SERVICE PROCEDURES ON THE EXHAUST

GAS RECIRCULATION SYSTEM AND COMPO-

NENTS.

EXHAUST SYSTEM DIAGNOSIS

Ä

EXHAUST SYSTEM AND INTAKE MANIFOLD

11 - 3

SERVICE PROCEDURES

INDEX

page

page

Exhaust Pipes, Mufflers and Tailpipes

. . . . . . . . . . 4

Intake and Exhaust Manifolds Service—TBI Engine

Intake and Exhaust Manifolds—Flexible Fuel Engine

Intake and Exhaust Manifolds—TBI Engine

. . . . . . 5

Intake/Exhaust Manifold Service—3.0L Engine

. . . 13

Intake/Exhaust Manifold Service—3.3/3.8L Engines

Intake/Exhaust Manifolds and Turbocharger

Service—Turbo III Engine

. . . . . . . . . . . . . . . . . . 9

Intake/Exhaust Manifolds Service—Flexible Fuel

Engines

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EXHAUST PIPES, MUFFLERS AND TAILPIPES

REMOVAL

(1) Raise vehicle on hoist and apply penetrating oil

to clamp bolts and nuts of component being removed.

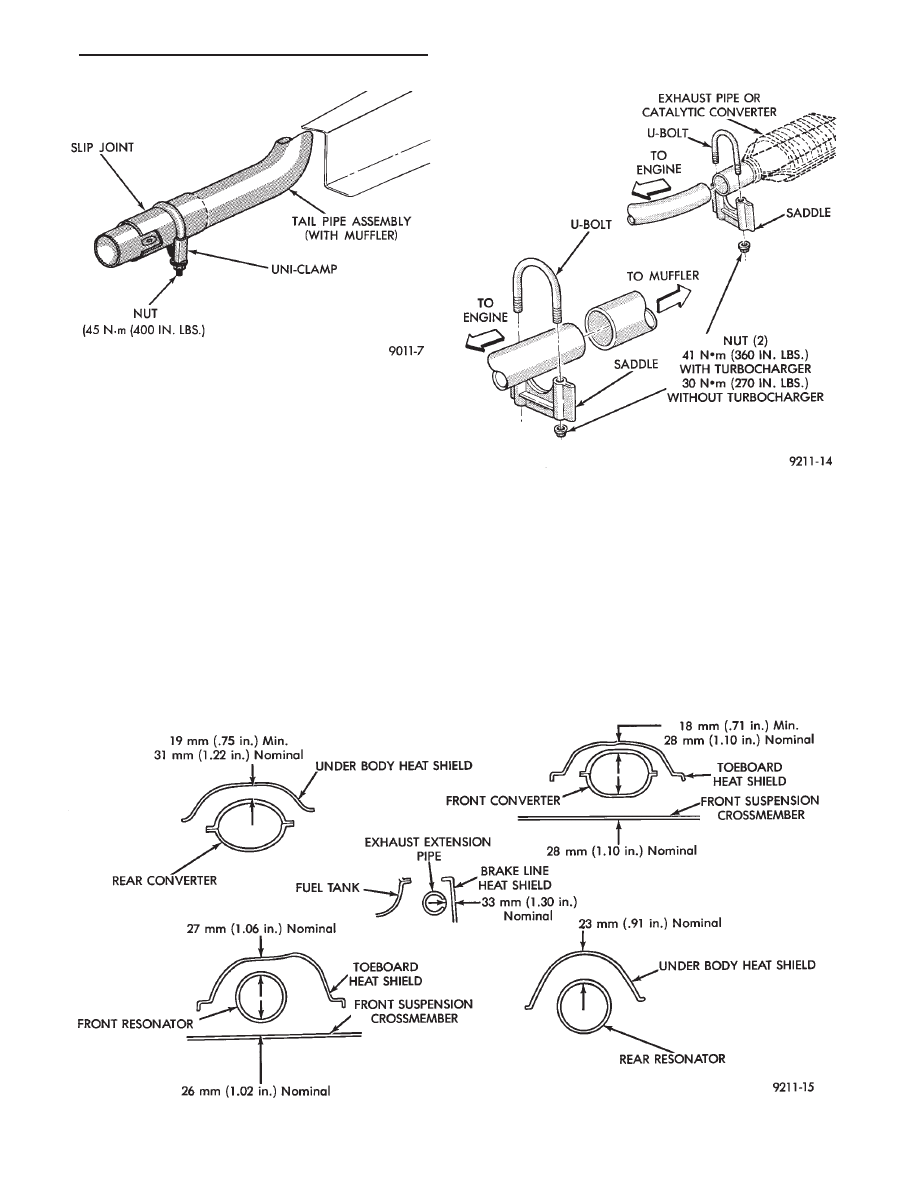

(2) Tail pipes are integral with the muffler (Fig. 5).

Remove clamp at slip joint. Separate at slip joint.

(3) Remove clamps and supports (Figs. 6, 7, 8, and 9)

from exhaust system to permit alignment of parts

during assembly.

(4) When removing tailpipe, raise rear of vehicle to

relieve body weight from rear springs to provide clear-

ance between pipe and rear axle parts.

(5) Clean ends of pipes and/or muffler to assure

mating of all parts. Discard broken or worn insulators,

rusted clamps, supports and attaching parts.

When replacement is required on any compo-

nent of the exhaust system, it is most important

that original equipment parts (or their equiva-

lent) be used;

• To insure proper alignment with other parts in the

system.

• Provide acceptable exhaust noise levels and does not

change exhaust system back pressure that could affect

emissions and performance.

INSTALLATION

(1) Assemble ball joint connection pipes, supports

and clamps loosely to permit alignment of all parts.

Fig. 6 Insulator Tail Pipe and Muffler Support

Fig. 7 Underfloor Converter or Extension Pipe

Support—2 Places

Fig. 5 Tail Pipe with Muffler—Typical

11 - 4

EXHAUST SYSTEM AND INTAKE MANIFOLD

Ä

(2) Beginning at the ball joint, align and torque

shoulder bolts (Fig. 3).

(3) Working from the front of system, align and

clamp each component to maintain position and

proper clearance with underbody parts (Fig. 10).

(4) Tighten all clamps and supports to the proper

torques and clearances.

INTAKE AND EXHAUST MANIFOLDS—TBI ENGINE

INTAKE MANIFOLD

Naturally Aspirated Die-cast aluminum long-

branch fan design with remote plenum. The throttle

body is installed on the upper plenum of the mani-

fold.

EXHAUST MANIFOLD

All high strength iron casting that intermesh with

the intake manifold. For standard engines a four

branch design collects and directs exhaust gases to

the conical (articulated joint connection) outlet.

THROTTLE BODY AIR HEATER

The throttle body air heater (Fig. 1) is attached to

the exhaust manifold and is removable.

Inspect air heater connector tube; replace if dam-

aged. Refer to Emission Control Systems Group 25,

Fig. 9 First Slip Joint Connection

Fig. 10 Exhaust Clearance

Fig. 8 Front Tail Pipe Uni-Clamp

Ä

EXHAUST SYSTEM AND INTAKE MANIFOLD

11 - 5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст