Infiniti FX35 / FX45. Manual — part 344

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-137

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.

CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1.

Start engine.

2.

Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK

>> 1.

Detect malfunctioning part of mass air flow sensor circuit and repair it.

Refer to

.

2.

GO TO 29.

NG

>> GO TO 23.

23.

CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK

>> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and then GO TO 29.

24.

REPLACE ECM

1.

Replace ECM.

2.

Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs.

Refer to

BL-187, "ECM Re-Communicating Function"

3.

4.

EC-85, "Accelerator Pedal Released Position Learning"

5.

EC-85, "Throttle Valve Closed Position Learning"

.

6.

EC-85, "Idle Air Volume Learning"

>> GO TO 29.

25.

CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK

>> GO TO 27.

NG

>> Repair or replace malfunctioning part, and then GO TO 26.

26.

CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK

>> INSPECTION END

NG (Less than the SP value)>>GO TO 27.

27.

CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK

>> GO TO 28.

NG (Less than the SP value)>>Replace mass air flow sensor, and then GO TO 30.

28.

CHECK INTAKE SYSTEM

EC-138

< SERVICE INFORMATION >

[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

• Disconnection, looseness, and cracks in air duct

• Looseness of oil filler cap

• Disconnection of oil level gauge

• Open stuck, breakage, hose disconnection, or cracks of PCV valve

• Disconnection or cracks of EVAP purge hose, open stuck of EVAP canister purge volume control solenoid

valve

• Malfunctioning seal of rocker cover gasket

• Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

• Malfunctioning seal of intake air system, etc.

>> GO TO 30.

29.

CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK

>> INSPECTION END

NG

>> Detect malfunctioning part according to

.

30.

CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and then make sure that the indication is

within the SP value.

OK or NG

OK

>> INSPECTION END

NG

>> Detect malfunctioning part according to

.

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

EC-139

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

Description

INFOID:0000000001325944

Intermittent incidents may occur. In many cases, the malfunction resolves itself (the part or circuit function

returns to normal without intervention). It is important to realize that the symptoms described in the customer's

complaint often do not recur on (1st trip) DTC visits. Realize also that the most frequent cause of Intermittent

incidents occurrences is poor electrical connections. Because of this, the conditions under which the incident

occurred may not be clear. Therefore, circuit checks made as part of the standard diagnostic procedure may

not indicate the specific malfunctioning area.

Common Intermittent Incidents Report Situations

Diagnosis Procedure

INFOID:0000000001325945

1.

INSPECTION START

Erase (1st trip) DTCs. Refer to

EC-55, "Emission-Related Diagnostic Information"

.

>> GO TO 2.

2.

CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection.

Refer to

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace.

3.

SEARCH FOR ELECTRICAL INCIDENT

Perform

GI-25, "How to Perform Efficient Diagnosis for an Electrical Incident"

, “INCIDENT SIMULATION

TESTS”.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace.

4.

CHECK CONNECTOR TERMINALS

Refer to

GI-22, "How to Check Terminal"

, “HOW TO PROBE CONNECTORS”, “How to Check Enlarged Con-

tact Spring of Terminal”.

OK or NG

OK

>> INSPECTION END

NG

>> Repair or replace connector.

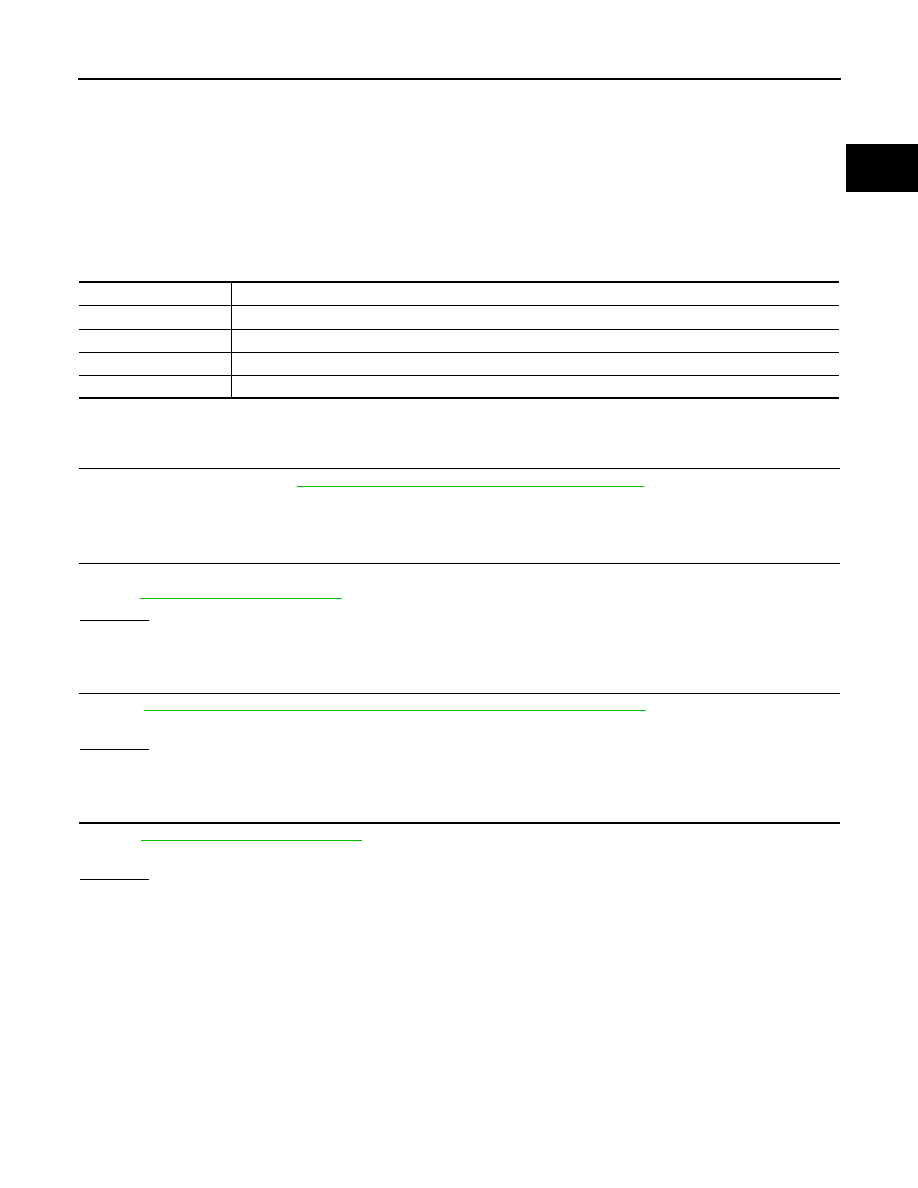

STEP in Work Flow

Situation

2

The CONSULT-III is used. The SELF-DIAG RESULTS screen shows time data other than [0] or [1t].

3 or 4

The symptom described by the customer does not recur.

5

(1st trip) DTC does not appear during the DTC Confirmation Procedure.

10

The Diagnostic Procedure for PXXXX does not indicate the malfunctioning area.

EC-140

< SERVICE INFORMATION >

[VQ35DE]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Wiring Diagram

INFOID:0000000001325946

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TBWM1377E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст