Infiniti FX35 / FX45. Manual — part 332

TROUBLE DIAGNOSIS

EC-89

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction

INFOID:0000000001325927

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the WORK FLOW on “WORK FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A DIAGNOSTIC WORKSHEET like the

example on “DIAGNOSTIC WORKSHEET” should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

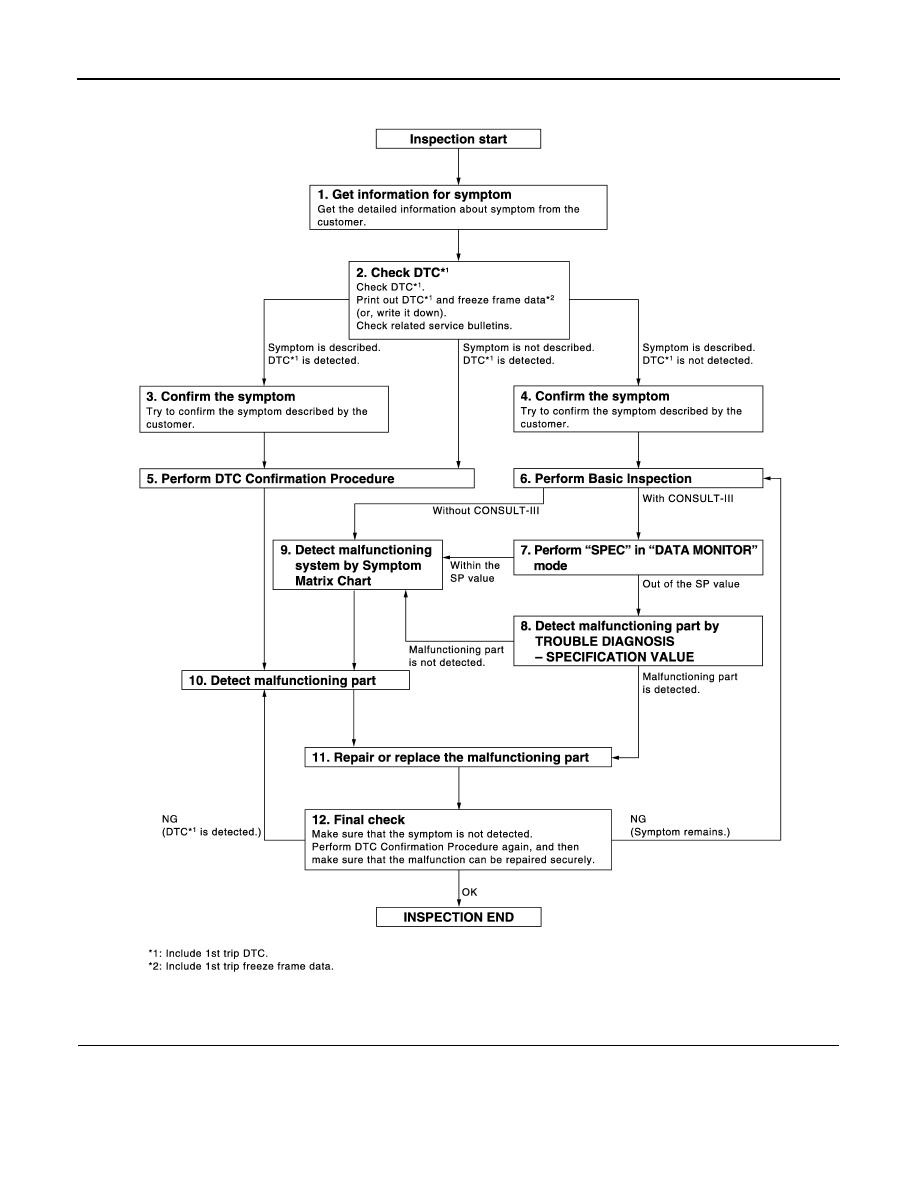

WORK FLOW

MEF036D

SEF233G

SEF234G

EC-90

< SERVICE INFORMATION >

[VQ35DE]

TROUBLE DIAGNOSIS

Overall Sequence

Detailed Flow

1.

GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using the “DIAGNOSTIC WORKSHEET”.

>> GO TO 2.

PBIB3637E

TROUBLE DIAGNOSIS

EC-91

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

CHECK DTC*

1

1.

Check DTC*

1

.

2.

Perform the following procedure if DTC*

1

is displayed.

-

Record DTC*

1

and freeze frame data*

2

. (Print them out with CONSULT-III or GST.)

-

Erase DTC*

1

. (Refer to

EC-55, "Emission-Related Diagnostic Information"

-

Study the relationship between the cause detected by DTC*

1

and the symptom described by the cus-

tomer. (Symptom Matrix Chart is useful. Refer to

3.

Check related service bulletins for information.

Is any symptom described and any DTC detected?

Symptom is described, DTC*

1

is displayed>>GO TO 3.

Symptom is described, DTC*

1

is not displayed>>GO TO 4.

Symptom is not described, DTC*

1

is displayed>>GO TO 5.

3.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer (except MIL ON).

DIAGNOSIS WORK SHEET is useful to verify the incident.

Connect CONSULT-III to the vehicle and check diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

4.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

DIAGNOSIS WORK SHEET is useful to verify the incident.

Connect CONSULT-III to the vehicle and check diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6.

5.

PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure for the displayed DTC*

1

, and then make sure that DTC*

1

is detected

again.

If two or more DTCs*

1

are detected, refer to

EC-93, "DTC Inspection Priority Chart"

diagnosis order.

NOTE:

• Freeze frame data*

2

is useful if the DTC*

1

is not detected.

• Perform Overall Function Check if DTC Confirmation Procedure is not included on Service Manual. This

simplified check procedure is an effective alternative though DTC*

1

cannot be detected during this check.

If the result of Overall Function Check is NG, it is the same as the detection of DTC*

1

by DTC Confirmation

Procedure.

Is DTC*

1

detected?

Yes

>> GO TO 10.

No

>> Check according to

.

6.

PERFORM BASIC INSPECTION

Perform

With CONSULT-III>>GO TO 7.

Without CONSULT-III>>GO TO 9.

7.

PERFORM SPEC IN DATA MONITOR MODE

With CONSULT-III

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL”, and “A/F ALPHA-B1”, “A/F ALPHA-B2” are within the SP

value using CONSULT-III “SPEC” in “DATA MONITOR” mode. Refer to

.

EC-92

< SERVICE INFORMATION >

[VQ35DE]

TROUBLE DIAGNOSIS

Are they within the SP value?

Yes

>> GO TO 9.

No

>> GO TO 8.

8.

DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to

Is malfunctioning part detected?

Yes

>> GO TO 11.

No

>> GO TO 9.

9.

DETECT MALFUNCTIONING SYSTEM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to

based on the confirmed symptom

in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.

DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in

25, "How to Perform Efficient Diagnosis for an Electrical Incident"

Is malfunctioning part detected?

Yes

>> GO TO 11.

No

>> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

EC-127, "CONSULT-III Reference Value in Data Monitor Mode"

11.

REPAIR OR REPLACE THE MALFUNCTIONING PART

1.

Repair or replace the malfunctioning part.

2.

Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3.

Check DTC. If DTC is displayed, erase it, refer to

EC-55, "Emission-Related Diagnostic Information"

>> GO TO 12.

12.

FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*

1

is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK

>> 1.

Before returning the vehicle to the customer, make sure to erase unnecessary DTC*

1

in ECM

and TCM (Transmission Control Module). (Refer to

EC-55, "Emission-Related Diagnostic

AT-38, "OBD-II Diagnostic Trouble Code (DTC)"

.)

2.

If the completion of SRT is needed, drive vehicle under the specific driving pattern. Refer to

EC-55, "Emission-Related Diagnostic Information"

3.

INSPECTION END

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DIAGNOSTIC WORKSHEET

Description

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст