Infiniti FX35, FX50 (S51). Manual — part 430

CHG

CHG-1

ELECTRICAL & POWER CONTROL

C

D

E

F

G

H

I

J

K

L

B

SECTION

CHG

A

O

P

N

CONTENTS

CHARGING SYSTEM

BASIC INSPECTION . . . . . . . . .

DIAGNOSIS AND REPAIR WORKFLOW . . ..

Work Flow . . . . . . . . . . . . . . . .....

SYSTEM DESCRIPTION . . . . . . . ..

CHARGING SYSTEM . . . . . . . . . . ..

System Diagram . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . ...

VQ35HR . . . . . . . . . . . . . . . . . ...

VQ35HR : Component Parts Location . . . . . ..

VK50VE . . . . . . . . . . . . . . . . . ...

VK50VE : Component Parts Location . . . . . ...

Component Description . . . . . . . . . . ....

POWER GENERATION VOLTAGE VARI-

ABLE CONTROL SYSTEM . . . . . . . . .

System Diagram . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . ...

VQ35HR . . . . . . . . . . . . . . . . . ...

VQ35HR : Component Parts Location . . . . . ..

VK50VE . . . . . . . . . . . . . . . . . ...

VK50VE : Component Parts Location . . . . . ...

Component Description . . . . . . . . . . .....

DTC/CIRCUIT DIAGNOSIS . . . . . . .

B TERMINAL CIRCUIT . . . . . . . . . ..

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

L TERMINAL CIRCUIT (OPEN) . . . . . . .

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

L TERMINAL CIRCUIT (SHORT) . . . . . ...

Description . . . . . . . . . . . . . . . ..

Diagnosis Procedure . . . . . . . . . . . ...

S TERMINAL CIRCUIT . . . . . . . . . .

Description . . . . . . . . . . . . . . . ...

Diagnosis Procedure . . . . . . . . . . . ...

CHARGING SYSTEM . . . . . . . . . ...

Wiring Diagram - CHARGING SYSTEM - . . . ...

SYMPTOM DIAGNOSIS . . . . . . . ..

CHARGING SYSTEM . . . . . . . . . ...

Symptom Table . . . . . . . . . . . . . ...

PRECAUTION . . . . . . . . . . . ..

PRECAUTIONS . . . . . . . . . . . . .

Precaution for Power Generation Voltage Variable

Control System . . . . . . . . . . . . . .

PREPARATION . . . . . . . . . . ...

PREPARATION . . . . . . . . . . . . .

Special Service Tools . . . . . . . . . . . ..

Commercial Service Tools . . . . . . . . . ...

PERIODIC MAINTENANCE . . . . . .

CHARGING SYSTEM PRELIMINARY IN-

SPECTION . . . . . . . . . . . . . .

Inspection Procedure . . . . . . . . . . . ...

Inspection Procedure . . . . . . . . . . . ...

REMOVAL AND INSTALLATION . . . ...

ALTERNATOR . . . . . . . . . . . . ..

CHG-2

VQ35HR : Exploded View . . . . . . . . . ..

VQ35HR : Removal and Installation (2WD) . . ....

VQ35HR : Removal and Installation (AWD) . . ...

VQ35HR : Inspection . . . . . . . . . . . ..

VK50VE . . . . . . . . . . . . . . . . . .

VK50VE : Exploded View . . . . . . . . . ...

VK50VE : Removal and Installation . . . . . ....

VK50VE : Inspection . . . . . . . . . . . ...

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . ..

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . . . .

CHG

DIAGNOSIS AND REPAIR WORKFLOW

CHG-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000005242953

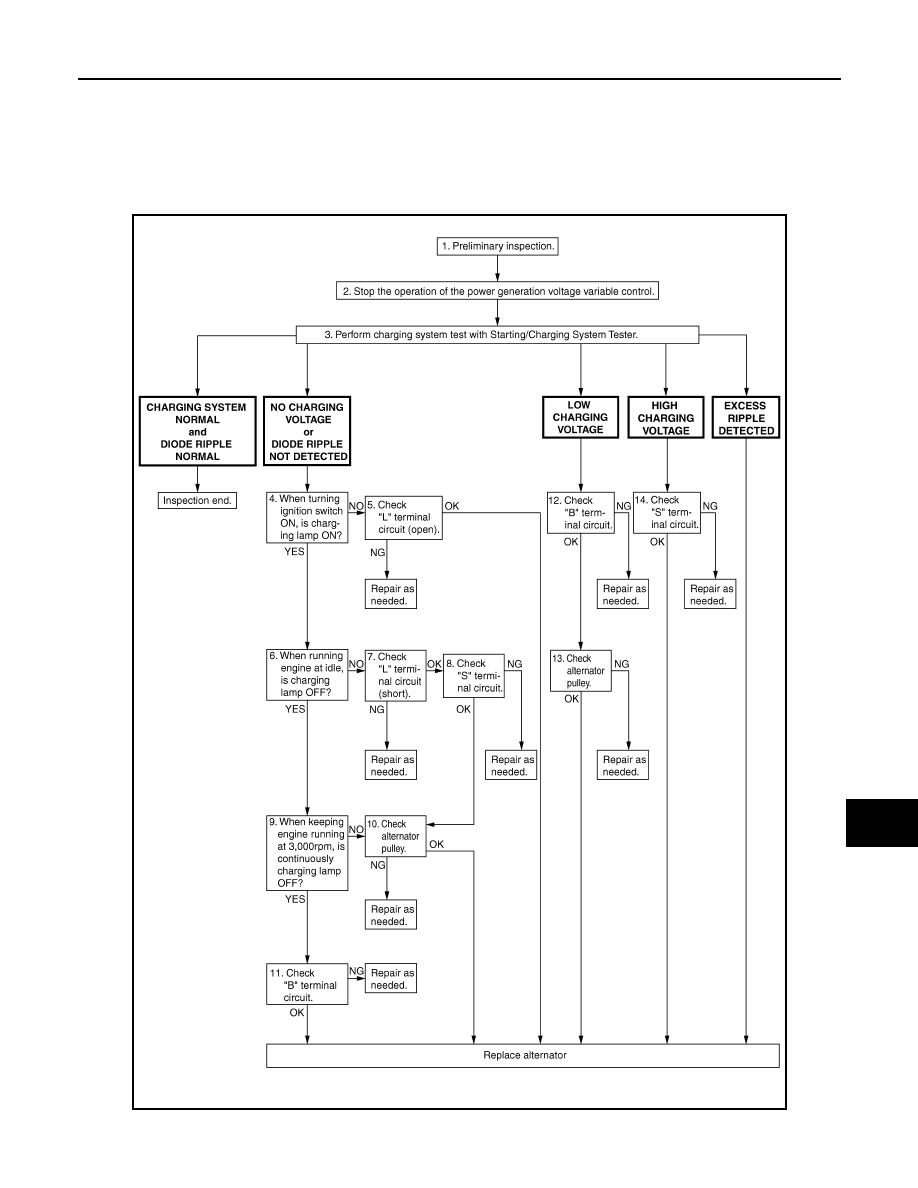

OVERALL SEQUENCE

DETAILED FLOW

JSMIA0009GB

CHG-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

1.

PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to

CHG-26, "Inspection Procedure"

.

>> GO TO 2.

2.

STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures.

• After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-III, set the DUTY value of “ALTERNATOR

DUTY” to 0 % by selecting “ALTERNATOR DUTY” of “Active Test”. Continue “Active Test” until the end of

inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the

characteristic of the IC voltage regulator of the alternator.)

• Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550 -

P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connec-

tor and erase the self-diagnosis results history of the engine using CONSULT-III.]

>> GO TO 3.

3.

DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (SST: J-44373). For details and oper-

ating instructions, refer to Technical Service Bulletin.

Test result

CHARGING SYSTEM NORMAL>>Charging system is normal and will also show “DIODE RIPPLE” test

result.

NO CHARGING VOLTAGE>>GO TO 4.

LOW CHARGING VOLTAGE>>GO TO 12.

HIGH CHARGING VOLTAGE>>GO TO 14.

DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the alternator. Perform “DIODE RIPPLE” test again using Starting/

Charging System Tester (SST: J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4.

4.

INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

“L” TERMINAL CIRCUIT (OPEN) INSPECTION

Check “L” terminal circuit (open). Refer to

Is the “L” terminal circuit normal?

YES

>> Replace alternator.

NO

>> Repair as needed.

6.

INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES

>> GO TO 9.

NO

>> GO TO 7.

7.

“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to

Is the “L” terminal circuit normal?

YES

>> GO TO 8.

NO

>> Repair as needed.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст