Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1770

DIAGNOSIS 7A2-131

Step

Action

Yes

No

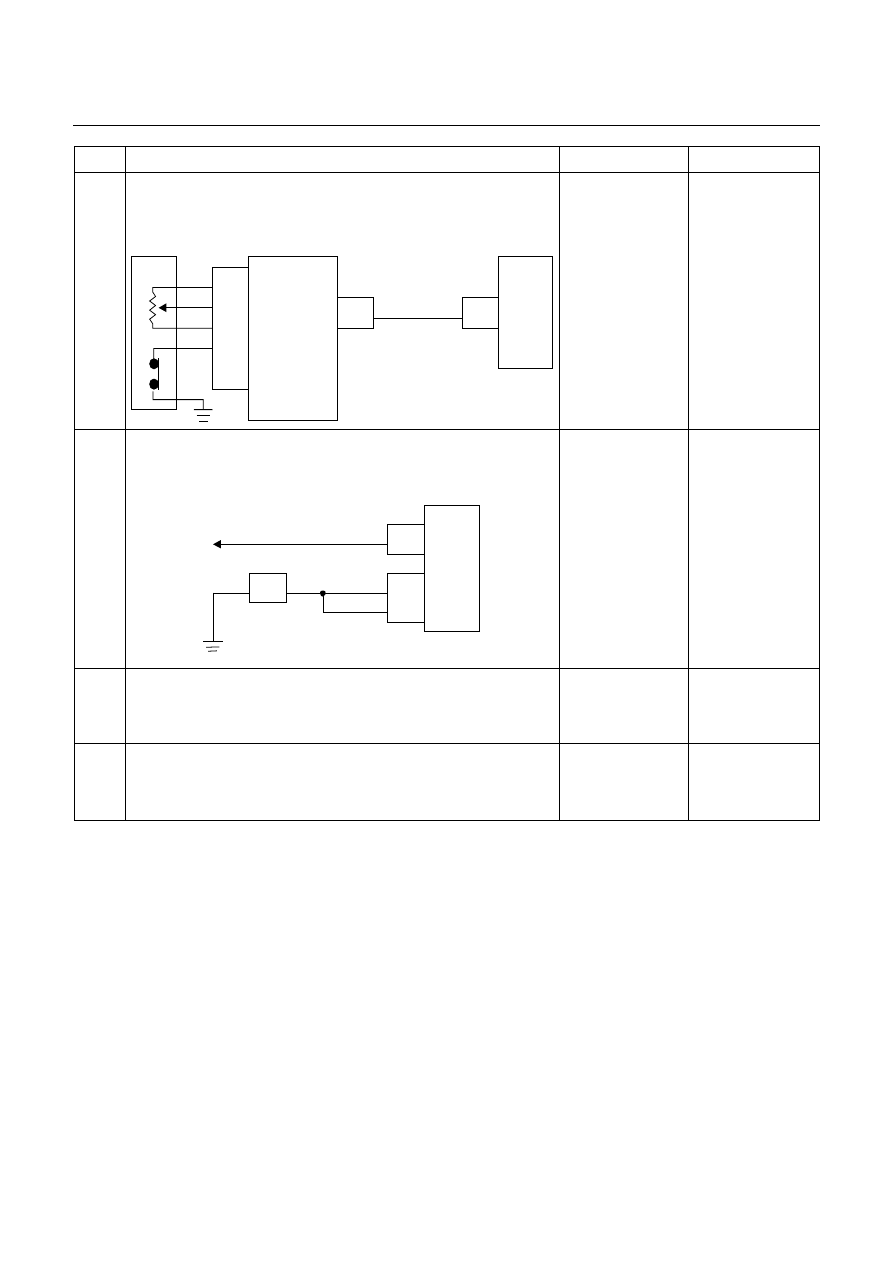

6

Inspect the output voltage and throttle opening signal of the

throttle position sensor using a Tech 2 or circuit tester.

Is a voltage value in proportion to the throttle opening output?

TPS

TCM

A16

C56

(28)

C94

(16)

RED/WHT

C56

(49)

(38)

(57)

(69)

ECM

A47 (GND)

A35 (Output)

A26

A55 (+5V)

A69 (Idle SW)

Go to Step 7

Repair the defect or

replace.

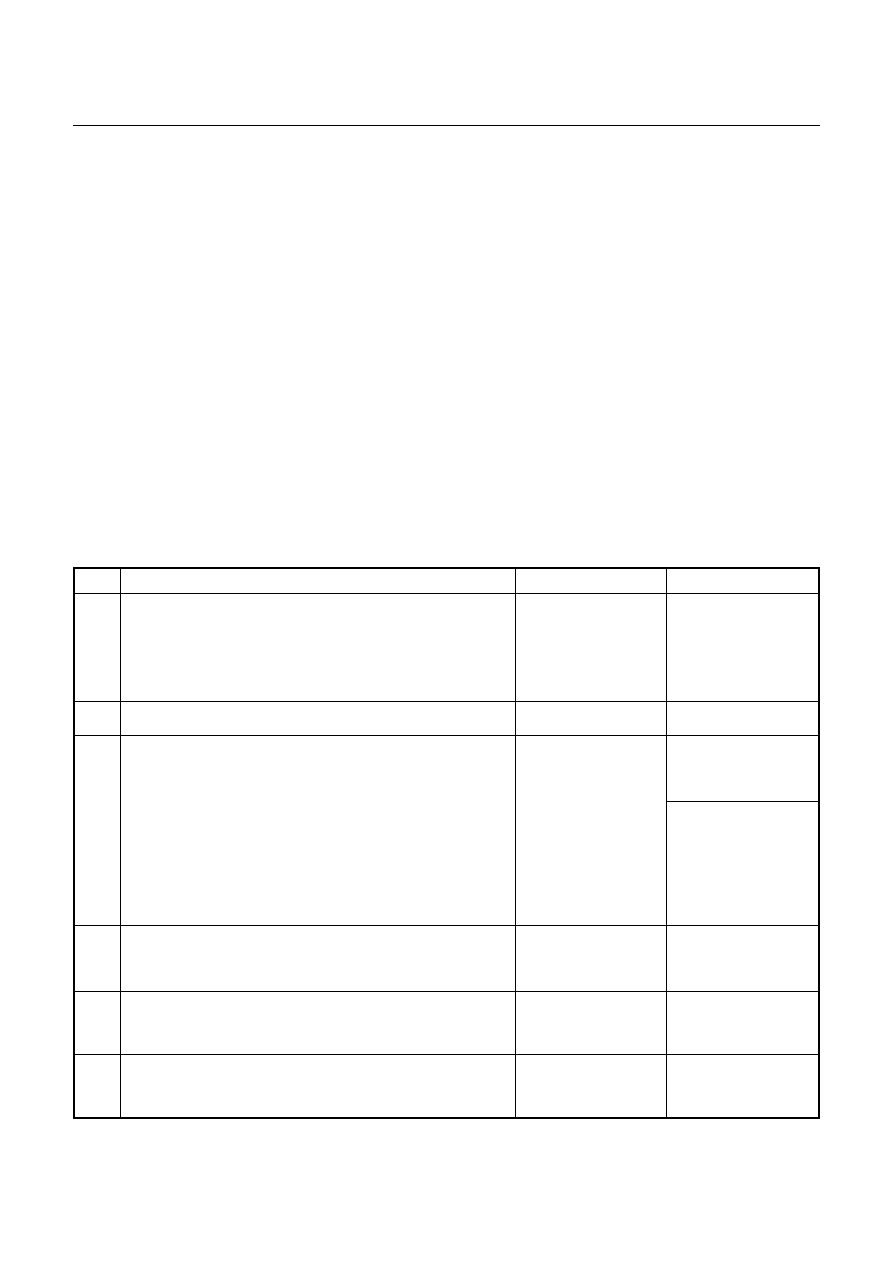

7

Check of power supply to and earth of TCM.

Are the power supply and earth proper?

TCM

A1 (+B)

B5

B15

H23

(15)

C95

(5)

(15)

BLK/YEL

BLK

BLK

Battery

C94

(1)

BLK

Go to Step 8

Check the power

source harness and

earth harness (bolt

tightening to the

body).

8

Is the stall revolution correct in D, 3, 2 and L range? Refer the

STALL TEST section in this manual.

Go to Step 6

Repair the defect or

replace.

9

Is the line pressure correct? Refer the LINE PRESSURE TEST

section in this manual.

Trouble in the AT

assembly or control

valve.

Repair the defect or

replace.

7A2-132 DIAGNOSIS

No. F2: Engine Races Up During Acceleration (Slip)

Description:

•

The engine speed up when the accelerator pedal is stepped on for acceleration and the gear is shifted up or

down.

•

Only the engine speeds up but vehicle speed does not increase when the accelerator pedal is stepped on for

acceleration during the running.

Diagnosis Hints:

•

Basically same causes as "No. C1 - C8: Engine races up (slip) by shift up or shift down" are considered.

When the condition of No. C1-C8 grows worse, symptom of No. F2 results.

No. F3: Noise or Vibration During the Running in R, D, 3, 2 or L Range

Description:

•

Noise or vibration is generated in the vicinity of AT during the running.

Diagnosis Hints:

•

Cause other than AT can be also considered. It is effective means to reproduce a running condition using a lift

up, chassis dynamo, etc. to investigate the origin (generating condition) of noise and vibration.

Caution:

Lifting up some unit to test it accompanies danger. Provide safety measures as far as possible and

carry out the test with sufficient care.

Possible Cause:

Following sources of noise or vibration other than the AT can be considered.

•

Noise from differential gears.

•

Noise from propeller shaft.

•

The bearing support in the middle of the propeller shaft has fatigued, and the bend angle of the propeller shaft

has changed, causing vibration at the time of start.

•

Unbalanced and poor uniformity of tires cause vibration.

No. F4: Engine Brake Does Not Apply in L Range

Description:

•

The engine brake does not apply, allowing the vehicle to run freely when the accelerator pedal is released at low

speed in L range.

Possible Cause:

•

Slip of clutch (low & reverse brake)

If slip of clutch is caused, a DTC (gear ratio error) is stored.

•

Faulty input/output signal system.

Low & reverse brake duty solenoid

•

Faulty control valve (faulty operation, sticking).

DIAGNOSIS 7A2-133

No. F5: Engine Stalls Before Vehicle Stops from Running

Description:

•

The engine stalls simultaneously with the vehicle stop when the brake pedal is stepped on to stop the vehicle

during the running.

Possible Cause:

•

Trouble on the engine system side (fuel injection control, engine speed control, etc.) is considered.

•

Refer

to

"No. B5: Engine stalls when selecting from N range to R, D, 3, 2 or L range".

No. G1: Vehicle Moves in P Range or Parking Gear is Not

Disengaged other than P Range

Description:

•

Vehicle moves though it stops at a slope and P range is selected.

•

The engine stalls and vehicle does not move though other than P range is selected and the accelerator pedal is

stepped on.

Possible Cause:

•

Trouble of the parking mechanism (noise or shock may result).

•

Disordered selector cable (only when traveling in the P range).

•

If the vehicle moves in the N range, follow the procedure of "No. B1: Vehicle runs in N range".

No. G2: Creep Force is Large

Description:

•

Vehicle accelerates in D, 3, 2, L, and R ranges though the accelerator pedal is not stepped on.

Possible Cause:

•

Too high engine idling speed (not attributable to AT).

7A2-134 DIAGNOSIS

No. G3: Creep Force is small

Description:

•

Vehicle does not move though a run range is selected on a flat road during the idling.

Diagnosis Hints:

•

When the creep force is small in all ranges, low engine output is considered. Another possible cause is slip of

clutch. If the creep is normal only in the R range, operation of the fail-safe function due to a trouble in the electrical

system is considered.

Possible Cause:

•

Slip of clutch (low clutch).

If slip of clutch is caused, a DTC (gear ratio error) is stored.

•

Low engine output (low idling speed, out of injection timing, lowered compression pressure, etc.).

•

Shortage or faulty quality of ATF.

•

Disconnection or short circuit of solenoid valve output.

•

Clogged oil passage of solenoid valve output.

•

Faulty ground return line in AT assembly.

If the ground return line earth is faulty, clutch pressure may decrease causing slip of the clutch.

•

Trouble in the torque converter system (faulty operation).

Step

Action

Yes

No

1

Gear ratio trouble diagnosis.

Travel in the following sequence for about 7 seconds or

more in each range: Start in the L range (1st) to 2 range

(2nd) to 3 range (3rd) to D range (4th) (to detect the gear

ratio trouble exactly, this process should be carried out)

Go to Step 2

Go to Step 2

2

Are any DTCs stored?

Go to DTC Chart

Go to Step 3

3

Are the quantity, contamination and smell normal?

If the ATF level is low,

replenish up to the

specified level.

Go to Step 4

If ATF is extremely

black and

contaminated and

smells burnt, slip of the

clutch is supposed.

Overhaul the AT unit.

4

Are the idling speed and other engine system normal?

Go to Step 5

Repair the defect or

replace.

5

Is the stall revolution normal in D, 3, 2 and L range? Refer

the STALL TEST section in this manual.

Go to Step 6

Repair the defect or

replace.

6

Is the line pressure normal? Refer the LINE PRESSURE

TEST section in this manual.

Trouble in the AT

assembly or control

valve.

Repair the defect or

replace.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст