SsangYong Korando II (1996-2006 year). Manual — part 78

M161 ENGINE MECHANICAL 1B2 -- 17

DAEWOO MY_2000

Operation When Full- Load at Partial Load

D

The throttle valve (6) is partially opened or fully

opened.

The air flows very rapidly through the vent line (5) s

connection (D) and the intake air duct when full--load

at partial load.

Consequently, most of the low--by gases are supplied

to the combustion chamber through the timing gear

case cover (15), chain housing (17), oil separation

chamber (3), vent line (5), throttle valve (6), and in-

take manifold (8).

1B2 -- 18 M161 ENGINE MECHANICAL

DAEWOO MY_2000

GENERATOR

1 Bolt (M8 X 40, 3 pieces)

22.5--27.5 NSm (16.6--20.3 lb-ft)

. . . . . . . . . . . . .

2 Bolt (M8 X 70, 2 pieces)

22.5--27.5 NSm (16.6--20.3 lb-ft)

. . . . . . . . . . . . .

3 Bolt (M8 X 85, 1 piece)

22.5--27.5 NSm (16.6--20.3 lb-ft)

. . . . . . . . . . . . .

4 Generator Bracket

Removal & Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the drive belt.

3. Remove the generator.

4. Unscrew the generator carrier bolts and remove the

carrier.

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

Notice: Apply 3 Nm of torque when mounting the bolt

(1) ; apply 25 Nm of torque when mounting the bolts (2),

and (3) ; and then tighten the bolt (1) with 25 Nm of

torque.

5. Installation should follow the removal procedure in

the reverse order.

M161 ENGINE MECHANICAL 1B2 -- 19

DAEWOO MY_2000

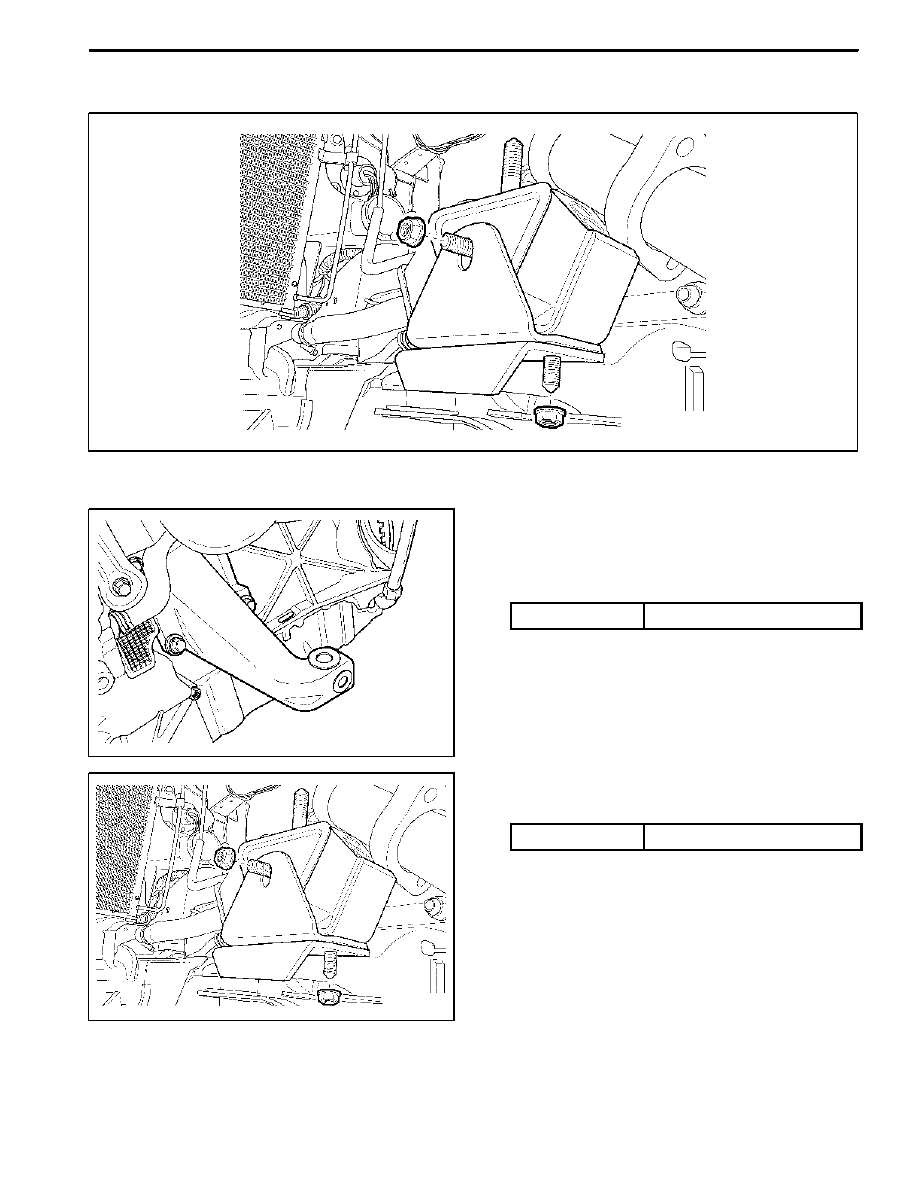

ENGINE MOUNT

Removal & Installation Procedure

1. Unscrew the upper engine mount nuts and remove

the engine.

Installation Notice

Tightening Torque

70 NSm (52 lb-ft)

2. Unscrew the lower nuts.

Installation Notice

Tightening Torque

38 NSm (28 lb-ft)

3. Remove the hydraulic engine mounting insulator.

4. Installation should follow the removal procedure in

the reverse order.

1B2 -- 20 M161 ENGINE MECHANICAL

DAEWOO MY_2000

POLY V -- BELT

Preceding Work: Removal of cooling fan

1 Poly V--belt (2,155 mm)

2 Belt Tensioning Pulley

3 Belt Tensioner

Removal & Installation Procedure

1. Release the belt tension by turning the stud on the

cap with 12 sided wrench or spanner counterclock-

wise.

2. Remove the poly v--belt.

Notice: Check the belt for damage and tensioning

pulley bearing point for wear and replace them if neces-

sary.

3. Install the belt after prying the tensioning pulley.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст