Infiniti FX35, FX50 (S51). Manual — part 1413

PCS-10

< SYSTEM DESCRIPTION >

[IPDM E/R]

POWER CONSUMPTION CONTROL SYSTEM

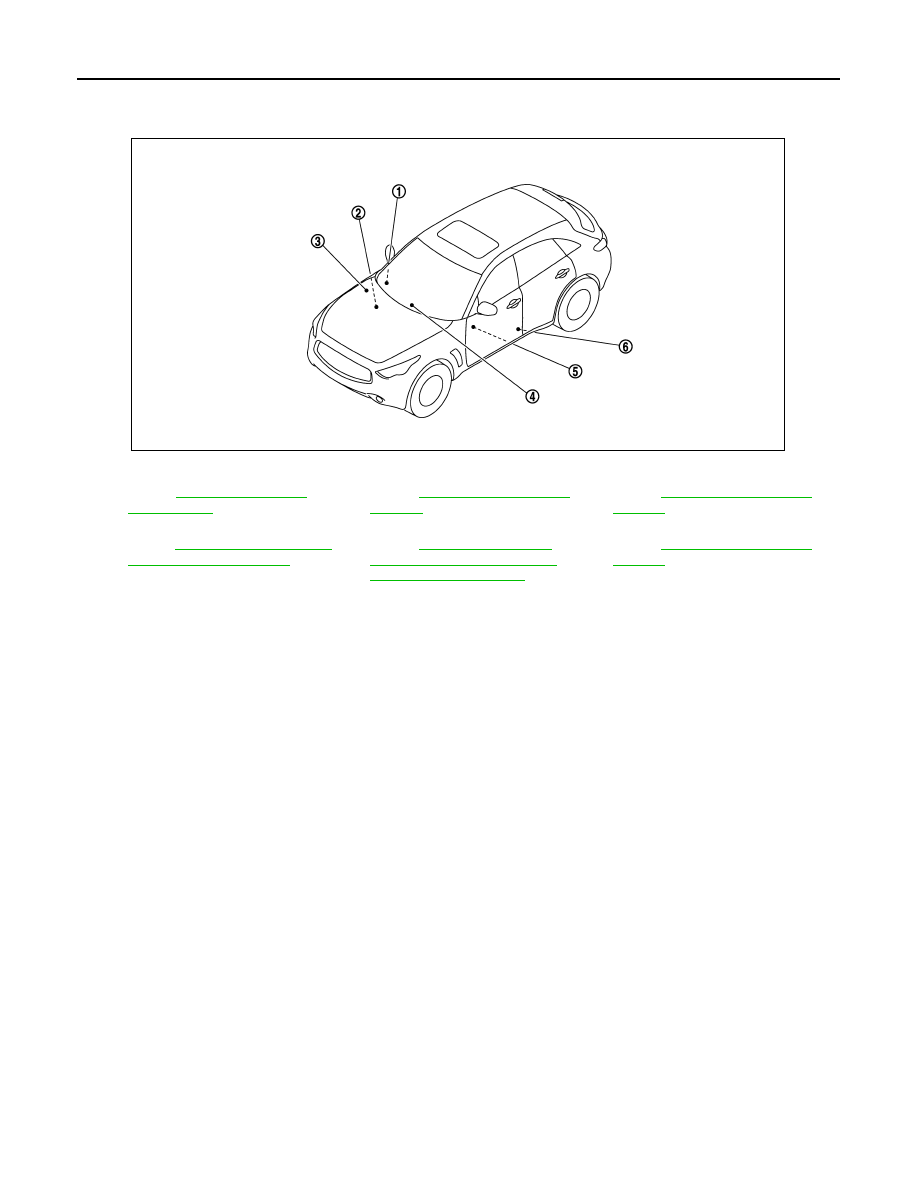

Component Parts Location

INFOID:0000000005688776

1.

.

2.

BCM

Refer to

3.

.

4.

Unified meter and A/C amp.

Refer to

5.

Driver seat control unit

Refer to

DRIVE POSITIONER SYSTEM :

Component Parts Location"

6.

Pre-crash seat belt control unit

Refer to

.

JMMIA0297ZZ

PCS

DIAGNOSIS SYSTEM (IPDM E/R)

PCS-11

< SYSTEM DESCRIPTION >

[IPDM E/R]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis Description

INFOID:0000000005240638

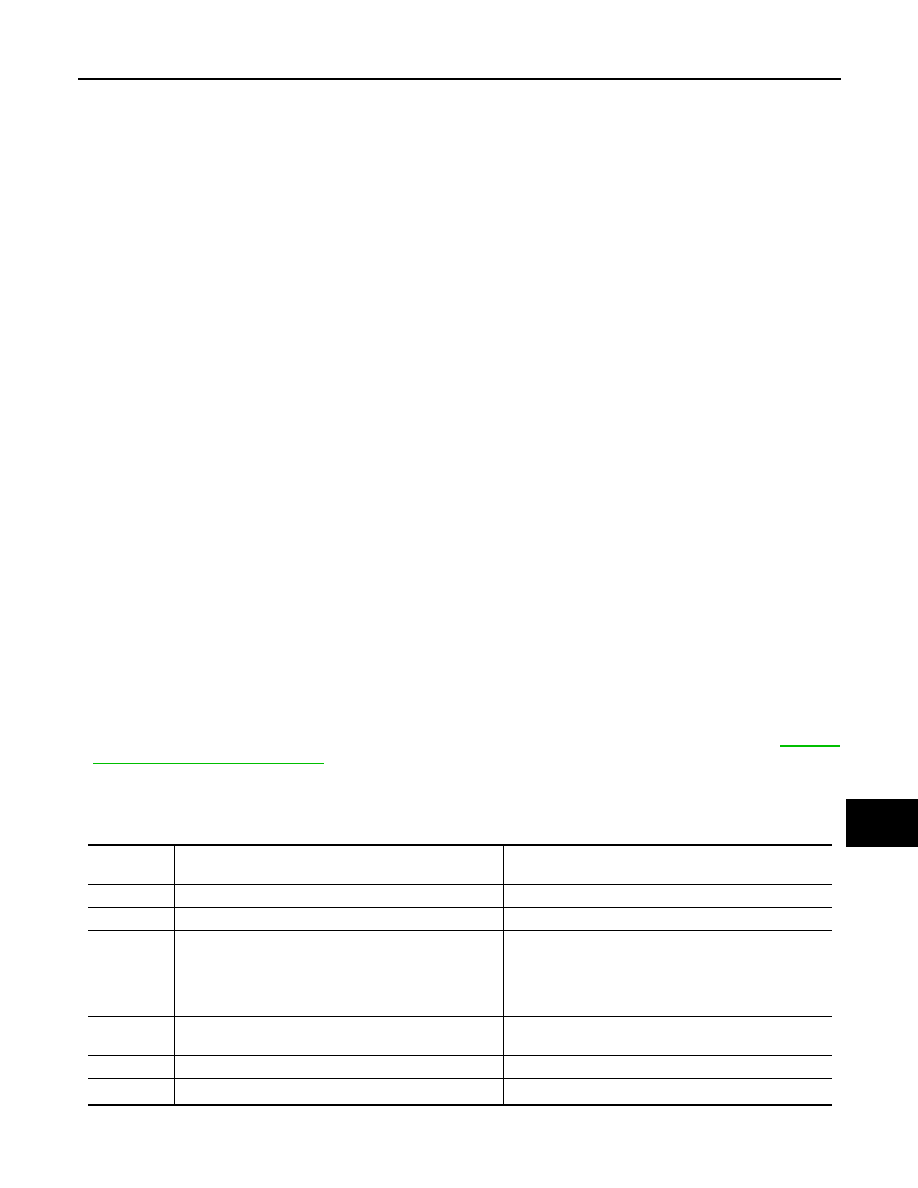

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

• Oil pressure warning lamp

• Front wiper (LO, HI)

• Parking lamps

• License plate lamps

• Side marker lamps

• Tail lamps

• Front fog lamps

• Headlamps (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan (cooling fan control module)

Operation Procedure

1.

Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2.

Turn the ignition switch OFF.

3.

Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4.

Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5.

The oil pressure warning lamp starts blinking when the auto active test starts.

6.

After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to

.

• Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

*: Outputs duty ratio of 50% for 5 seconds

→

duty ratio of 100% for 5 seconds on the cooling fan control module.

Operation

sequence

Inspection location

Operation

A

Oil pressure warning lamp

Blinks continuously during operation of auto active test

1

Front wiper

LO for 5 seconds

→

HI for 5 seconds

2

• Parking lamps

• License plate lamps

• Side marker lamps

• Tail lamps

• Front fog lamps

10 seconds

3

Headlamps

• LO 10 seconds

• HI ON

⇔

OFF 5 times

4

A/C compressor (magnet clutch)

ON

⇔

OFF 5 times

5

*

Cooling fan

MID for 5 seconds

→

HI for 5 seconds

PCS-12

< SYSTEM DESCRIPTION >

[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

• IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

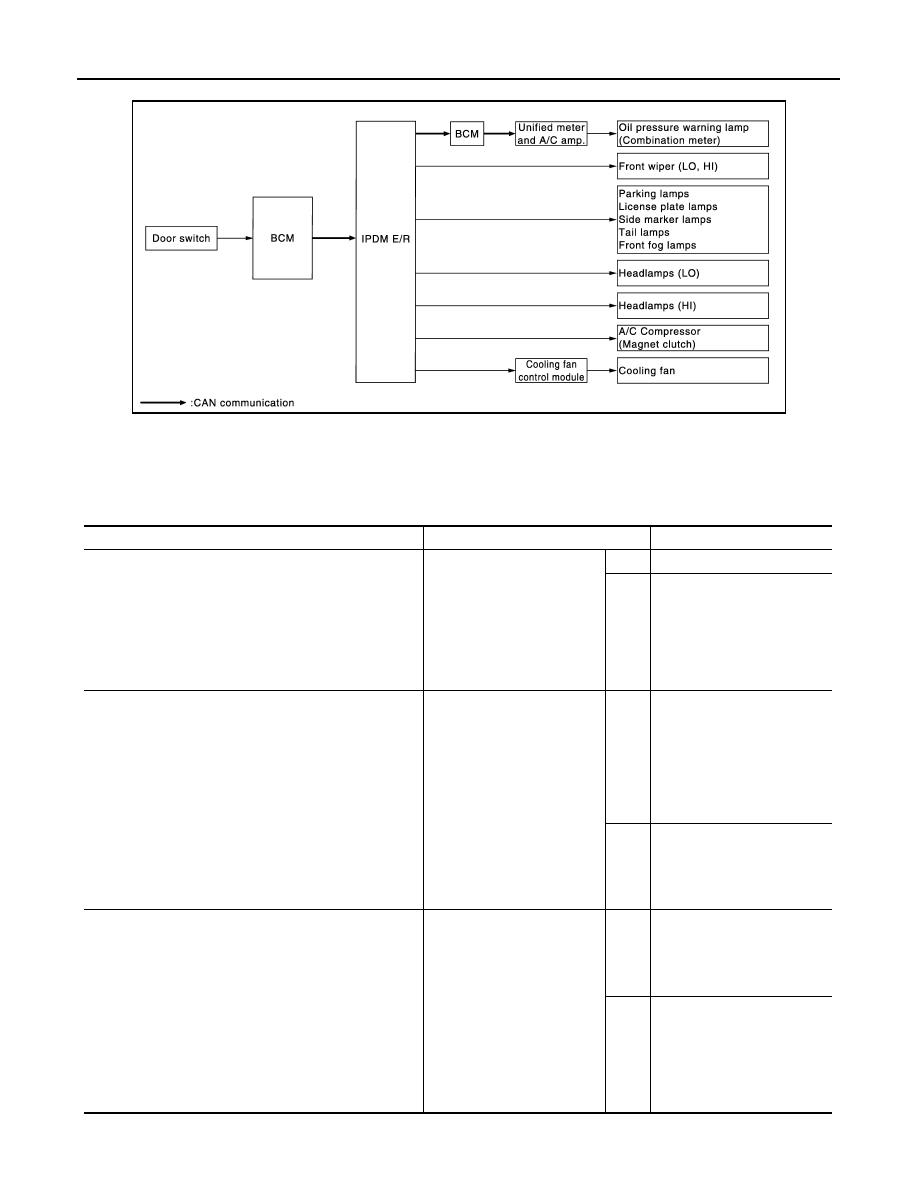

Diagnosis chart in auto active test mode

JPMIA1068GB

Symptom

Inspection contents

Possible cause

Any of the following components do not operate

• Parking lamps

• License plate lamps

• Side marker lamps

• Tail lamps

• Front fog lamps

• Headlamp (HI, LO)

• Front wiper

Perform auto active test.

Does the applicable system

operate?

YES

BCM signal input circuit

NO

• Lamp or motor

• Lamp or motor ground cir-

cuit

• Harness or connector be-

tween IPDM E/R and appli-

cable system

• IPDM E/R

A/C compressor does not operate

Perform auto active test.

Does the magnet clutch oper-

ate?

YES

• Unified meter and A/C amp.

signal input circuit

• CAN communication signal

between unified meter and

A/C amp. and ECM

• CAN communication signal

between ECM and IPDM E/

R

NO

• Magnet clutch

• Harness or connector be-

tween IPDM E/R and mag-

net clutch

• IPDM E/R

Oil pressure warning lamp does not operate

Perform auto active test.

Does the oil pressure warning

lamp blink?

YES

• Harness or connector be-

tween IPDM E/R and oil

pressure switch

• Oil pressure switch

• IPDM E/R

NO

• CAN communication signal

between IPDM E/R and

BCM

• CAN communication signal

between BCM and unified

meter and A/C amp.

• Combination meter

PCS

DIAGNOSIS SYSTEM (IPDM E/R)

PCS-13

< SYSTEM DESCRIPTION >

[IPDM E/R]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

CONSULT-III Function (IPDM E/R)

INFOID:0000000005240639

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

DATA MONITOR

Monitor item

Cooling fan does not operate

Perform auto active test.

Does the cooling fan operate?

YES

• ECM signal input circuit

• CAN communication signal

between ECM and IPDM E/

R

NO

• Cooling fan

• Harness or connector be-

tween cooling fan and cool-

ing fan control module

• Cooling fan control module

• Harness or connector be-

tween IPDM E/R and cool-

ing fan control module

• Cooling fan relay

• Harness or connector be-

tween IPDM E/R and cool-

ing fan relay

• IPDM E/R

Symptom

Inspection contents

Possible cause

Diagnosis mode

Description

Ecu Identification

Allows confirmation of IPDM E/R part number.

Self Diagnostic Result

Displays the diagnosis results judged by IPDM E/R.

Data Monitor

Displays the real-time input/output data from IPDM E/R input/output data.

Active Test

IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor

The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item

[Unit]

MAIN SIG-

NALS

Description

RAD FAN REQ

[%]

×

Displays the value of the cooling fan speed signal received from ECM via CAN

communication.

AC COMP REQ

[Off/On]

×

Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TAIL&CLR REQ

[Off/On]

×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On]

×

Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On]

×

Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On]

×

Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi]

×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P]

×

Displays the status of the front wiper stop position signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK]

×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст