SsangYong Korando II (1996-2006 year). Manual — part 317

AUTOMATIC TRANSMISSION 5A-171

SSANGYONG MY2002

ASSEMBLY PROCEDURE

Transmission

Tools Required

0555-336256 Transmission Bench Cradle

0555-336258 Cross Shaft Pin Remover/Installer

(Detent Lever)

0555-336262 Cross Shaft Seal Installer

0555-336263 Cross Shaft bullet

0555-336265 Cross Shaft Pin Remover/Installer

(Inhibitor Switch)

Notice:

•

The transmission is assembled in modular fashion

and details of assembly for each module are given

under the appropriate subject.

•

Technicians overhauling these transmissions will

also require a selection of good quality Torx bit

sockets, in particular numbers 30, 40 and 50, and

an 8 mm, 10 mm and 12 mm double hex socket.

•

Ensure that the B1R circlip is fitted to the case. (If

this is not fitted, the valve will peen its way into

and through the separator plate)

•

Ensure that the ’E’clip is fitted to the cross shaft.

•

Ensure that all aspects of the parking mechanism

are working.

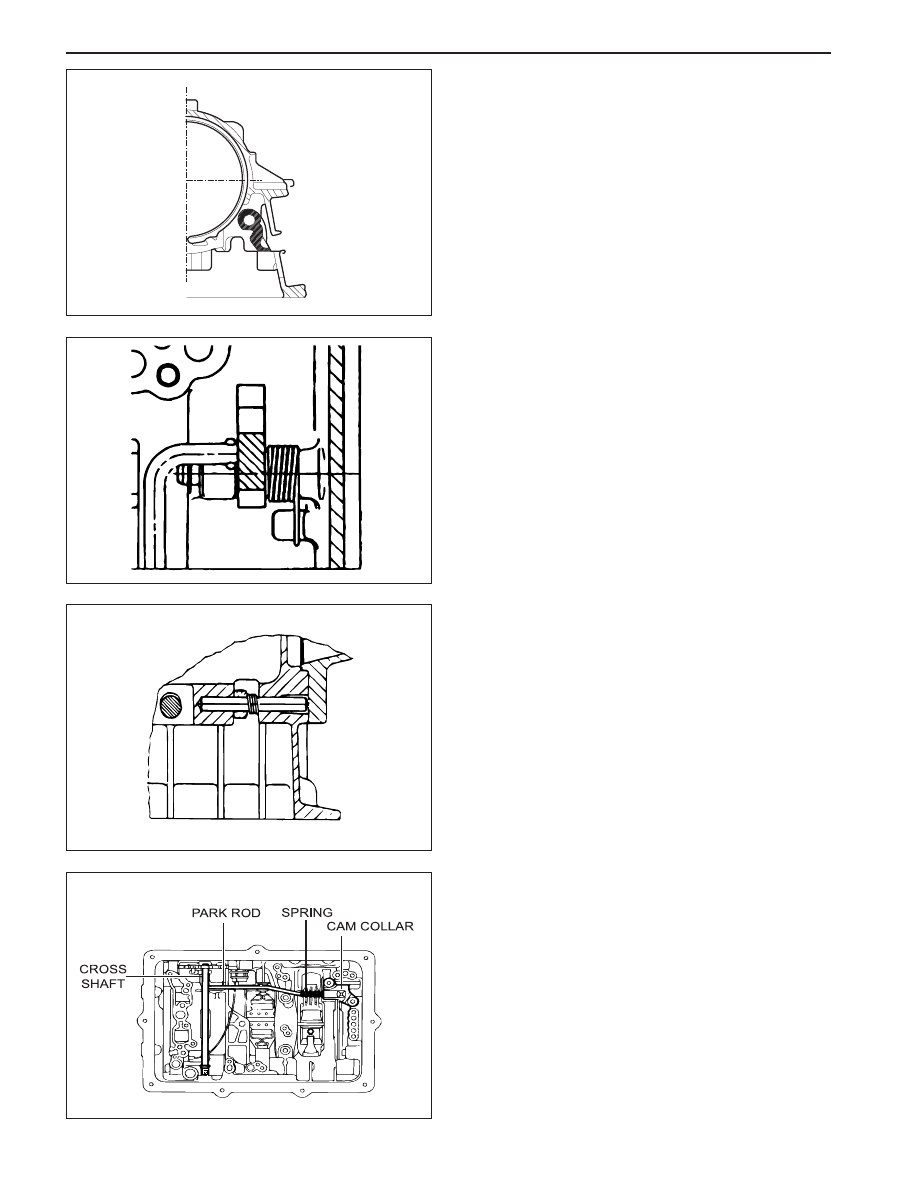

3. Assemble the B1R valve and spring, and secure

with the circlip. Ensure that the circlip is completely

seated in its groove.

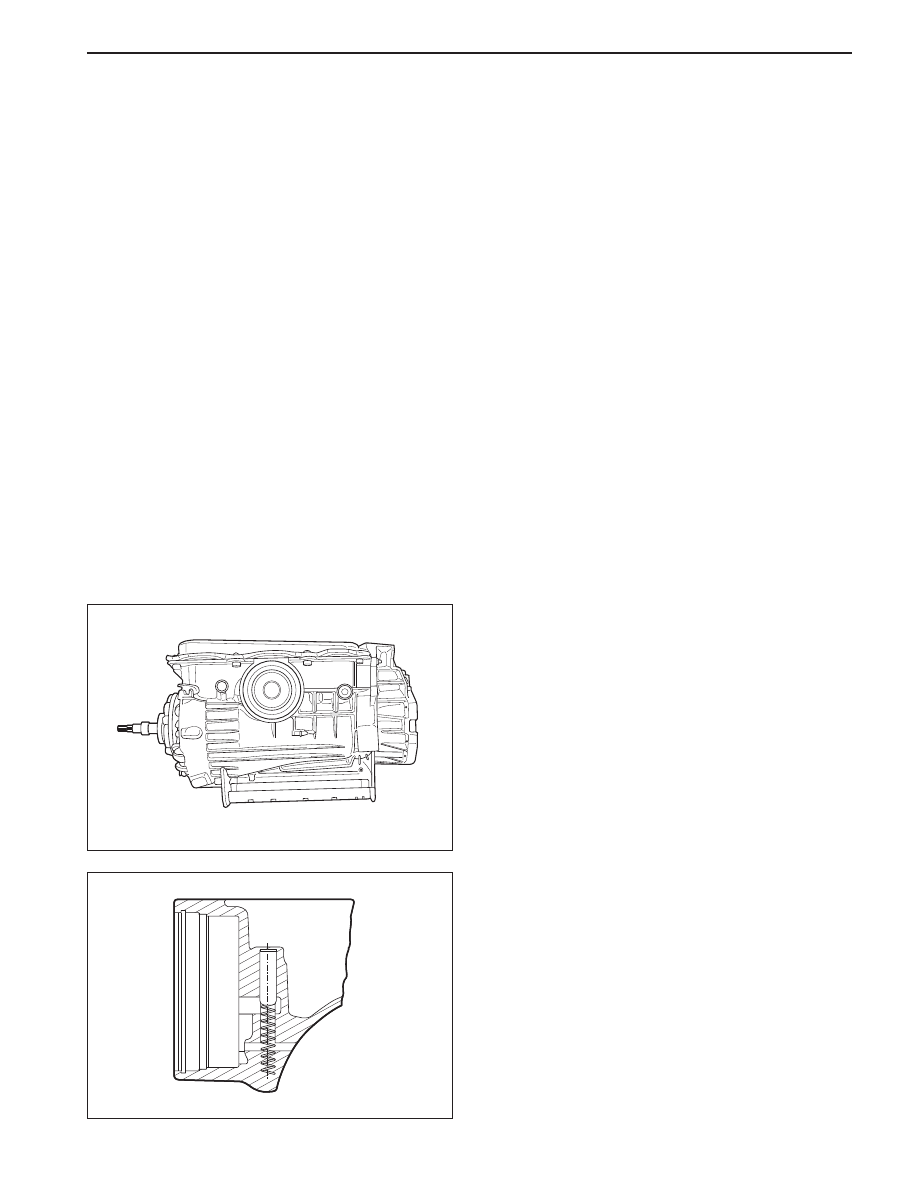

1. Turn the transmission case upside down on the

bench and mount it to the transmission bench cradle

0555-336256.

2. Install all fittings, plugs and the breather, applying

a sealant where applicable, Tighten the fittings to

specifications. Ensurethatthebreatheris clear,

andcheckthat the lube fitting in the rear of the case

is fittedand clear of obstruction.

KAA5A500

KAA5A880

5A-172 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

4. Install the rear servo lever and pivot pin.

Notice: The lever must pivot freely on its pin.

5. Assemble the park rod lever, complete with the

return spring and pivot pin, applying a small

amount of sealant to the outer end of the pivot

pin.

Notice: Care must be taken when applying sealant

to ensure that it is not applied between the pin and

the lever.

6. Secure the pivot pin with the circlip.

Notice: The lever must pivot freely on its pin and

the spring must return the park rod lever to its correct

location.

7. Install the parking pawl pivot pin and spring.

Notice: The pawl must pivot freely on its pin.

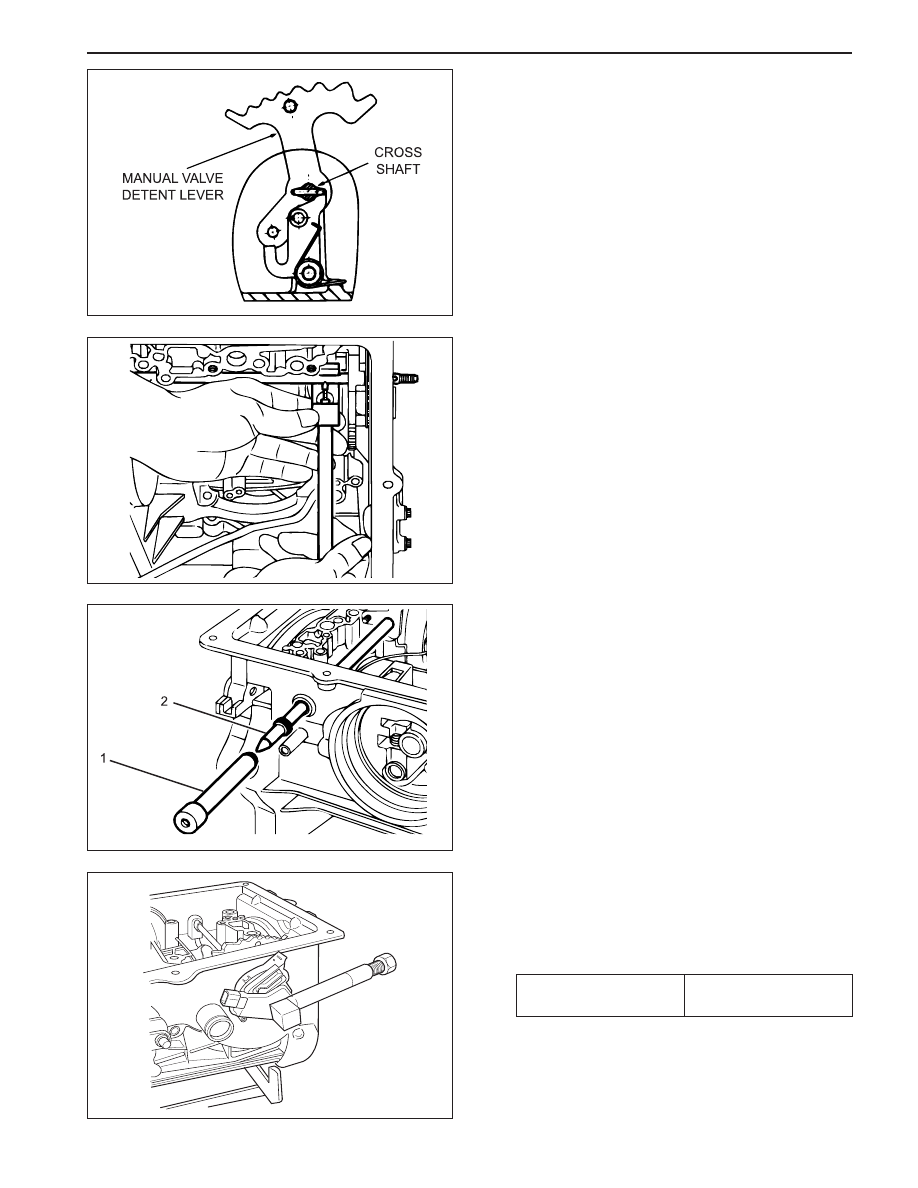

8. Connect the park rod to the manual valve detent

lever. Ensure the spring and cam collar is firmly

installed on the rod.

9. Check that the cam collar slides freely on the rod.

10. Insert the cross shaft into the case, from the side

opposite to the inhibitor switch, then install the

antirattle spring on the shaft.

KAA5A890

KAA5A640

KAA5A900

KAA5A910

AUTOMATIC TRANSMISSION 5A-173

SSANGYONG MY2002

11. Poition the manual valve detent lever, aligning it

with the cross-shaft bore in the case.

12. Push the shaft through the detent lever until it

starts in the detent lever side of the case.

16. Install the new cross shaft seals using cross shaft

seal installer 0555-336262 (1) and cross shaft

bullet 0555-336263 (2).

17. Install the inhibitor switch on the case. Torque the

bolts as per specifications. Press the pin into the

shaft until the tool bottoms using cross shaft pin

installer/ remover (inhibitor switch) 0555-336265.

Installation Notice

18. Thoroughly check the terminal wiring loom for

condition and continuity.

13. Install the detent lever drive pin in the shaft using

cross shaft pin remover/installer (detent lever)

0555-336258 with the adaptor over the pin.

14. Press the pin into the shaft until the tool bottoms.

15. Remove the tool and fit the spring retaining circlip

to the shaft.

KAA5A920

KAA5A600

KAA5A930

KAA5A580

Tightening Torque

4 - 6 N•m

(35 - 53 lb-in)

5A-174 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

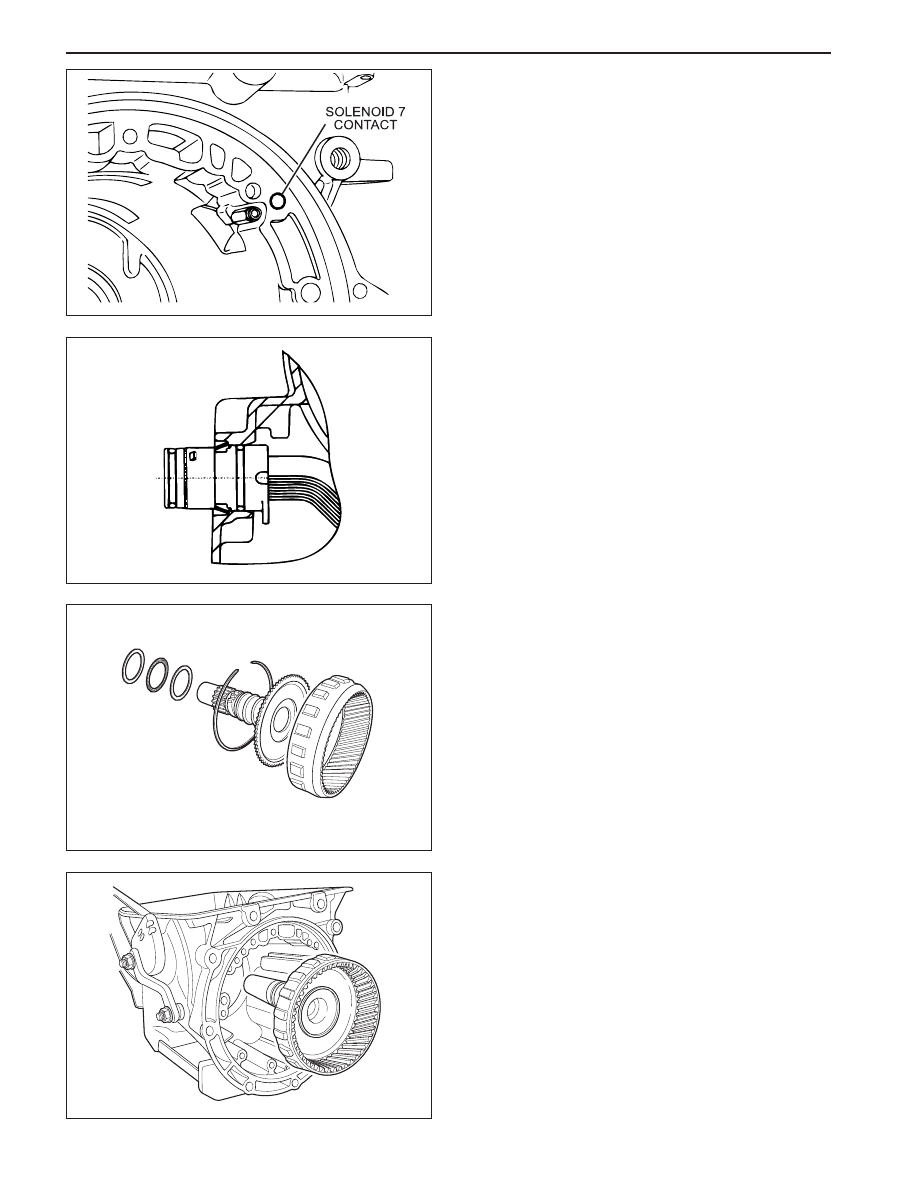

19. Position the wiring loom and locate the solenoid 7

contact and terminal in the pump mounting flange

at the front of the case. The solenoid 7 wire is

routed under the park rod and cross shaft in the

case.

20. Install the 10 pin connector in the case engaging

the tangs on the connector in the notches in case.

Output Shaft and Gear Assembly

1. Check that the output shaft bush is not worn or

damaged. Replace if necessary.

2. Check for damage to parking pawl teeth on the

ring gear. Replace if necessary.

3. Check that the sealing ring grooves have not been

damaged.

4. Lubricate the sealing rings with automatic

transmission fluid.

5. Assemble the sealing rings to the output shaft

with the scarf cut uppermost.

6. If previously dismantled, assemble the ring gear

to the output shaft and secure with circlip. Ensure

that the circlip is firmly seated in its groove.

7. Install the No. 10 needle bearing assembly onto

the output shaft using petroleum jelly.

8. Carefully install the output shaft assembly in the

case to prevent damage to the sealing rings.

KAA5A940

KAA5A610

KAA5A970

KAA5A980

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст