Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 549

6A – 34 ENGINE MECHANICAL

VALVE CLEARANCE ADJUSTMENT

1. Bring the piston in either the No. 1 cylinder or the No. 4

cylinder to TDC on the compression stroke by turning

the crankshaft until the crankshaft damper pulley TDC

line is aligned with the timing pointer.

2. Check the rocker arm shaft bracket nuts for

looseness.

Tighten any loose rocker arm shaft bracket nuts

before adjusting the valve clearance.

Rocker Arm Shaft Bracket Nut Torque

kg·m (lb·ft/N·m)

5.5

± 0.5 (39.8 ± 3.6/53.9 ± 4.9)

3. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

Adjust the No.1 or the No. 4 cylinder valve clearances

while their respective cylinders are at TDC on the

compression stroke.

Valve Clearance (At Cold)

mm (in)

0.4 (0.016)

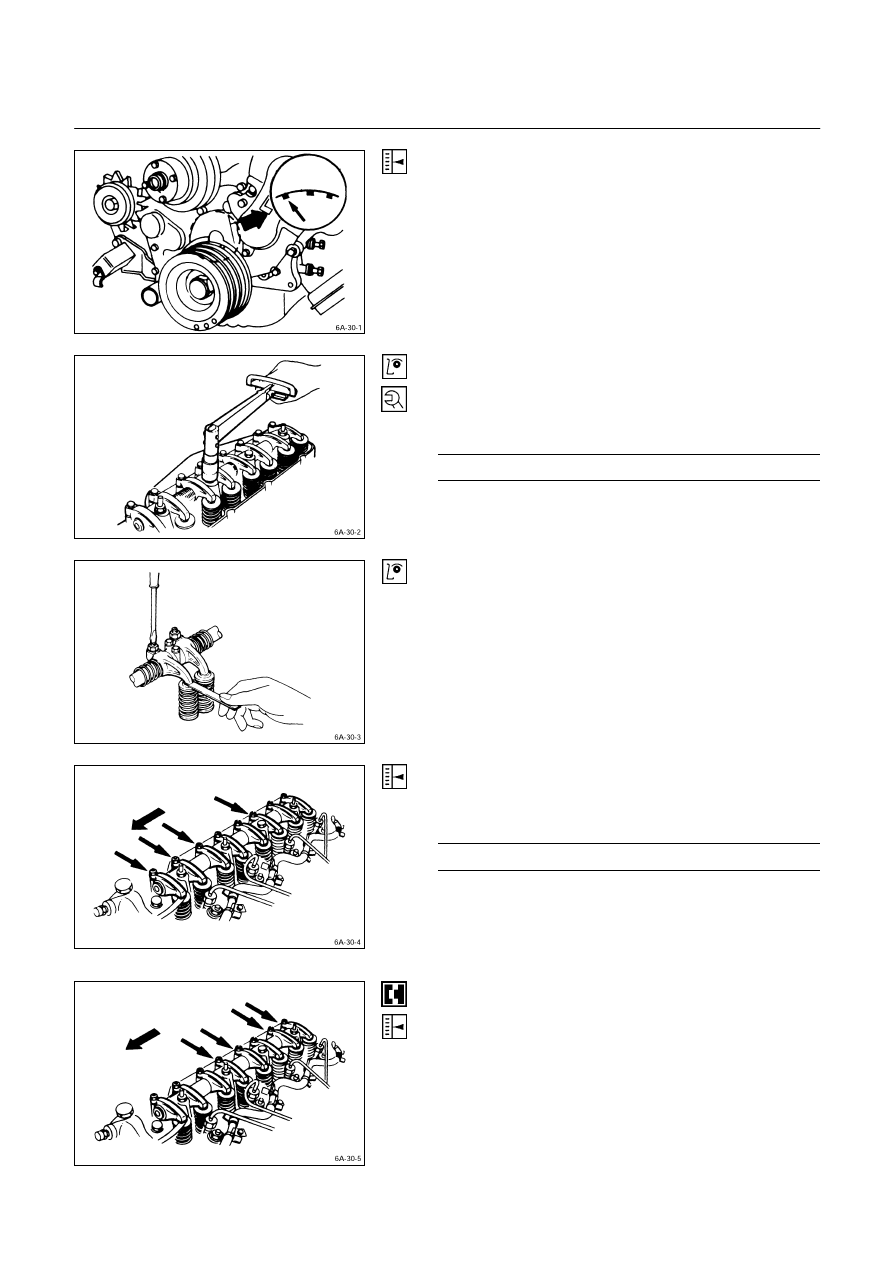

4. Loosen each valve clearance adjusting screw as

shown in the illustration.

5. Insert a feeler gauge of the appropriate thickness

between the rocker arm and the valve stem end.

6. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

7. Tighten the lock nut securely.

8. Rotate the crankshaft 360

°.

9. Realign the crankshaft damper pulley TDC notched

line with the timing pointer.

10 Adjust the clearances for the remaining valves as

shown in the illustration.

ENGINE MECHANICAL 6A – 35

INJECTION TIMING ADJUSTMENT

(Except 4JA1TC, 4JH1TC)

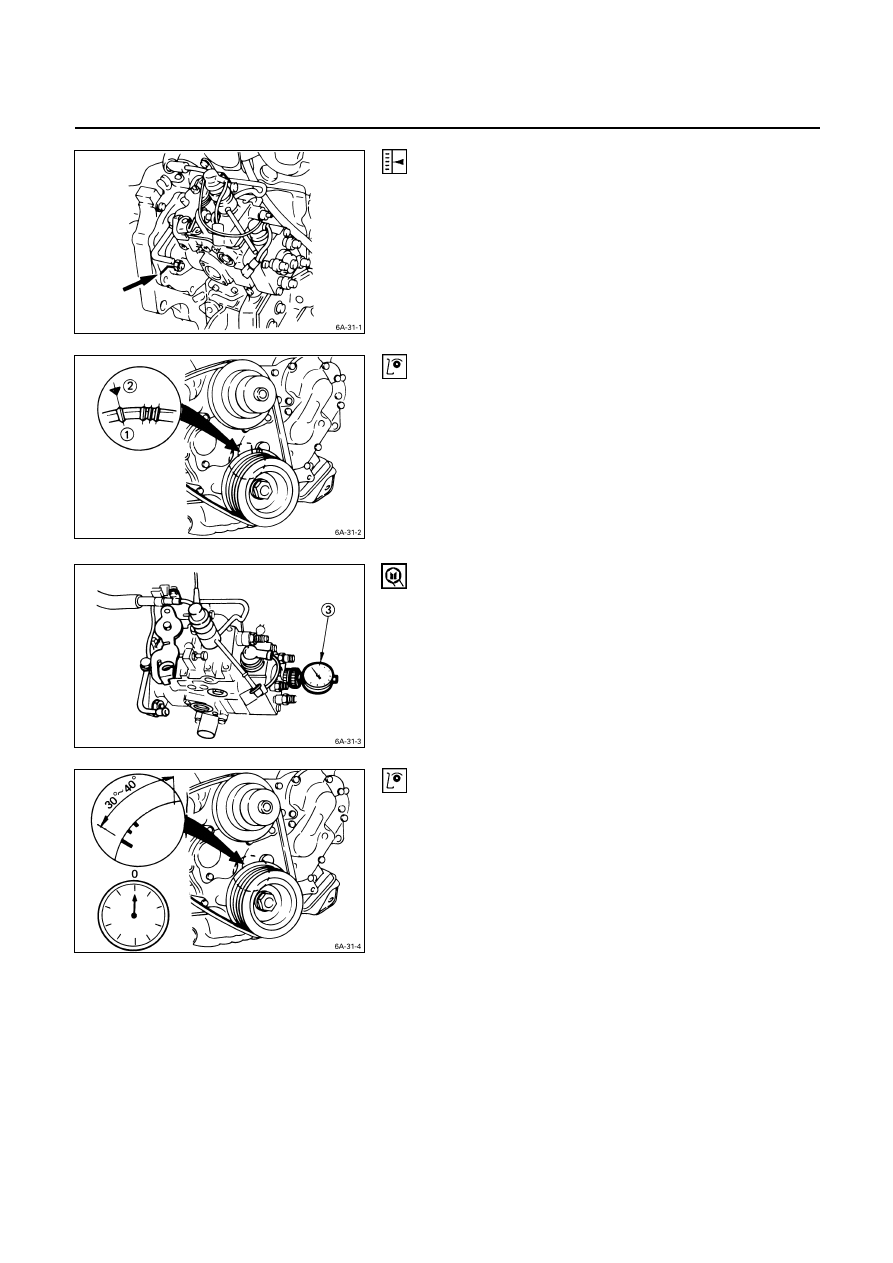

1. Check that the notched line on the injection pump

flange is aligned with the front plate or the timing gear

case notched line.

2. Bring the piston in the No. 1 cylinder to TDC

Q

on the

compression stroke by turning the crankshaft until the

crankshaft pulley TDC line is aligned with the timing

mark

R

.

Note:

Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

3. Disconnect the injection pipe from the injection pump

4. Remove one bolt from the distributor head.

5. Insert a screwdriver into a hole in the fast idle lever

and turn the lever to release the W-C.S.D. function. (if

so equipped)

6. Install the static timing gauge

S

.

The probe of the gauge should be depressed inward

approximately 2 mm (0.079 in).

Static Timing Gauge: 5-8840-0145-0 (J-28827)

7. Rotate the crankshaft to bring the piston in the No. 1

cylinder to a point 30 - 40

° BTDC.

8. Set the timing gauge needle to zero.

9. Move the crankshaft pulley slightly in both directions to

check that the gauge indication is stable.

6A – 36 ENGINE MECHANICAL

10. Turn the crankshaft clockwise and read the gauge

indication when the crankshaft pulley timing mark (12

°

(4JA1, 4JA1T) 11

° (4JB1T) 0° (4JG2T) on pulley) is

aligned with the pointer.

4JA1 4JA1T 4JB1T 4JG2T

BTDC

12

± 2°

BTDC

12

± 2°

BTDC

11

± 2°

TDC

0

± 2°

Standard Reading

mm (in)

0.5 (0.02)

If the injection timing is outside the specified range,

continue with the following steps.

11. Loosen the injection pump fixing nuts and bracket

bolts.

12. Adjust the injection pump setting angle.

When

large

than

standard value

When smaller than

standard value

Gear drive

R

A

A: Move the injection pump toward the engine.

R: Move the injection pump away from the engine.

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80

°C (158 – 176 °F).

2. Remove the following parts.

• Glow

plugs

• Fuel cut solenoid connector

3. Set the adapter and compression gauge to the No. 1

cylinder glow plug hole.

Compression Gauge: 5-8840-2675-0

Adapter; Compression Gauge: 5-8531-7001-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure

kg/cm

2

(psi/MPa) at 200 rpm

Standard

Limit

4JH1TC

28 (398/2.8)

20 (284/2.0)

Others

31 (441/3.0)

22 (313/2.2)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

If the measured value is less than the specified limit,

refer to “Troubleshooting” in this Manual.

ENGINE MECHANICAL 6A – 37

PRE-HEATING SYSTEM

System Inspection Procedure

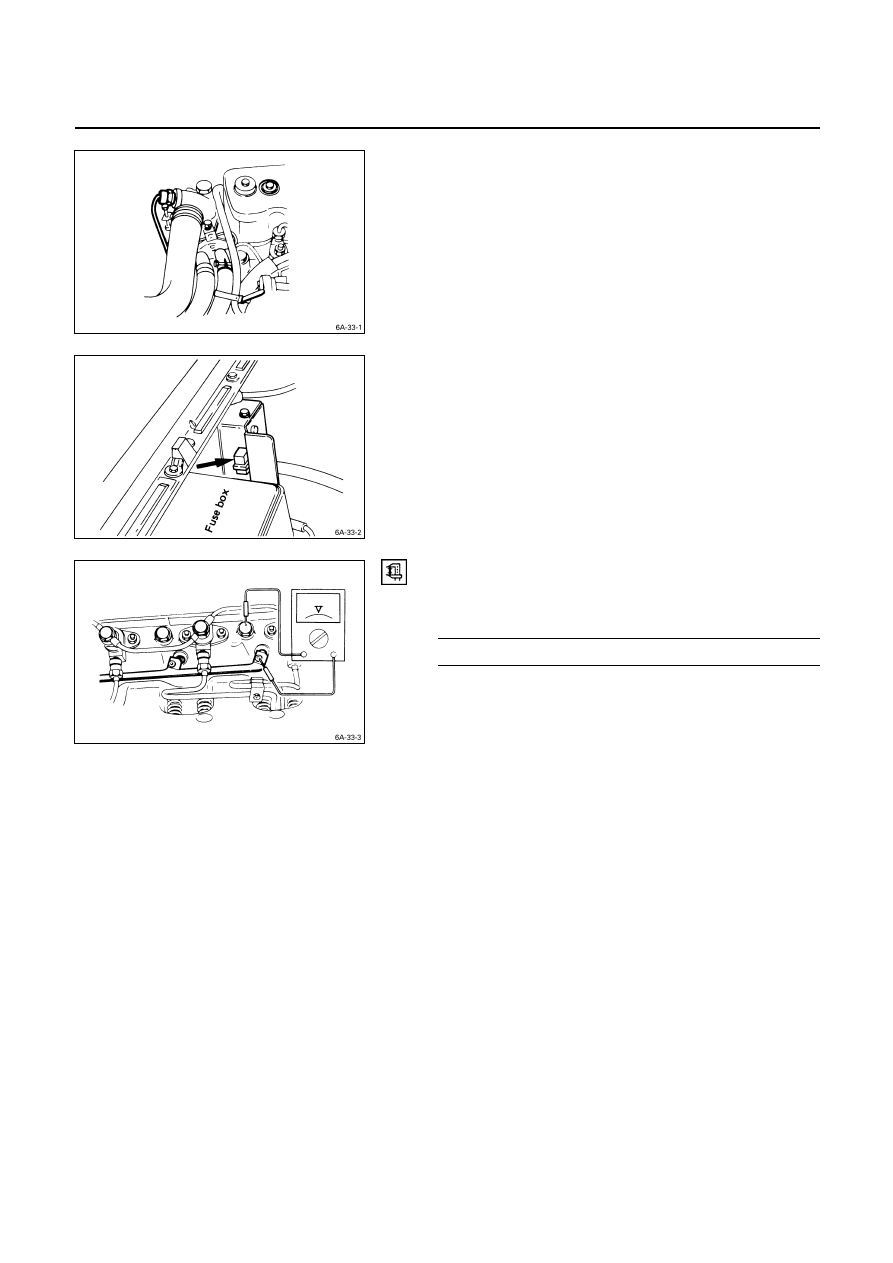

1. Disconnect the thermo-switch on the thermostat outlet

pipe.

2. Turn the starter switch to the “ON” position.

If the Pre-heating System is operating properly, the

glow relay will make a clicking sound about seven

seconds after the starter switch is turned on.

3. Measure the glow plug terminal voltage with a circuit

tester immediately after turning the starter switch to

the “ON” position.

Glow Plug Terminal Voltage

V

Approx. 11

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст