Infiniti EX35. Manual — part 540

DLN-110

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

SIDE SHAFT

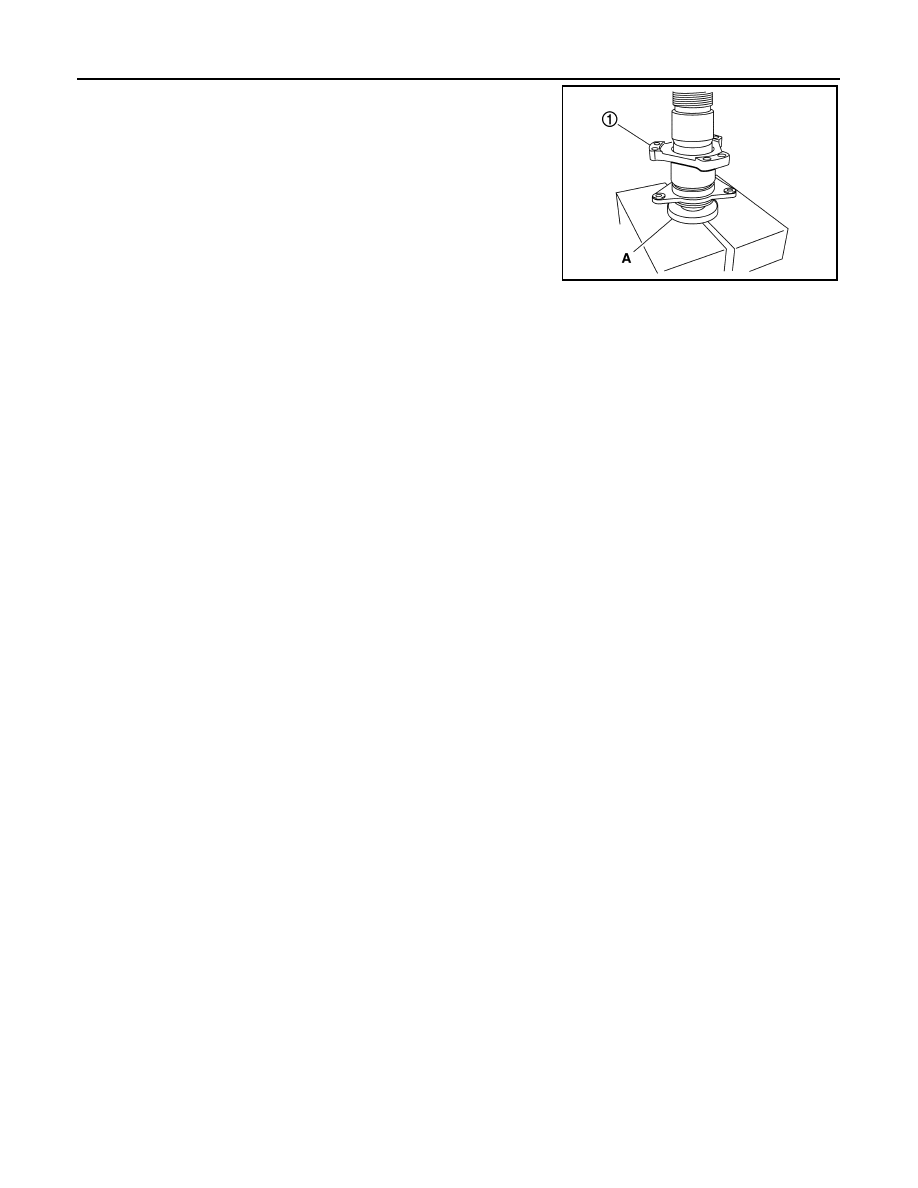

3.

Support side shaft bearing with the drift (A) [SST: ST30032000

(J-26010-01)], then press side shaft (1) into the side shaft bear-

ing using a press.

4.

Apply multi-purpose grease to O-ring, and install it to extension

tube retainer.

CAUTION:

Never reuse O-ring.

Inspection After Disassembly

INFOID:0000000003135794

DRIVE GEAR AND DRIVE PINION

• Clean up the disassembled parts.

• If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

• If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive

gear and drive pinion as a set.

BEARING

• Clean up the disassembled parts.

• If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is

observed, replace as a bearing assembly (as a new set).

SIDE GEAR AND PINION MATE GEAR

• Clean up the disassembled parts.

• If any cracks or damage on the surface of the tooth is found, replace.

• If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

SIDE GEAR THRUST WASHER AND PINION MATE THRUST WASHER

• Clean up the disassembled parts.

• If it is chipped (by friction), damaged, or unusually worn, replace.

OIL SEAL

• Whenever disassembled, replace.

• If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

DIFFERENTIAL CASE

• Clean up the disassembled parts.

• If any wear or crack on the contact sides of the differential case is found, replace.

COMPANION FLANGE

• Clean up the disassembled parts.

• If any chipped mark [about 0.1 mm, (0.004 in)] or other damage on the contact sides of the lips of the com-

panion flange is found, replace.

PDIA0815J

DIFFERENTIAL ASSEMBLY

DLN-111

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

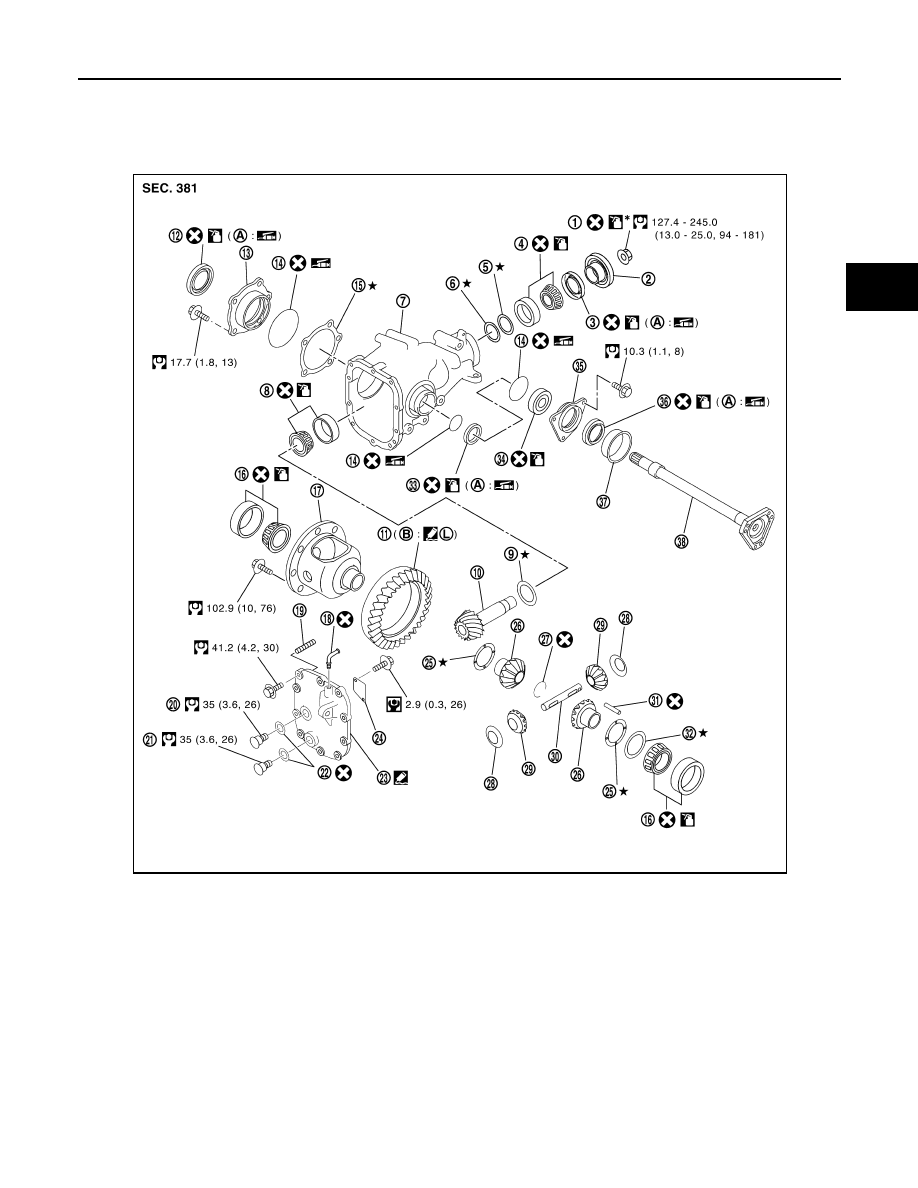

DIFFERENTIAL ASSEMBLY

Exploded View

INFOID:0000000003135795

1.

Drive pinion lock nut

2.

Companion flange

3.

Front oil seal

4.

Pinion front bearing

5.

Drive pinion bearing adjusting wash-

er

6.

Drive pinion adjusting washer

7.

Gear carrier

8.

Pinion rear bearing

9.

Pinion height adjusting washer

10. Drive pinion

11.

Drive gear

12. Side oil seal (right side)

13. Side retainer

14. O-ring

15. Side bearing adjusting shim

16. Side bearing

17. Differential case

18. Breather connector

19. Dowel pin

20. Filler plug

21. Drain plug

22. Gasket

23. Carrier cover

24. Gear oil defense

25. Side gear thrust washer

26. Side gear

27. Circular clip

28. Pinion mate thrust washer

29. Pinion mate gear

30. Pinion mate shaft

31. Lock pin

32. Side bearing adjusting washer

33. Side oil seal (left side)

JSDIA0020GB

DLN-112

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

DIFFERENTIAL ASSEMBLY

Disassembly

INFOID:0000000003135796

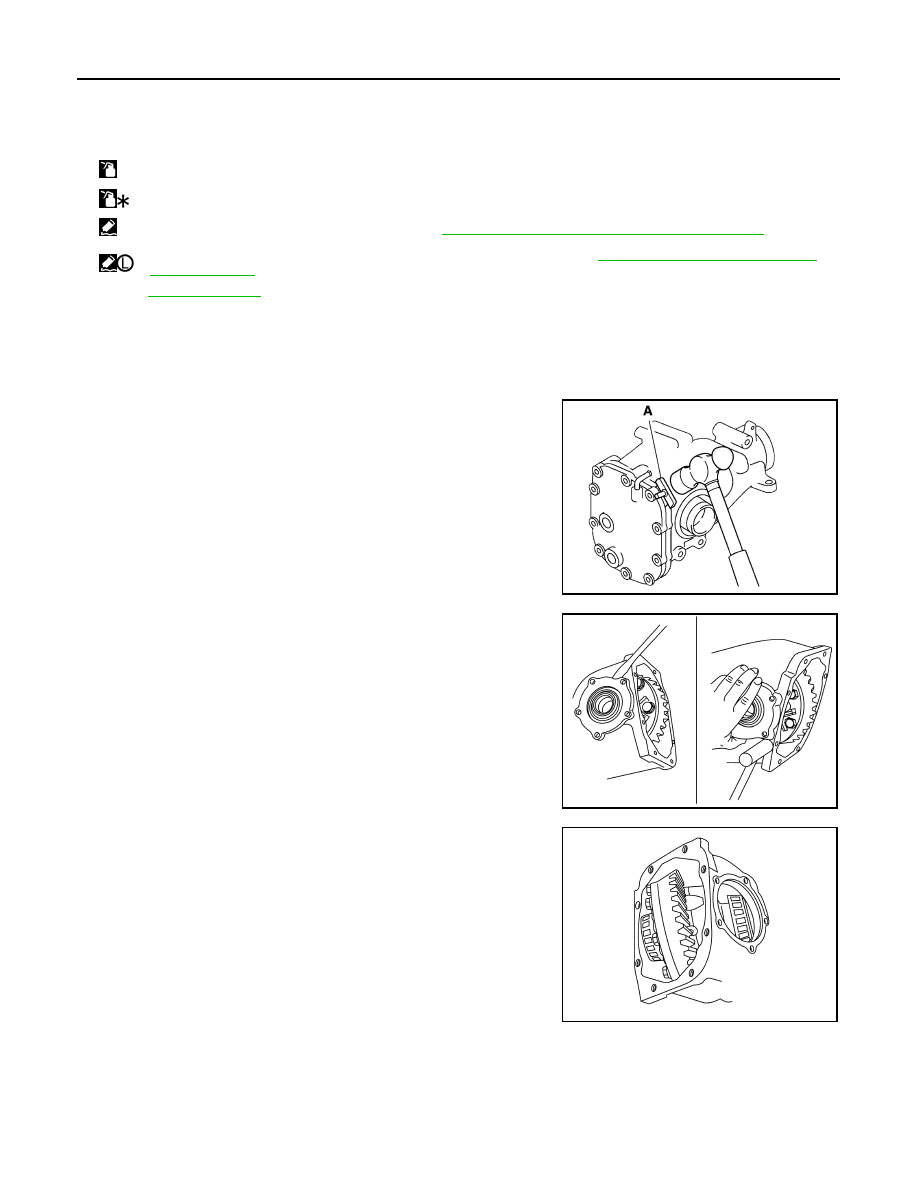

1.

Drain gear oil, if necessary.

2.

Remove carrier cover mounting bolts.

3.

Remove carrier cover to insert the seal cutter (A) [SST:

KV10111100 (J-37228)] between gear carrier and carrier cover.

CAUTION:

• Never damage the mating surface.

• Never insert flat-bladed screwdriver, this may damage the

mating surface.

4.

Remove side retainer.

5.

Remove side bearing adjusting shim.

6.

Remove O-ring from side retainer.

7.

Remove differential case assembly from gear carrier.

34. Side shaft bearing

35. Extension tube retainer

36. Side shaft oil seal

37. Dust seal

38. Side shaft

A:

Oil seal lip

B:

Screw hole

:

Apply gear oil.

:

Apply anti-corrosion oil.

:

Apply Genuine Silicone RTV or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

:

Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Prod-

.

Refer to

for symbols not described above.

PDIA0795J

PDIA0670E

PDIA0671E

DIFFERENTIAL ASSEMBLY

DLN-113

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: F160A]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

8.

Remove side oil seal (right side) from side retainer.

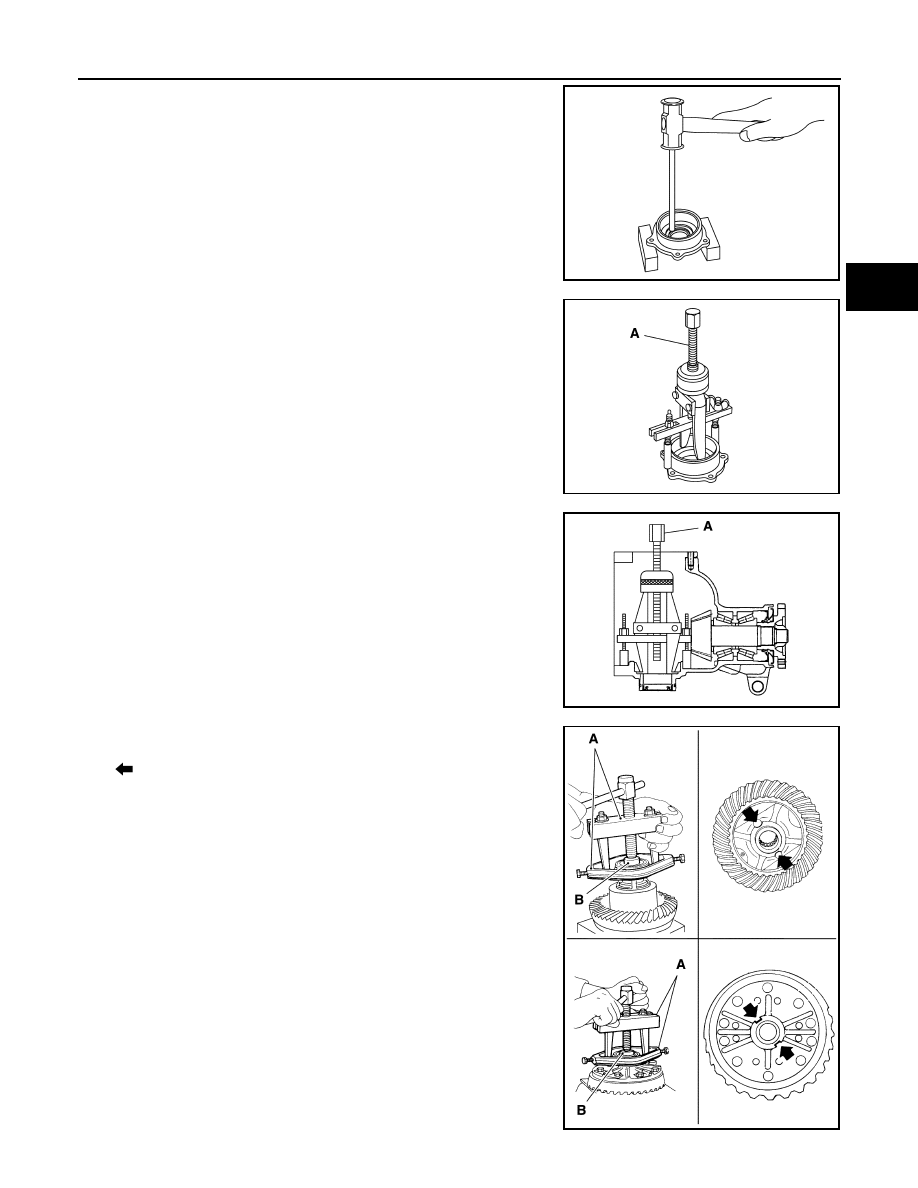

9.

Remove side bearing outer race with puller (A) [SST:

KV381054S0 (J-34286)].

10. Remove O-ring from gear carrier.

11. Remove side oil seal (left side) from gear carrier.

12. Remove side bearing outer race with puller (A) [SST:

KV381054S0 (J-34286)].

13. Remove side bearing inner race.

To prevent damage to bearing, engage puller jaws in groove

(

).

CAUTION:

• To prevent damage to the side bearing and drive gear,

place copper plates between these parts and vise.

• It is not necessary to remove side bearing inner race

except if it is replaced.

PDIA0672E

PDIA0796J

PDIA0797J

A: Puller [SST: ST33051001 (J-22888-20)]

B: Base [SST: ST33061000 (J-8107-2)]

PDIA0758J

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст